The gummy market is thriving, and it’s an exciting time to consider jumping in!

Investing in gummy manufacturing equipment can be a strategic move due to increasing market demand, technological advancements, and the need for efficiency. The right equipment enhances production capacity, reduces costs, and ensures quality compliance.

As we explore this topic further, you’ll see that the potential benefits are not just numbers—they're real opportunities for your business. Let's dive in!

Gummy market growth is driven by health-conscious consumers.True

Health-conscious consumers prefer gummies for vitamins and supplements.

What Are the Current Trends in the Gummy Market?

The gummy market is experiencing unprecedented growth, driven by health-conscious consumers seeking alternative supplement formats.

Current trends in the gummy market include a shift towards health-oriented products, increased demand for CBD-infused options, and innovations in vegan and sugar-free gummies.

Health-Conscious Consumer Trends

As more individuals focus on health and wellness, the demand for functional gummies like vitamins and supplements is soaring. Consumers prefer gummy vitamins1 for their convenience and palatability over traditional pills.

CBD-Infused Gummies

The popularity of CBD products has skyrocketed, with gummies becoming a favored method of consumption due to their ease of use and perceived benefits. This trend is particularly strong in markets where CBD regulations are more relaxed.

Innovations in Vegan and Sugar-Free Options

With the rise in veganism and concerns about sugar intake, manufacturers are innovating to create products that cater to these needs. Vegan and sugar-free gummies are gaining traction, appealing to a wider audience looking for guilt-free indulgence.

Private Label and White-Label Expansion

Businesses are increasingly exploring private-label opportunities as a way to enter or expand in the gummy market. This approach allows companies to leverage existing manufacturing capabilities without significant investment.

E-Commerce Growth

The shift towards online shopping has been accelerated by recent global events, leading to a boom in e-commerce sales for gummies. Companies are optimizing their digital presence to capture this growing market share effectively.

These trends highlight the dynamic nature of the gummy market, offering multiple opportunities for businesses willing to adapt and innovate.

Gummy vitamins are preferred over pills for convenience.True

Consumers find gummies more convenient and palatable than pills.

Sugar-free gummies have decreased in popularity recently.False

Sugar-free gummies are gaining traction due to health trends.

How Can Automation Boost Your Gummy Production Efficiency?

Unlocking the full potential of your production line starts with automation, enhancing both speed and efficiency.

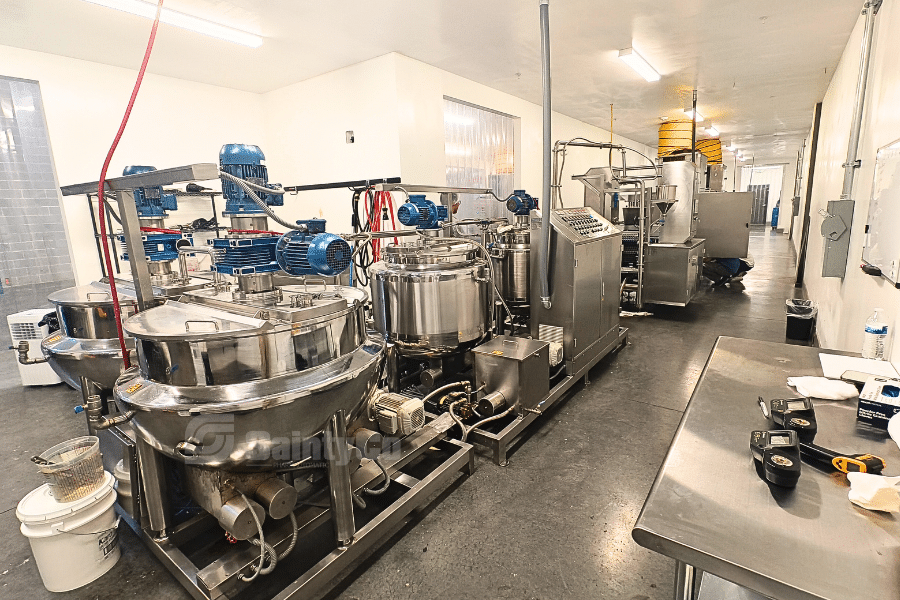

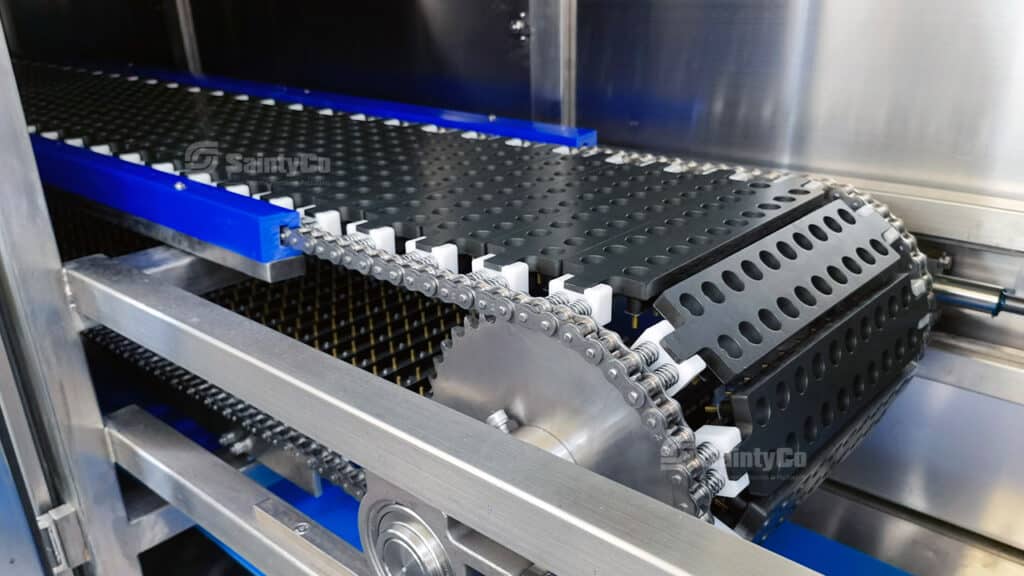

Automation significantly boosts production efficiency by increasing output, lowering labor costs, and reducing waste. Automated systems streamline processes, ensuring consistent quality and compliance, ultimately leading to higher productivity and profitability.

Enhancing Production Capacity and Speed

Automation transforms production capabilities by significantly increasing output and speed. With automated systems, you can produce large volumes2 of gummies quickly without compromising quality. This is particularly beneficial in meeting rising market demands, especially in sectors like health and wellness where consumer interest is rapidly growing.

Reducing Labor Costs and Human Error

One of the most immediate benefits of automation is the reduction in labor costs. By relying less on manual labor, companies can save on wages and training while minimizing human errors that can lead to costly rework. Automated systems3 perform repetitive tasks with precision, ensuring consistency in product quality.

Ensuring Quality and Compliance

Automation aids in maintaining high-quality standards and compliance with industry regulations. For instance, automated machines ensure precise dosing and consistent production processes. This not only enhances product quality but also ensures that production meets FDA and GMP requirements, which is crucial for nutraceutical-grade gummies.

Streamlining Processes with Real-Time Monitoring

Modern automated equipment often comes with real-time monitoring features. These systems can adjust parameters such as temperature and viscosity during production to maintain optimal conditions. This capability reduces downtime and minimizes errors, leading to a more efficient production process4.

Reducing Waste and Improving Consistency

Automation minimizes production waste by ensuring accurate ingredient measurement and precise cooking processes. By reducing variability in the production process, automation improves product consistency, leading to less waste and higher efficiency.

By implementing automation in your gummy production line, you not only enhance efficiency but also position your business for long-term growth. As demand continues to rise, having a streamlined, automated process will be essential for maintaining competitive advantage.

Automation reduces labor costs by 50%.False

The context mentions reduced labor costs but not a specific percentage.

Automated systems ensure consistent product quality.True

Automation maintains quality by minimizing human error and ensuring precision.

What Are the Compliance Considerations for Gummy Production?

Ensuring compliance in gummy production is vital for meeting regulatory standards and maintaining product quality.

Compliance in gummy production involves adhering to FDA and GMP standards, ensuring hygienic processes, and implementing quality control measures. This ensures the safety and efficacy of the products while avoiding regulatory pitfalls.

Understanding Regulatory Standards

For gummy manufacturers, compliance is non-negotiable. Adhering to FDA guidelines5 is crucial, especially if you're producing nutraceutical or pharmaceutical-grade gummies. These guidelines help ensure that your products are safe for consumption and meet quality standards.

GMP (Good Manufacturing Practice) compliance is another cornerstone. It involves systematic control of manufacturing processes and facilities to ensure consistent product quality. Adopting GMP means your production facility must maintain rigorous standards, from equipment calibration to employee hygiene practices.

Importance of Hygienic Manufacturing

Contamination is a significant concern in gummy production, making hygienic manufacturing processes essential. This involves using advanced machinery designed to minimize contamination risks by maintaining cleanliness throughout the production line. Ensuring all equipment is sanitized and employees follow strict hygiene protocols can significantly reduce contamination risks.

Implementing Quality Control Measures

Quality control is not just about meeting regulatory standards; it’s about ensuring customer satisfaction. Implementing a robust quality control system involves:

- Regular Testing: Frequent testing of raw materials and finished products to verify purity and potency.

- Batch Consistency: Ensuring each batch of gummies meets specified criteria for taste, texture, and active ingredient content.

- Documented Procedures: Keeping detailed records of manufacturing processes to trace any issues back to their source.

A comprehensive quality control plan enhances product reliability and reinforces consumer trust.

Navigating Labeling Requirements

Proper labeling is integral to compliance. Labels must accurately reflect the contents of the gummies, including active ingredients, dosage, and potential allergens. Mislabeling can lead to severe consequences, including product recalls and legal actions.

Consulting with regulatory experts or using specialized software can help ensure your labeling meets all legal requirements, protecting your business from compliance breaches.

GMP compliance is optional for gummy production.False

GMP compliance is mandatory to ensure consistent product quality.

Proper labeling prevents legal actions in gummy production.True

Accurate labeling avoids recalls and protects against legal issues.

Is Your Gummy Business Ready for Technological Advancements?

As technology evolves, businesses must adapt to remain competitive. Is your business prepared for the latest technological shifts?

Assessing your business's readiness for technological advancements involves evaluating current infrastructure, staff skills, and market positioning. Embracing new technology can enhance productivity, drive innovation, and maintain competitive advantage.

Watch this video showcasing the SaintyCo's G150 Gummy Line in action!

Evaluating Current Infrastructure

The first step in determining your readiness for technological advancements is evaluating your existing infrastructure. Ask yourself: Are your systems up-to-date? Can they support new technologies efficiently? If your current infrastructure is outdated, it may hinder the integration of new solutions.

Assess whether your hardware and software can accommodate advanced tools without significant downtime or costly upgrades. Investing in scalable and flexible systems now can save time and money in the long run.

Analyzing Staff Skills

The next critical area is the skillset of your workforce. Technology is only as effective as the people who use it. Do your employees have the necessary skills to operate and benefit from new technologies? Consider providing training programs to bridge any gaps.

Encouraging continuous learning can help your team stay ahead of technological trends and ensure smooth transitions when implementing new systems.

Examining Market Positioning

Your business's position in the market is another crucial factor. Are you in an industry where technological advancements are driving change? If so, delaying adoption could put you at a competitive disadvantage.

Perform a competitive analysis6 to understand how technology is impacting your sector. Knowing where you stand compared to your competitors can guide strategic decisions.

Financial Considerations

Finally, evaluate the financial implications of adopting new technology. While initial costs can be high, the return on investment (ROI) often justifies the expense. Consider creating a detailed cost-benefit analysis to forecast potential financial outcomes.

Explore financing options7 if budget constraints are a concern. Leasing or installment plans can make these advancements more accessible and manageable for your business.

Outdated infrastructure hinders new tech integration.True

Old systems may not support new technologies efficiently, causing delays.

High initial costs of tech upgrades never justify ROI.False

Initial costs can be high, but ROI often makes the expense worthwhile.

Conclusion

Investing in gummy manufacturing equipment now can strategically position your business for growth and adaptability.

At GummyGenix by SaintyCo, we don’t just provide equipment—we empower your gummy business with solutions tailored to your success. Here’s what makes us the ideal partner for your venture:

- Competitive Pricing: Top-tier machinery at affordable rates, ensuring a strong return on investment.

- High-Quality Machinery: GMP-compliant, precision-engineered equipment designed to meet evolving industry standards.

- Equipment Financing & Referral Support: Access flexible payment options and financing resources through our trusted partners, helping you secure affordable payments and potential tax advantages.

- Quick Startup SOPs: Basic recipes and production workflows for a fast, hassle-free start. Additionally, we can connect you with leading formulation consultants and global ingredient suppliers for more advanced product development.

- Custom Molds & Recipes: Stand out in the market with bespoke gummy shapes and innovative recipes tailored to your brand.

- Comprehensive After-Sales Support: From setup and training to troubleshooting, we provide the guidance needed to ensure smooth operations and sustained success.

Contact GummyGenix by SaintyCo, you’ll gain the expertise, resources, and support to build a thriving gummy production business. Let’s succeed together.

Gummy Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Discover the latest innovations and consumer preferences in gummy vitamins.: Vitamin gummies dominated the market with a share of 23.9% in 2023, owing to the increasing prevalence of vitamin deficiencies. Many people are deficient in ... ↩

-

Learn how automation scales your production efficiently.: Automation in manufacturing offers many advantages – increased worker safety, better production capacity, reduced employee cost, ... ↩

-

Discover cost savings from reduced labor dependency.: Automation reduces labor costs and gives manufacturers the ability to lower raw material costs by reducing waste. It's clear that automation has come a long ... ↩

-

Explore how real-time monitoring enhances production efficiency.: Essentially, by tracking real-time production performance, a company can improve efficiency, productivity, and quality related to both machine and process ... ↩

-

Learn FDA compliance essentials to ensure safe gummy production.: CGMP regulations generally address matters including appropriate personal hygienic practices, design and construction of a food plant and maintenance of plant ... ↩

-

Competitive analysis reveals how technology impacts your industry, guiding strategic decisions.: Begin by examining your business's core values, objectives, and offerings. This will help you identify other brands that potential customers ... ↩

-

Understanding financing options makes technology upgrades more accessible and manageable.: Alternative financing solutions offer tech-driven companies flexible options beyond a traditional business loan and equity investments. ↩