Your one-stop-shop partner for

Gummy Making Machines

From small size machinery to production lines and packaging equipment—GummyGenix streamlines your gummy bear production.

Enjoy easy sourcing, full support, and cost-effective solutions that meet regulatory standards. Create gummies that captivate and grow your brand.

For 25 years, trusted by businesses like yours—private labels, contract manufacturers, and leaders in the pharmaceutical, nutraceutical, and cannabis sectors.

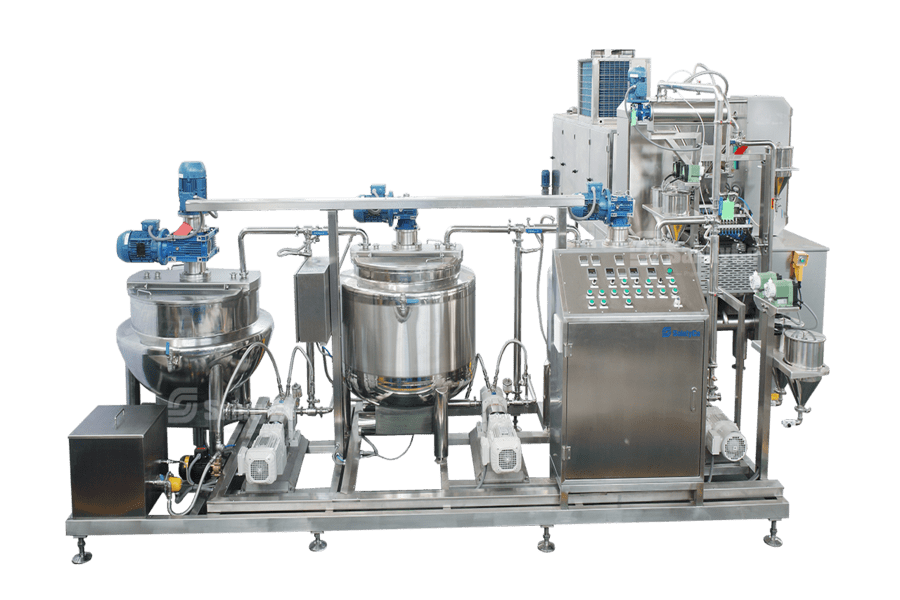

Gummy Production Technology: Boost Efficiency & Output

Starting or expanding a gummy line can be intricate. You can trust our two-decade-strong gummy technologies to simplify the process. From raw material dissolution to final product packaging, our technologies ensure consistent quality, seamless integration, and innovation at every step of your gummy production.

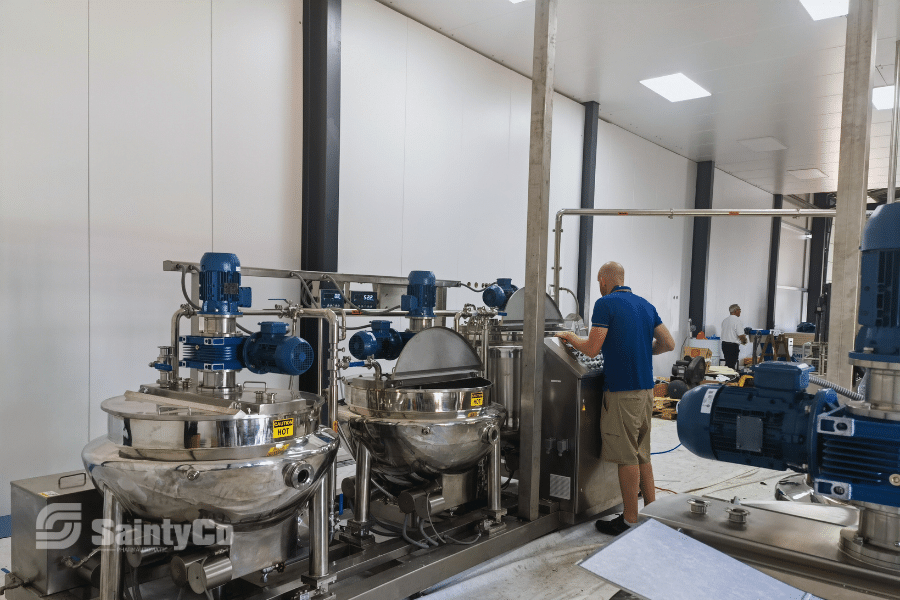

Incorporate industry-standard processes and a modular design, ensuring precise ingredient weighing, thorough mixing, controlled syrup boiling, and cooking.

Handle ingredients gently, promotes energy efficiency, and guarantees accurate recipes, clear gummy textures, and easy cleaning.

Utilize precise CFA systems and automatic metering pumps to transfer liquid and dry ingredients, including Vitamin, colors, flavors, and acid, for premixing with syrup.

Enable customized flavor profiles and enhances gummy product quality and possibilities.

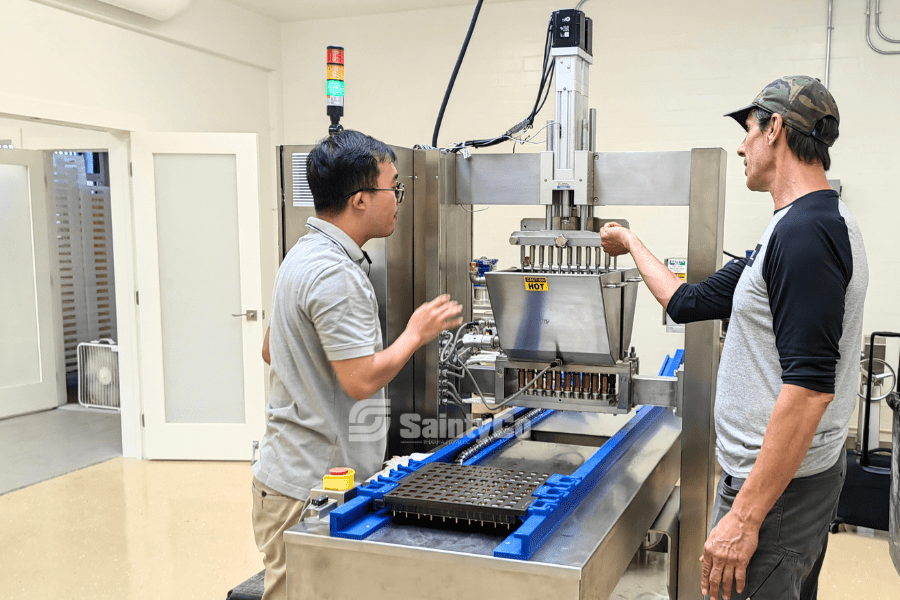

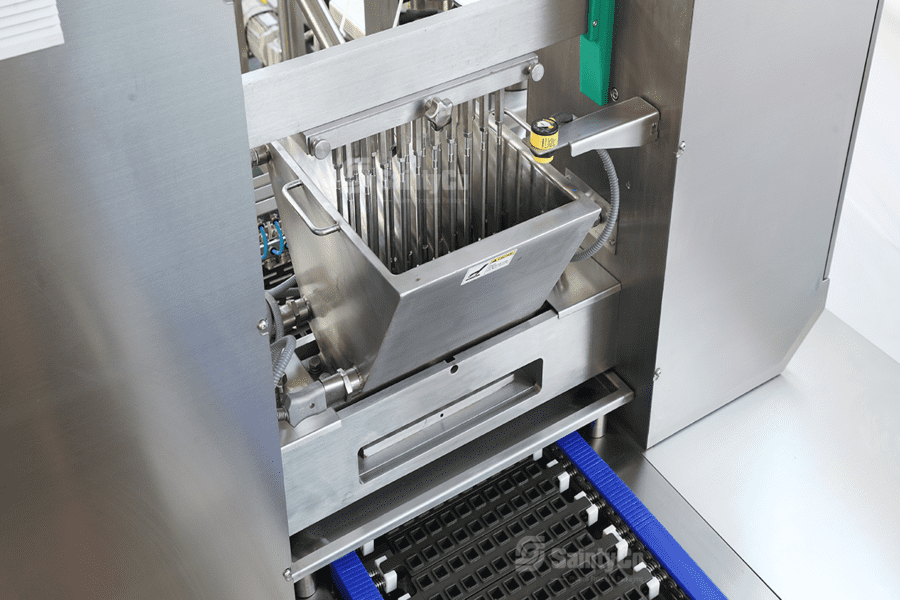

Pour gelatinous syrup accurately into molds using specific-sized nozzles, powered by servo-driven technology. Eliminate the need for drying with the cooling process, allowing the production of solid, striped, layered, and filled gummies in both 2D and 3D formats.

Enhances creative possibilities in product development.

Provide gentle handling, thorough polishing, and flexible settings to accommodate different coatings.

Protect gummy candies from sticking, drying, and environmental factors, while achieving the desired shiny or matte finishes.

Enable efficient counting and packing of gummy and sticky products into bags, pouches, or bottles.

Save time and effort.

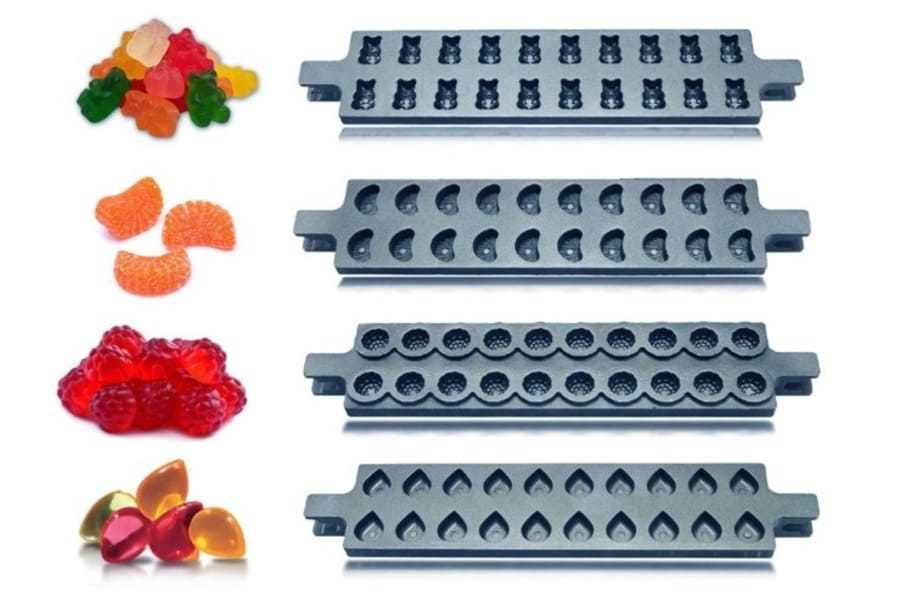

Discover our custom-made gummy molds in diverse shapes, crafted from metal or silicone. Personalize your gummies with custom logos, symbols, or shapes. Choose between standard or quick-release designs for easy demolding.

Reliable, Affordable Gummy Equipment: Fit Your Production Goals

Amplify production 4X with our DM- and G-series gummy depositors: 6,000-18,000 gummies/hour for small batches, up to 240,000 for large-scale.

Need supporting machinery or custom molds? We’ve got that too. Experience precision, budget-friendly options, and customization all in one place.

Small Scale Gummy Making Equipment

Ancillary Equipment for Gummy Manufacturing

Customizable Gummy Packaging Machines

Custom Gummy Molds

Gummy Production Support: Complete Services for Success

At GummyGenix, we offer more than machines—we provide the support you need to buy with confidence, run smoothly, and grow your profits. You’re building your business, but with GummyGenix, you’re never alone. Let’s see how we can help you succeed.

Types of Gummies:

Expand Your Production Potential

- Mono

- Center-filled

- Side-by-side

- Double-layered

Gummy Manufacturing Equipment Supplier: Your Trusted Partner for Project Success

At GummyGenix, a sub-brand of SaintyCo (Sainty International Group), we leverage over 20 years of SaintyCo’s expertise in advanced pharmaceutical machinery. This foundation drives our automated gummy production and packaging solutions for industries like confectionery, cannabis, and nutraceuticals.

We’re committed to empowering entrepreneurs with innovative solutions, comprehensive support, and a proven track record in building lasting partnerships.

- 20+ Years in Confectionery and Pharmaceutical Industries

- 10+ In-house Professional Staff

- 5+ Patented Technologies

- 1000+ Custom Strategies

- 48-Hour Quote Turnaround

- Price Match Guarantee

- Flexible Payment Plans

- 30% Faster Lead Times

- 24/7 Customer Support

countries SERVED

Happy Clients

Avg. Production Growth

Installed depositing lines

GMP & CE Certified Gummy Machinery:

Reliable Performance

Gummy Manufacturing Success Stories

Empowering CBD Startups

A comprehensive machinery solution enhances gummy production for a Texas entrepreneur – By February 2023, this investment resulted in a 30% surge in production output. This progression exemplifies the real-world advantages startups can harness with machinery that melds fiscal prudence with operational excellence.

From Market Entry to Strategic Upscaling

A fast-growing pharma and wellness manufacturer’s transition to SaintyCo’s medium-scale automatic production line –

In North Carolina, Mr. Martin’s startup launched with our DM-20S Semi-Auto Depositor, gaining a fast reputation for high-quality CBD/THC gummies. As white-label demand soared, scaling became essential.

Transitioning to the G150 gummy production line wasn’t just an upgrade—it enabled larger orders, expanded client partnerships, and set the stage for long-term growth.

Clients' Trust in Gummy Making Machines

SaintyCo's machines cost us half of what we used to pay, yet they outperform by miles. With their team flying in from Vancouver for on-site assistance streamlined our setup. For those in the gummy business wanting quality without the big spend, you can't go wrong with SaintyCo.

The equipment From Sainty Co is working great. The team and l have proved that they can produce 150 thousand gummies per day. That's with a split shift that starts at 5AM and ends at 6 PM. Leo is great about responding to anything that is brokenand sends parts that are warrantable quickly. I would recommend the G-80 to other people looking to get into this field.

From the moment I started with the G150, moving up to the G800 with SaintyCo was a natural progression. My multiple visits allowed for in-depth collaboration. It's not every day you find a partner willing to integrate your unique engineering ideas and requirements into their lines. With SaintyCo, it felt less like a purchase and more like co-creation.

How can we help you succeed?

Partnering with GummyGenix, you will benefit from:

Expertise: Over 20 years in confectionery and pharmaceutical machinery design.

Custom Solutions: Tailored, cost-effective gummy machinery solutions.

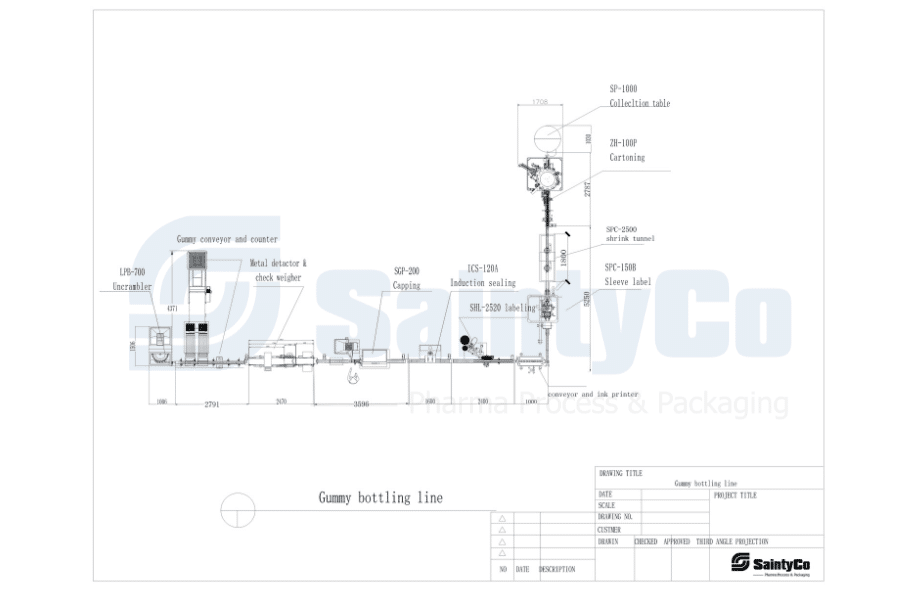

Support: Financing, custom gummy formula, facility layout design, SOP optimization, installment, training, and more reliable after-sales service.

Productivity: Seamless operations for peak productivity.