Are you dreaming of launching your own supplements and OTC gummies factory in Indonesia? Get ready for an exciting journey ahead!

To set up a successful supplements and OTC gummies factory in Indonesia, it's crucial to comply with BPOM regulations, obtain GMP and Halal certifications, and choose suitable production machinery. These steps ensure regulatory compliance, product quality, and market acceptance.

Now that you've got the basics down, let's dive deeper into each aspect. From understanding local regulations to mastering the art of gummy production, this guide offers valuable insights and practical advice to help your business thrive.

BPOM regulates dietary supplements in Indonesia.True

BPOM oversees dietary supplements, ensuring safety and efficacy.

What Are the Key Regulatory Requirements for Setting Up a Factory in Indonesia?

Setting up a factory is no walk in the park. Understanding regulatory requirements is crucial for success.

To set up a confectionary or nutraceutical factory, ensure compliance with environmental, health and safety regulations, obtain necessary permits, and adhere to industry-specific standards. This includes zoning laws, waste management, and operational guidelines to maintain safe and efficient production environments.

Environmental, Health, and Safety Regulations

Before you even think about turning the lights on in your new factory, you need to get your ducks in a row with the local environmental, health, and safety regulations. This is like making sure your shoes are tied before you run a marathon. Not only is it the law, but it also ensures that you aren't inadvertently creating a health hazard or environmental disaster.

Factories must adhere to stringent standards that often include air quality checks, waste disposal protocols, and even noise pollution limits. Ignoring these could lead to hefty fines or worse — forced closures. Consider consulting local experts or firms specializing in environmental compliance to guide you through the maze of regulations.

Obtaining Necessary Permits

Think of permits as your ticket to the big dance. Without them, you're not getting on the floor. Depending on your factory's location and what you'll be producing, the required permits can vary widely.

For instance, if you're setting up in a bustling urban area, zoning permits are crucial to ensure your operations don’t disrupt the neighborhood vibe. Meanwhile, food or pharmaceutical production facilities may require specific licenses related to hygiene and safety standards. Research permit requirements1 thoroughly before laying down any brickwork.

Adhering to Industry-Specific Standards

Every industry has its playbook of do's and don'ts. Whether you're manufacturing microchips or gummy bears, there are industry-specific standards you must follow. For example, if you’re setting up a food production factory in Indonesia, BPOM regulations are not just suggestions but mandates that dictate everything from ingredient sourcing to packaging.

It’s like baking a cake; you need all the right ingredients in the correct order. Failing to comply could result in your products being pulled faster than you can say "compliance audit." Establishing a dedicated compliance team can help keep track of changes in regulations and ensure that every batch meets the required standards.

Navigating Zoning Laws

Zoning laws are like the fine print on a warranty card — often overlooked but incredibly important. These laws determine where you can build your factory and what activities you can conduct there. They prevent industrial activities from being a stone's throw away from residential neighborhoods.

A thorough understanding of local zoning laws can save you from future headaches. Collaborate with local authorities or consultants who can offer guidance on finding the right location that aligns with your business goals without crossing any legal lines.

Ensuring compliance with these key regulatory requirements is essential for setting up a successful factory. It might seem daunting, but think of it as building a strong foundation for your business — one that ensures longevity and prosperity.

Zoning permits are optional for factory setup.False

Zoning permits are essential to ensure the factory location complies with local laws.

Ignoring environmental regulations can lead to factory closure.True

Non-compliance with environmental regulations can result in fines or forced closures.

How Can You Achieve GMP and Halal Certifications Effectively?

Achieving GMP and Halal certifications is crucial for market success in Indonesia. Here's how to do it efficiently.

To achieve GMP and Halal certifications effectively, focus on understanding and complying with specific standards, conducting thorough audits, and maintaining continuous improvement in processes and documentation. These steps ensure compliance, build trust, and enhance marketability in Indonesia's diverse market.

Understanding Certification Standards

Navigating the maze of certifications starts with grasping what each certification entails. GMP (Good Manufacturing Practice) ensures products are consistently produced and controlled according to quality standards. It encompasses everything from raw material handling to the final product. For startups2, opting for third-party GMP certification might be more feasible initially to boost credibility. Larger enterprises might prefer in-house compliance, integrating comprehensive training and sophisticated quality control labs.

Halal certification is indispensable in Indonesia, with its large Muslim population. The Indonesian Ulema Council (MUI) is the authority granting this certification. It involves ensuring that all ingredients and processes comply with Islamic law. Whether you’re a small startup or a large corporation, having Halal certification can significantly expand your market reach.

Conducting Thorough Audits

Audits are your best friend when it comes to maintaining certification standards. They help identify gaps and areas for improvement. Startups should conduct regular audits, perhaps quarterly, to ensure compliance without letting issues pile up. Larger companies might integrate continuous monitoring systems that offer real-time compliance checks, reducing the need for frequent manual audits.

Continuous Improvement and Documentation

Certification isn’t a one-time achievement; it’s an ongoing commitment. Maintaining detailed records is crucial for both GMP and Halal certifications. This documentation serves as evidence during audits and helps track changes over time. Implementing a culture of continuous improvement not only ensures ongoing compliance but also enhances overall product quality and safety. Medium to large enterprises3 may benefit from advanced digital solutions that streamline documentation processes and facilitate easier updates.

Practical Tips for Effective Certification

- Start Small: Initially focus on certifying one product line before scaling up.

- Engage Experts: Consider hiring consultants who specialize in GMP or Halal certification.

- Employee Training: Regularly train your team on compliance protocols.

This journey towards certification might feel like climbing a mountain, but with careful planning and commitment, you’ll reach the summit, ready to conquer new markets.

GMP certification ensures product quality standards.True

GMP certification mandates consistent production and control according to quality standards.

Halal certification is optional for Indonesian markets.False

Halal certification is crucial in Indonesia due to its large Muslim population.

Which Machinery Is Best Suited for Gummy Production in Indonesia?

Finding the right machinery for gummy production in Indonesia can be a game-changer for your business.

For gummy production in Indonesia, choose machinery that aligns with your production scale and meets BPOM, GMP, and Halal standards. Consider equipment with environmental controls to handle the country's humid climate effectively.

Factors to Consider in Machinery Selection

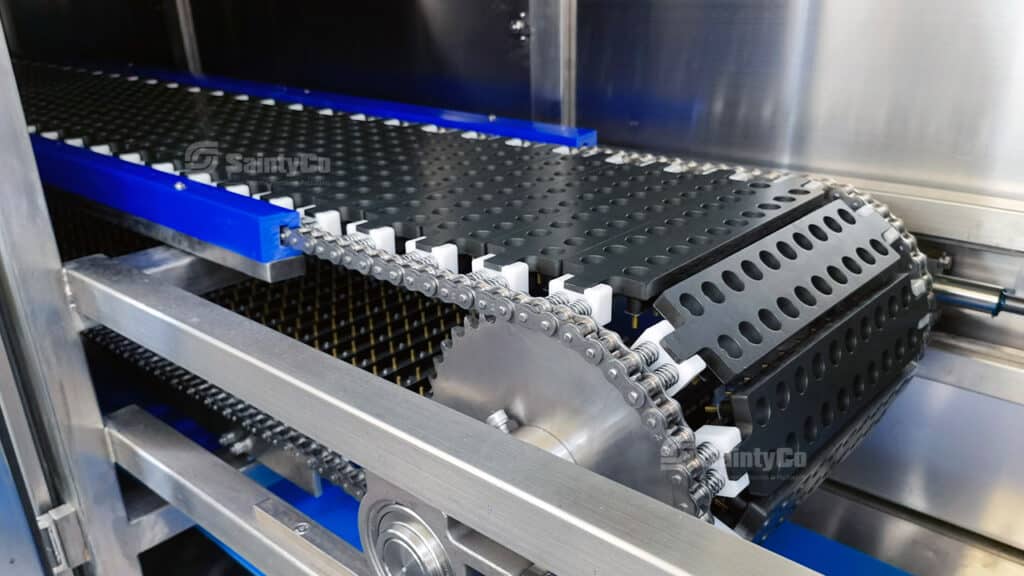

When choosing machinery for gummy production in Indonesia, several factors come into play. The first is the production scale4. Startups often opt for flexible, cost-effective machines capable of handling smaller batches without extensive retooling. Meanwhile, larger enterprises may prefer high-throughput automated lines with advanced controls, which seamlessly integrate with existing IT systems.

| Production Scale | Machinery Type |

|---|---|

| Startups | Cost-effective, versatile machines |

| Medium-Large | High-throughput automated lines |

Another critical consideration is regulatory compliance. Machines should support adherence to BPOM regulations and facilitate the acquisition of GMP and Halal certifications. Selecting equipment with these capabilities ensures your products meet local and international standards.

Environmental Controls and Product Quality

Indonesia's humid climate can pose challenges to gummy consistency and shelf life. Therefore, it's essential to invest in machinery equipped with environmental controls that maintain optimal humidity and temperature levels.

For example, some machines offer integrated dehumidifiers and climate control systems, which can be particularly beneficial. This feature helps maintain product quality from raw materials through to packaging.

Navigating BPOM Regulations

Lastly, understanding BPOM regulations is crucial when selecting machinery. Machines should not only produce gummies efficiently but also ensure that every batch meets safety and efficacy standards. For startups, seeking machines that simplify the pre-market approval process can save time and resources.

In contrast, medium to large companies should focus on continuous compliance programs that include regular audits and updates to machinery as needed.

Gummy machines must meet BPOM, GMP, and Halal standards.True

Compliance with these standards ensures legal production and marketability.

Startups should avoid high-throughput automated lines for gummies.True

These lines are costly and inflexible, unsuitable for small-scale needs.

How Can Environmental Factors Impact Your Gummy Production Process?

Ever wondered how Indonesia's humid climate affects gummy production? Let's uncover the challenges and solutions.

Environmental factors like humidity and temperature can significantly impact the production process of gummy supplements by affecting their texture, shelf life, and overall quality. Ensuring the right equipment and control measures are in place is crucial for maintaining product consistency and compliance.

The Climate Challenge: Humidity and Temperature

Imagine trying to make perfect gummies in a sauna. Not easy, right? Indonesia’s humidity can turn your gummies into sticky blobs if you’re not careful. High moisture in the air can wreak havoc on texture and consistency. Temperature swings can also cause problems, altering the gel strength and causing sugar to crystallize or bloom.

To combat this, look for machinery with climate control features. Investing in dehumidifiers or air conditioning systems can maintain a stable environment in your production area.

Equipment Adaptation: Building a Resilient Setup

Choosing machinery that withstands Indonesia's climate is essential. Equip your factory with machines that offer precision control over temperature and humidity levels during production. This ensures your gummies don’t melt or become too hard before they even hit the shelves.

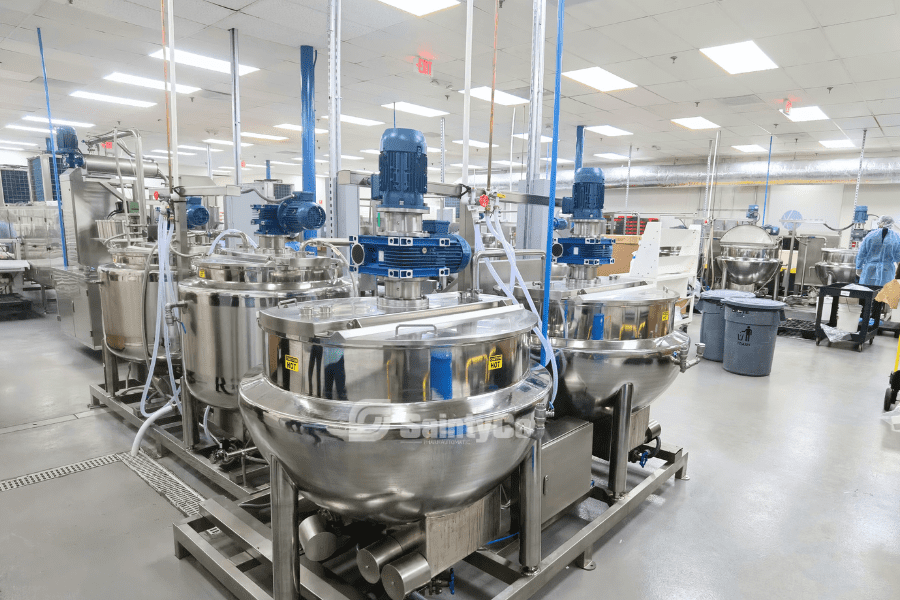

For instance, using jacketed kettles allows for precise temperature regulation during cooking, ensuring that your gelatin or pectin reaches the perfect consistency. In addition, consider having a controlled cooling tunnel to set gummies properly, even in tropical heat.

Watch this video showcasing the SaintyCo's G150 Gummy Line in action!

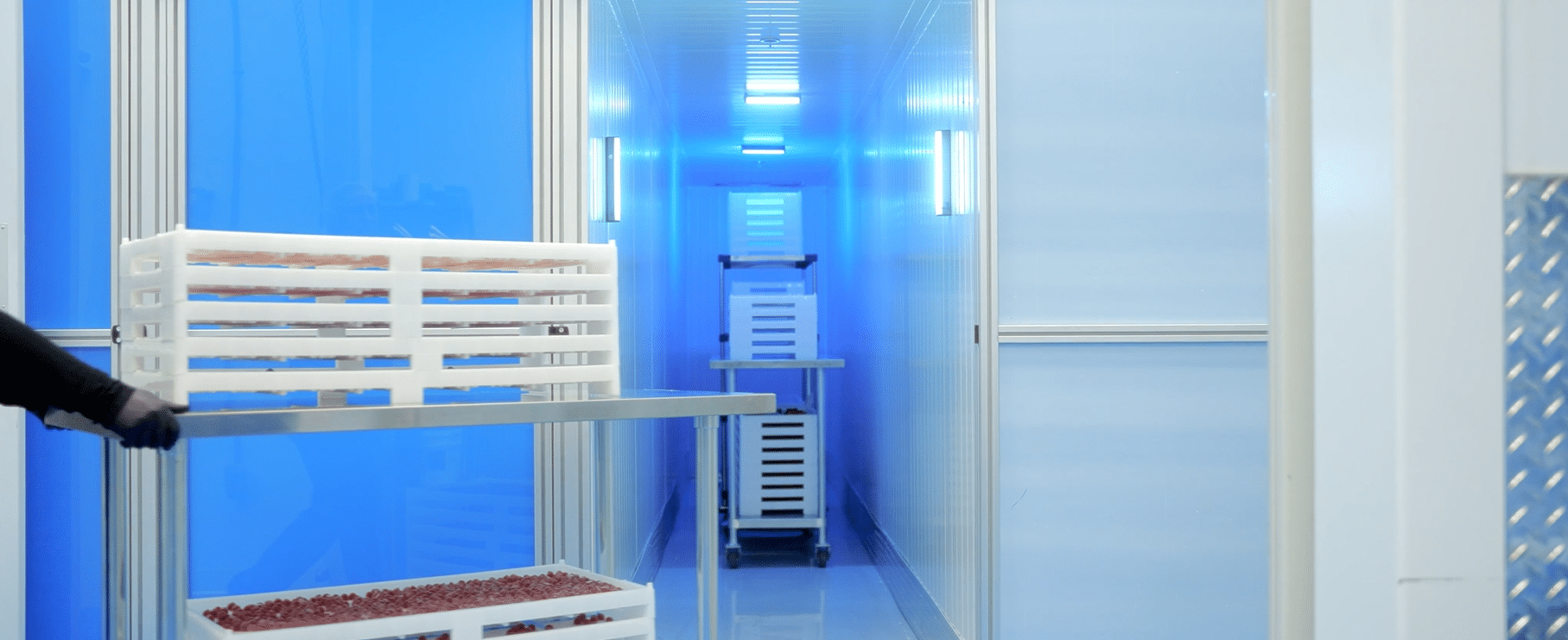

Storage Solutions: Keeping Quality Intact

Once produced, gummies face another hurdle: storage. Improper storage can lead to moisture absorption, affecting taste and texture. Ensure that your storage facilities are equipped with appropriate climate controls to avoid these issues.

Consider using vacuum-sealed packaging or adding desiccants to keep moisture out. Implementing proper storage5 not only preserves quality but also extends shelf life, keeping your products fresh for longer.

Regulatory Considerations: Meeting Compliance Standards

Adhering to BPOM regulations requires you to manage these environmental factors diligently. Ensuring that your production environment complies with GMP standards means regular audits and updates to your environmental controls.

Consulting with local experts can help you navigate these requirements efficiently. Regular training for staff on managing environmental controls is also crucial. Understanding local regulations6 will help you stay ahead of compliance needs and avoid costly penalties.

By addressing these environmental factors head-on, you can ensure that your gummy production process remains smooth, efficient, and compliant with Indonesian regulations. Whether it's through advanced machinery or strategic climate control measures, adapting to your surroundings is key to success in the gummy business.

Humidity affects gummy texture during production.True

High humidity can make gummies sticky, affecting their consistency.

Temperature swings have no impact on gummy quality.False

Temperature changes can alter gel strength and cause sugar issues.

Conclusion

To succeed in Indonesia's supplements market, focus on compliance, quality, and smart investments in machinery. Stay informed and adaptable for long-term growth. Ready to take the plunge? Dive into the details and start planning today!

At GummyGenix by SaintyCo, we're here to support your journey with cutting-edge, GMP-compliant gummy manufacturing equipment designed for efficiency, precision, and adaptability. Our machines are fully compatible with regulatory standards, and we offer reliable after-sales support to keep your operations running smoothly.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality gummy products to life—together.

Gummy Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Discover specific permits needed for setting up factories in Indonesia.: Industrial companies are required to first obtain Principal license from the Investment coordinating board of Indonesia. Principal license ... ↩

-

Discover why startups should consider third-party GMP certification.: If a company has a good quality control system in place, the products itmakes will be of consistent quality, said V. Srini Srinivasan, vice presidentof the DSVP ... ↩

-

Learn how digital tools can streamline documentation processes.: Improve production processes with manufacturing document management solutions. Learn how we can expedite production, reduce risks, and contain costs. ↩

-

Discover machines ideal for small-scale operations' efficiency and versatility.: Gummy Depositor · Gummy Molds · Gummy Coating Machine · Auxiliary Manufacturing Equipment · Quality Control Equipment · Packaging Equipment. ↩

-

Learn effective storage methods to maintain quality in humid conditions.: Instead of storing your vitamins in the kitchen or bathroom, consider a cool and dry space where they will be out of direct sunlight. A bedroom drawer or linen ... ↩

-

Discover how to meet BPOM standards for environmental compliance.: The food category regulation sets guidelines for setting standards, assessments, inspections and certifications for food safety controls. ↩