How to Choose Small Gummy-Making Machines for Your Restaurant?

This ultimate guide helps restaurants choose the right small gummy-making machines by considering production volume, space, customization options, ease of use, budget, and after-sales support for optimal operations.

How Are Creatine Gummies Made and Which Machines Ensure the Best Production?

Creatine gummies are transforming the supplement market by offering a convenient, tasty alternative to traditional powders. Made through a meticulous process involving specialized machines like gummy depositors and cooling tunnels, these gummies ensure precise dosing and maintain ingredient efficacy. Their appeal lies in their chewable format, pleasant flavors, and ease of use for athletes and everyday consumers alike. As consumer preferences shift towards more accessible supplement forms, creatine gummies stand out for their ability to deliver essential nutrients without the hassle of mixing or measuring. The production process faces challenges such as managing creatine’s hygroscopic nature and ensuring even distribution of ingredients; however, innovative machinery addresses these issues effectively. Customization options in flavor profiles and dosages further enhance their marketability, making them a popular choice among health-conscious individuals.

What Makes Baker Perkins Depositors So Expensive?

Baker Perkins depositors are recognized for their high cost, attributed to innovative technologies like ServoForm™, which enhance precision and speed in gummy production. These machines also feature air ejection systems that improve hygiene by minimizing contamination risks. Customization capabilities allow businesses to adapt machinery to specific needs, fostering innovation and ensuring compliance with FDA and GMP standards. Additionally, Baker Perkins provides extensive process support, including recipe optimization and training programs that maximize equipment efficiency. While the initial investment may be significant, the long-term benefits in operational efficiency and product quality make these depositors a worthwhile investment for manufacturers aiming to excel in the competitive confectionery market.

What Makes Truffly Made Depositors So Expensive?

Truffly Made depositors command a premium price due to their exceptional build quality, precision engineering, and advanced features tailored for specialized gummy production. Their durability and reliability make them a preferred choice in the market. However, businesses seeking cost-effective alternatives can consider options like SaintyCo’s DP10S and DM-50X models. These alternatives provide similar benefits at lower prices while maintaining efficiency and ease of use. The DP10S is ideal for startups with small batch needs, while the DM-50X caters to larger operations with higher production speeds. By evaluating specific business requirements, companies can find suitable solutions that balance quality and affordability in gummy production.

What Are the Key Steps to Commercially Manufacturing Mushroom Gummies?

Mushroom gummies are gaining popularity due to their health benefits and ease of consumption. The commercial manufacturing process includes selecting functional mushrooms like Chaga and Reishi, using gelling agents such as gelatin or agar-agar, and employing advanced machinery for precision. Key steps involve grinding mushrooms into powder, mixing ingredients thoroughly, and utilizing automated depositors for uniform gummy shapes. Understanding the specific health benefits of various mushrooms enhances product appeal. Additionally, manufacturers must adhere to strict quality control measures throughout the production process to ensure safety and efficacy. As consumer demand grows for innovative health products, mushroom gummies stand out as a convenient supplement option that combines taste with nutritional value.

How Are Drying Trays and Dollies Essential in Gummy Manufacturing?

Ever tried making gummy bears without the right tools? It’s like baking without an oven! Drying trays and dollies are crucial in gummy production, enhancing efficiency, space management, and product quality. Let’s dive into how these unsung heroes make a difference in the manufacturing process!

Gummy Depositors: Common Clogging Issues and How to Prevent Gummy Clogs?

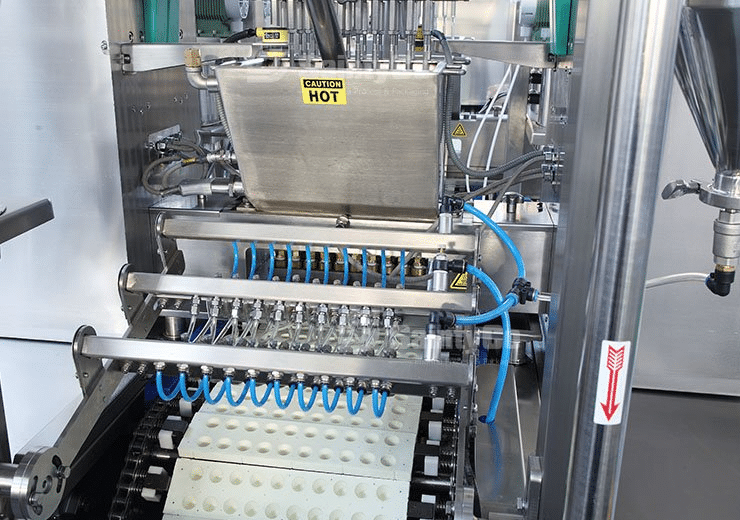

Gummy depositors can experience clogs due to various factors such as thick mixtures, temperature changes, and residual build-up. To prevent these issues, it’s crucial to select appropriate ingredients and maintain consistent temperatures. Regular cleaning and inspections are essential for optimal performance. Implementing strategies like using vacuum degassing systems can help minimize air entrapment while ensuring smooth operations. By understanding the causes of clogs and taking proactive measures, manufacturers can enhance production efficiency and product quality in gummy candy manufacturing.

What Are the Most Important Gummy Manufacturing Equipment for Scaling Production?

Gummy candies have taken the confectionery world by storm, and scaling production to meet demand requires the right equipment. From depositors to packaging machines, each piece plays a vital role. In this article, we’ll dive into the key equipment necessary for a successful gummy manufacturing process.

Gummy Depositors: What Are the Most Common Issues When Using Them?

Gummy depositors are vital in the confectionery industry, but they can encounter several issues. This article explores the most common problems such as inconsistent filling, clogging, and temperature sensitivity, while providing actionable insights to overcome these challenges. By understanding and addressing these issues, manufacturers can optimize their production processes and ensure high-quality gummy products.

What Are the Most Affordable Automation Options for Gummy Production?

If you’re looking to automate your gummy production without breaking the bank, you’ve landed in the right place! This guide explores various affordable options ranging from manual tools to semi-automatic and fully automated systems. Discover how each can enhance your production process while keeping costs manageable. Let’s dive in!