In a fast-paced candy industry, manufacturers need innovative solutions to boost production efficiency and maintain top-quality output. Silicone gummy molds are transforming the way businesses, from small startups to large-scale operations, create gummies. But why should your business choose silicone over other materials? This guide will delve into the unique advantages of silicone gummy molds—highlighting how they can help you cut costs, streamline production, and deliver consistent, high-quality products. Whether you're aiming to scale up or refine your current processes, you'll find everything you need to know right here.

Why Opt for Silicone Gummy Molds for Candy-Making

Silicone gummy molds are a staple for candy businesses for their numerous benefits, including the following:

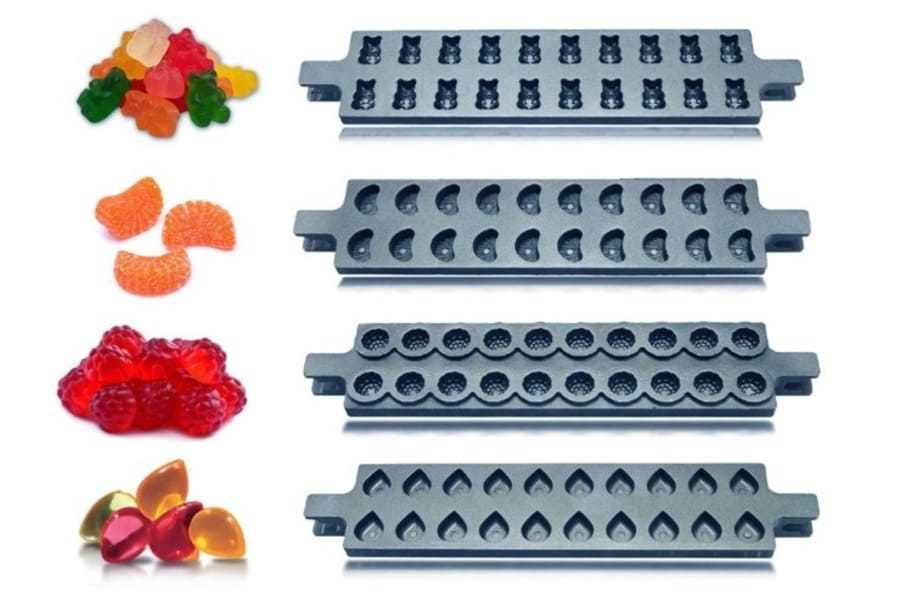

1. The Versatility of Silicone Molds for Gummy Production

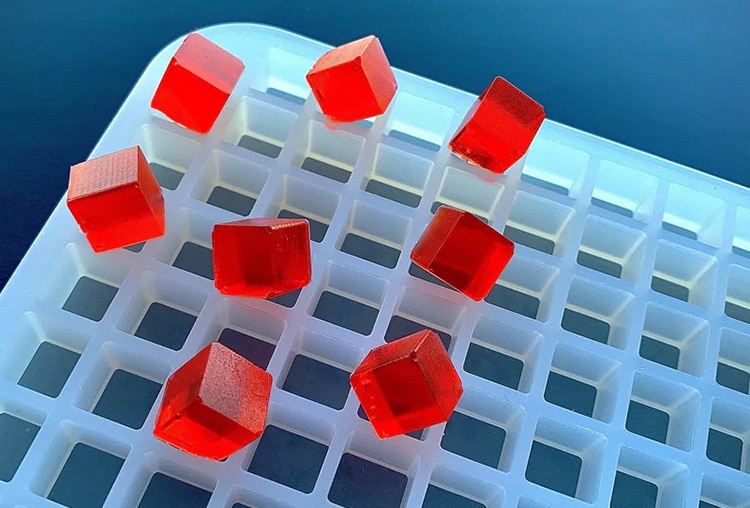

Silicone gummy molds are easily adaptable to different candy manufacturing requirements and preferences. They are used to create various gummy shapes, from classic gummy bear silicone molds and fruits to custom intricate design trends.

2. Durability

Silicone gummy molds are tried and tested for their long-lasting performance. They are built to last using high-quality silicone. Thus, they eliminate the need for frequent replacements, saving a gummy manufacturer time and money.

3. Cost-effectiveness for Long-Term Use

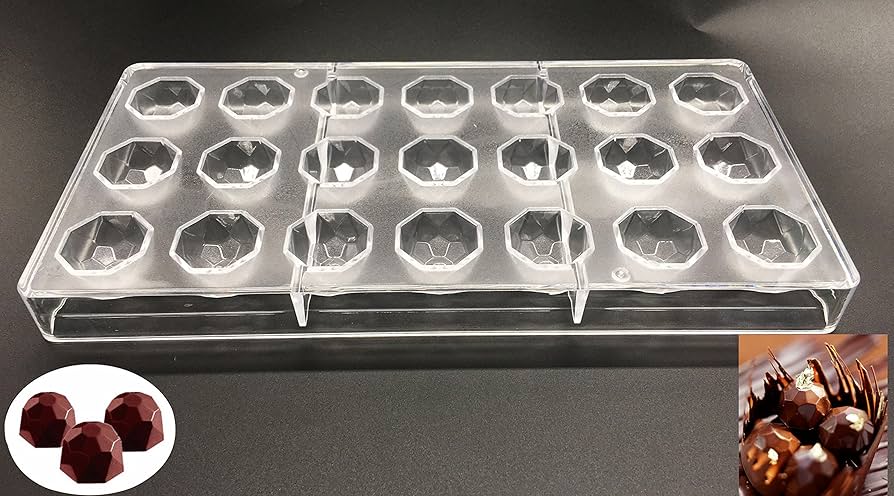

Generally, silicone gummy molds are more affordable than other mold materials, such as metal and polycarbonate. They also have a longer lifespan and low maintenance costs, which further contributes to their affordability in the long run.

4. Ease of Use: Flexible, Non-Stick, and Easy to Clean

Candy manufacturers prefer silicone gummy molds because they are highly flexible. You can pop your gummy candies without cracking or breaking them. Moreover, silicone is non-stick and easy to clean. A simple wash using warm, soapy water is often sufficient.

5. Safety

Gummy candy-making should prioritize consumer health and well-being. One way to do so is to use silicone gummy molds, which are non-toxic and free from harmful chemicals like BPA. They can also be sterilized after cleaning to further contribute to their hygiene.

6. Chemical resistance for High-Quality Gummies

Silicone is tough to endure various chemicals in candy recipes and gummy mold cleaning agents. It is also resistant to acids and alkalis, preventing the gummy mold from degrading. This ensures candy manufacturers create safe final gummy treats.

7. Heat resistance for Optimal Candy Manufacturing

Silicone molds can withstand the high temperatures of the gummy mixture during baking and cooking candies without warping or melting. They are also resistant to cold temperatures and are perfect for use in the gummy cooling stage.

Ready to streamline your gummy-making process? Our silicone molds offer unparalleled flexibility and durability for large-scale production. Browse our selection at GummyGenix and start improving your candy production today!

.

Gummy Mold Material: Silicone V.S. Metal V.S. Plastic

The following table comprehensively compares silicone, metal, and plastic materials for making gummy molds.

| Gummy Mold Material: Silicone V.S. Metal V.S. Plastic | |||

| Feature | Silicone | Metal | Plastic |

| Flexibility | High | Low | Medium |

| Durability | High | High | Medium |

| Heat Resistance | High | High | Medium |

| Chemical Resistance | High | High | Medium |

| Non-Stick Properties | High | Low | Medium |

| Cost | Medium | High | Low |

| Ease of Cleaning | High | Medium | Medium |

| Food Safety | High | High | Medium |

Silicone mold material reigns in terms of flexibility, durability, and ease of use compared to metal and plastic gummy molds. Silicone gummy molds are highly flexible, making them perfect for more complex gummy treat designs. They are non-sticky, facilitating the effortless removal of gummies from the molds.

Unlike metal molds, which can be heavy and difficult to handle, silicone molds are lightweight and portable. Silicone is a non-toxic material, ensuring the safety of the gummies produced. In contrast, metal molds can be prone to rust and corrosion. This may affect the gummies’ quality and potentially pose health risks to consumers.

Plastic molds, on the other hand, while more affordable, may not be as durable or heat-resistant as silicone molds. Silicone molds can withstand a variety of temperatures throughout the entire gummy manufacturing process. They are not prone to breakages and are thus usable for prolonged periods.

.

So, in general, silicone's superiority in various aspects is what makes it the most preferred choice among gummy manufacturers.

.

Need help deciding which mold material is right for your business? Let GummyGenix's expert team guide you. Get in touch today and discover why silicone molds are the best choice for your production needs.

.

How to Choose the Right Silicone Gummy Mold Set for Your Candy Business

Since you may feel overwhelmed by the vast array of options for silicone gummy mold sets, you should consider the following factors to guide you:

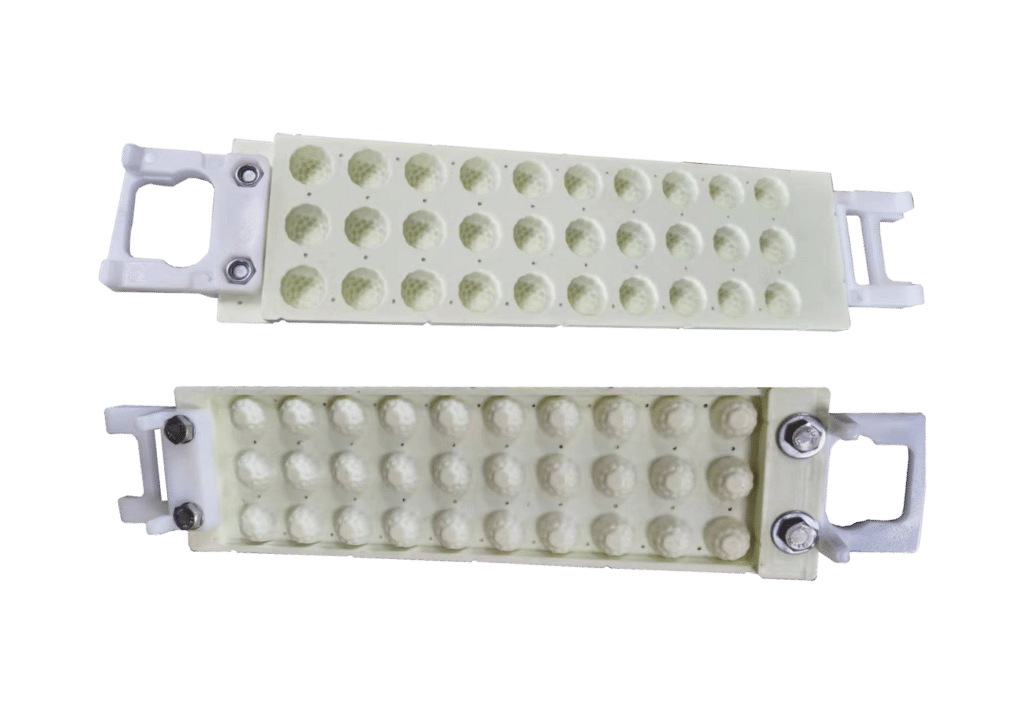

1. Consider Production Volume and Mold Tray Size

Size: This is crucial because the mold tray size dictates your production volume. Also, the cavity sizes will determine the size of individual gummy pieces. You should consider each gummy size and candy production scale to choose a silicone gummy mold set accordingly.

2. Select Gummy Shapes That Match Your Brand Identity

Shape: The gummy mold’s design dictates the final shape of your chewy treats, like animals, fruits, or letters. You must choose a silicone gummy mold for candy-making that aligns with your brand. For example, a weed plant design is perfect for CBD gummies.

3. The Importance of Cavity Numbers for Production Efficiency

Number of cavities: The number of cavities determines how many gummies can be produced at once. The more cavities per molding tray, the higher the production efficiency. If you make large quantities of gummies, you should opt for a silicone mold set with multiple cavities.

4. Design Complexity and Its Impact on Production Speed

The complexity of the design: Another critical factor is your experience level and the intricacy of the silicone mold set design. Beginners might find simpler molds easier to work with, while experienced candy makers can tackle more intricate designs.

.

.

So, are you ready to bring your silicone gummy mold ideas to life? GummyGenix is your trusted partner in this journey. We are a reliable silicone gummy mold supplier, whether you produce confectionary, pharmaceuticals, nutraceuticals, or cannabis-infused gummies. We also provide the whole production line equipment.

Our gummy molds are made of premium-quality silicone, which ensures a longer lifespan. You can consult our sales team for orders. They will ask you to send them drawings of your desired molds. Once you agree and make your down payment, the mold-making process commences and may take 3 to 4 weeks.

.

Common Uses for Silicone Gummy Molds

Silicone gummy molds offer versatility with many benefits that make them applicable for the uses below:

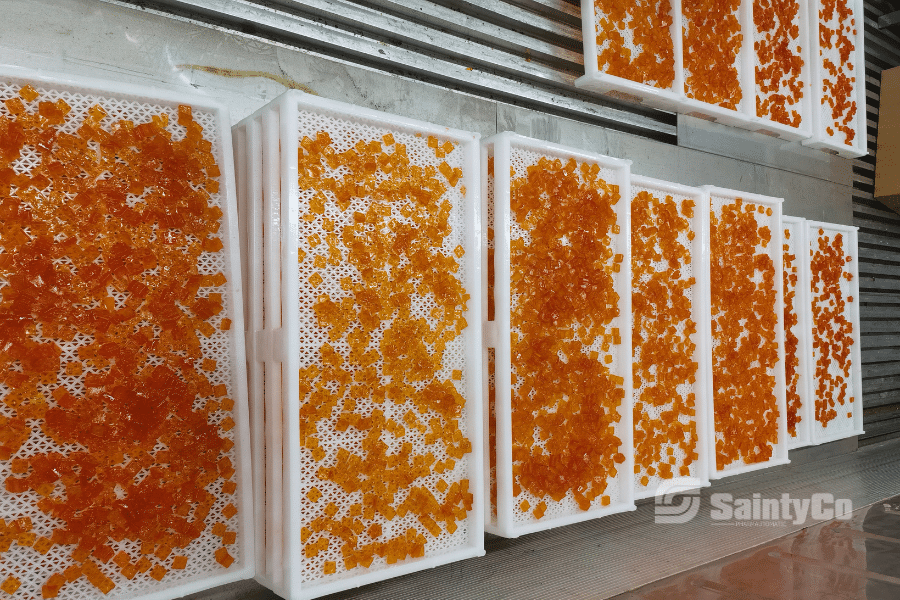

Large-scale production

Silicone gummy molds are well-suited for high-volume candy production for their durability and ease of usage. They can endure repeated use and both high and low temperatures, ensuring consistent performance. Silicone's non-stick properties also simplify the mold cleaning process, reducing downtime and increasing efficiency. The silicone molds also seamlessly integrate with automated candy-making machines, further enhancing production capacity.

.

.

Semi-automated gummy manufacturing

Another use for silicone molds is integrating them into semi-automated production lines for medium-volume candy manufacturing. Their flexibility and versatility allow for easy adaptation to different production setups. They can be used with automated dosing and mixing equipment, streamlining the candy-making process and improving consistency.

.

Home-based candy making

Due to their affordability, silicone molds are an excellent choice for hobbyists and small-scale gummy makers. Their non-stick properties and flexibility simplify the candy-making process, even for those with limited experience. Additionally, silicone molds offer a wide range of shapes and designs, allowing home-based candy makers to create unique and personalized products.

.

.

Educational and artistic applications

Beyond gummy production, silicone molds are used for educational and artistic purposes. They can be used in schools and workshops to demonstrate the candy-making process, providing hands-on learning experiences. Additionally, artists can use silicone molds to create unique and decorative candy sculptures or pieces for art installations.

Whether you’re scaling up for large-scale production or running a home-based candy business, GummyGenix has the right mold solution for you. Contact us now to explore our versatile range of silicone molds designed for all levels of gummy-making!

.

Top Tips for Using Silicone Gummy Molds Effectively

Preparation Techniques to Optimize Mold Performance

Proper mold preparation is essential for successful candy removal and preventing sticking. Before using your silicone mold, ensure it is clean and dry. Lightly dust the mold with a non-stick spray or cornstarch to enhance non-stick properties. This will help prevent the gummy mixture from adhering to the mold, reducing the risk of wasted product due to sticking.

.

Filling Techniques for Consistent Gummy Production

Filling silicone molds with a gummy syrup mixture requires precision to ensure even distribution and prevent spillage. Here’s what to do:

- You should use a piping bag or spoon to fill the mold cavities precisely and carefully transfer the mixture into them.

- Only fill the cavities to the desired level, leaving little space for expansion. Overfilling can deform the cavities or cause the gummy syrup to overflow.

- Lastly, after filling, gently tap the mold on a flat surface to eliminate air bubbles and ensure the even distribution of the mixture.

.

Demolding Best Practices for Undamaged GummiesDemolding

Proper demolding techniques are crucial to prevent damaging the gummies and ensure clean removal from the silicone molds.

1. You must allow the gummies to cool completely before attempting to demold them. This will prevent them from sticking to the mold and reduce the risk of breakage.

2. If the gummies are still sticking, gently use a tool like a small spatula or a toothpick to lift the edges and release them from the mold.

3. Try to be gentle when demolding gummies to prevent misshapen or broken pieces. Excessive force can damage both the gummies and the mold.

.

How Proper Cleaning and Storage Prolong Mold Life

You can maintain the longevity of your silicone gummy molds and prevent contamination by thoroughly cleaning them and ensuring proper storage. Check these guidelines:

- After each use, wash the gummy molds to remove any residue. Avoid harsh detergents or abrasive materials that could damage the silicone.

- Ensure the silicone gummy molds are completely dry before storing them. If you store them with moisture, they may grow mold, which could affect your gummies' taste.

- Store the molds in a clean, dry place, away from direct sunlight and heat sources. This will help prevent the silicone from deteriorating or becoming discolored.

.

Want to maximize your silicone mold's efficiency? GummyGenix offers high-quality molds and expert guidance to help you get the most out of your production process. Get your free consultation today!

.

Conclusion

Investing in silicone gummy molds is a smart move for any candy manufacturer looking to increase production capacity and enhance product quality. Their flexibility, durability, and non-toxic nature make them the go-to choice for manufacturers seeking to reduce costs and improve operational efficiency.

With GummyGenix's premium range of silicone molds and equipment, you can maximize your production potential and stay ahead in the competitive gummy market. Don't miss the chance to transform your candy-making process—explore our selection today and see how we can help you achieve your business goals.

.

FAQs

Can I use silicone gummy molds for other types of candy besides gummies?

Yes, you can use silicone gummy molds for candies, too. They are versatile and applicable in making chocolate treats, hard candies, Jello, and even ice cream. Their flexibility and non-stick properties make silicone molds applicable to most candy and gummy types.

.

What is the temperature range for silicone gummy molds?

Silicone gummy molds are typically resistant to a range of hot and cold temperatures, from -40°F to 446°F (-40°C to 230°C). This makes them suitable for both freezing and baking applications in gummy production.

.

How long do silicone gummy molds last?

It depends. Usage frequency, cleaning methods, and storage conditions can influence the longevity of silicone gummy molds. You should avoid exposing silicone molds to extreme temperatures, harsh chemicals, or sharp objects. Additionally, store your silicone molds in a cool, dry place away from direct sunlight. This will extend their lifespan.

.

Do silicone molds need to be greased for gummies?

No, silicone molds are typically non-stick, so greasing is not necessary. However, if you use a new mold or a particularly sticky gummy mixture, dust the mold lightly with cornstarch or an edible oil spray. This will enhance the non-stickiness.

.

Still have questions about silicone gummy molds? Our experts at GummyGenix are here to help! Contact us for personalized advice on choosing and using silicone molds for your specific needs.