Why Working with a Single Source Machine Supplier is Essential for Efficient Gummy Production

In the competitive world of gummy manufacturing, efficiency and consistency are crucial. Managing multiple equipment suppliers can be a hassle. Opting for a single source machine supplier simplifies your production process, making it smoother and more efficient.

If you want to streamline your gummy production and cut your operational costs, you need to work with a single source machine supplier. This will give you consistency, reduce your downtime, and make your logistics easier. You can have one supplier do everything from cooking to packaging. This gives you a seamless and efficient production line. Working with one supplier solves many issues and keeps your operation running smoothly.

.

What Is the Manufacturing Process of Gummy Candy?

The manufacturing process of gummy candy is a series of critical steps, each requiring specific machinery to ensure you maintain a high-quality product and run an efficient operation.

- Raw Material Prep: Select and prepping key ingredients like gelatin/pectin, sugar, flavorings, and colorants. Measure and mix them carefully to form your gummy base.

- Mixing and Cooking: Mix and cook the ingredients into a smooth gummy syrup. Precise temperature control and mixing techniques are crucial here.

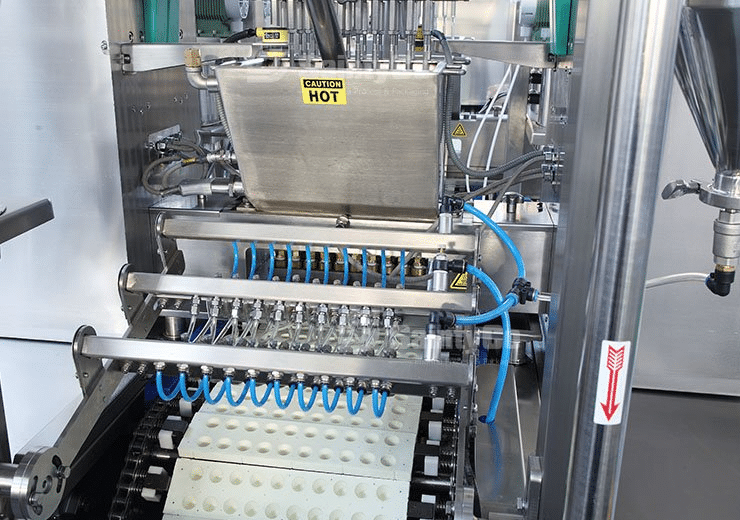

- Depositing: The syrup is then deposited into molds using a gummy depositing machine, ensuring accurate mold filling for consistent gummy size and shape.

- Cooling and Setting: The gummies need to cool and set once deposited. Typically, this is done in a cooling tunnel that gradually reduces the temperature to allow the gummies to solidify properly.

- Demolding and Packaging: After cooling, the gummies are demolded and packaged into different formats such as bottles, jars, and pre-made pouches. This ideally should be done with different automated packaging machines specially modified for handling with gummies to ensure accuracy, hygiene and get them ready for distribution.

.

Advantages of Working with a Single Source Machine Supplier

Teaming up with a single source machine supplier brings many benefits that can transform your gummy production.

- Consistency and Quality Control: Choosing a single supplier ensures that all your equipment is compatible and meets the same quality standards. This reduces machine issues and maintains consistent product quality.

- Simplified Logistics: Dealing with multiple suppliers can be cumbersome. A single supplier streamlines procurement, cuts lead times and simplifies inventory management.

- Reduced Downtime: When you need maintenance or repairs, dealing with one supplier is much easier. No more coordinating between different companies—issues get resolved faster, and downtime drops.

- Cost Efficiency: Bundling your equipment purchases can save you money. Single suppliers often offer discounts for bulk buys and integrated solutions, cutting down on additional costs.

- Improved Communication and Support: Having one supplier means streamlined communication and better support. You’ve got one point of contact for everything, reducing miscommunications and speeding up issue resolution.

- Streamlined Training and Onboarding: Training your staff on multiple systems is a pain. One supplier offers cohesive training programs covering all your equipment, ensuring your team is proficient.

- Customization Available: A single source supplier can tailor solutions to your specific needs, ensuring your gummy production line runs smoothly and efficiently.

- Extra Value-Added Support: Suppliers like SaintyCo offer consulting and technical support, making them a true one-stop solution for all your gummy manufacturing needs.

.

Choosing the Right Supplier: What to Look For

Choosing the right single source supplier is critical to your success in making gummies. Here are some things to consider:

- Certifications and Standards: Ensure the supplier meets or are capable of making you production line to meet top quality and safety standards. These include cGMP/GMP, ISO 9001:2015, CE Electrical Certification, FDA Quality Standards, and more. These are all signs of high-quality manufacturing practices.

- Local Support and Service: A strong local support network means you can quickly get maintenance and tech support. This helps minimize disruptions. Also, when you work with a single source supplier, managing parts and after-market services is easier. You can get components faster and you’ll have consistent service quality.

- Responsive Feedback: Choose a supplier with a reputation for responsive customer service. Quick, effective communication is key to resolving issues and keeping operations smooth.

- Logistics and Payment Methods: Consider the supplier’s logistics capabilities and payment flexibility. This helps manage cash flow and ensures timely equipment delivery.

.

How to Conduct Supplier Evaluation and Selection

Evaluating and picking the best single-source supplier involves a detailed process:

- Research and Shortlist: Research potential suppliers online, at trade shows, and through industry networks. Shortlist those specializing in gummy manufacturing equipment with a strong market presence.

- Request Proposals and References: Contact your shortlisted suppliers for detailed proposals. Ask for references to gauge their reliability and service quality.

- Conduct Site Visits: If feasible, visit the supplier’s manufacturing facility to inspect their production capabilities and quality control processes.

- Evaluate Technical Expertise: Assess the supplier’s technical know-how and their ability to offer comprehensive solutions. A supplier with a skilled technical team can provide valuable support and insights.

- Compare Offers and Negotiate: Compare proposals on cost, quality, support services, and other factors. Negotiate terms to get the best value for your investment.

.

SaintyCo: Your Trusted Partner for Gummy Production

Gummygenix by SaintyCo is a top-notch single-source supplier for gummy manufacturing equipment. SaintyCo specializes in providing expert automated systems for gummy production tailored to startups, retailers, and large manufacturers globally.

Our Gummy Machines’ Advantages:

- High Efficiency: Production lines with capacities from 6,000 to 240,000 gummies per hour.

- Advanced Technology: Our machines feature servo-driven systems, accurate temperature control, and hygienic designs, ensuring reliable and consistent production.

- Versatile Equipment: Our equipment is suitable for producing CBD, THC, vitamin gummies, and more, meeting diverse pharma-grade manufacturing needs.

Customer-Centric Approach

We focus on understanding and addressing our clients’ pain points, such as reducing production costs, improving production speed and accuracy, and ensuring high-quality output with minimal waste.

Global Support

SaintyCo provides global, online or remote technical support and after-sales service to ensure your equipment’s smooth operation and maintenance.

For more detailed information on our gummy production solutions and equipment, visit GummyGenix or SaintyCo’s website or contact me at [email protected].

.

Summary

Choosing a single source machine supplier for gummy production can supercharge your operational efficiency, ensuring consistent quality and simpler logistics. By focusing on certifications, local support, and responsive feedback, you can find the best supplier for your needs. A single-source approach cuts complexity and builds a stronger, more supportive relationship with your supplier, leading to a more resilient and successful production operation. SaintyCo’s expertise and comprehensive solutions make them the perfect partner for your gummy manufacturing journey.