Choosing the right mold for gummy production can greatly influence your final product's quality.

In the debate of silicone molds versus metal molds for gummy making commercially, metal molds often provide better texture consistency and faster production times. However, silicone molds can offer a more uniform finish without ejection pin dents. This article will dissect these options to help you choose the best fit for your gummy-making process.

Stay tuned as we delve deeper into the pros and cons of each mold type, their impact on production efficiency, and how they can affect your bottom line.

Metal molds provide better texture consistency for gummies.True

Metal molds are known for delivering uniform texture due to their rigidity, enhancing the quality of gummy products.

Silicone molds are faster for gummy production than metal molds.False

Contrary to popular belief, silicone molds typically take longer to set compared to the efficiency of metal molds in production.

What are the Key Differences Between Silicone and Metal Gummy Molds?

Understanding the differences between silicone and metal gummy molds for gummy candies can greatly influence your production success. Here’s an in-depth look at how these two materials compare.

The key differences between silicone and metal gummy candy molds lie in heat conductivity, ease of use, cleaning, durability, and the final gummy product's texture. Metal candy molds offer faster molding times and better structure, while silicone molds provide flexibility and ease of release.

|

|---|

Comparison of silicone and metal gummy molds

Heat Conductivity and Molding Performance

Metal molds excel in efficient heat distribution, leading to quicker cooling times. This is particularly beneficial for items that require precise cooking, like soft gummies or hard lollipop candies.

Silicone molds, conversely, have lower heat conductivity. This slower heat transfer can result in longer cooling times, which may be a disadvantage for certain recipes. However, this can also be advantageous for delicate items that require a gentle bake to avoid burning.

Ease of Use and Flexibility

Silicone molds are renowned for their flexibility. They allow for easy release of gummies without sticking, making them ideal for intricate shapes or detailed designs.

On the other hand, metal molds offer rigidity, which can be beneficial for certain recipes that require a stable structure for molding.

Cleaning and Maintenance

When it comes to cleaning, silicone gummy molds shine with their non-stick surface, making them easy to wash by hand or in a dishwasher. In contrast, metal gummy molds might require more effort to clean, particularly if food residue sticks.

However, the durability of metal gummy candy molds often means they can withstand harsher cleaning methods without damage.

Longevity and Durability

Metal molds typically outlast silicone options when properly maintained. They resist wear and tear from high temperatures better than silicone molds, which can degrade over time or lose their non-stick properties.

Final Texture and Appearance

The texture and appearance of demolded gummies can vary significantly based on the mold used.

Silicon molds generally produce gummies with a softer, more flexible texture. This is due to the inherent flexibility of silicon, which allows for easy removal of gummies without breaking. The texture tends to be more "chewy" and slightly more elastic.

Gummies made in silicon molds can have a smoother, glossier appearance. The molds' flexibility allows for intricate designs, but the surface finish might be slightly less crisp compared to metal molds.

Here’s a quick comparison:

| Feature | Silicone Gummy Candy Molds | Metal Gummy Candy Molds |

|---|---|---|

| Heat Conductivity | Low | High |

| Design Flexibility | High,allows for intricate and complex shapes | Best for uniform shapes and defined edges |

| Cooling Efficiency | Slower cooling due to flexibility | Faster, more even cooling due to heat conductivity |

| Gummy Removal | Easy removal without breakage | Requires more effort to remove, but offers better shape retention |

| Cleaning | Easy (dishwasher safe) | Moderate (hand wash preferred) |

| Durability | Good (can wear over time) | Excellent (long-lasting) |

| Gummy Texture | Softer, more flexible, chewy, and elastic | Firmer, denser, and more solid with a defined bite |

| Gummy Surface Finish | Smooth and glossy, but can be less crisp | Sharper, precise finish with a more uniform gloss |

Metal molds conduct heat better than silicone molds.True

Metal molds excel in heat conductivity, leading to quicker and more even baking, making them preferable for precise recipes.

Silicone molds are easier to clean than metal molds.True

Silicone molds feature a non-stick surface that simplifies cleaning, allowing for easy hand washing or dishwasher use, unlike metal molds.

How Do Molds Affect Gummy Texture and Quality?

Understanding how different molds impact gummy texture and quality is essential for achieving the perfect candy. Let's dive into the specifics of mold materials and their effects.

Gummy Molds significantly influence gummy texture and quality through factors like material type, ejection process, and production speed. Metal molds for gummy making offer quick cooling for consistency, while silicone gummy molds provide a smoother finish but may slow production.

The Impact of Mold Material on Gummy Texture

When producing gummies, the material of the molds plays a crucial role in determining the final product's texture and quality. Metal gummy molds are often favored due to their durability and ability to conduct heat efficiently. This leads to quicker curing times, which can prevent unwanted air bubbles that negatively impact texture.

Conversely, silicon molds may not release heat as quickly as metal molds, which can result in a softer gummy with a different mouthfeel.

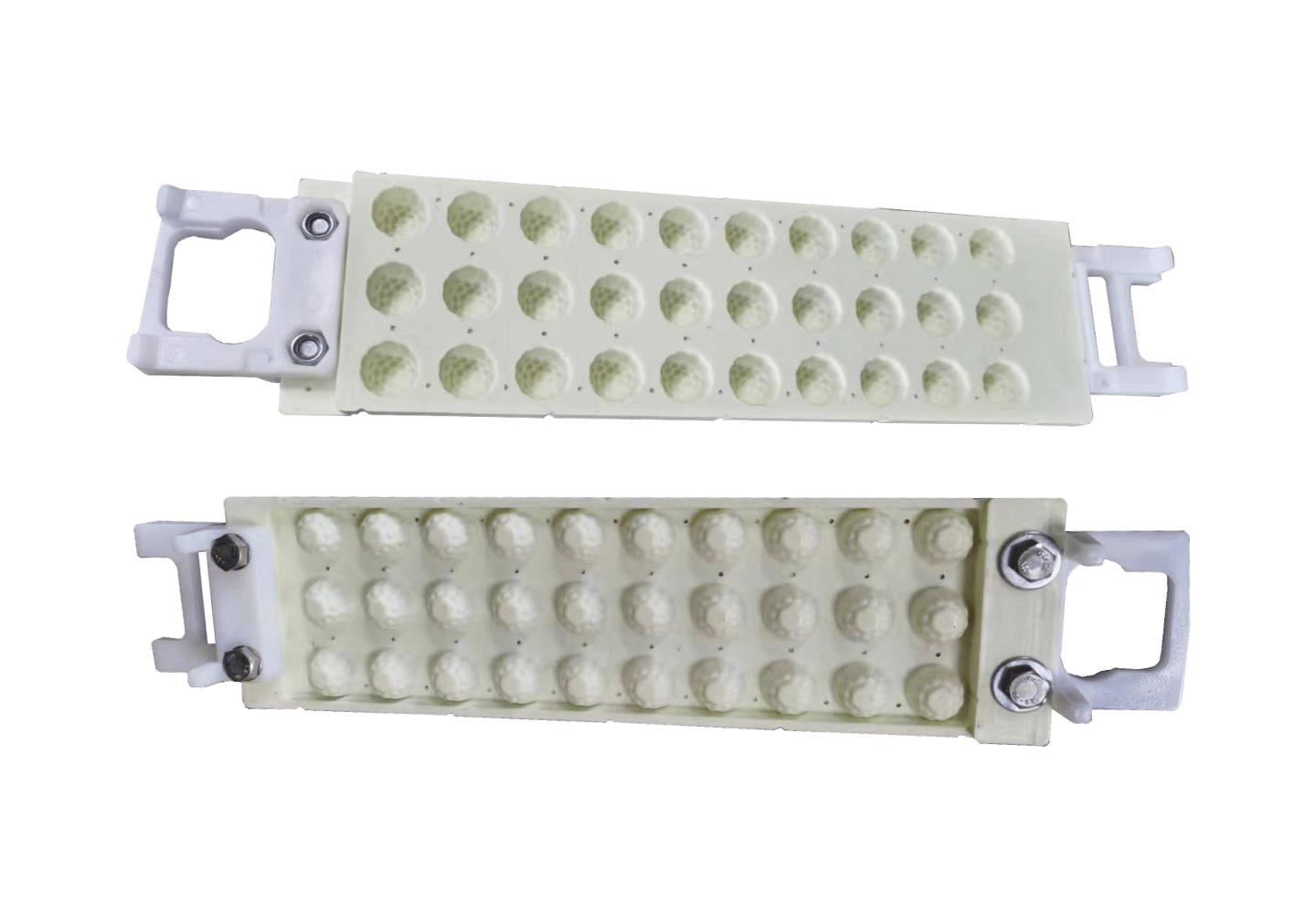

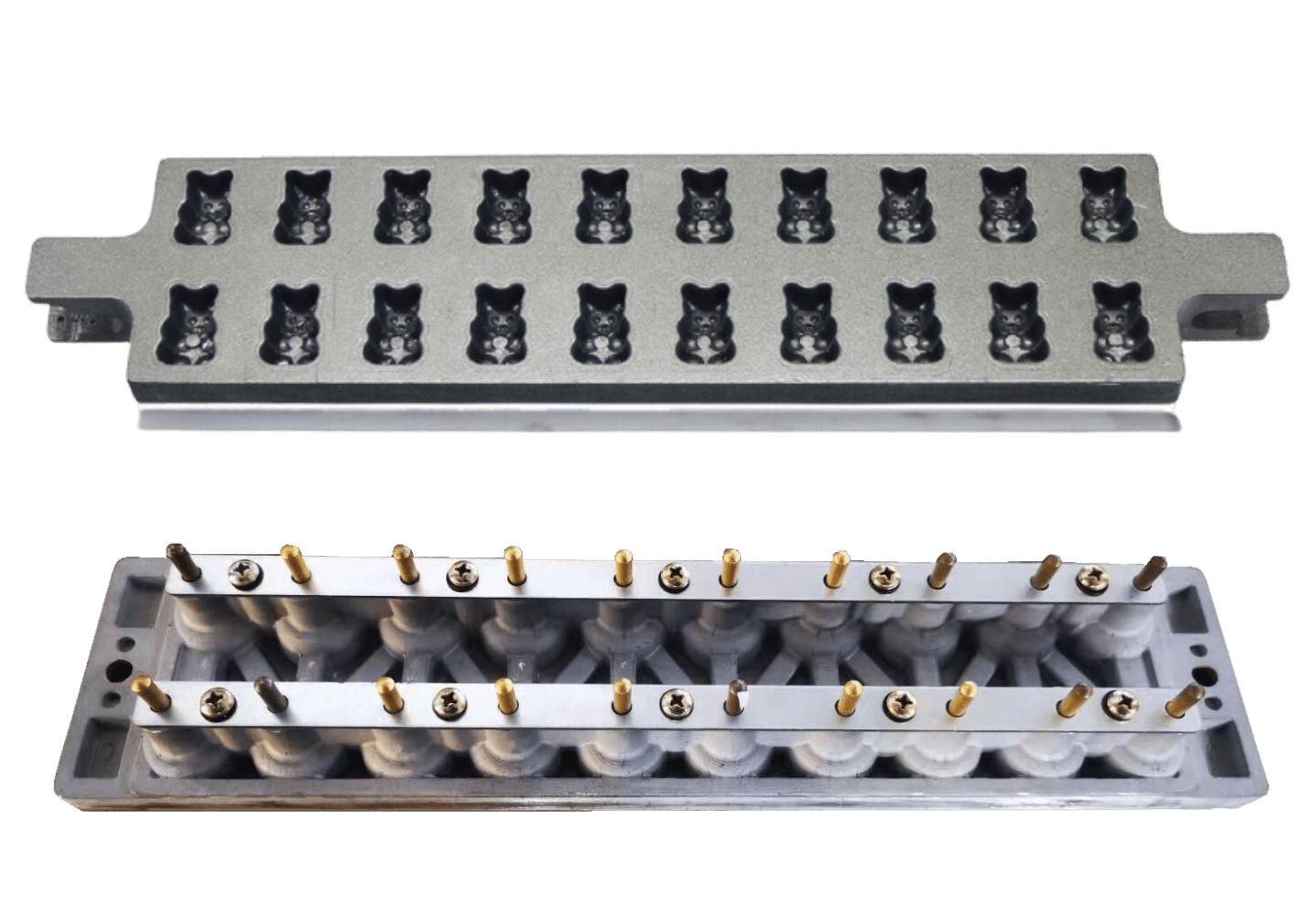

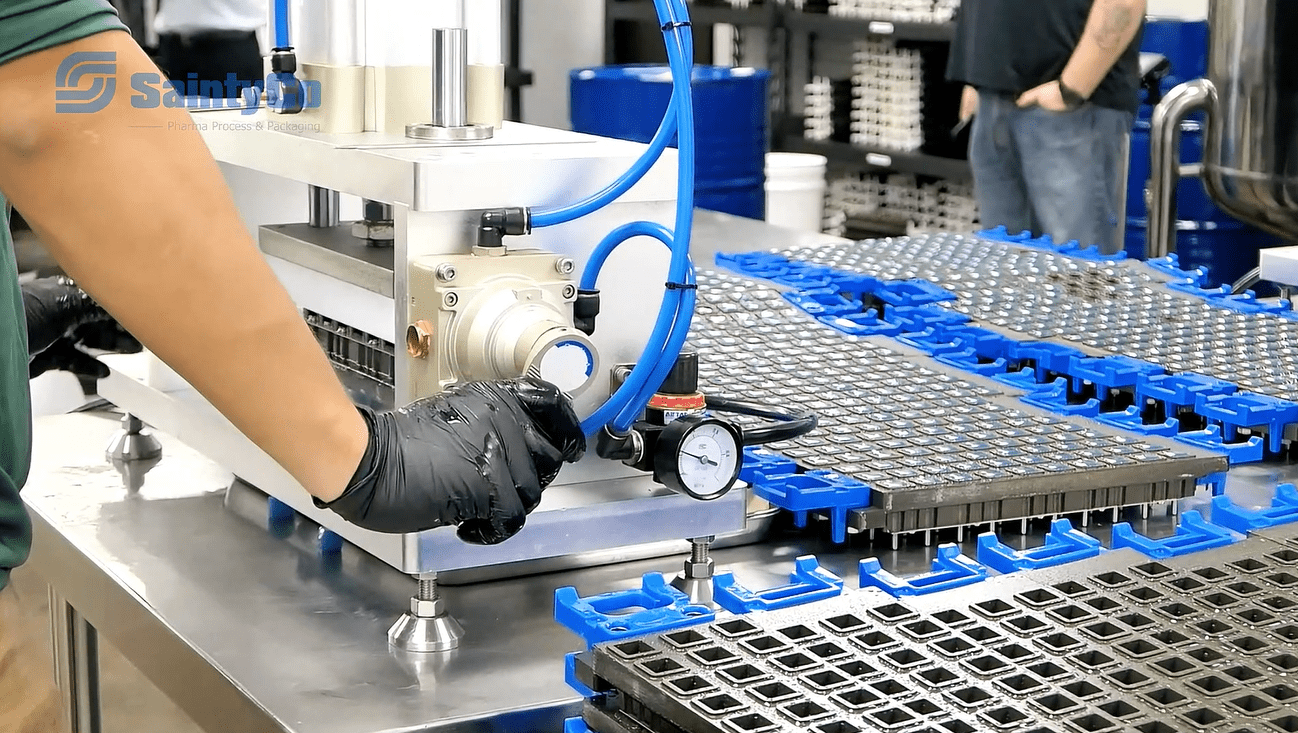

Ejection Process and Surface Quality

The ejection process used in gummy production can also affect texture. Metal gummy molds may leave gummies slight dents from ejection pins, potentially impacting the surface quality. These imperfections can be minimized with sugar coating but may still influence the perceived quality of the product.

Silicon gummy molds, on the other hand, do not typically leave such marks, leading to a smoother finish. However, the slower heat dissipation of silicon gummy molds can contribute to increased surface bubbles during production, which could diminish the overall aesthetic quality of the gummies.

Production Speed and Consistency

Production speed is another critical factor influenced by mold choice. Metal molds for gummy bears often allow for faster production cycles, as they cool gummies more rapidly. This efficiency is vital for businesses looking to maximize output while maintaining consistent quality.

In contrast, while silicon molds for gummy bears may yield a more aesthetically pleasing product, their longer curing times can slow down overall production. This trade-off must be carefully considered based on your operational needs and goals in gummy manufacturing.

|

|

|---|

Two Ways of Demolding Gummies from Metal Gummy Molds - by hand, by demolder

Formulation and Processing Parameters

It's important to note that even with the best molds for gummy production, the final gummy texture will heavily depend on your formulation and processing parameters. Factors like cooking time, curing time, and even the ingredients used will all play significant roles in determining the final product's quality.

For optimal results, it is advisable to experiment with different formulations and processing settings while taking gummy mold types into consideration. Understanding these relationships can lead to better control over the texture and quality of your gummies.

Exploring Further

For those interested in enhancing their gummy production processes, it may be beneficial to explore effective gummy recipes1. This can provide insights into formulation adjustments that complement mold selection.

Additionally, considering the latest trends in gummy production can provide valuable insights into improving both quality and efficiency—check out current market trends in confectionery2.

Metal molds enhance gummy texture by cooling faster.True

Metal molds cool gummies quickly, reducing air bubbles and ensuring a firmer texture, which is essential for high-quality gummy production.

Silicone molds always produce better quality gummies than metal.False

Silicone molds may create a smoother finish but can lead to softer gummies and slower production, making them less optimal for quality in some cases.

What Production Speed Can You Expect from Each Type of Gummy Candy Molds?

When selecting mold types for gummy production, understanding the expected production speeds is essential. Different molds yield varying efficiencies that can influence your output.

The production speed you can expect from each gummy mold type varies significantly. Metal molds for gummies offer faster heat discharge and shorter curing times, while silicon molds tend to be slower but yield smoother surfaces.

Understanding Production Speeds in Gummy Manufacturing

When discussing production speed, the type of mold you select plays a crucial role. It can significantly influence the efficiency of your gummy production process.

Metal molds for gummies, for instance, generally allow for a quicker heat discharge. This feature is critical as it reduces the curing time needed for gummies to set. Consequently, this results in a more efficient production cycle.

On the other hand, while silicon candy molds do not leave ejection pin dents, they exhibit a slower heat discharge, which can lead to extended curing times. This can result in surface bubbles, ultimately affecting the texture and appearance of the gummies produced.

For those focusing on high production speeds, the choice is clear. Metal molds provide a faster turnaround, leading to enhanced production rates. Conversely, silicon molds may be better suited for smaller batches where surface quality is paramount.

Most clients, around 95% of our SaintyCo customers, prefer metal molds because they provide consistency and speed in large-scale operations.

Factors Impacting Production Speed

Beyond mold material, various factors affect overall production speed. These include:

- Cooling Time: The duration required for gummies to cool also influences how quickly you can repeat production cycles.

- Injection Speed: Faster injection speeds can lead to quicker filling of molds.

- Formulation Variability: Different gummy recipes might require adjustments in processing times.

Understanding these variables allows businesses to optimize their production lines for efficiency and consistency. For deeper insights into maximizing your gummy production speed, consider exploring advanced gummy manufacturing techniques3.

Metal molds provide faster production speeds than silicon molds.True

Metal molds allow for quicker heat discharge, resulting in shorter curing times and enhanced production rates compared to silicon molds.

Silicon molds are preferred by 95% of gummy manufacturers.False

In reality, only about 5% of clients prefer silicon molds due to their slower production speed and longer curing times compared to metal molds.

Which Gummy Candy Mold Type is More Cost-Effective for Your Business?

When it comes to choosing the right mold type for gummy production, cost-effectiveness is key. Are you leaning towards metal or silicon? Let’s break down the factors influencing your decision.

To determine which gummy mold type is more cost-effective for your business, consider factors such as initial costs, longevity, production speed, and surface quality. Metal candy molds typically provide greater efficiency for large-scale production, while silicon candy molds excel in aesthetic quality.

Understanding Mold Types

When evaluating mold types, it's essential to consider the specific requirements of your gummy production. Two popular choices are metal molds and silicon molds. Each type comes with its unique advantages and challenges.

Metal Molds:

- Strength and Efficiency: Metal molds are typically known for their durability and ability to withstand high temperatures. They offer a smoother surface finish, resulting in better heat discharge, which can lead to quicker curing times. This feature is crucial for achieving a consistent gummy texture across larger batches.

- Cost Considerations: While the initial investment in metal molds may be higher, the long-term savings from increased production efficiency can offset these costs. Many businesses, like those in the cannabis sector4, find that metal molds contribute significantly to their bottom line due to reduced operational downtime.

Silicon Molds:

- Surface Quality: Silicon molds do not leave ejection pin dents, which is a significant advantage for achieving a uniform gummy surface. This factor is particularly important for brands that emphasize appearance in their products.

- Heat Discharge: However, silicon molds generally have slower heat discharge rates, which can result in longer curing times and potentially more surface imperfections like bubbles. This slower process might lead to increased production costs over time, especially if you're running high-volume operations.

Cost Analysis

To compare the cost-effectiveness of metal versus silicon molds, consider the following table:

| Factor | Metal Molds | Silicon Molds |

|---|---|---|

| Initial Cost | Higher | Lower |

| Longevity | Long-lasting | Moderate |

| Production Speed | Faster | Slower |

| Surface Quality | Smoother | Uniform without dents |

| Ideal for | Large scale production | Small batches or artisanal |

Client Insights

Based on feedback from our clients at GummyGenix, over 95% prefer metal molds due to their efficiency in large-scale operations. Clients often highlight the importance of consistency in texture as a major decision factor.

For businesses focused on quality and speed, investing in metal molds can yield significant returns. Conversely, companies aiming for unique product presentations may benefit from silicon molds despite their potential drawbacks in speed and surface quality.

Making Your Choice

Ultimately, the decision should align with your business goals and production needs. If you prioritize production efficiency and consistency, metal molds are likely your best bet. However, if your focus is on aesthetic quality, especially for niche markets, silicon might serve you better.

Exploring further insights from experienced professionals can enhance your understanding of this decision. Consider looking into community experiences on platforms like Reddit5 for real-world applications and comparisons.

Metal molds offer better production efficiency than silicon molds.True

Metal molds are known for faster production speeds and reduced operational downtime, making them more efficient for large-scale gummy production.

Silicon molds have a higher initial cost compared to metal molds.False

Silicon molds generally have a lower initial cost than metal molds, making them more accessible for small-scale operations.

Conclusion

Explore the pros and cons of silicone versus metal molds for gummy making, focusing on texture quality, production efficiency, cleaning ease, and cost-effectiveness.

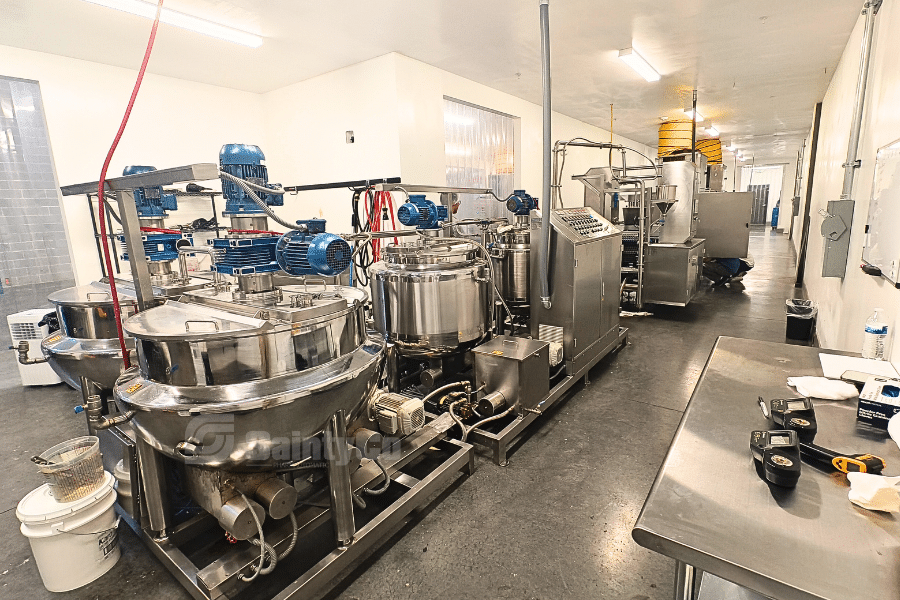

At GummyGenix by SaintyCo, we're here to support your journey with cutting-edge, GMP-compliant gummy manufacturing equipment designed for efficiency, precision, and adaptability. Our machines are fully compatible with regulatory standards, and we offer reliable after-sales support to keep your operations running smoothly.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality gummy products to life—together.

Gummy Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Clicking this link will reveal effective recipes that could help improve your gummy's texture and flavor profile. ↩

-

This link provides insights into current trends in gummy production that can enhance quality and efficiency. ↩

-

Explore advanced insights on gummy manufacturing techniques that can enhance your production speed. ↩

-

Discover expert insights on the cost-effectiveness of different mold types for gummy production. This link provides valuable comparisons and practical advice. ↩

-

Find community discussions on choosing between metal and silicon molds. This link offers real-world experiences that can guide your decision-making process. ↩