Choosing the right gummy production machine is vital for your business's success.

The key differences between pharma-grade and confectionery-grade gummy making machines revolve around regulatory compliance, material integrity, cleaning protocols, precision, and cost. Pharma-grade gummy machines are designed for strict pharmaceutical regulations, ensuring high-quality, compliant products, while confectionery-grade machines prioritize efficiency and volume.

This article will provide a detailed comparison of these two types of machinery, enabling you to make informed decisions that align with your production goals.

Pharma-grade machines ensure compliance with strict regulations.True

Pharma-grade gummy production machines are built to meet stringent pharmaceutical standards for safety and quality, ensuring compliance with regulatory requirements.

Confectionery-grade machines prioritize precision over efficiency.False

Confectionery-grade gummy production machines focus on high-volume output rather than precision, which is essential in pharmaceutical applications.

What Regulatory Standards Apply to Each Machine?

Regulatory standards play a crucial role in ensuring the safety and efficacy of gummy production machinery. What specific standards should you be aware of for pharma and confectionery machines?

Understanding regulatory standards for gummy production machinery is essential for compliance and safety. Pharma-grade gummy making machines must meet FDA and GMP requirements, while confectionery-grade machines follow less stringent regulations.

Understanding Regulatory Standards for Pharma-Grade Gummy Making Machines

Pharma-grade machines, crucial for producing medicinal gummies, must comply with stringent regulatory standards. The FDA (Food and Drug Administration) sets guidelines to ensure safety and efficacy in pharmaceutical manufacturing. Compliance with Good Manufacturing Practices (GMP) is essential, focusing on cleanliness, product quality, and batch traceability. This compliance involves using materials like SS316 stainless steel, known for its corrosion resistance and ability to endure rigorous cleaning processes.

For example, a pharma-grade gummy depositor may utilize advanced systems that ensure precise ingredient dosing while maintaining temperature control to protect sensitive components like CBD oil. This level of precision not only adheres to regulatory standards but also enhances product quality. For more on FDA guidelines1.

Compliance in Confectionery-Grade Gummy Machines

In contrast, confectionery-grade machines are designed primarily for efficiency and speed, focusing on high-volume production of standard gummies. While they maintain hygienic practices, they are subject to less stringent regulations compared to their pharma counterparts. Typically, these machines utilize SS304 stainless steel, which is durable but less resistant to harsh cleaning agents compared to SS316.

This means that while confectionery machines can produce safe edible products, they may not meet the exacting standards required for pharmaceuticals. If you’re considering entering the gummy market, understanding the difference in compliance requirements is critical. Explore more about confectionery standards2.

Key Regulatory Frameworks

| Regulatory Body | Relevant Standards | Applicability |

|---|---|---|

| FDA | GMP | Pharma-grade machines |

| ISO | Quality Management | Both grades of machines |

| OSHA | Workplace Safety | All machinery used in production |

The ISO (International Organization for Standardization) standards also apply across both machine types, focusing on quality management systems. Implementing ISO standards can improve overall operational efficiency and safety. For detailed information about ISO standards.

Importance of Safety Regulations for Gummy Production

Safety is paramount in any production environment. The OSHA (Occupational Safety and Health Administration) regulations ensure that all machinery operates within safe parameters, reducing the risk of workplace accidents. This includes guidelines on machine maintenance and operator training to prevent hazards associated with equipment operation.

For instance, regular inspections and adherence to safety protocols can mitigate risks related to equipment failure or improper handling of materials. Engaging with OSHA guidelines ensures your operation remains compliant while fostering a safe work environment. More insights on OSHA regulations3.

By understanding these standards, you can make informed decisions when investing in gummy production machinery, ensuring compliance and safety while maximizing product quality.

Pharma-grade machines must comply with FDA regulations.True

FDA guidelines ensure safety and efficacy in pharmaceutical manufacturing, making compliance essential for pharma-grade machines.

Confectionery-grade machines follow the same standards as pharma machines.False

Confectionery-grade machines are subject to less stringent regulations than pharma-grade machines, focusing primarily on efficiency over strict compliance.

How Do Material Choices Impact Gummy Production Quality?

Material choices significantly impact production quality in gummy manufacturing. Different types of machines and their materials can affect hygiene, ingredient integrity, and compliance with regulations.

Material choices directly affect the production quality of gummies. Pharma-grade gummy manufacturing equipment with SS316 stainless steel ensure hygiene and precision, while confectionery-grade gummy machines with SS304 focus on cost efficiency but may compromise on safety.

Understanding Material Selection in Production Quality

Material choices play a crucial role in determining the overall quality of products manufactured in various industries. When it comes to gummy production, the materials used in equipment can directly influence the final product's safety, consistency, and compliance with regulations.

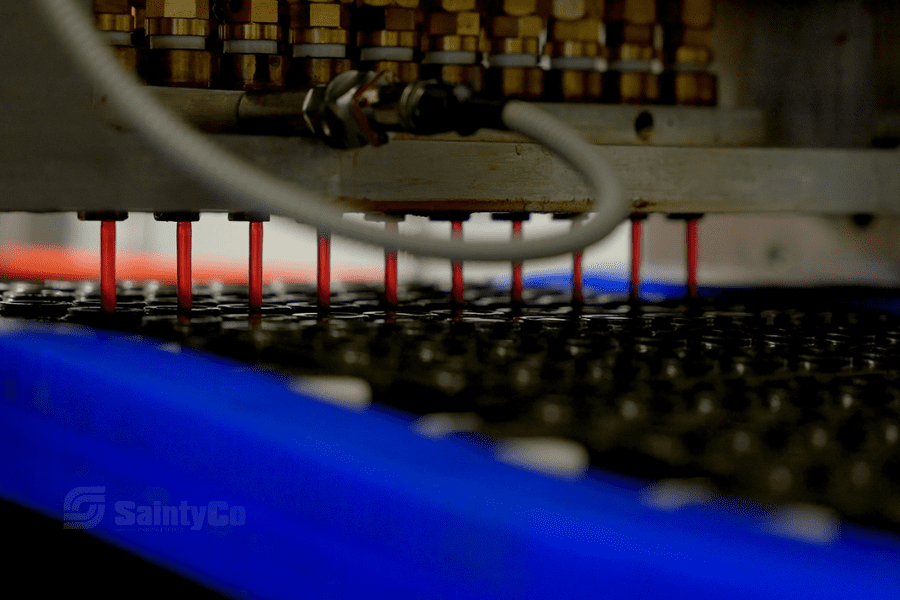

For instance, pharma-grade gummy machines utilize 316 stainless steel, which is highly resistant to corrosion. This is vital in environments where acidic ingredients are present or when dealing with sticky formulations. The right materials can withstand rigorous cleaning protocols like Clean-In-Place (CIP)4 systems, ensuring that no residual contaminants affect the health of consumers.

In contrast, confectionery-grade machines often rely on 304 stainless steel. While it’s durable, it is not as resistant to harsh cleaning agents or acids. This can lead to increased maintenance needs and potential product safety issues if not managed properly. Understanding these differences can guide businesses in selecting the right machinery for their production goals.

The Impact of Material on Hygiene and Safety

Hygiene is non-negotiable in food production, especially when producing medicinal or nutraceutical gummies. The materials used in machinery should facilitate easy cleaning and minimize contamination risks.

| Machine Type | Material | Hygiene Features | Cleaning Method |

|---|---|---|---|

| Pharma-Grade Gummy Making Machines | SS316 | CIP/SIP capabilities | Automated high-pressure clean |

| Confectionery-Grade Machines | SS304 | Basic hygienic design | Manual cleaning required |

By investing in pharma-grade machines, businesses can ensure that their production lines meet stringent regulatory standards. This is especially critical for products that require exact dosing of active ingredients like CBD oil or vitamins.

Material Handling and Ingredient Integrity

The ability to handle sensitive ingredients effectively hinges on the material and design of the equipment. Pharma-grade machines often include features like temperature-sensitive heating jackets that help maintain the integrity of active components during processing.

When comparing this to confectionery-grade machines, the focus shifts towards speed rather than precision. For example, while a pharma-grade gummy depositor may ensure consistent temperature control, a confectionery machine might lack the necessary capabilities to manage delicate formulations effectively. For businesses dealing with high-value ingredients, this distinction can significantly impact product quality.

Cost Implications of Material Choices

Investing in higher-quality materials and machinery can lead to significant cost savings over time. While pharma-grade equipment has a higher upfront cost due to its advanced materials and technology, the long-term benefits often outweigh these initial expenses. This is particularly true when targeting regulated markets where quality and compliance are paramount.

Conversely, confectionery-grade machines provide a lower entry cost and are suitable for high-volume production of non-medical gummies. However, these savings may be offset by increased maintenance costs or potential recalls due to quality issues.

| Consideration | Pharma-Grade Machines | Confectionery-Grade Machines |

|---|---|---|

| Initial Investment | Higher | Lower |

| Long-Term Savings | Yes | Limited |

| Market Access | Regulated markets | General candy markets |

| Maintenance Requirements | Lower | Higher |

Navigating Material Choices for Quality Production

Choosing the right materials for gummy production machinery is essential for achieving high-quality outcomes. Understanding how different materials affect hygiene, ingredient integrity, and overall production efficiency can empower businesses to make informed decisions that enhance their operational success.

Pharma-grade machines ensure higher hygiene standards than confectionery machines.True

Pharma-grade machines use SS316 stainless steel, enhancing hygiene and compliance, unlike confectionery machines that may compromise safety due to lower material quality.

Confectionery-grade machines are more cost-effective than pharma-grade machines.True

While confectionery-grade machines have lower initial costs, they may incur higher maintenance costs and potential quality issues over time compared to pharma-grade options.

What Cleaning Protocols Should You Consider?

Discover essential cleaning protocols that are crucial for maintaining hygiene in gummy production environments.

Consider implementing cleaning protocols such as Clean-In-Place (CIP) for pharma-grade gummy making machines and routine manual cleaning for confectionery-grade machines to ensure product safety and compliance.

Understanding Cleaning Protocols

Cleaning protocols are essential in maintaining a hygienic environment, particularly in sectors like food production, healthcare, and manufacturing. These protocols involve systematic procedures to ensure thorough cleaning, sanitizing, and disinfecting of surfaces and equipment.

For gummy production, adhering to stringent cleaning protocols can prevent contamination and ensure product safety. The following sections explore the protocols that should be considered based on the type of equipment used.

Cleaning Protocols for Pharma-Grade Equipment

Pharma-grade machinery demands the highest standards of cleaning. Here are key cleaning protocols:

- Clean-In-Place (CIP): This method allows for cleaning without disassembling the machinery. Cleaning solutions are circulated through the system to remove residues.

- Sterilization-In-Place (SIP): Involves using steam or chemical agents to sterilize equipment internally.

Example of CIP Process:

| Step | Action |

|---|---|

| 1 | Circulate cleaning solution through the system. |

| 2 | Rinse with water to remove residues. |

| 3 | Apply sterilization agent if needed. |

| 4 | Final rinse and dry. |

Implementing these protocols significantly reduces contamination risks, especially when switching between different product lines. For those producing medicinal gummies, CIP/SIP capabilities are crucial to maintain compliance with health regulations.

Cleaning Protocols for Confectionery-Grade Gummy Manufacturing Equipment

While confectionery-grade machines do not require as strict protocols as pharma-grade, cleanliness is still vital. Common practices include:

- Manual Cleaning: Parts may need to be disassembled for thorough cleaning, especially after handling sticky substances.

- Routine Sanitation: Regularly scheduled cleaning to avoid buildup and maintain hygiene standards.

Manual Cleaning Checklist:

| Task | Frequency |

|---|---|

| Disassemble equipment parts | After every batch |

| Clean contact surfaces | Daily |

| Inspect for residues | Each shift |

Utilizing a structured manual cleaning approach ensures that equipment remains sanitary and operational efficiency is maintained.

Importance of Training and Compliance

Both pharma-grade and confectionery-grade operations should prioritize training staff on cleaning protocols. Knowledgeable personnel can effectively execute these protocols, ensuring adherence to safety standards.

- Training Programs: Implement regular training sessions on cleaning techniques and compliance with industry standards.

- Documentation: Keep detailed records of cleaning procedures and schedules for accountability.

For more information on establishing effective training programs, consider exploring best practices in staff training5 that can help enhance your operational efficiency.

To maintain cleanliness in gummy production, it is essential to implement robust cleaning protocols tailored to your specific equipment type. Whether utilizing advanced systems like CIP for pharma-grade machines or effective manual methods for confectionery-grade equipment, a commitment to hygiene will safeguard your products and uphold your brand's reputation. Explore more about enhancing your cleaning processes through advanced sanitation technologies6.

CIP methods are essential for pharma-grade equipment cleaning.True

Clean-In-Place (CIP) ensures thorough cleaning without disassembly, crucial for preventing contamination in pharma-grade machinery.

Manual cleaning is unnecessary for confectionery-grade machines.False

Confectionery-grade equipment requires manual cleaning to maintain hygiene and prevent residue buildup after production runs.

Which Machine Offers Better Precision in Dosage?

Exploring which machine offers better precision in dosage is crucial for manufacturers aiming for quality and compliance. Let's delve into the capabilities of pharma-grade versus confectionery-grade machinery.

When choosing between machines for dosage precision, pharma-grade machines offer superior accuracy and compliance for regulated products, while confectionery-grade machines focus on speed and efficiency for standard gummies.

Understanding Machine Precision in Dosage

Precision in dosage is paramount, especially in industries such as pharmaceuticals and nutraceuticals. Here, the accuracy of each ingredient dispensed can significantly impact product efficacy and compliance with regulatory standards. To explore this topic, we will evaluate Pharma-Grade versus Confectionery-Grade machines.

Pharma-Grade Gummy Making Machines

Pharma-grade machines are designed for environments where precise dosage is non-negotiable. They often include advanced features like:

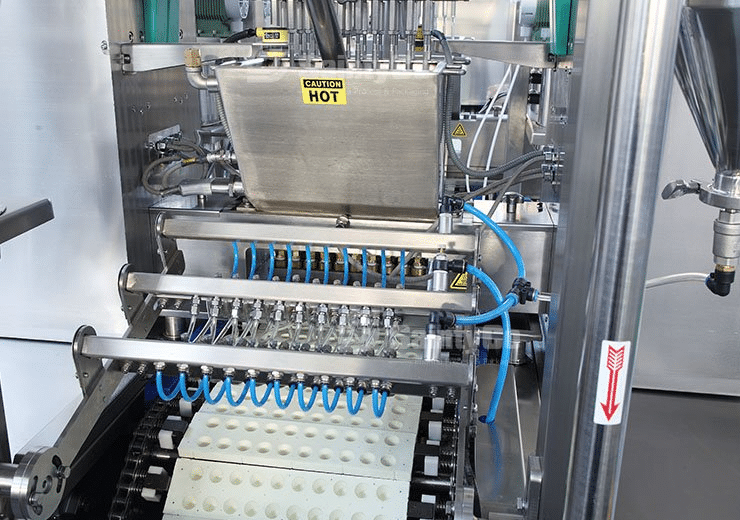

- Automated dosing pumps that ensure consistent ingredient amounts in each gummy.

- Temperature-sensitive heating jackets which maintain the integrity of active ingredients.

Example: A pharma-grade gummy depositor can dispense a precise amount of CBD oil per gummy, ensuring compliance with industry regulations. For detailed insights on these machines, check out Pharma equipment precision[^wmobpid-1].

Confectionery-Grade Gummy Making Machines

Conversely, confectionery-grade machines prioritize high throughput and efficiency over precision. While they can produce gummies quickly, they lack the sophisticated systems necessary for exact ingredient dosing. Features include:

- Simpler dosing mechanisms that may lead to variations in ingredient amounts.

- Standard cooling systems that do not cater to temperature-sensitive ingredients.

In practice, this means a confectionery-grade machine might dispense varying amounts of sugar or gelatin, which is generally acceptable for standard candy production but not for regulated products.

Key Considerations

When selecting a machine, consider the following:

| Feature | Pharma-Grade Machines | Confectionery-Grade Machines |

|---|---|---|

| Precision | High | Moderate |

| Compliance | Strict FDA/GMP standards | Basic hygiene practices |

| Material | SS316 stainless steel | SS304 stainless steel |

| Cleaning Systems | CIP/SIP capable | Manual cleaning required |

| Production Speed | Moderate | High |

Real-World Applications

For instance, if you are producing CBD gummies, the precision of each dose is critical for both legal compliance and consumer safety. In this case, investing in a pharma-grade gummy making machine would be advisable. On the other hand, for producing everyday fruit gummies, a confectionery-grade machine suffices.

Pharma-grade machines ensure precise ingredient dosing.True

Pharma-grade machines are designed for accuracy, featuring automated systems that guarantee consistent ingredient amounts, crucial for compliance in regulated industries.

Confectionery-grade machines prioritize speed over precision.True

These machines focus on high throughput and efficiency, often resulting in variations in ingredient amounts, acceptable for non-regulated candy production.

What Are the Cost Implications of Each Type of Gummy Machines?

Understanding the cost implications of gummy production machinery is crucial for making informed investment decisions.

When choosing between pharma-grade and confectionery-grade gummy machines, consider initial purchase costs, maintenance, operational efficiency, and potential market access to evaluate long-term financial impact.

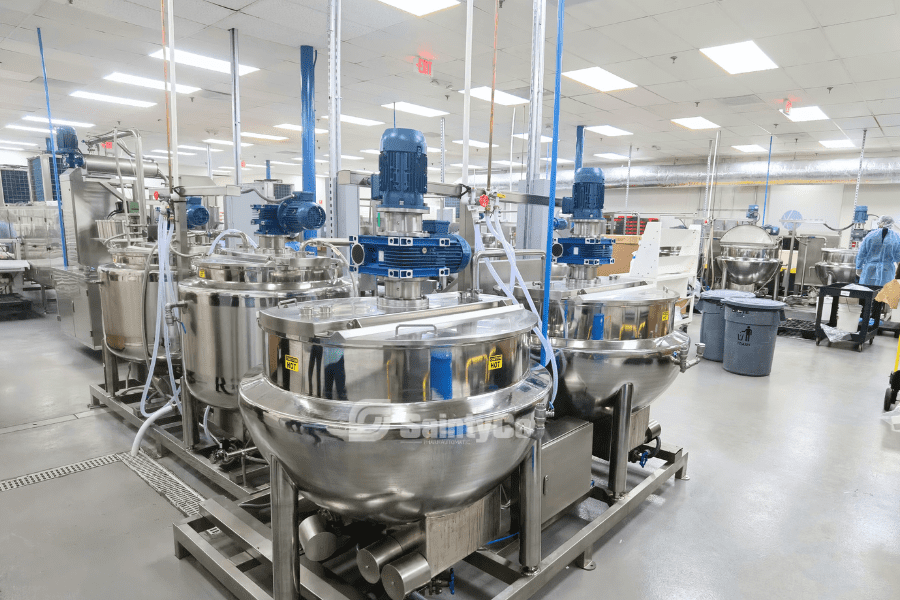

Watch this video showcasing the SaintyCo's Pharma-grade, cGMP comliant G150 Gummy Line in action!

Understanding Cost Implications of Pharma-Grade Machines

Pharma-grade gummy machines require a significant upfront investment due to their advanced features and materials like SS316 stainless steel. This type of machinery is essential for businesses that produce regulated products, such as CBD gummies. The costs associated with these machines include:

- Purchase Cost: Higher due to certification and compliance systems.

- Maintenance Costs: Ongoing maintenance is critical to ensure regulatory compliance and machine longevity.

- Operational Efficiency: While the initial costs are steep, the long-term benefits include access to premium markets and higher profit margins.

For example, investing in a high-quality manufacturing process7 can yield returns in the form of brand reputation and customer trust.

Financial Analysis of Confectionery-Grade Machines

In contrast, confectionery-grade gummy machines are more affordable and designed for high-volume production. They offer:

- Lower Initial Investment: Suitable for businesses looking to enter the market quickly without stringent regulatory constraints.

- Operational Flexibility: These machines can produce a variety of gummies but may not meet the specifications for medical products.

- Maintenance Requirements: Cleaning and maintenance are typically less complex but may require more frequent manual interventions.

This can lead to higher downtime and operational costs in the long run. A business focusing on large-scale candy production8 may find these machines more advantageous initially but could face challenges if they decide to pivot into regulated markets later on.

Cost-Benefit Analysis Table

| Cost Category | Pharma-Grade Machines | Confectionery-Grade Machines |

|---|---|---|

| Initial Purchase Cost | High | Low |

| Maintenance Cost | Moderate to High | Low |

| Operational Efficiency | High (due to automation) | Moderate (manual cleaning) |

| Market Access | Regulated markets (higher margins) | General markets (lower margins) |

| Long-term ROI | Higher due to premium pricing | Moderate, dependent on volume |

Strategic Insights for Business Owners

For gummy business owners like David, understanding these cost implications is vital for strategic planning. If you're focused on high-value products, investing in pharma-grade equipment might be crucial despite the initial financial strain. Conversely, if you aim to capture the broader candy market quickly, confectionery-grade options could suffice.

Ultimately, consider your long-term business goals when evaluating these investments. Using a cost-benefit analysis9 will help clarify which machinery aligns best with your operational needs and market ambitions.

Pharma-grade machines have a higher initial purchase cost.True

Pharma-grade gummy machines require significant investment due to advanced features and compliance systems, making them costlier than confectionery-grade options.

Confectionery-grade machines are ideal for regulated products.False

Confectionery-grade machines are designed for high-volume production but do not meet the stringent specifications required for regulated medical products like CBD gummies.

Conclusion

Explore the key differences between pharma-grade and confectionery-grade gummy production machines regarding compliance, materials, cleaning protocols, precision, and costs for better business decisions.

At GummyGenix by SaintyCo, we don’t just provide equipment—we empower your gummy business with solutions tailored to your success. Here’s what makes us the ideal partner for your venture:

- Competitive Pricing: Top-tier machinery at affordable rates, ensuring a strong return on investment.

- High-Quality Machinery: GMP-compliant, precision-engineered equipment designed to meet evolving industry standards.

- Equipment Financing & Referral Support: Access flexible payment options and financing resources through our trusted partners, helping you secure affordable payments and potential tax advantages.

- Quick Startup SOPs: Basic recipes and production workflows for a fast, hassle-free start. Additionally, we can connect you with leading formulation consultants and global ingredient suppliers for more advanced product development.

- Custom Molds & Recipes: Stand out in the market with bespoke gummy shapes and innovative recipes tailored to your brand.

- Comprehensive After-Sales Support: From setup and training to troubleshooting, we provide the guidance needed to ensure smooth operations and sustained success.

Contact GummyGenix by SaintyCo, you’ll gain the expertise, resources, and support to build a thriving gummy production business. Let’s succeed together.

Gummy Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Explore this link to discover detailed information about FDA regulations affecting gummy production machinery. ↩

-

Find out more about ISO standards relevant to both pharma-grade and confectionery-grade machines. ↩

-

Learn about OSHA safety regulations that impact the operation of all production machinery. ↩

-

Discover how material selection influences production outcomes and quality. Gain insights that can enhance your manufacturing processes. ↩

-

Learn effective cleaning strategies tailored to your industry needs by exploring this resource. ↩

-

Understand advanced sanitation technologies that can enhance your operational efficiency. ↩

-

This link provides detailed insights into the financial ramifications of various types of machinery investments in gummy production. ↩

-

Explore cost-benefit analyses tailored to gummy production machinery investments, helping you make informed decisions. ↩

-

Learn more about strategic financial planning for gummy businesses to maximize profitability. ↩