Optimized Semi and Fully Automated Gummy Packaging Equipment for Supplements, Edibles, and Confectionary,

Ensuring High-Speed, Precise, and Clump-Free Operations.

We Can Handle It All for Gummies

Gummies, with their diverse shapes and sizes, pose unique challenges in packaging, especially those with higher stickiness levels. Yet, with GummyGenix, rest assured, you’re in capable hands.

With 25 years of experience, GummyGenix by SaintyCo specialises in designing, manufacturing, integrating, and servicing innovative, advanced, user-friendly packaging machines for pharmaceutical and food products worldwide.

Packaging Automation Designed for Gummies

Our cutting-edge automation tackles gummy packaging challenges with precision. From pouch and bottle filling to flow wrapping and blister packaging, we ensure precise separation and filling, overcoming clumping issues for containers with wide or narrow openings. Trust us for accurate counts, preventing jams, and preserving product quality. Our easy-to-use machinery ensures maximum throughput and high yield, meeting all size operations’ requirements for packaging integrity and speed.

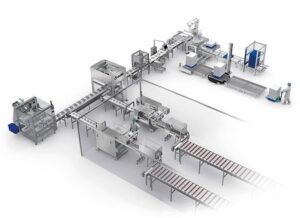

GummyGenix - Your Single-Source Supplier

We tailor primary, secondary, and end-of-line packaging solutions to meet your needs and budget. Our streamlined process covers everything from sourcing, integrating, configuring, testing, to coordinating installation and service, ensuring integration and optimal operation. Experience reduced stress and faster ROI with our dedicated support. We stand behind our systems, ensuring they perform as promised. Trust GummyGenix to optimize your packaging process from start to finish.

Your Packaging Types, Our engineering expertise

At GummyGenix, you’ll find machinery designed to optimize your packaging process, cutting your labor costs, enhancing efficiency, and ensuring safety. Choose your packaging type, and let our expert show you how our gummy packaging equipment can streamline your operations and significantly boost your brand’s visibility.

Your Gummy Specifications, Our Precision Filling Systems

Ensuring precision in packaging nutraceuticals, vitamins, and THC- or CBD-infused gummies is vital for compliance, consumer safety, and satisfaction. Whether it’s multi head weighing for consistent weight or optical counting for accurate dosages, our systems are tailored to fulfil your requirements.

Explore our range of gummy packaging solutions today and discover the perfect fit for your production needs.

Optical Counting & Filling Solutions for Gummies

- Reduces handling to keep gummies clean.

- Delivers consistent quantities for customer trust.

Multihead Weighing Systems for Efficient Gummy Packaging

- Speeds up production for large batches.

- Adapts to various product weights.

Gummy Counting & Bottle Filling Machines

Precision in every piece, speed for any size operation. Count and fill containers at 20 to 60 units per minute. Explore our solutions. Boost your production efficiency now.

SC V1/SC V4

Semi-Automatic Vibration Bowl Counter

UP TO 10 BOTTLES PER MINUTE WITH MANUAL ASSISTANCE

GummyGenix’s SC Series counters are engineered for precision and ease of use, ideal for semi-automated environments.

Perfect for small-scale operations or as reliable backup systems, these counters maintain continuous high-quality production, ensuring efficiency even in limited spaces.

| MODEL | SC-V1 | SC-V4 | Electrics | 220V,50/60Hz, Single Phase, 2.2kW | 220V,50/60Hz, Single Phase, 2.2kW |

|---|---|---|

| Dimensions | 900* 860*1500mm | 1560*1200*1600mm |

| Weight | 200Kg | 300Kg |

FC Series

Fully Automatic

Vibration Bowl Counter

UP TO 20 BOTTLES/MINS WITH PRECISION COUNTING

Our FC Series Fully Automatic Vibration Bowl Counter is engineered with Teflon-coated vibratory bowls for seamless gummy handling and a product level sensor for on-demand feeding, ensuring optimal precision and speed. This system automates the counting and batching of gummies into pre-opened containers, minimizing manual intervention. Its compact design, user-friendly interface, and onboard control system facilitate easy integration into existing lines for quick setup.

With multiple bowl configurations available, it adapts quickly to various product types, enhancing flexibility in your operations without requiring extensive modifications.

| MODEL | FC-V1 | FC-V2 | FC-V3 | FC-V4 | Speed | 10 bottles /min | 20 bottles /min | 25 bottles /min | 35 bottles /min |

|---|---|---|---|---|

| Dimensions | 2000*899*1500mm | 2000*951*1500mm | 2000*865*1500mm | 2000*987*1500mm |

| Weight | 180Kg | 200Kg | 210Kg | 220Kg |

Note: The speed is based on 10 counts 3g gummy per bottle.

GummyCount 90

Rapid Channel Gummy Counter

UP TO 60 BOTTLES/MIN for 30-60 COUNTS

GummyGenix GummyCount 90 Counter is an advanced gummy counting machine that combines speed with unmatched accuracy. This machine is equipped with 18 channels and dual silicone funnels, optimizing the processing of large volumes. It features a three-level rear vibrator, adjustable head heights, and variable speeds for enhanced flow control. Optical sensors and dynamic memory flaps ensure accurate counts for continuous, uninterrupted operation without machine stops. Maintenance is streamlined with tool-free dismantling.

The GummyCount 90 outperforms traditional weighing systems, making it perfect for environments that demand precise handling of edible gummies, vitamins, supplements, and other solid dosages such as soft gels, capsules, tablets, and candies.

| MODEL | GummyCount 90 | Capacity | 50-60 bottles/min for 30 and 60 counts; 30-40 bottles/min for 90 and 120 counts |

|---|---|

| Output (Standard product/min) | Maximum 9,000 pcs |

| Product Size Range | 2-30mm |

| Container Height Range | 25-100mm |

| Dimensions | 3000mm W *1900mm H *1250mm D |

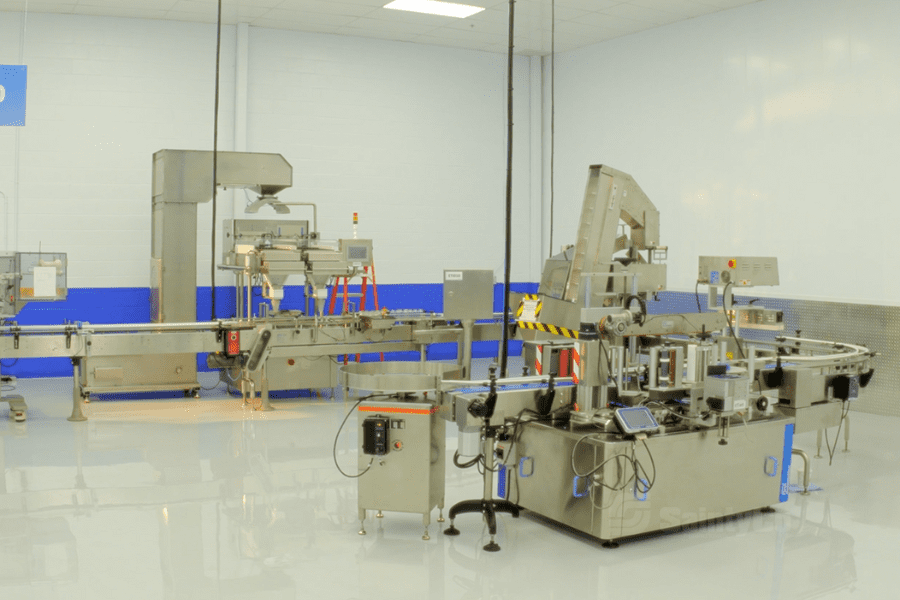

Turnkey Packaging Line for

Gummy Counting, Bottle Filling and Capping

SEAMLESS INTEGRATION FOR UP TO 120 BOTTLES/MIN

Elevate your gummy packaging process with our FC Series, designed for unerring precision and operational efficiency.

This system features advanced sensor technology for exact counts, minimizing discrepancies. Its compact design and user-friendly interface ensure easy integration into existing lines, facilitating a seamless transition and rapid setup, ideal for enhancing automation without major system overhauls.

Gummy Weighing & Bottle Filling Lines

Streamline your packaging with precise weigh fillers and automated capping and labeling for bottles and jars. Tailor setups to boost your bottling efficiency.

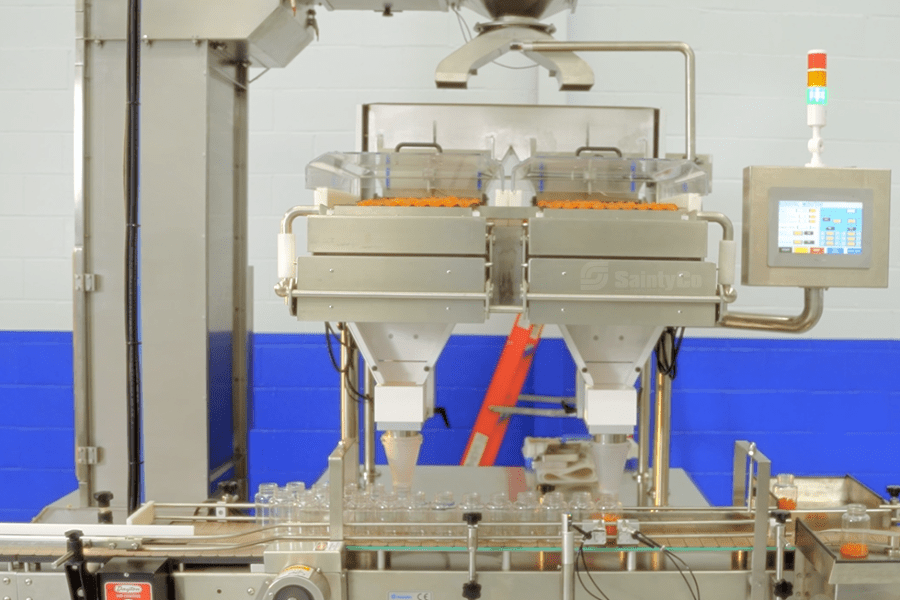

Weighing & Bottling Line

for Gummies

INTEGRATED WEIGHING AND BOTTLE FILLING CAPACITY UP TO 60 BOTTLES/MIN

This integrated system merges a Multi-Head Combination Weigher with a rotary bottle-filling machine, optimizing packaging for gummies in rigid containers like bottles and jars. It delivers fast, precise packaging while ensuring uniform quality, avoiding underfilling or overfilling, and enhancing product presentation. Suited for various gummy sizes and shapes, it includes a continuous motion star wheel, traveling funnels, and quick-change setups, minimizing downtime. Gentle handling preserves the quality and appearance of each piece.

Full automation seamlessly enhances processes such as bottle unscrambling, weighing, filling, capping, induction sealing, and labeling, boosting efficiency and reducing labor costs—ideal for large-scale operations.

Gummy Counting & Pouch Filling Equipment

Streamline your packaging process with our versatile system that integrates gummy counting and fill-and-seal operations. This solution is tailored for custom pouches, eliminating the need for rollstock. Experience swift pouch size changes, efficient setups, and the flexibility to adapt to market changes.

Ultra-1

Pre-made Pouch Filling Machine

FILLS UP TO 15 POUCHES PER MINUTE

Teaming up our optical counting machine, the Ultra-1 Mini Pre-made Pouch Filling Machine streamlines your gummy packaging into doypacks from pickup to opening, filling, and sealing with its compact, single-station design.

This machine features a 7″ user-friendly HMI and PLC control for high-efficiency operations, accommodating large pouches and significant weights. It offers optional enhancements like a date printer, MAP function, automatic zipper opener, and an output conveyor for increased functionality. Engineered with a new generation sanitary design, the Ultra-1 ensures easy cleaning and low maintenance. Its automatic sensors optimize material use by preventing waste.

Ideal for small to medium production lines, this machine boosts operational flexibility and reliability, accommodating a variety of pouch styles and sizes.

| MODEL | Ultra-1 | Speed | 8-15 pouches/min |

|---|---|

| Pouch Size | Width 100-300mm; Length 130-350mm |

| Pouch Materials | Heat sealable laminated film |

| Pouch Type | Stand-up, resealable, pre-formed, flat-bottom, three-side seal, and zipper pouches (zip lock, top zip, heat seal). Additional options include Kraft window open paper pouches and PE/soft pouches, with customization available |

| Dimensions | 1760*900*1870 mm |

Note: Machine speed varies depending on product characteristics and filling volume.

GummyCount 40 Counter & Ultra-8 Rotary Pouch Fill and Seal Packaging Machine

ACCURATELY COUNTS UP TO 40 POUCHES PER MINUTE

GummyGenix’s GummyCount 40 Rapid Channel Gummy Counter excels in rapid, accurate counting and filling, ideal for handling high-stickiness gummies or large production volumes and reducing downtime.

Complemented by the Ultra-8’s advanced rotary filling and sealing capabilities, this duo is perfect for medium-scale operations needing versatile pouch configurations and consistent quality.

| MODEL | Ultra-8 | Speed | 30-40 pouches/min |

|---|---|

| Pouch Size | Width 100-220mm; Length 150-330mm |

| Pouch Materials | Heat sealable laminated film |

| Pouch Type | Flat pouches, standup pouches, zipper pouches, gusset pouches, and corner spout pouches, customizable with different optional parts |

| Dimensions | 2680*1860*1675 mm |

Note: Machine speed varies depending on product characteristics and filling volume.

Gummy Weighing & Pouch Filling Equipment

Achieve consistent, accurate pouch fills with our advanced multi-head weigher, which dispenses precise weights seamlessly into a moving rotary base. Enhance your efficiency and cut operational costs. Act now to revolutionize your packaging process with our solutions.

Ultra-8S

Rotary Pouch Filling and Sealing System

with a Multi-Head Weigher

FILLS UP TO 40 POUCHES PER MINUTE

Combining the precision of the Multi-Head Weigher with the speed of the Ultra-8S, this system offers a superior packaging solution. Perfect for high-volume operations, it excels in rapid, accurate weighing and efficient sealing of diverse pouch types.

Ideal for industries demanding high throughput and consistent quality, enhancing productivity without compromising precision.

| MODEL | Ultra-8S | Speed | 30-40 pouches/min |

|---|---|

| Pouch Size | Width 100-220mm; Length 150-330mm |

| Pouch Materials | Heat sealable laminated film |

| Pouch Type | Flat pouches, standup pouches, zipper pouches, gusset pouches, and corner spout pouches, customizable with different optional parts |

| Dimensions | 2680*1860*1675 mm |

Gummy Weighing & Vertical wrappers (VFFS)

Maximize cost-effective gummy packaging with our Vertical Form Fill Seal Machine, offering multi-head weighing and precise film control. Elevate your production economically with our sanitary, servo-driven system. Explore our solutions now.

VF-420 Vertical Flow Wrapper

PACKAGES UP TO 40 BAGS PER MINUTE

The system will finish all the processes automatically: feeding, dosing, filling, sealing, date printing and finished product conveying. It has the advantages of highly accurate weighing and high efficiency without broken material.

Its compact design is perfect for maximizing space efficiency in production environments where floor space is at a premium.

| MODEL | VF-420 | Speed | 30-80 bags /min |

|---|---|

| Bag Size | Width 60-200mm; Length 60-300mm |

| Packaing Material | OPP, PE, PVC, OPP/CPP, OPP/PE, PET/VMPET/PE |

| Roll Film Size |

Outer diameter D≤Ø300mm, Inner diameter D=74mm |

| Dimensions | 4600*2000*3600mm |

Horizontal Flow Wrapper Machine

for Individual Gummies

Stand out by individually wrapping your gummies with our Horizontal Flow Wrappes. Enjoy high-quality seals, flexible packaging options, and sustainable materials to elevate your brand. Discover the transformational impact on your product presentation.

HSB-400/800/1200

High-Speed Bowl Wrapper

WRAPS UP TO 1200 PCS/MIN

This series adapts to both small and large-scale operations, ensuring product integrity with high-speed efficiency.

Packaging films include OPP, CPP, PET, VMPET, Aluminum Film, and Single and Multi-layer Hot-Seal Films.

Equipped with advanced control systems, the HSB wrappers deliver consistent quality, ideal for businesses aiming to enhance their production capabilities.

| MODEL | HSB-400 | HSB-800 | HSB-1200 | Speed (pcs/min) | 50-400 | 100-800 | 100-1200 |

|---|---|---|---|

| Gummy Size (mm) |

L: 12-60mm, W: 12-30mm, T: 5-25mm |

L: 12-60mm, W: 12-30mm, T: 5-25mm |

L: 10-40mm, W: 10-30mm, T: 5-18mm |

| Package Length (mm) | 55-80 | 55-80 | 45-65 |

| Film Roll Outer Diameter(mm) | Ø350-400 | Ø350-400 | Ø350-400 |

| Film Roll Inner Diameter(mm) | Ø75-76 | Ø75-76 | Ø75-76 |

| Dimensions | 3450*1240*1580mm | 3450*1240*1580mm | 3012*1334*1885mm |

Blister Packaging Equipment for Gummy Products

Ensure your gummies are ready for medical use or consumption with our hygienic, easy-to-use blister packaging unit dose machines. Benefit from our advanced form-fill-seal (FFS) technology for rapid, secure market entry, free from contamination.

BP-120/150/260

Blister Packing Machine for Gummies

SEALS UP TO 60 CYCLES PER MINUTE

Optimize your gummy packaging with the BP Series Blister Packaging Machine, which is ideal for operations requiring product safety, extended shelf life, and high-speed capabilities.

Designed for the pharmaceutical and food industries, this advanced system efficiently seals products in cavities with options for paper, aluminum, or film backings, adapting to various production speeds.

Your Challenges, Our Optimized Packaging Solutions

Discover how GummyGenix’s packaging machinery, designed specifically for gummy products and compliant with regional regulations, outperforms traditional confectionary equipment. Explore advanced features tailored to your unique packaging needs, with additional customization options to enhance your operations.

Leading Supplier of Gummy Production & Packaging Machines

At GummyGenix, we harness our parent company SaintyCo’s expertise in pharmaceutical machinery to deliver advanced, automated processing and packaging solutions specifically designed for the gummy industry.

Our commitment at GummyGenix goes beyond equipment – we’re devoted to nurturing entrepreneurship. Our systems are built to support your growth from small-scale operations to large-scale enterprises, offering flexible and innovative solutions that set industry benchmarks.

Discover Why GummyGenix is your strategic choice?

Choose GummGenix for more than just equipment—partner with us for a partnership that promises comprehensive, innovative solutions tailored to your needs. Our dedication to customer-centric service and reliable processing & packaging technology positions your gummy business for success.

Pharm Grade Compliance

Our machines are designed to meet GMP, cGMP, WHO, CE, 21CFR Part II standard compliance , using FDA-approved materials, ensuring precision and hygiene for enhanced global market access and customer satisfaction.

Labor-Saving Technology

Our automation solutions significantly reduce labor requirements, with clients reporting up to 50% savings in labor costs.

Custom Designs for Clump-Free Packaging

We tailor packaging lines using more gummy-friendly materials and mechanical innovations to prevent clumping, enhancing both quality and efficiency.

Guaranteed Quality & Support

Each unit undergoes a comprehensive Factory Acceptance Test (FAT) , documented extensively to ensure it performs optimally under your specific conditions.

Worldwide Support

Our staff and representatives around the world, including in the United States, Canada, and Europe, ensure prompt and effective technical support, minimizing downtime.

Rapid Customer Service

We guarantee responses within 1 working day, focusing on minimizing production interruptions and ensuring smooth operations.

Benefitsof working with gummyGenix

Complete Product Testing & Support

Every packaging challenge is unique. We invite you to send product, bag, label, and container samples for a free evaluation, ensuring our recommended equipment meets your specific needs. Our commitment to quality and reliability includes ongoing support for the lifespan of your equipment.

Machines to Fit Your Budget

Whether you're new to packaging, expanding, or well-established, GummyGenix offers the ideal machine for you. Our range includes cost-effective entry-level models and advanced high-speed packaging lines, designed to meet your specific operational and financial goals.

Seamless System Integration

Our engineers specialize in tailoring packaging machinery to enhance performance, versatility, and efficiency. We're ready to help design and integrate the ideal workflow that complements your current operations, boosting productivity.

Decades of Product Experience

Our automated packaging machines come with tooling options, suitable for a range of products from soft gummies to hard candies, as well as softgels and tablets. For those handling multiple products, easily customize your tooling to guarantee seamless performance between your equipment and products.

Expanding services, Your Accelerator to Gummy Success

At GummyGenix, we’re all about your satisfaction. From choosing your machine to cranking up production, We cut the hassle so you can quickly start seeing profits. We’ve got your back, every step of the way.

Documentation and Certification

- GMP documentation package (IQ/OQ/PQ)

- Standard CE certification on all machines

- Optional Certifications compliant with CAS (Canada) and UL (USA) for Electrical and Mechanical Safety

Onboarding & SOP Development

- Ensures compliant, safe, and hygienic packaging procedures.

- Covers full-line assembly, installation, and testing by trained staff

Production Planning

- Facility layout optimization

- Packaging line design

- Integrated system solutions for max output

Team Empowerment

- On-site training for supervisors and operators

- Comprehensive guidance covers assembly, maintenance, and troubleshooting

Logistics Support

- Tailored logistics for timely, budget-friendly delivery

- Facilitates customs clearance

- Optional door-to-door delivery

Ongoing Support and Assurance

- Spare parts and technical help

- 2-year warranty

- Prompt solutions via video calls, and on-site assistance

Industry Proven

Empowering gummy manufacturers and entrepreneurs with GummyGenix: with you from day one, forging ahead.

Our Clients Share Their Recommendations

Our selection of SaintyCo machinery — ULTRA-8 Pouch Filling, Gummy Elevator, GummyCount 40, Inline Capping, and Check Weigher — has markedly elevated our operational efficiency. Their user-friendly setup and rapid service align perfectly with our emphasis on ROI and productivity. I recommend SaintyCo for reliability in service and technology.

SaintyCo's gummy packaging machines have transformed our production. Their counting, filling, capping, labeling, and UV sterilizing machines are top-notch. Communication with Leo's team is smooth. Their support and knowledge stand out. We're growing, thanks to this partnership.

We're stepping up our game with SaintyCo's dual-lane liquid filler. It's all about taking our packaging to the next level, especially with our latest health-conscious food products. And the responsive LA-based technical support from SaintyCo is appreciated. on-site commissioning ensures our operations continue to run like a well-oiled machine.

SaintyCo's pouch filling and packaging machine has proven to be an invaluable asset in our production line, efficiently catering to our specific need to package infused gummies into Child Resistant Mylar Bags. Its rapid and reliable performance ensures we meet our operational targets while maintaining product integrity, truly a testament to our drive for innovative,efficient, and compliant solutions.

Implementingh SaintyCo's G150 gummy production line and GummyCount 90 has been a strategic move for us, ensuring adherence to the stringent standards mandated by Health Canada. These machines are pivotal in reinforcing our commitment to quality and compliance in gummy manufacturing and packaging.

SaintyCo's G80 line, gummy counter, labeling machine have elevated our operational efficiency, offering the adaptability we require for our diverse gummy products. SaintyCo staff's responsiveness and the machinery's cost-effectiveness are why we highly recommend GummyGenix by SaintyCo.

We chose SaintyCo's Ultra-8 Pouch Filling machine, along with the GummyCount 40, a gummy loader, and a metal detector. Each piece of equipment has been a fantastic addition to our line. They've really boosted our packaging capabilities. What I appreciate most is their focus on health and safety. It's clear SaintyCo understands what companies like ours need. They offer solutions that truly align with our mission. And that's invaluable to us.

Frequently Asked questions

Still can’t find the information you want? Don’t hesitate to contact us.

Our gummy packaging machines are designed with the medical and recreational cannabis sectors in mind, offering unmatched versatility and compliance. They efficiently handle specialized tasks like filling preprinted mylar bags and custom packaging, meeting the rigorous standards these industries demand. With certifications such as cGMP, ISO 9001:2015, and CE, our machines guarantee that your packaging processes adhere to the highest levels of regulatory compliance, ensuring your products meet industry requirements and customer expectations alike.

Our gummy packaging machines are designed with the medical and recreational cannabis sectors in mind, offering unmatched versatility and compliance. They efficiently handle specialized tasks like filling preprinted mylar bags and custom packaging, meeting the rigorous standards these industries demand. With certifications such as cGMP, ISO 9001:2015, and CE, our machines guarantee that your packaging processes adhere to the highest levels of regulatory compliance, ensuring your products meet industry requirements and customer expectations alike.

Our advanced channel counter addresses the common challenge of feeding sticky gummies through standard counting equipment. This technology allows for precise counting of gummies into containers, improving dose accuracy compared to traditional weight-based packaging. Our solution enhances efficiency and accuracy in gummy packaging, setting a new industry standard.

We provide bespoke modifications to align perfectly with your production needs. Please contact us at [email protected] for a tailored solution.

Absolutely. Our machines can be easily adapted to work with various types of gummy production equipment, ensuring a smooth and efficient packaging process that enhances your overall operation.

Our machines are equipped with advanced technology that allows them to adapt to various gummy shapes and sizes seamlessly. Utilizing precision sensors and adjustable settings, the machines can quickly switch between different product specifications while maintaining high-speed operation and accuracy in packaging. This flexibility ensures that our clients can cater to diverse market demands without the need for extensive machine reconfiguration.

By automating the packaging process, our machines boost productivity and reduce manual labor, ensuring consistent quality, faster production, and lower operational costs.

GummyGenix, is a wholly owned subsidiary of Sainty International Group (SaintyCo). GummyGenix, leveraging its parent company's 25 years of expertise in pharmaceutical and nutraceutical sectors, delivers high-quality production and packaging equipment in the gummy industry. Our strengths range from crafting top-tier machinery to providing excellent post-sales services, solidifying our role as a dependable partner in your comprehensive gummy production journey.

GummyGenix offers comprehensive consultation, implementation, and after-sales service. We walk with you through every stage of the process, from understanding your requirements, testing in our innovation center, to assisting you in the launch. Our commitment doesn't end with installation. We are always available for training services and optimization of your machines.

Sure, we will send you machine demos. And we provide comprehensive information, specifications, and customer service to help you make the best decision.

The order process at GummyGenix involves several steps:

- Confirmation of requirements

Issuing of Proforma Invoice (PI) outlining business terms, prices, services, guarantees - Payment of 30% deposit

- Creation of CAD layout design

- Designing of molds

- Production

Inspection of your machines before shipping - Balance payment

- Shipment

- Installation at your facility

- Training of your staff

Reach out to us via our website's contact form or email us directly via [email protected], and one of our team members will assist you promptly. We'll walk you through the process and ensure a seamless experience.

Our payment terms involve a 50% initial deposit, followed by the remaining 50% before shipping. We always strive for flexibility to accommodate our customers' financial needs.

Typically, our lead time ranges between 30-40 working days for manufacturing, depending on the machine and customization details. We always strive to deliver within the agreed-upon timeline.

Absolutely! We welcome dealers to join us in spreading our services. The commission structure can be discussed upon application.

Solution Inquiries?

Contact us Today

By partnering with GummyGenix, you will benefit from:

- Expertise: Our 20+ years in designing and manufacturing confectionery and pharmaceutical machinery.

- Custom Solutions: Affordable, tailor-made for your gummy-making and packaging needs.

- Technical Mastery: Trust in our deep knowledge of intricate gummy machinery.

- Support: Depend on our responsive after-sales service.

- Productivity: Enjoy seamless operations and optimal productivity.

+1 941-993-6198

via Zoom or at our facility