What Are the Key Steps to Commercially Manufacturing Mushroom Gummies?

Mushroom gummies are gaining popularity due to their health benefits and ease of consumption. The commercial manufacturing process includes selecting functional mushrooms like Chaga and Reishi, using gelling agents such as gelatin or agar-agar, and employing advanced machinery for precision. Key steps involve grinding mushrooms into powder, mixing ingredients thoroughly, and utilizing automated depositors for uniform gummy shapes. Understanding the specific health benefits of various mushrooms enhances product appeal. Additionally, manufacturers must adhere to strict quality control measures throughout the production process to ensure safety and efficacy. As consumer demand grows for innovative health products, mushroom gummies stand out as a convenient supplement option that combines taste with nutritional value.

What Ingredients Are Commonly Used by Private Label Gummy Manufacturers?

In the burgeoning world of private label gummy manufacturing, understanding the core ingredients is essential for creating successful products. This article explores the most common ingredients, their impacts on texture and flavor, and important manufacturing considerations.

What Are the Most Important Gummy Manufacturing Equipment for Scaling Production?

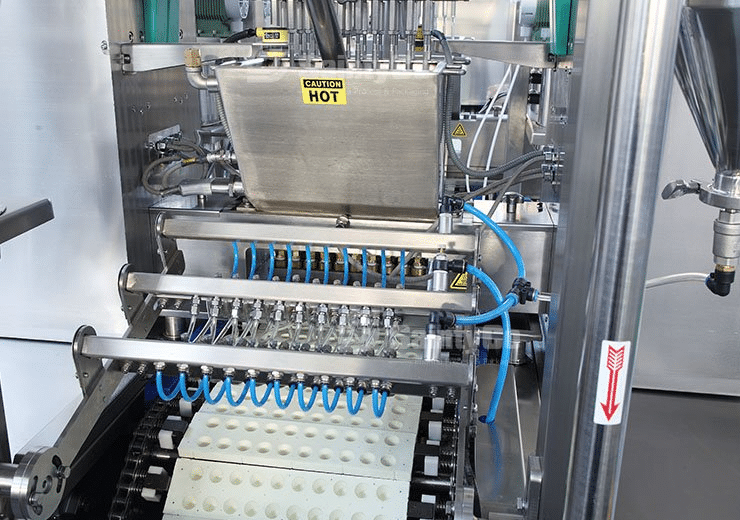

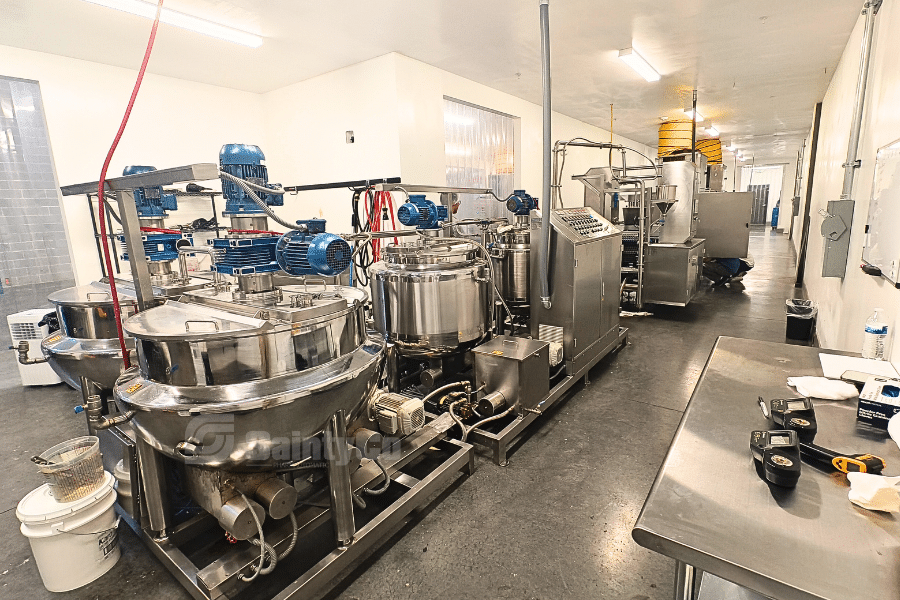

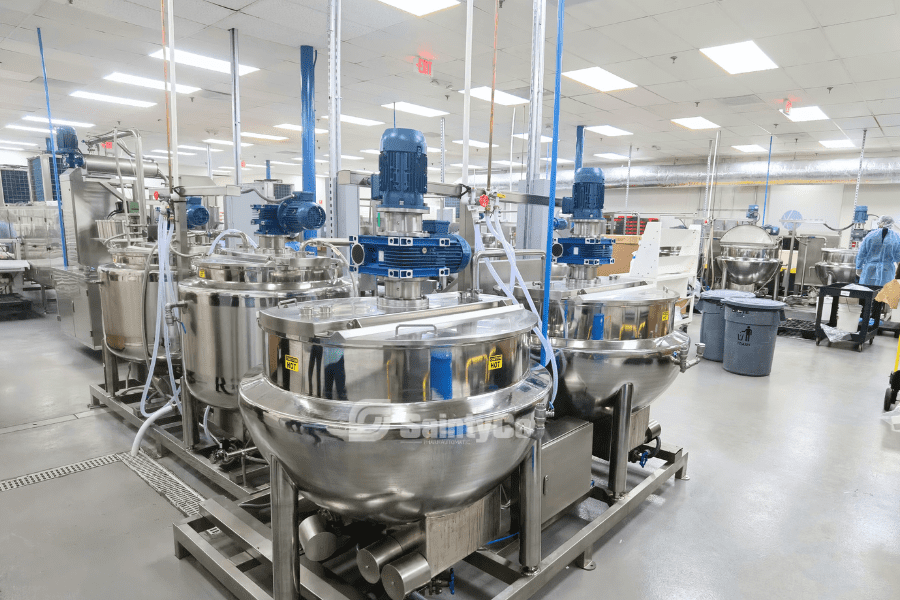

Gummy candies have taken the confectionery world by storm, and scaling production to meet demand requires the right equipment. From depositors to packaging machines, each piece plays a vital role. In this article, we’ll dive into the key equipment necessary for a successful gummy manufacturing process.

What Are the Most Affordable Automation Options for Gummy Production?

If you’re looking to automate your gummy production without breaking the bank, you’ve landed in the right place! This guide explores various affordable options ranging from manual tools to semi-automatic and fully automated systems. Discover how each can enhance your production process while keeping costs manageable. Let’s dive in!

What Are the cGMP Requirements for Equipment in Gummy Manufacturing?

Have you ever stopped to think about what makes gummy manufacturing a sticky business? It’s all about the equipment! Understanding cGMP requirements is essential for ensuring quality and safety in production. From hygienic designs to precise dosing systems, let’s dive into the sweet details that keep your favorite gummies safe and compliant.

How to Make Gummy: Step-by-Step Guide For Homemade & Commercial Production

In 2024, the global gummy candy market is booming. The Grand View Research says that the gummy market size is projected to grow at an 11.8% compound annual growth rate by 2030. Whether you’re a hobbyist or looking to enter the gummy business, this guide will explain how gummies are made at home and on […]

Signs It Is Time to Upgrade Your Gummy Equipment (12-Point Checklist)

The gummy industry is highly competitive, and staying ahead means keeping up with the latest technology. Are your gummy production machines holding you back? Discover the signs that it’s time to upgrade your gummy making equipment to ensure quality and efficiency in your production process. If your gummy making equipment is leading to slow production […]

How to Choose the Best Gummy Making Machine for Sale

Choosing the right gummy making machine is a big decision for any gummy business owner. The right machine can help you make your gummies faster, make better gummies, and make more money. This guide will help you choose the best industrial gummy making machine for your business. Determining the production capacity of a gummy-making machine […]

Are You Ready to Start Your Gummy Production Game? A Guide to Using Semi-Automatic Machines

Are you looking to begin your gummy production journey? Semi-automatic gummy machines offer cost-effective and flexible solutions for small to medium-scale production. They provide high precision and quality while being easier to operate and maintain, giving you greater control and reducing waste. This guide will walk you through each step, from mixing raw materials to […]

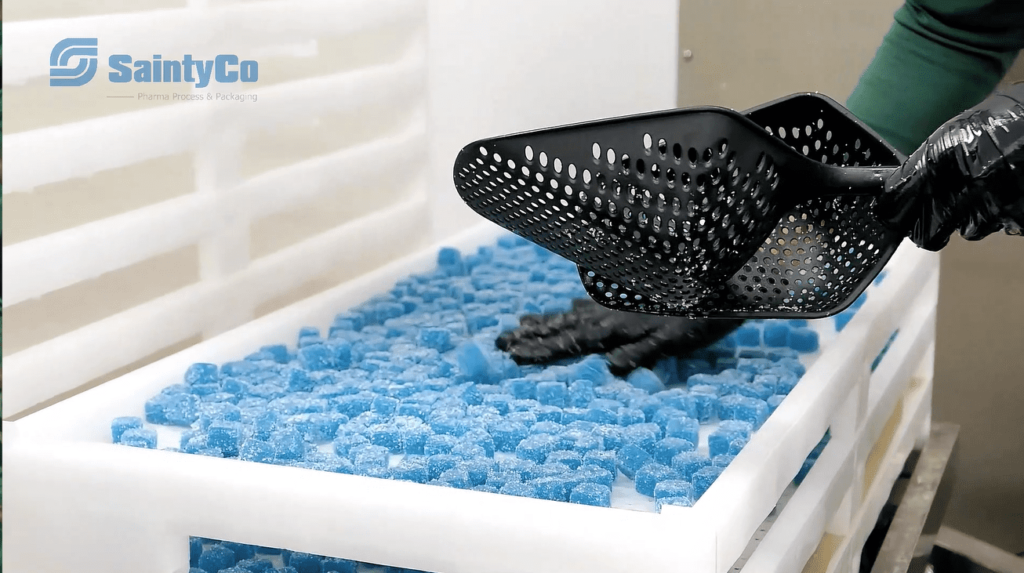

How To Keep Gummy Vitamins From Sticking Together (5 More Tips to Know)

In the growing gummy market, especially for CBD, THC, hemp, and essential vitamin-infused gummies, it’s important to maintain quality during production. One problem many manufacturers face is gummies sticking together. This affects how they look, but it also affects how people feel about them and how they use them. In this article, I’ll show you […]