Gummy Production Line Maintenance: Daily & Deep Cleaning Tips

Maintaining hygiene in gummy production is crucial. This guide outlines effective daily and weekly cleaning methods, safety protocols, and best practices to ensure optimal machine performance and product quality.

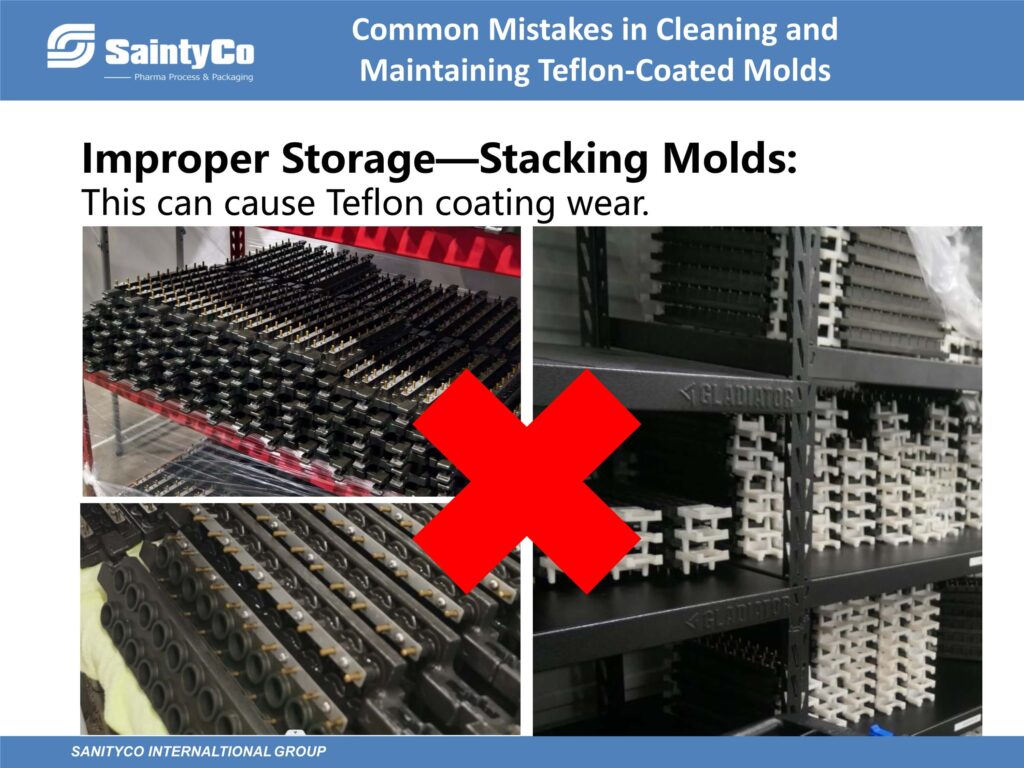

Teflon-Coated Metal Gummy Molds: Best Tips for Cleaning and Maintaining

To maintain Teflon-coated molds for gummies and candies, clean immediately after use with mild detergents, avoid harsh chemicals, dry thoroughly, and store properly to extend their lifespan and effectiveness.

Gummy Depositors: What Are the Most Common Issues When Using Them?

Gummy depositors are vital in the confectionery industry, but they can encounter several issues. This article explores the most common problems such as inconsistent filling, clogging, and temperature sensitivity, while providing actionable insights to overcome these challenges. By understanding and addressing these issues, manufacturers can optimize their production processes and ensure high-quality gummy products.

Gummy Production Tips: How to Maintain Your Gummy Depositor Effectively?

Maintaining a gummy depositor is essential for efficient production and high-quality output. By focusing on regular cleaning, inspections, and operator training, I can ensure smooth operations and minimize downtime. Let’s dive into the key components and innovative technologies that can help enhance maintenance practices.