In the quest to meet consumer demands for healthier gummies, manufacturers face pivotal decisions involving ingredients and production techniques.

Choosing between gelatin and pectin as gelling agents significantly affects the texture, taste, and dietary suitability of gummies. Gelatin offers a chewy texture ideal for traditional and cannabis-infused gummies, while pectin suits vegan-friendly, firmer gummies. The choice of sugar levels further influences health appeal and manufacturing precision.

While this brief overview introduces the fundamental choices, delving deeper into each option reveals insights essential for making informed manufacturing decisions. Let's explore the benefits and challenges associated with each choice to help you craft the perfect healthy gummy.

Gelatin gummies are suitable for vegan diets.False

Gelatin is derived from animal collagen, making it unsuitable for vegans.

Pectin provides a firmer texture in gummies than gelatin.True

Pectin creates a firmer texture, preferred in vegan and firmer gummies.

What Makes Gelatin-Based Gummies Unique?

Gelatin-based gummies hold a special place in the candy world due to their distinct texture and versatility. This chewy delight, derived from animal collagen, offers unique characteristics that set it apart from other gelling agents.

Gelatin-based gummies are unique due to their chewy, elastic texture, derived from animal collagen. They offer flexibility under various conditions, making them ideal for conventional candies and CBD/THC applications.

The Chewy, Elastic Texture

The hallmark of gelatin-based gummies is their chewy, elastic texture. Unlike pectin gummies1 which offer a firmer bite, gelatin allows for a softer chew that many people find satisfying. This texture arises because gelatin forms a network of proteins that trap water, creating an elastic structure. This makes them ideal for those who enjoy a gummy that bounces back with each bite.

Versatility in Applications

Gelatin-based gummies are not just about texture; they are versatile in application. They can be used in conventional gummy candies, but also excel in CBD and THC-infused versions due to their ability to retain flexibility under different conditions. This adaptability is crucial for products that need to maintain their shape and consistency when infused with oils or extracts.

Production Considerations

Producing gelatin-based gummies involves cooling the mixture to set the gel, which requires precise temperature control. Machines like the G-40AW or G300 are recommended for medium to large-scale operations due to their adaptability to gelatin recipes. The use of these machines ensures even distribution and proper setting.

| Factor | Gelatin-Based Gummies |

|---|---|

| Texture | Chewy, Elastic |

| Main Ingredient | Animal Collagen |

| Setting Process | Cooling Required |

| Ideal Applications | Conventional, CBD/THC |

Health Aspects and Benefits

Beyond texture and versatility, gelatin offers health benefits that make it appealing. It contains amino acids that support joint health and skin elasticity. For those interested in the nutritional side, gelatin2 can be an ingredient that contributes to a balanced diet. When choosing between sugar-free or low-sugar options, gelatin's natural properties can help maintain the desired gummy texture without compromising on health goals.

Gelatin-based gummies are firmer than pectin gummies.False

Gelatin gummies are softer, while pectin gummies offer a firmer bite.

CBD/THC-infused gummies retain flexibility due to gelatin.True

Gelatin's structure maintains flexibility, ideal for infused products.

Why Choose Pectin for Vegan Gummy Options?

As vegan diets become increasingly popular, finding suitable alternatives for gelatin in gummies is essential. Pectin, a plant-based gelling agent, offers a promising solution. But why should you choose pectin for your vegan gummy options?

Pectin is preferred in vegan gummies for its plant-based origin and ability to create a firm, jelly-like texture. Unlike gelatin, it suits dietary restrictions and is ideal for health-focused and vegan markets.

Understanding the Difference: Gelatin vs. Pectin

Gelatin, derived from animal collagen, is traditionally used in gummy candies due to its elastic texture and versatility. In contrast, pectin comes from plant sources, making it a suitable choice3 for vegan and vegetarian markets. Pectin-based gummies offer a firmer and more jelly-like texture, which many consumers prefer for health-focused products.

Texture and Stability

The texture of pectin gummies tends to be firmer and less chewy than gelatin-based ones. This distinction can be advantageous for certain product lines, such as those emphasizing health and wellness. Pectin's specific pH and temperature sensitivity require precise cooking methods to achieve the desired consistency. Machines like the G-800X ensure even cooling and consistency in pectin-based products4.

Health Considerations

Pectin is not only vegan but also aligns with various health-conscious consumer demands. It is rich in dietary fiber, which can contribute to a healthier digestive system. Unlike gelatin, which may raise concerns among some due to its animal origin, pectin supports dietary restrictions, making it an excellent choice for the growing market of vegan and health-oriented consumers. Consider the nutritional benefits of incorporating pectin into your gummy formulations through various recipes5.

Market Trends and Consumer Preferences

The demand for vegan products is rising steadily across global markets. Vegan gummies are not only targeted at vegans but also appeal to those with dietary restrictions or ethical considerations. Pectin-based gummies can be marketed as a healthier alternative, attracting a broader audience interested in ethical consumption6.

| Property | Gelatin Gummies | Pectin Gummies |

|---|---|---|

| Source | Animal Collagen | Plant-based |

| Texture | Elastic & Chewy | Firm & Jelly-like |

| Vegan | No | Yes |

| Sensitivity | Less sensitive | Sensitive to pH & Temp |

Adopting pectin for vegan gummy production involves understanding its unique characteristics and requirements compared to traditional gelatin. With careful formulation and the right equipment, pectin can yield products that satisfy modern consumer demands.

Pectin is derived from animal collagen.False

Pectin is plant-based, unlike gelatin, which comes from animal collagen.

Pectin gummies are firmer than gelatin gummies.True

Pectin creates a firmer, jelly-like texture compared to the elastic chewiness of gelatin.

How Do Sugar-Free Gummies Compare to Traditional Ones?

In the sweet world of gummies, sugar-free varieties are gaining popularity. But how do they stack up against traditional sugar-laden gummies in terms of taste, texture, and health benefits? Let's explore!

Sugar-free gummies differ from traditional ones primarily in sweeteners used. While traditional gummies use sugar, sugar-free options use alternatives like stevia or maltitol, offering fewer calories and reduced risk of cavities but may cause digestive issues.

Taste and Texture Comparison

Traditional gummies boast a sweet, full-bodied flavor due to sugar7 and glucose syrups, creating a pleasant chewy texture. In contrast, sugar-free gummies use sugar substitutes like stevia or maltitol, resulting in a similar yet slightly different taste profile. Some consumers find them less sweet, while others appreciate the reduced sweetness.

Texture Table:

| Gummy Type | Texture Profile |

|---|---|

| Traditional Gummies | Chewy, elastic |

| Sugar-Free Gummies | Slightly firmer, less chewy |

Health Considerations

A significant advantage of sugar-free gummies is their lower calorie content, appealing to those watching their sugar intake8 or managing weight. Additionally, these gummies may reduce the risk of cavities since they lack regular sugar. However, some sugar substitutes can lead to digestive issues like bloating or diarrhea in sensitive individuals.

Health Factor Table:

| Gummy Type | Caloric Content | Dental Impact |

|---|---|---|

| Traditional Gummies | High | Potential cavities |

| Sugar-Free Gummies | Lower | Reduced cavity risk |

Market Trends and Preferences

The growing demand for healthier snacks has led to an increased presence of sugar-free gummies in the market. Many consumers9 are exploring these options not only for dietary reasons but also to adhere to vegan or plant-based diets since some sugar-free variants use pectin instead of gelatin.

Manufacturers are responding by improving the taste and texture profiles of sugar-free options, making them closer to their traditional counterparts. The shift towards health-conscious snacking trends emphasizes the importance of innovation in the gummy industry.

Key Ingredients Table:

| Ingredient | Traditional Gummies | Sugar-Free Gummies |

|---|---|---|

| Sweetener | Sugar | Stevia/Maltitol |

| Gelling Agent | Gelatin/Pectin | Pectin |

Exploring these elements offers insights into how consumer preferences shape the confectionery market. As health trends10 evolve, so do the products that cater to these changing demands. Whether opting for traditional or sugar-free gummies, understanding their differences helps make informed choices that align with personal health goals and taste preferences.

Sugar-free gummies are less sweet than traditional ones.True

Sugar substitutes like stevia or maltitol result in a less sweet taste.

Traditional gummies have lower caloric content than sugar-free ones.False

Traditional gummies have higher calories due to sugar content.

What Are the Challenges in Producing Low-Sugar Gummies?

Creating low-sugar gummies involves balancing taste, texture, and health considerations, which presents unique manufacturing challenges. From selecting suitable sweeteners to ensuring product stability, producers must navigate a complex landscape to meet consumer demands for healthier confections.

Producing low-sugar gummies involves balancing taste, texture, and stability. Manufacturers face challenges with sweetener selection, maintaining gummy texture, and preventing crystallization while meeting health and flavor expectations.

Sweetener Selection and Taste Balance

Choosing the right sweetener is crucial in producing low-sugar gummies. Traditional sugar provides not only sweetness but also bulk and texture. Alternative sweeteners like stevia11 and erythritol12 can replace sugar but often alter the taste profile and mouthfeel.

Many manufacturers struggle to achieve a flavor balance13 that satisfies consumers accustomed to the taste of traditional gummy candies. The challenge is magnified by the limited range of flavors that complement the bitterness or aftertaste of some sugar substitutes.

Maintaining Texture and Consistency

Low-sugar gummies require careful formulation to maintain the desirable chewy texture associated with their sugary counterparts. The absence of sugar affects the gelling process, requiring precise adjustments in gelling agents such as gelatin14 or pectin15.

A detailed table of common gelling agents used in low-sugar gummies:

| Gelling Agent | Benefits | Challenges |

|---|---|---|

| Gelatin | Provides elasticity and chewiness | Requires cooling for setting |

| Pectin | Plant-based, firmer texture | Sensitive to pH and temperature |

Stability and Crystallization Issues

Preventing crystallization is another significant challenge. Sugar typically inhibits crystallization, but its reduction or elimination can lead to an unstable gummy structure. Alternative stabilizers and precise cooking techniques are required to ensure product consistency.

Manufacturers often use advanced syrup cooking methods to address this issue. Machines like SaintyCo G300/G150 gummy production lines16 allow for precise control over temperature and ingredient integration, ensuring that low-sugar gummies retain their intended texture and appearance.

Consumer Expectations and Market Demand

Consumers expect low-sugar gummies to taste as good as their sugary counterparts while being a healthier option. This expectation drives innovation in flavor development and marketing strategies.

The market for health-conscious confectionery is growing rapidly, pushing manufacturers to continually adapt their processes and formulations to meet consumer preferences and dietary trends.

Manufacturers need to keep abreast of market trends and consumer preferences by engaging in continuous research and development. This includes experimenting with new ingredients and technologies that can help them maintain competitive advantage in the confectionery market17.

Stevia enhances the texture of low-sugar gummies.False

Stevia is used as a sweetener, not for enhancing texture.

Low-sugar gummies are prone to crystallization issues.True

Reducing sugar can lead to crystallization, affecting stability.

Which Equipment is Best for Your Gummy Production Needs?

Choosing the right equipment is crucial for efficient gummy production. Explore options tailored for gelatin, pectin, sugar-based, sugar-free, and low-sugar gummies to meet diverse market demands.

For effective gummy production, select equipment based on the gelling agent and sugar content. Gelatin-based gummies require machines with precise temperature control, while pectin-based need high precision cooking. Choose specific machines for sugar-based or sugar-free options to ensure quality and efficiency.

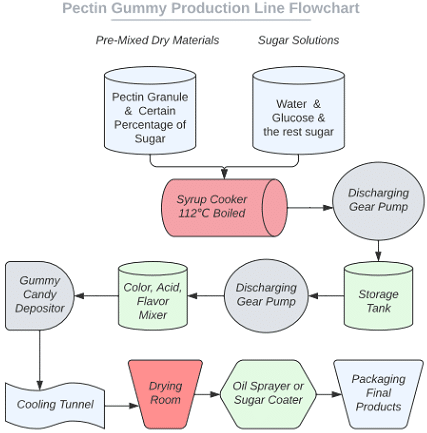

Gelatin vs Pectin Gummies: Cooking Requipment Recommendations

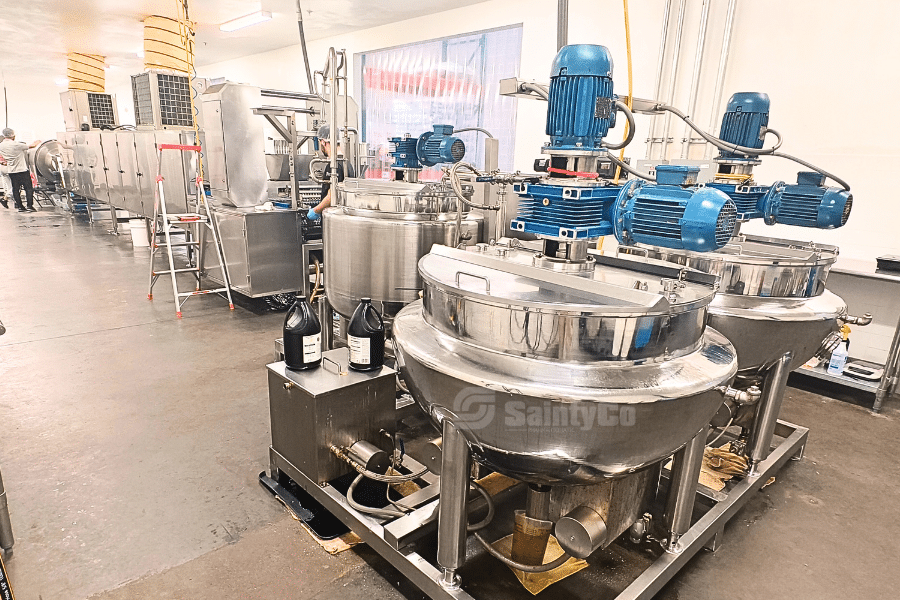

1. Jacket Kettle with High-Shear Mixer

Best for: Pectin Gummies

-

Why High-Shear Mixing?

Pectin requires thorough hydration and dissolution to form a stable gel. A high-shear mixer ensures:- Complete dissolution of pectin into water or sugar syrup, avoiding clumping.

- Creation of uniform 4-8% pectin solutions needed for gummy consistency.

- Efficient mixing with other ingredients like glucose and sugar during pre-cooking.

-

Advantages:

- Handles viscous materials effectively.

- Provides consistent temperature control (0-150°C) with jacket heating.

- Prevents localized overheating, preserving pectin's gelling properties.

- Ideal for achieving pre-cooking requirements in a controlled environment.

-

Additional Features to Look For:

- Scraper-type stirrers to prevent product sticking and ensure uniform mixing.

- Pneumatic discharge valves for seamless transfer to depositing systems.

- Jacket heating with precise temperature monitoring for optimal results.

Suggested Use Case:

Use jacket kettles with high-shear mixers during the pectin pre-dissolution and primary cooking stages. For larger-scale production, combine them with continuous vacuum cookers for final concentration and cooling to optimize pectin gummy texture and gel strength.

2. Vacuum Cooker

Best for: Gelatin Gummies

-

Why Vacuum Cooking?

Gelatin requires precise temperature control to preserve gel strength, which can be compromised by excessive heat. Vacuum cookers ensure:- Lower cooking temperatures (~80°C under vacuum conditions) while achieving high solids content (90%+).

- Minimal thermal degradation, preserving the texture, clarity, and functional quality of gelatin-based gummies.

- Bubble-free syrup preparation for smooth, clear gummies.

- Rapid moisture removal to achieve the desired syrup consistency efficiently.

-

Advantages:

- Reduces cooking time by removing moisture efficiently under vacuum.

- Maintains gelatin's functional properties by preventing exposure to high heat.

- Energy-efficient, making it ideal for high-output operations.

- Essential for creating consistent and bubble-free syrups for premium gummy textures.

-

Additional Features to Look For:

- Multi-stage cooking chambers for precise control of syrup concentration.

- Integrated vacuum pumps for stable pressure control.

- Adjustable settings for diverse gummy recipes and production scales.

Suggested Use Case:

Vacuum cookers are optimal for gelatin-based gummy syrup preparation, especially during the final stages of cooking and temperature control. Pair them with a jacket kettle for pre-melting and integrating gelatin into the syrup at precise conditions.

Comparison Summary

| Feature | Jacket Kettle with High-Shear Mixer | Vacuum Cooker |

|---|---|---|

| Best for | Pectin-based gummies | Gelatin-based gummies |

| Primary Function | Dissolving and mixing | Moisture removal and bubble-free cooking |

| Temperature Range | 0-150°C | ~80°C under vacuum |

| Capacity | Flexible for small to medium batches | Optimal for medium to large batches |

| Advantages | Thorough mixing and dissolution | Maintains product quality, energy-saving |

| Integration | Pre-cooking or ingredient preparation stage | Final cooking before depositing |

3. Suggested Hybrid Approach

For high-capacity, precise gummy production:

- Pectin Gummies: Use a high-shear mixer for pre-dissolution, followed by a vacuum cooker for final syrup concentration and cooling.

- Gelatin Gummies: Utilize a vacuum cooker for syrup cooking and temperature control, then a jacket kettle for gelatin dissolution and integration.

4. Tailored Recommendations

- For small-scale or entry-level production: DM-50X is versatile and supports both gelatin and pectin production. It’s compact, easy to maintain, and ideal for R&D or startups.

- For medium-to-large scale production: G300 suits high-output operations with multi-layer cooling for gelatin and pectin. G800X is optimized for pectin, offering up to 240,000 gummies per hour.

5. Why Choose SaintyCo Gummy Machinery?

Our equipment integrates advanced features like:

- Precise temperature and pH control tailored to both gelatin and pectin gummies.

- Scalable solutions to support startups and high-output manufacturers.

Sugar-Based vs. Sugar-Free Gummies: Equipment Considerations

For traditional sugar-based gummies, machinery like the SaintyCo G80 and G150 lines are optimal. These machines are designed to handle conventional recipes with sugar and glucose syrups, offering flexibility in molding and demolding processes.

Sugar-free gummies demand precise control to prevent crystallization. SaintyCo gummy making machines also offer advanced dosing systems ideal for this purpose. They help maintain the intended texture while catering to diabetic-friendly markets.

Low-Sugar Gummies: Balancing Health and Taste

For low-sugar gummy production, integrating equipment that supports innovative syrup cooking and precise sweetener dosing is essential. The All-in-One G300/G150 gummy production lines allows efficient integration of unique recipes, ensuring reduced sugar levels without compromising flavor.

Watch this video showcasing the SaintyCo's G150 Gummy Line in action!

Additional Equipment for Enhancing Gummy Production

Consider implementing oil coating systems18 like the CW-600 oil coating drum to enhance sheen and prevent stickiness in sugar-free gummies. Efficient drying trays are also crucial, especially for low-sugar recipes where moisture control is vital.

Customization options available in SaintyCo gummy making machines like the G-40AW support recipe versatility and are beneficial for evolving market demands.

G150 machines prevent crystallization in sugar-free gummies.True

G150 offers advanced dosing systems to maintain texture.

How Can You Ensure Quality and Consistency in Gummy Production?

Quality and consistency are crucial for successful gummy production. Achieving these requires careful selection of ingredients, precise machinery, and stringent quality control measures.

Ensuring quality and consistency in gummy production involves selecting the right gelling agent, maintaining precise temperature controls, using advanced gummy manufacturing equipment, and implementing thorough quality checks at each stage.

Watch this client video showcasing smooth gummy production process with SaintyCo's DM-50X Gummy Depositor and adds-on equipment in action!

Choosing the Right Ingredients

Selecting the ideal gelling agent is fundamental. Gelatin19 offers a chewy texture, suitable for traditional gummies, while pectin20 caters to vegan markets with a firmer bite. Each requires specific temperature and pH conditions for optimal results.

| Gelling Agent | Key Characteristics | Ideal Use Case |

|---|---|---|

| Gelatin | Chewy, elastic | Conventional gummies |

| Pectin | Firm, jelly-like | Vegan/health gummies |

Precision in Gummy Machinery

Advanced machinery ensures consistent quality. Equipment like the G-40AW excels in gelatin processing due to its precise temperature control. In contrast, pectin-based21 products benefit from the G-800X, designed to handle their specific cooling needs.

Controlling Temperature and Humidity

Maintaining optimal temperature and humidity is vital. High-precision machines like the G150 provide accurate controls to prevent crystallization, crucial in sugar-free22 formulations. Implementing a robust system for monitoring these parameters can significantly enhance product consistency.

Quality Assurance Practices

Implementing comprehensive quality assurance practices is essential. This includes regular testing of ingredient batches, continuous monitoring during production, and post-production checks to ensure each batch meets set standards. Employing methods such as sample testing23 and feedback loops can identify issues early, ensuring consistent quality across all products.

Continuous Innovation and Adaptation

Staying ahead involves embracing new technologies and formulations. For instance, integrating advanced dosing systems can enhance precision in low-sugar gummies24, balancing health trends with flavor and texture.

These strategies collectively support maintaining high standards in gummy production, ensuring every batch meets consumer expectations for quality and consistency.

Gelatin is suitable for vegan gummy production.False

Gelatin is derived from animals, unsuitable for vegan products.

Precision machinery aids in consistent gummy quality.True

Advanced machines ensure precise temperature control, vital for consistency.

Conclusion

Explore the healthiest gummy options, comparing gelatin and pectin as gelling agents, along with sugar-free alternatives. Discover their textures, health benefits, and market trends for informed choices.

At GummyGenix by SaintyCo, we're here to support your journey with cutting-edge, GMP-compliant gummy manufacturing equipment designed for efficiency, precision, and adaptability. Our machines are fully compatible with regulatory standards, and we offer reliable after-sales support to keep your operations running smoothly.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality gummy products to life—together.

Gummy Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Explore why some prefer the chewy texture of gelatin over the firmer texture of pectin. ↩

-

Learn how gelatin can support joint health and improve skin elasticity. ↩

-

Explore why pectin is a superior choice for vegan gummy production over gelatin. ↩

-

Discover machines designed to maintain the consistency and quality of pectin-based gummies. ↩

-

Find recipes that highlight the health benefits of using pectin in gummies. ↩

-

Understand how consumer preferences are shifting towards more ethical and sustainable choices. ↩

-

Explore why sugar is a common ingredient in traditional gummies and its role in flavor and texture. ↩

-

Understand the benefits of choosing sugar-free gummies when aiming to reduce sugar consumption. ↩

-

Learn about what drives consumers towards choosing sugar-free gummies over traditional ones. ↩

-

Discover how health trends influence the production and marketing of gummy candies. ↩

-

Learn about the benefits of using stevia as a natural sweetener in candies, including its health benefits. ↩

-

Discover how erythritol impacts gummy texture and taste, balancing sweetness with a lower calorie count. ↩

-

Find techniques to balance flavors in candies when using alternative sweeteners. ↩

-

Explore how gelatin contributes to gummy texture and its role in candy production. ↩

-

Understand why pectin is preferred for vegan gummies due to its plant-based origin. ↩

-

See how these machines optimize low-sugar gummy production with precise temperature control. ↩

-

Stay updated on confectionery market trends that influence product development. ↩

-

Explore how oil coating can enhance your gummy's texture and appearance. ↩

-

Understand why gelatin is preferred for its unique texture properties in conventional gummy production. ↩

-

Learn about the advantages of pectin for creating vegan-friendly gummies with a distinct texture. ↩

-

Explore why specialized machines are crucial for handling pectin's unique processing requirements. ↩

-

Discover methods to maintain texture in sugar-free gummies by preventing crystallization. ↩

-

Identify sample testing techniques that ensure consistent quality in candy production. ↩

-

Explore new low-sugar gummy recipes that align with health trends without compromising taste. ↩