Mushroom gummies are becoming increasingly popular for their health benefits and ease of consumption. But how are they made commercially?

Commercial manufacturing of mushroom gummies involves selecting functional mushrooms like Chaga or Reishi, using gelling agents such as gelatin or agar-agar, and employing advanced machinery for precision and efficiency. Key steps include grinding mushrooms into powder, mixing ingredients, and using automated depositors for uniform gummies.

While the basic overview gives you a glimpse into the process, mastering the art of mushroom gummy production involves understanding each step in detail. From the specific health benefits of various mushrooms to the intricacies of equipment like decarboxylators and depositors, there's much more to explore.

Mushroom gummies use agar-agar as a gelling agent.True

Agar-agar is a common gelling agent used in mushroom gummy production.

Decarboxylators are used to grind mushrooms into powder.False

Decarboxylators are not used for grinding; they activate compounds in cannabis.

How Do Functional Mushrooms Benefit Gummy Formulations?

Discover how the integration of functional mushrooms into gummy formulations can enhance health benefits, offering a convenient and tasty way to improve well-being.

Functional mushrooms in gummies provide immune support, cognitive benefits, and energy boosts. They combine the health advantages of mushrooms with the convenience and taste of gummies, making them a popular supplement choice.

Benefits of Integrating Functional Mushrooms

Functional mushrooms are renowned for their health-enhancing1 properties, making them a valuable addition to gummy formulations. These mushrooms are rich in antioxidants, adaptogens, and bioactive compounds, which contribute to various health benefits.

| Mushroom Type | Key Benefits |

|---|---|

| Chaga | Antioxidant support |

| Lion’s Mane | Cognitive health |

| Reishi | Relaxation & immunity |

| Cordyceps | Energy & endurance |

Enhancing Nutritional Profile

The nutritional profile of gummies is significantly enhanced by functional mushrooms. For example, Lion's Mane2 is celebrated for promoting brain health, which can be beneficial for individuals seeking cognitive support. Similarly, Cordyceps3 is often included to improve energy levels and physical endurance, making it ideal for athletes and active individuals.

Improved Consumer Appeal

Mushroom gummies appeal to consumers looking for a convenient, enjoyable way to consume supplements. The combination of delicious flavors and the health benefits of mushrooms makes these gummies particularly attractive to health-conscious individuals. By masking the earthy taste of mushrooms with natural flavors like lemon or strawberry, manufacturers can create a product that is both palatable and beneficial.

Market Growth and Innovation

The market for functional mushroom gummies is growing rapidly, driven by consumer demand for innovative health products. As more people seek natural solutions for health issues, mushroom gummies stand out due to their unique combination of taste and efficacy. With growing research4 supporting their benefits, these products are becoming a staple in the nutraceutical industry.

Manufacturing Considerations

Producing mushroom gummies requires careful consideration of ingredients and manufacturing processes. High-quality equipment ensures the uniform distribution of mushroom extracts and other ingredients, maintaining the integrity of bioactive compounds. Incorporating advanced production technology5 helps maintain product quality while enhancing efficiency and scalability.

With the integration of functional mushrooms into gummy formulations, consumers can enjoy a tasty, effective means of supplementing their diet with valuable nutrients and compounds.

Functional mushrooms enhance gummy nutritional value.True

Mushrooms add antioxidants and bioactive compounds, boosting health benefits.

Lion's Mane in gummies improves physical endurance.False

Lion's Mane is known for cognitive health, not endurance.

What Types of Equipment Are Essential for Gummy Production?

Discover the essential equipment required to kickstart your gummy production line, from mixing tanks to cooling tunnels. Understanding these key machines will streamline your manufacturing process and enhance product quality.

To produce high-quality gummies, essential equipment includes industrial grinders, mixing tanks, vacuum cookers, depositors, molds, cooling tunnels, demolding machines, coating systems, and packaging machines. Each plays a crucial role in the consistency and efficiency of gummy manufacturing.

Industrial Grinders

Industrial grinders are crucial in converting ingredients like dried mushrooms into a fine powder for even extraction. These machines ensure a uniform texture in the final product. For instance, using a high-precision grinder6 can minimize variability in potency.

Mixing Tanks with Agitators

A large mixing tank is necessary for combining mushroom extracts, gelling agents, sweeteners, and flavors. Tanks with agitators offer controlled temperature settings, ensuring a smooth mix. A 100L dissolving tank with high-shear mixing7 guarantees seamless dispersion.

| Feature | Description |

|---|---|

| Capacity | 100 Liters |

| Temperature Control | Up to 200°C |

| Construction Material | Stainless Steel |

Continuous Vacuum Cookers

These cookers are designed to maintain the bioactive integrity of ingredients like mushroom extracts by cooking under vacuum. They help prevent thermal degradation while optimizing syrup consistency. Explore how vacuum cookers8 can extend shelf life.

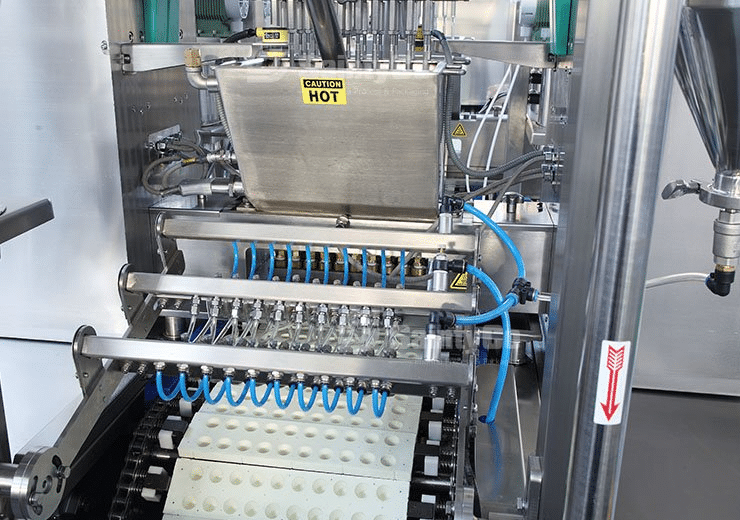

Automated Depositors and Molds

The depositor machine accurately fills molds, ensuring uniform size and weight. Choosing between silicone or metal molds allows customization in gummy shapes. Servo-driven depositors are crucial for maintaining precision even in small batch variations.

Cooling Tunnels

Post-deposition, cooling tunnels set gummies with consistent texture and shape. Maintaining temperatures between 0–20°C ensures even cooling. Learn about multi-layer cooling tunnels9 that maximize floor utilization.

Demolding and Coating Machines

Automated demolding systems reduce labor costs by ejecting gummies without manual intervention. Coating machines enhance appearance and texture. Consider a CW-600 Oil Coating Drum10 for uniform coating efficiency.

Packaging Machines

Gummies must be packed in airtight containers to preserve freshness. Packaging machines like the GummyCount 90 offer precise counting and sealing to prevent errors. Check out options for automated packaging solutions for gummies11 that cater to different styles like pouches or bottles.

Industrial grinders ensure uniform gummy texture.True

Grinders convert ingredients into fine powder, ensuring even extraction.

Cooling tunnels set gummies at temperatures above 50°C.False

Cooling tunnels maintain temperatures between 0–20°C for even cooling.

How Can You Ensure Quality Control in Mushroom Gummies?

Ensuring quality control in mushroom gummies is crucial for consumer safety and product efficacy. With the rise in popularity of functional foods, manufacturers must adhere to strict guidelines to maintain quality.

To ensure quality control in mushroom gummies, implement stringent ingredient testing, utilize precise manufacturing equipment, and conduct rigorous batch testing. Regular audits and compliance with industry standards are essential.

Importance of Ingredient Testing

Before production begins, ingredient testing is vital. This involves verifying the purity and potency of mushroom extracts12, ensuring no contaminants are present. Reliable suppliers provide certificates of analysis13, confirming each batch's quality.

Utilizing Advanced Manufacturing Equipment

Employing state-of-the-art machinery ensures consistency and quality in every batch. Equipment such as a continuous vacuum cooker helps maintain the bioactive integrity of the mushroom extracts by minimizing thermal degradation. Additionally, an automated depositor machine ensures uniform size and shape, crucial for consumer trust.

| Equipment | Purpose | Features |

|---|---|---|

| Industrial Grinder | Consistency in powder | Adjustable settings for uniformity |

| Vacuum Cooker | Preserve bioactives | Reduces thermal degradation |

| Depositor Machine | Uniform gummy production | Precision filling system |

Conducting Rigorous Batch Testing

Every batch should undergo thorough testing to ensure it meets the desired potency and safety standards. This includes testing for microbial contamination, pesticide residues, and heavy metals.

Adhering to Industry Standards

Compliance with industry standards14 like ISO 9001 and FDA guidelines is non-negotiable. Regular audits and certifications not only boost consumer confidence but also align your production with global quality expectations.

Regular Audits and Staff Training

Conducting regular audits ensures that all processes remain compliant with current regulations. Additionally, investing in staff training programs can drastically reduce human errors, ensuring consistent production quality. Staff well-versed in GMP (Good Manufacturing Practices) can spot potential issues before they escalate.

Continuous Improvement and Feedback Loops

Establishing a feedback loop with consumers allows manufacturers to refine their products continuously. Using consumer insights, coupled with scientific research15, can lead to improvements in taste, texture, and efficacy, ensuring the product remains competitive in the market.

Ingredient testing ensures mushroom purity.True

Testing verifies the purity of mushroom extracts, preventing contamination.

Automated depositors lead to inconsistent gummy sizes.False

Automated machines ensure uniform size and shape in production.

What Are the Common Challenges in Manufacturing Gummies?

Gummy manufacturing is a complex process, fraught with potential challenges that can affect quality and efficiency. From ingredient sourcing to final packaging, each step requires precision and expertise. Let's explore these hurdles in detail.

Manufacturing gummies involves challenges like ingredient consistency, equipment precision, and regulatory compliance. Addressing these issues ensures high-quality products, consumer safety, and efficient production.

Ingredient Consistency

Maintaining consistent quality in gummy ingredients16 is crucial. Variability in mushroom extracts or gelling agents can lead to inconsistent flavor, texture, or potency. For example, fluctuations in gelatin strength can alter gummy firmness, impacting consumer experience.

| Ingredient | Common Issue | Impact on Product |

|---|---|---|

| Gelatin | Variable bloom strength | Inconsistent texture |

| Sweeteners | Flavor changes due to heat | Unpredictable taste |

| Flavorings | Inadequate masking | Earthy mushroom taste |

Equipment Precision

Precision in equipment like mixers and depositors is vital for uniformity in gummy size and shape. An automated depositor17 ensures each mold is filled accurately, but machinery misalignment can result in waste or misshapen gummies.

A high-shear mixing system is critical to disperse ingredients evenly, but improper settings can cause air bubbles, affecting gummy clarity. Precise calibration minimizes these risks.

Regulatory Compliance

Navigating regulatory landscapes for food safety and labeling is another significant challenge. Each region has specific guidelines for nutraceutical products, necessitating comprehensive knowledge of compliance standards to avoid legal issues.

Compliance involves ensuring ingredient traceability and adhering to packaging requirements. Investing in a robust compliance management system18 helps manufacturers meet these demands efficiently.

Environmental Control

Controlling environmental factors such as temperature and humidity is essential during production. These variables can influence the stability of gelling agents and the shelf life of the final product.

A cooling tunnel19 that maintains precise temperatures prevents over-hardening or stickiness, ensuring gummies have a desirable chewiness.

Understanding these challenges allows manufacturers to strategize effectively, adopting technologies and processes that enhance quality while minimizing disruptions.

Inconsistent gelatin affects gummy texture.True

Variable bloom strength in gelatin leads to inconsistent gummy firmness.

Automated depositors eliminate all production waste.False

Misalignment in machinery can still cause waste, despite automation.

How to Market Mushroom Gummies to Health-Conscious Consumers?

Mushroom gummies are gaining traction among health-conscious consumers for their unique benefits. How can brands effectively market these innovative products? This guide explores strategies to capture the interest of wellness enthusiasts.

To market mushroom gummies to health-conscious consumers, emphasize their health benefits, use credible testimonials, engage in educational content marketing, and leverage social media platforms to reach your target audience effectively.

Understanding Your Target Audience

Health-conscious consumers prioritize natural ingredients20, transparency, and quality. Understanding their preferences is crucial. These consumers often research before purchasing, valuing brands that provide detailed product information.

Highlighting Health Benefits

Clearly communicate the health benefits of each mushroom used in your gummies. For instance, Chaga and Reishi are known for boosting immunity, while Lion’s Mane supports cognitive function. Use simple and appealing visuals like tables to summarize benefits:

| Mushroom | Benefit |

|---|---|

| Chaga | Antioxidant support |

| Lion’s Mane | Cognitive health |

| Reishi | Relaxation |

Leveraging Educational Content

Create engaging content that educates consumers on the functional benefits21 of mushroom gummies. Blog posts, infographics, and videos can explain how mushrooms enhance health. This builds trust and positions your brand as an industry expert.

Utilizing Social Proof and Testimonials

Testimonials and user-generated content can significantly influence purchasing decisions. Encourage satisfied customers to share their experiences on social media or your website. Highlighting real-life success stories can enhance credibility.

Effective Use of Social Media

Social media platforms are powerful tools for reaching health-conscious audiences. Utilize Instagram and Pinterest to share visually appealing content, such as recipes or lifestyle tips involving mushroom gummies. Engage with followers through Q&A sessions or live demonstrations.

Building Partnerships

Collaborate with health influencers22 or wellness brands to widen your reach. Influencers can introduce your product to a broader audience, lending authenticity and trustworthiness to your brand.

Packaging and Branding

Ensure your packaging reflects the natural and health-focused attributes of your product. Use eco-friendly materials and emphasize transparency in labeling. Clear information about ingredients and benefits can reassure consumers about the product's quality.

Running Promotions and Samples

Consider offering samples or running promotions to entice first-time buyers. Discounts or free samples can lower the barrier to trial, allowing consumers to experience the benefits firsthand before making a purchase decision.

Incorporating these strategies can effectively market mushroom gummies to health-conscious consumers, ensuring they resonate with their values and needs.

Mushroom gummies are popular among health-conscious consumers.True

Health-conscious consumers seek products with natural benefits, like mushroom gummies.

Reishi mushrooms do not support relaxation benefits.False

Reishi mushrooms are known for their relaxation and stress-reducing properties.

Conclusion

Commercially manufacturing mushroom gummies involves selecting functional mushrooms, precise ingredient mixing, and advanced machinery to ensure quality, consistency, and health benefits for consumers.

At GummyGenix by SaintyCo, we're here to support your journey with cutting-edge, GMP-compliant gummy manufacturing equipment designed for efficiency, precision, and adaptability. Our machines are fully compatible with regulatory standards, and we offer reliable after-sales support to keep your operations running smoothly.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality gummy products to life—together.

-

Understand how functional mushrooms can improve health and wellness when used in supplements like gummies. ↩

-

Explore the cognitive advantages provided by Lion's Mane mushroom in dietary supplements. ↩

-

Learn how Cordyceps mushrooms boost energy levels and physical performance. ↩

-

Access the latest research supporting the health benefits of functional mushrooms. ↩

-

Discover advanced technologies used in producing high-quality gummy supplements. ↩

-

Learn how high-precision grinders enhance uniformity in gummy production. ↩

-

Discover how high-shear mixing improves ingredient dispersion. ↩

-

Understand how vacuum cookers maintain ingredient integrity. ↩

-

Explore how multi-layer cooling tunnels improve energy efficiency. ↩

-

Examine how CW-600 drums ensure uniform gummy coating. ↩

-

Investigate automated packaging options that preserve gummy freshness. ↩

-

Learn about the best practices for testing mushroom extracts to ensure purity and potency. ↩

-

Discover why certificates of analysis are crucial for verifying the quality of mushroom extracts. ↩

-

Understand how ISO 9001 standards apply to food production and their benefits. ↩

-

Explore recent scientific studies that can inform improvements in mushroom gummy formulations. ↩

-

Learn about typical problems with gummy ingredients and how they affect final product quality. ↩

-

Discover why automated depositors are crucial for consistency in gummy manufacturing. ↩

-

Understand the essential compliance requirements that gummy manufacturers must adhere to. ↩

-

Explore how cooling tunnels help maintain optimal gummy texture and quality. ↩

-

Discover why natural ingredients appeal to health-conscious consumers, enhancing product appeal. ↩

-

Explore the specific health benefits provided by different types of functional mushrooms. ↩

-

Learn how collaborating with health influencers can enhance brand credibility and reach. ↩