Starting a gummy production line? I’ve been there—it’s not just about having a tasty recipe.

To ensure regulatory compliance in gummy production, manufacturers must adhere to FDA guidelines, including Good Manufacturing Practices (GMP) and accurate labeling. Choosing the right machinery involves selecting equipment that meets hygienic design standards and offers scalability, precision, and energy efficiency.

While the basics cover compliance and machinery, diving deeper reveals critical nuances. From labeling intricacies to advanced machine features, this guide offers insights to ensure your gummy production thrives amidst regulatory landscapes.

Gummy production in the USA must comply with FDA regulations.True

FDA mandates compliance with DSHEA, GMP, and labeling laws for gummies.

What Are the Key FDA Regulations for Gummy Production?

Understanding FDA regulations is crucial for successful gummy production in the US.

Key FDA regulations for gummy production include adherence to the Dietary Supplement Health and Education Act (DSHEA), Good Manufacturing Practices (GMP), proper labeling, New Dietary Ingredient (NDI) notifications, and comprehensive record-keeping and reporting.

FDA Oversight and DSHEA Compliance

The U.S. Food and Drug Administration (FDA) regulates gummy vitamins as dietary supplements under the Dietary Supplement Health and Education Act (DSHEA) of 1994. This legislation mandates that manufacturers ensure their products are safe and properly labeled. Compliance with DSHEA involves not only adhering to safety standards but also ensuring that any health claims made on labels are truthful and not misleading. For instance, if a gummy vitamin claims to improve immune health, the manufacturer must have evidence to support this statement.

Good Manufacturing Practices (GMP)

Good Manufacturing Practices (GMP), outlined in 21 CFR Part 111, are crucial for keeping products safe and of high quality. GMP covers every step of production, from selecting raw materials to packaging the final product. Manufacturers must follow strict quality controls to avoid contamination and ensure product consistency. Regular audits and inspections are also required to make sure facilities stay clean and equipment is well-maintained and sanitized.

Labeling Requirements

The FDA enforces strict labeling requirements to prevent misbranding. Gummy product labels must provide a full list of ingredients, serving sizes, and nutritional information. Additionally, any claims regarding health benefits must be substantiated by scientific evidence. Manufacturers must also comply with the Food Allergen Labeling and Consumer Protection Act (FALCPA), which requires clear identification of potential allergens in the product.

New Dietary Ingredients (NDI) Notification

If a gummy supplement includes a "new dietary ingredient" that was not sold in the U.S. before October 15, 1994, manufacturers must submit an NDI notification to the FDA at least 75 days before marketing the product. This notification must include comprehensive safety data and evidence demonstrating that the new ingredient is safe for consumption.

Record-Keeping and Reporting

Maintaining detailed records of all production batches and their distribution is another critical regulatory requirement. These records help trace any issues that may arise post-distribution, facilitating prompt corrective actions. In addition, manufacturers are required to report adverse events through the FDA's Safety Reporting Portal to ensure any potential health risks are communicated promptly.

Compliance Challenges and Best Practices

Navigating these regulations can be challenging for manufacturers, especially those new to the market. Partnering with compliance experts or consulting firms can provide valuable guidance on US gummy production compliance1. Implementing robust internal compliance programs and training staff on regulatory requirements are also effective strategies for maintaining adherence to FDA standards.

Gummies must comply with DSHEA for safe production.True

DSHEA mandates safety and proper labeling for dietary supplements.

NDI notifications are optional for new gummy ingredients.False

NDI notifications are required for new dietary ingredients.

How Do Good Manufacturing Practices Impact Gummy Manufacturing?

Good Manufacturing Practices (GMP) are the backbone of quality and safety in gummy production.

GMP impacts gummy manufacturing by ensuring products are consistently produced and controlled according to quality standards. This includes stringent guidelines on hygiene, ingredient sourcing, and production processes to prevent contamination and ensure safety.

Ensuring Product Consistency and Quality

GMP guidelines ensure that every batch of gummies is produced with the same high level of quality. This involves standardizing processes and implementing control measures across all stages of production. The goal is to minimize variations and defects, which can affect both the efficacy and safety of the product.

Hygiene and Facility Standards

Maintaining a clean and sanitized production environment is critical in gummy manufacturing. GMP mandates strict hygiene practices, including regular cleaning schedules and sanitary facility designs. These practices help reduce the risk of contamination, protecting both the product and consumer health.

Ingredient Sourcing and Handling

Under GMP, manufacturers must carefully select and monitor their ingredient suppliers. Raw materials should meet predefined quality criteria and be free from harmful contaminants. Moreover, proper storage conditions must be maintained to preserve ingredient integrity.

Employee Training and Responsibilities

Training personnel in GMP is essential to maintain quality standards. Employees should understand their role in the manufacturing process, from handling ingredients to operating machinery. Regular training updates ensure staff remain compliant with current regulations and best practices.

Documentation and Record-Keeping

GMP requires detailed documentation of every production stage. This includes recording ingredient sources, production parameters, and any deviations from standard procedures. Such records facilitate traceability, allowing manufacturers to identify the cause of potential issues quickly.

Compliance with Regulatory Bodies2

Adhering to GMP not only ensures product quality but also compliance with regulatory bodies such as the FDA. Regular audits and inspections verify that manufacturers uphold these standards consistently.

Technological Integration

Incorporating advanced technology in production lines can enhance GMP compliance. Automated systems, for instance, provide precision in dosing and control, reducing human error. This technological integration supports consistency and efficiency in gummy manufacturing.

GMP ensures all gummy batches have consistent quality.True

GMP standardizes processes to minimize variations and defects.

GMP compliance is optional for gummy manufacturers.False

GMP compliance is mandatory for safety and regulatory adherence.

What Features Should You Look For in Gummy Production Machinery?

Selecting the right gummy production machinery is crucial for efficiency and quality.

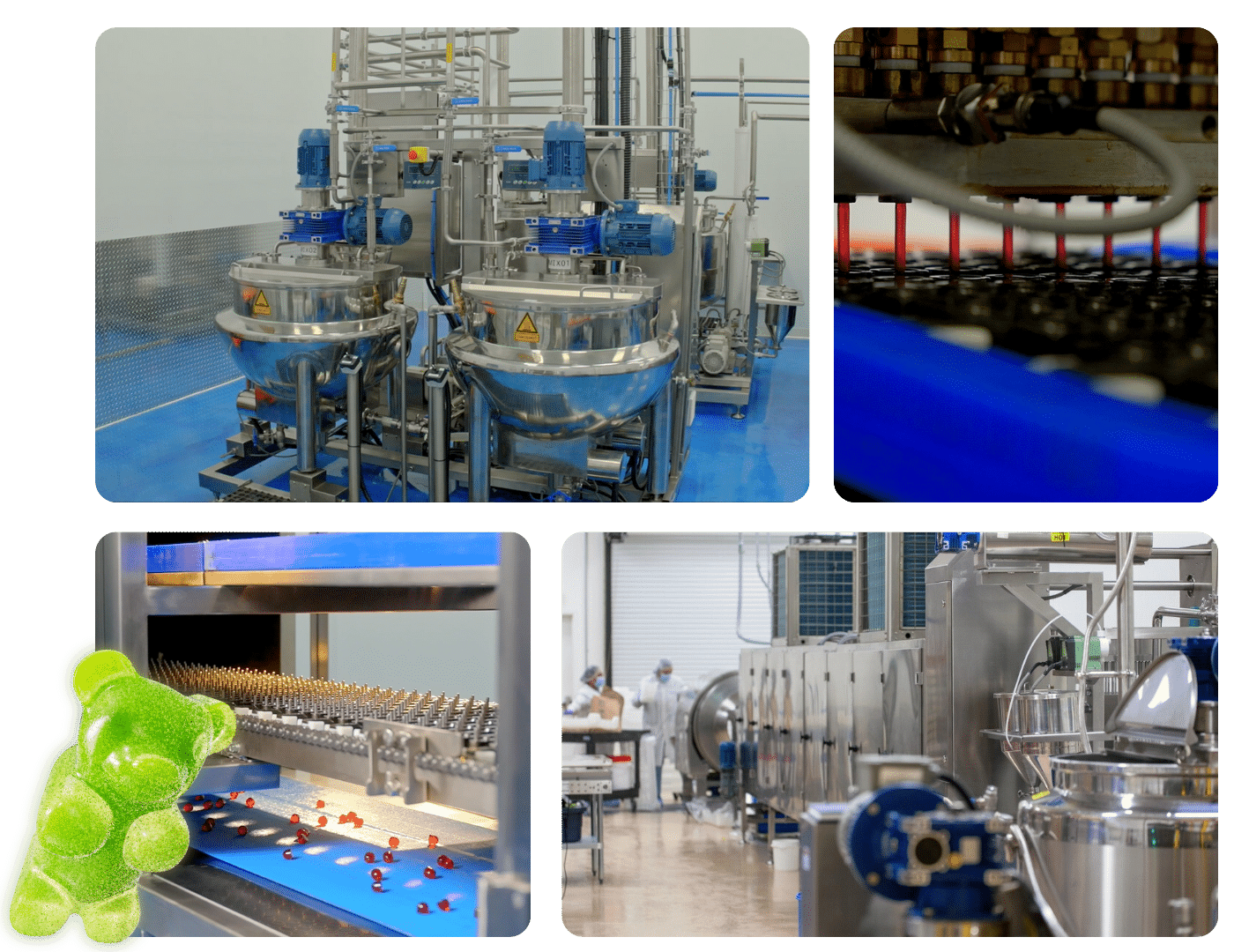

Key features in gummy production machinery include hygienic design, scalability, precision control, automation, energy efficiency, and robust after-sales support. These elements ensure compliance with FDA regulations and enhance production efficiency.

Hygienic Design and Compliance

When choosing gummy production machinery, the first consideration should be hygienic design. Equipment must adhere to sanitary design principles to facilitate easy cleaning and maintenance. This reduces contamination risks and aligns with FDA Good Manufacturing Practices3 (GMP) requirements. Look for machines with stainless steel components, smooth surfaces, and minimal contact parts to ensure thorough cleaning and minimize microbial hazards.

Versatility and Scalability

A versatile machine can handle various formulations, whether your gummies are gelatin or pectin-based, or if they involve multiple layers or colors. This adaptability allows manufacturers to innovate without investing in completely new lines. Scalability is equally important, as it supports increased production volumes to meet market demand without requiring significant overhauls.

| Feature | Description |

|---|---|

| Versatility | Ability to process different gummy formulations |

| Scalability | Capacity to expand production without major changes |

Precision Control Systems

Advanced control systems are essential for maintaining consistent product quality in terms of size, shape, and nutritional content. Precision dosing ensures that each gummy meets specified standards, which is critical for compliance with FDA labeling requirements4. Machines equipped with sophisticated control systems can adjust parameters in real-time, reducing waste and improving efficiency.

Automation and Efficiency

Fully automated production lines enhance efficiency by reducing human error and increasing throughput. Machines with self-diagnostic capabilities and real-time production adjustments not only boost productivity but also help maintain quality. Automation can significantly lower operational costs and improve product consistency.

Energy Efficiency

In the era of stringent environmental regulations, energy-efficient machines are a necessity. They not only help reduce operational costs but also support sustainability goals. Selecting equipment designed to consume less energy and minimize waste will benefit both your bottom line and your environmental footprint.

After-Sales Support and Compliance Assistance

Finally, robust after-sales support is crucial. Opt for suppliers who provide comprehensive support, including guidance on FDA compliance, operator training, and regular maintenance services. This ensures that your machinery remains in top condition and continues to meet regulatory standards.

Choosing the right machinery is a pivotal step in gummy production. By focusing on these features, manufacturers can ensure their operations are efficient, compliant, and ready to meet market demands.

Hygienic design is crucial for gummy machinery.True

Ensures compliance with FDA GMP, reducing contamination risks.

Automation increases operational costs in gummy production.False

Automation reduces human error and operational costs, boosting efficiency.

Why Is Energy Efficiency Important in Gummy Manufacturing?

Energy efficiency is more than a cost-saving measure; it’s crucial for sustainable gummy manufacturing.

Energy efficiency in gummy manufacturing reduces operational costs, minimizes environmental impact, and ensures compliance with stringent regulations. By optimizing energy use in machinery, manufacturers can enhance production efficiency and sustainability.

Understanding the Role of Energy Efficiency

In the context of gummy manufacturing equipment5, energy efficiency plays a pivotal role not only in minimizing operational costs but also in ensuring the sustainability of production processes. As the world pivots towards greener practices, the pressure on industries to adopt energy-efficient technologies has increased. This shift is particularly significant in gummy manufacturing, where machinery and production lines are often extensive and energy-intensive.

Cost-Effectiveness and Operational Efficiency

Energy-efficient machines are designed to consume less power while maintaining or even enhancing production output. This efficiency translates into significant cost savings over time. For instance, by selecting machinery with advanced automation capabilities, manufacturers can reduce waste and optimize resource use, leading to lower utility bills and reduced material costs.

Consider a gummy production line6 that incorporates energy-efficient heating elements. Such systems often use less power to maintain optimal temperatures required for the melting and molding processes. Moreover, these systems frequently include features that allow for rapid heating and cooling, further enhancing operational efficiency and reducing energy consumption.

| Aspect | Energy-Efficient Feature | Benefit |

|---|---|---|

| Heating | Advanced thermal management | Reduced energy use |

| Automation | Smart sensors and controls | Minimized waste and errors |

| Cooling Systems | Efficient heat exchangers | Lower energy costs |

| Machine Design | Lightweight, sustainable materials | Enhanced production speed |

Compliance with Environmental Regulations

Manufacturers are increasingly required to adhere to environmental standards that dictate reduced energy consumption and lower emissions. In regions where regulatory frameworks are stringent, such as the European Union or certain states in the USA, compliance can be a deciding factor in market access. By investing in energy-efficient gummy production equipment7, companies can meet these standards more easily.

Moreover, implementing energy-efficient technologies can improve a company’s environmental footprint, which is becoming an important metric for consumers and investors alike. As customers grow more environmentally conscious, aligning production practices with eco-friendly principles can enhance brand reputation and customer loyalty.

Enhancing Production Scalability

Energy-efficient machinery often comes with scalable features that allow production lines to expand without a proportional increase in energy consumption. For example, machinery equipped with modular components can be upgraded or expanded as demand grows, without necessitating complete overhauls or excessive energy use.

By focusing on energy efficiency, gummy manufacturers can position themselves as leaders in sustainable practices while also securing economic benefits. This approach not only meets current regulatory demands but also prepares businesses for future sustainability challenges.

Energy-efficient machines reduce gummy production costs.True

Energy-efficient machines consume less power, lowering utility bills.

Energy efficiency in gummy manufacturing is optional.False

Energy efficiency is crucial for cost savings and regulatory compliance.

Conclusion

Building a successful gummy production line requires attention to essential regulatory requirements, from FDA compliance and Good Manufacturing Practices (GMP) to accurate labeling and careful ingredient handling. Selecting machinery that supports hygiene, scalability, and precision is also critical for consistent, quality production.

While regulatory compliance and machinery are foundational, they’re just the beginning. As demand grows, having the right equipment and support can streamline operations, ensure regulatory adherence, and set you up for long-term success.

GummyGenix by SaintyCo is here to support your journey. With over 23 years of experience, we specialize in end-to-end gummy production solutions—from innovative, industry-compliant machinery to expert guidance at every step. Whether you're a new business or expanding production, our customized solutions, efficient equipment, and dedicated after-sales support can help you meet your goals.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality gummy products to life—together.

-

Learn from experts about maintaining regulatory adherence in gummy production.: Gummies should also undergo rigorous testing throughout the production process to ensure microbiological safety, absence of heavy metals, and ... ↩

-

Learn about regulatory compliance benefits in gummy manufacturing.: cGMP certification ensures that a manufacturer adheres to strict quality control and safety standards set forth by regulatory bodies. By ... ↩

-

Learn detailed GMP regulations that ensure your gummy production is compliant.: CGMP regulations generally address matters including appropriate personal hygienic practices, design and construction of a food plant and maintenance of plant ... ↩

-

Understand the FDA's strict labeling rules for accurate compliance.: Notably, by requiring that most foods, including dietary supplements, bear nutrition labeling. The Dietary Supplement Health and Education Act ... ↩

-

Explore how energy-efficient equipment can boost production sustainability.: To create quality gummy bears, you need quality equipment. Here we will showcase a complete guide on gummy manufacturing equipment. ↩

-

Discover cutting-edge technologies in gummy production lines.: SaintyCo is a leading provider of high-quality gummy production machines for the pharmaceutical industry. ↩

-

Learn about the advantages of adopting energy-efficient machinery.: These advancements minimize energy consumption without compromising the quality or productivity of the manufacturing process. Additionally, some ... ↩