Are you ready to dive into the vibrant world of dietary supplements in Colombia? Launching your own gummies factory could be your ticket to success!

To set up a supplements and OTC gummies factory in Colombia, start by complying with INVIMA regulations and obtaining necessary licenses. Invest in versatile and hygienic machinery to ensure quality and precision in production. Develop a detailed production plan and source high-quality ingredients to establish an efficient production process. Consider key cost considerations for setting up the factory. Finally, implement a tailored distribution strategy to effectively penetrate the Colombian market.

While this overview provides a starting point, each step requires careful planning and execution. Let’s delve deeper into a comprehensive guide filled with valuable insights that can propel your business forward.

INVIMA oversees dietary supplements in Colombia.True

INVIMA regulates supplements, ensuring safety and quality compliance.

What Regulatory Approvals Are Needed for Supplements Manufacturing in Colombia?

Navigating the regulatory landscape is crucial for a successful supplements manufacturing venture in Colombia. Are you prepared?

In Colombia, manufacturing dietary supplements requires compliance with INVIMA regulations, obtaining health registration, and adhering to labeling standards. This ensures products meet safety and quality benchmarks.

Understanding INVIMA's Role

The National Institute for Food and Drug Surveillance1 (INVIMA) is the regulatory body overseeing dietary supplements in Colombia. It enforces safety, quality, and efficacy standards. To operate legally, your factory must comply with INVIMA's guidelines.

Health Registration Process

Before production begins, secure a health registration from INVIMA. This involves submitting a detailed dossier of your product's composition, intended use, and manufacturing process. The review ensures your product is safe for consumer use and meets Colombian health standards.

Labeling Standards

Compliance with labeling regulations is essential. Labels must include ingredients, nutritional information, manufacturer details, and expiration dates. Ensuring accuracy and transparency helps build consumer trust and avoids legal issues.

Good Manufacturing Practices (GMP)

Adhering to GMP ensures your manufacturing process meets quality standards. These practices cover everything from hygiene to documentation and are crucial for maintaining consistent product quality.

Environmental Considerations

Colombia emphasizes environmental responsibility. Environmental licenses2 might be necessary depending on your factory's location and size. Consult local authorities to understand specific requirements.

Importing Raw Materials

If sourcing ingredients internationally, ensure compliance with Colombian import regulations. This may involve securing permits and ensuring raw materials meet national safety standards.

Navigating these regulatory approvals is integral to establishing a successful supplements manufacturing operation in Colombia. Each step not only ensures legal compliance but also supports product quality and consumer trust.

INVIMA regulates dietary supplements in Colombia.True

INVIMA oversees safety and quality standards for supplements.

Labels must include only ingredients and expiration dates.False

Labels must also have nutritional info and manufacturer details.

How Do You Choose the Right Machinery for Gummy Production?

Choosing the right machinery for gummy production is crucial to ensure quality and efficiency.

Selecting machinery for gummy production involves considering compliance with hygienic standards, versatility, precision, automation levels, energy efficiency, and robust after-sales support.

Understanding Compliance with Hygienic Standards

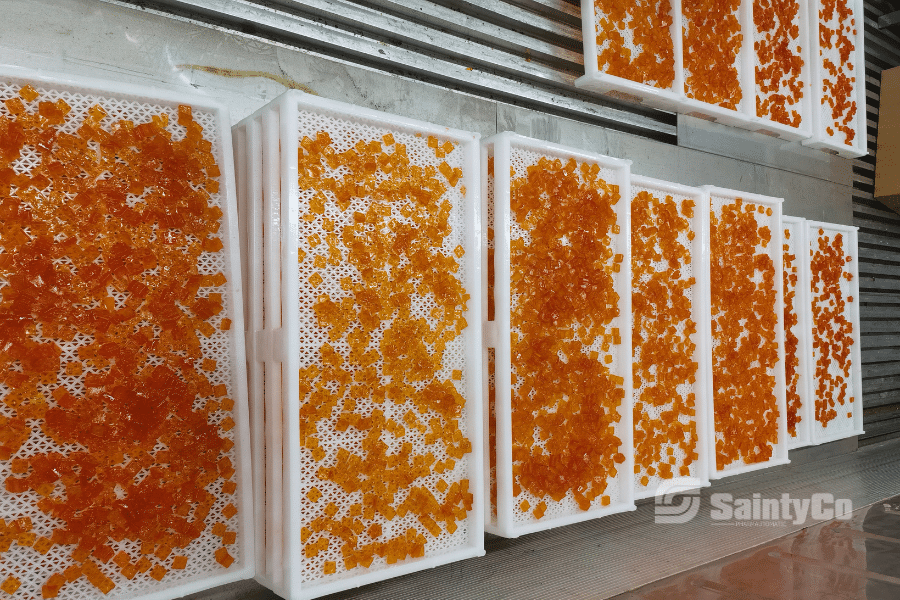

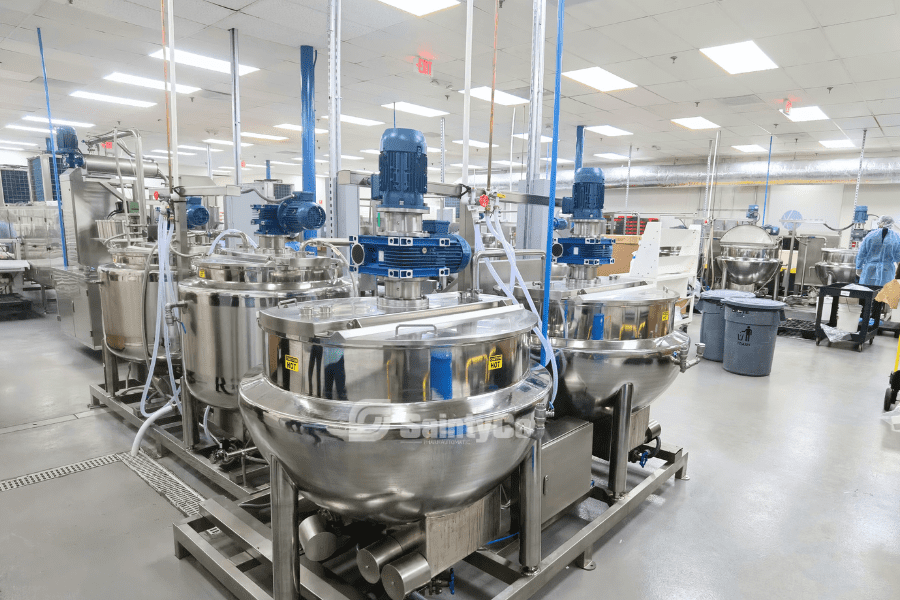

In the world of gummy production, hygiene isn’t just a nicety; it’s a necessity. Machines should adhere to stringent sanitary design principles. Think stainless steel components and smooth surfaces that make cleaning a breeze. Look for machinery with minimal contact parts to reduce contamination risks. This keeps your gummy bears safe and sound!

The Importance of Versatility and Scalability

Imagine your gummy line as a chameleon. It needs to adapt. Machines that handle different formulations—be it gelatin or pectin bases—are golden. Plus, they should allow for adding layers or colors. Scalability is the cherry on top, letting you ramp up production without replacing everything. It’s like upgrading your phone, not your whole life!

Precision and Control Matter

Precision isn’t just for surgeons; it’s for gummy makers too. Advanced control systems in machines ensure each gummy is the right size and shape. Consistency is king when meeting nutritional labeling requirements. A well-measured gummy is a happy gummy.

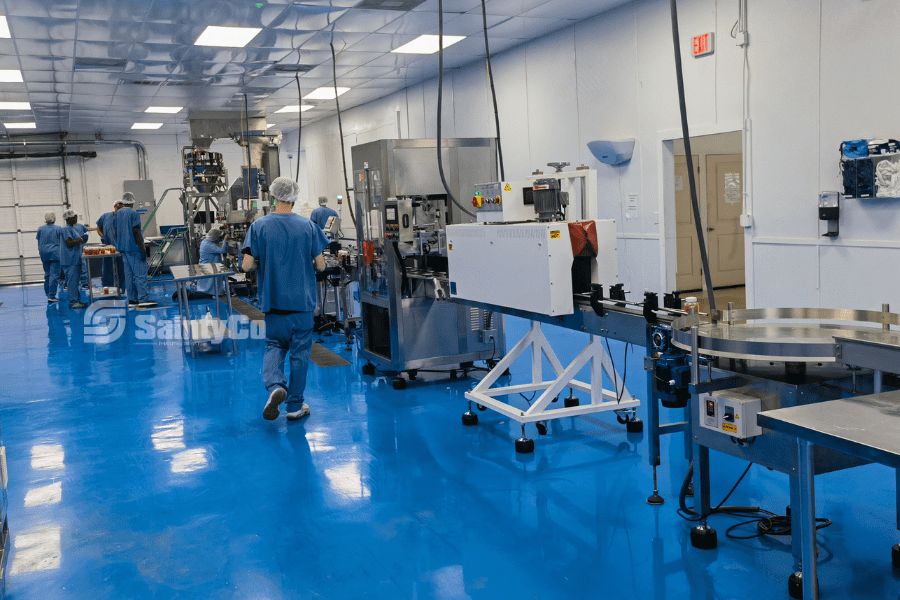

Embracing Automation

Automated production lines aren’t just a tech geek’s dream. They reduce human error and boost efficiency. Machines with self-diagnosis capabilities are like having a personal assistant who never sleeps. Real-time adjustments? Yes, please!

Energy Efficiency: Saving Green While Being Green

Energy-efficient machines don’t just save on bills—they save the planet. Opt for machinery that minimizes waste and complies with environmental regulations. You’ll be a hero for your wallet and Mother Earth.

After-sales Support: The Unsung Hero

After-sales support shouldn’t be an afterthought. Equipment suppliers should offer compliance guidance, especially with U.S. regulations, training, and regular maintenance services. It’s like having a tech support friend who doesn’t mind late-night calls.

Consider these factors wisely, and your gummy production line will be as sweet as the gummies themselves! For more insights on choosing machinery, check out this detailed guide3.

Gummy production machines must be made of stainless steel.True

Stainless steel is crucial for hygiene and easy cleaning in food production.

Automation decreases efficiency in gummy production lines.False

Automation increases efficiency by reducing human error and enabling real-time adjustments.

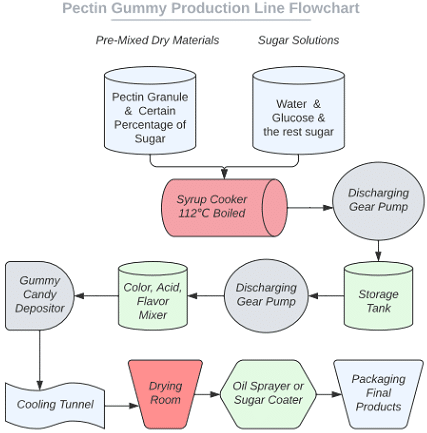

How to Design an Efficient Production Process for Gummies?

Creating a streamlined production process for gummies is key to maximizing output and ensuring consistent quality.

To design an efficient gummy production process, focus on precise ingredient measurement, optimal mixing techniques, and maintaining consistent temperatures throughout production. Implement quality control checks at every stage to ensure product standards are met.

Understanding the Ingredients

The foundation of any efficient gummy production4 begins with understanding your ingredients. Each ingredient should be carefully selected for quality and compatibility. Consider using natural sweeteners and flavorings, which not only appeal to health-conscious consumers but also help in distinguishing your product in a competitive market.

Precise Measurement and Mixing Techniques

Precise measurement is crucial in maintaining consistency across batches. Utilize automated systems to ensure accuracy and reduce human error. When it comes to mixing, invest in high-quality mixers that can uniformly combine ingredients without compromising texture or flavor.

| Equipment | Description |

|---|---|

| Mixer | Ensures even distribution of ingredients |

| Scale | Provides precise measurements for ingredients |

| Thermometer | Monitors temperature during cooking process |

Temperature Control

Temperature plays a vital role in the gummy production process, affecting both the texture and the setting time. Consistent temperatures should be maintained during cooking and cooling phases to avoid issues like crystallization or stickiness.

Implementing Quality Control

Quality control is an ongoing process that should occur at multiple stages: from ingredient inspection to final packaging. Develop protocols for testing gummies for texture, flavor, and appearance. By implementing rigorous quality checks, you ensure that each batch meets your set standards.

Streamlining Production Workflow

Evaluate each step of the production process to identify potential bottlenecks. Implementing lean manufacturing techniques can help minimize waste and optimize workflow. For instance, adopt a just-in-time inventory system to reduce storage costs and improve efficiency.

Continuous Improvement

Encourage feedback from your production team and continuously seek ways to improve your process. Incorporating technology, such as AI-driven analytics, can provide valuable insights into process optimization.

For additional insights on enhancing production efficiency, consider researching current gummy production technologies5.

Precise ingredient measurement ensures gummy consistency.True

Accurate measurements prevent batch variations, ensuring uniform quality.

Quality control checks are unnecessary in gummy production.False

Quality checks ensure product standards are met, maintaining consistency.

Why Is Hygiene Crucial in Gummy Manufacturing?

In gummy manufacturing, hygiene isn't just a nice-to-have—it's a must-have. It safeguards consumers and ensures product quality.

Hygiene in gummy manufacturing prevents contamination, preserves product integrity, and complies with health regulations, ensuring safe consumption.

Preventing Contamination in Gummy Production

In gummy manufacturing, the risk of contamination is omnipresent. The presence of foreign particles or microbial contamination can lead to product recalls, which are costly and damage brand reputation. Adhering to strict hygiene standards means ensuring all equipment is clean and sanitized, reducing the risk of contamination.

One major aspect involves selecting machines that comply with hygienic design standards. Sanitary design principles6 focus on using materials like stainless steel, which resists corrosion and prevents bacterial growth. These machines should also feature smooth surfaces and minimal contact parts to facilitate easy cleaning.

Enhancing Product Integrity and Safety

Hygiene is not just about avoiding contamination; it’s also about preserving the product's integrity. Gummies are sensitive to environmental conditions such as humidity and temperature. A clean production environment helps maintain the desired texture and flavor profile.

Implementing advanced control systems7 in production lines can significantly enhance dosing precision, ensuring consistent product size and shape. This consistency is critical for meeting nutritional labeling requirements.

Meeting Regulatory Compliance

Hygiene practices play a crucial role in meeting regulatory compliance standards, especially in regions like Colombia. Compliance with local health regulations, such as those set by INVIMA, requires manufacturers to maintain detailed records of cleaning procedures and quality checks.

Choosing equipment suppliers who offer compliance assistance and regular maintenance services can help manufacturers stay aligned with these regulations. After-sales support8 that includes training for machine operation further ensures adherence to hygiene standards.

The Role of Automation in Maintaining Hygiene

Automation can significantly enhance hygiene levels by minimizing human contact with the product. Fully automated lines reduce the potential for human error and increase production efficiency. Machines equipped with self-diagnosis capabilities and real-time adjustments during production maintain cleanliness without halting operations.

Moreover, energy-efficient machines not only cut costs but also align with environmental regulations. They reduce waste and energy consumption, which indirectly supports a cleaner production process.

By focusing on these aspects, gummy manufacturers can ensure they produce safe, high-quality products that consumers can trust.

Hygiene prevents gummy contamination.True

Hygiene practices prevent foreign particles and microbial contamination.

Automation increases human error in gummy production.False

Automation reduces human contact, minimizing the potential for errors.

What Are the Key Cost Considerations for Setting Up a Factory?

Setting up a factory involves complex cost calculations beyond just initial investments.

Key cost considerations for setting up a factory include land acquisition, construction, machinery, labor, regulatory compliance, and operational expenses. Carefully evaluating each factor is crucial to ensure financial sustainability and competitive pricing in your industry.

Initial Investment Costs

The foremost costs when establishing a factory involve acquiring land and building the infrastructure. In Colombia, land prices can vary significantly depending on proximity to urban areas. Evaluating potential locations involves balancing accessibility with cost efficiency.

Construction and Machinery

Construction costs entail building factories to suit your production needs. This includes ensuring facilities comply with local safety standards. Equipping your factory with the necessary machinery is another major investment. Opt for high-quality equipment that balances cost with long-term reliability to minimize maintenance expenses9.

Operational and Labor Costs

Labor costs in Colombia can be attractive, but they also involve training and retaining skilled workers. Offering competitive wages and benefits ensures productivity and reduces turnover rates. Consider all operational expenses such as utilities, raw materials, and supply chain logistics10.

Regulatory Compliance and Licensing

Understanding and adhering to Colombian regulations is vital. Regulatory costs include obtaining permits, adhering to safety standards, and regular inspections. Non-compliance can result in fines and halt operations, making it imperative to incorporate these costs into your budget from the outset.

Financial Planning and Budgeting

A comprehensive financial plan is essential. It should include a detailed budget that accounts for unexpected costs, allowing flexibility in financial management. Consider consulting financial experts or using advanced budgeting tools for precise planning.

Table: Sample Budget Outline

| Cost Category | Estimated Cost (USD) |

|---|---|

| Land Acquisition | $200,000 - $500,000 |

| Construction | $300,000 - $700,000 |

| Machinery | $250,000 - $600,000 |

| Labor | $100,000 annually |

| Regulatory Compliance | $50,000 - $100,000 |

| Operational Expenses | $150,000 annually |

These estimates can vary based on specific industry requirements and scale of production. Use them as a guideline while tailoring your budget to meet your unique needs. Strategic financial management will ensure the longevity and success of your factory in Colombia.

Land acquisition is the largest initial cost for a factory.True

Land acquisition is often the biggest upfront expense when setting up a factory.

Ignoring regulatory compliance can halt factory operations.True

Non-compliance with regulations can lead to fines and operational halts.

How to Effectively Market and Distribute Supplements in Colombia?

In Colombia's thriving supplement market, a strategic approach to marketing and distribution can set your brand apart.

To market and distribute supplements in Colombia effectively, focus on understanding consumer needs, leveraging digital marketing channels, and establishing strong partnerships with local distributors. Tailor your messaging to cultural preferences and ensure regulatory compliance to build trust and brand loyalty.

Understanding the Colombian Consumer

Before entering the Colombian market, it's crucial to understand the consumer behavior11 specific to dietary supplements. Colombian consumers are increasingly health-conscious, seeking products that offer tangible benefits such as improved energy levels or enhanced immune support. Conduct market research to identify key demographics and tailor your product offerings to meet their needs.

Leveraging Digital Marketing

Digital marketing is a powerful tool for reaching a wide audience in Colombia. Utilize platforms such as Facebook, Instagram, and WhatsApp, which are popular among Colombian consumers, to engage with potential customers. Develop targeted advertising campaigns that highlight the benefits of your supplements. Consider influencer marketing to tap into established networks of trust.

Establishing Local Partnerships

Partnering with local distributors and retailers is vital for gaining market penetration. These partners can provide valuable insights into local market dynamics and consumer preferences. Build relationships with pharmacies, health food stores, and online retailers to expand your distribution network.

| Channel | Strategy |

|---|---|

| Pharmacies | Offer exclusive promotions or bundles |

| Health Food Stores | Provide educational workshops or sampling events |

| Online Retailers | Utilize targeted ads and SEO optimization |

Navigating Regulatory Compliance

Regulatory compliance is critical when marketing supplements in Colombia. Familiarize yourself with INVIMA regulations, which govern the safety and efficacy of health products. Ensure all marketing materials are compliant with advertising standards to avoid legal pitfalls. Regularly review updates to regulations to stay ahead of compliance issues.

Crafting Culturally Relevant Messaging

Cultural nuances play a significant role in how supplements are perceived in Colombia. Craft messaging that resonates with Colombian values, such as family health and wellness. Use testimonials from local influencers or satisfied customers to build credibility and trust among potential buyers.

By combining these strategies, you can effectively navigate the complexities of the Colombian supplement market, ensuring your brand reaches its full potential.

Colombian consumers prefer supplements for immune support.True

Market research indicates a high demand for immune-boosting products.

WhatsApp is not a popular platform in Colombia for marketing.False

WhatsApp is widely used in Colombia for digital marketing campaigns.

Conclusion

By following these steps, you can confidently navigate the complexities of launching a supplements factory in Colombia. Ready to take the first step?

At GummyGenix by SaintyCo, we're here to support your journey with cutting-edge, GMP-compliant gummy manufacturing equipment designed for efficiency, precision, and adaptability. Our machines are fully compatible with Mexican regulatory standards, and we offer reliable after-sales support to keep your operations running smoothly.

Thinking about launching a gummy production line in Columbia? Request a free consultation or request our brochure to explore machinery options that align with your compliance needs. With our expertise, you can confidently navigate the complexities of regulatory requirements and start producing high-quality gummies in no time.

-

Understand INVIMA's pivotal role in ensuring product safety.: The primary regulatory authority responsible for regulations and registration overseeing nutraceuticals and dietary supplements in Colombia is ... ↩

-

Learn the environmental responsibilities for setting up a factory.: ... require an environmental licence. In order to obtain the environmental licence, an environmental diagnosis of alternatives must be made, and ... ↩

-

Learn about cutting-edge techniques for efficient gummy manufacturing.: This comprehensive guide will delve into the various aspects of gummy manufacturing, from the machines used to the raw materials and the essential steps ... ↩

-

Discover innovative technologies in gummy production today.: GummieX™ is one of our most disruptive technologies, consisting of the development of formulas with a mixture of hydrocolloids to achieve the ideal gummy! This ... ↩

-

Discover detailed guidance on selecting efficient gummy production machinery.: Selecting the right depositor means considering several factors. Factors like manufacturing material compliance, specifications matching the ... ↩

-

Learn how sanitary design principles prevent contamination effectively.: Chemicals and procedures recommended for cleaning and sanitation must be compatible with the equipment and the manufacturing environment to prevent damage. 10. ↩

-

Discover how advanced control systems ensure product consistency.: The proper design and application of process controllers is essential for minimizing both operating costs and out-of- specification waste products in food ... ↩

-

Explore why robust after-sales support is crucial for compliance.: After-sales care is one of the most important parts of a purchase, it ensures the maintenance and quality of your Agricultural Machinery. ↩

-

Learn how to minimize long-term machinery maintenance costs effectively.: The annual maintenance cost value should include labor, contractor fees, end-of-life expenses, and costs occurred by downtime, but it should not include capital ... ↩

-

Understand logistics costs to optimize your supply chain efficiently.: The logistics costs of Transportation & Logistics market is expected to amount to US$57.69bn in 2029, potentially depicting how much the Transportation ... ↩

-

Explore detailed insights into Colombian consumer preferences and trends.: The Vitamins & Minerals market in Colombia is experiencing significant growth and development. Customer preferences are shifting towards a more health-conscious ... ↩