Commercial Gummy Making Machines

The Starting Point or Game Changer for Unleashing Your Gummy Manufacturing Potential

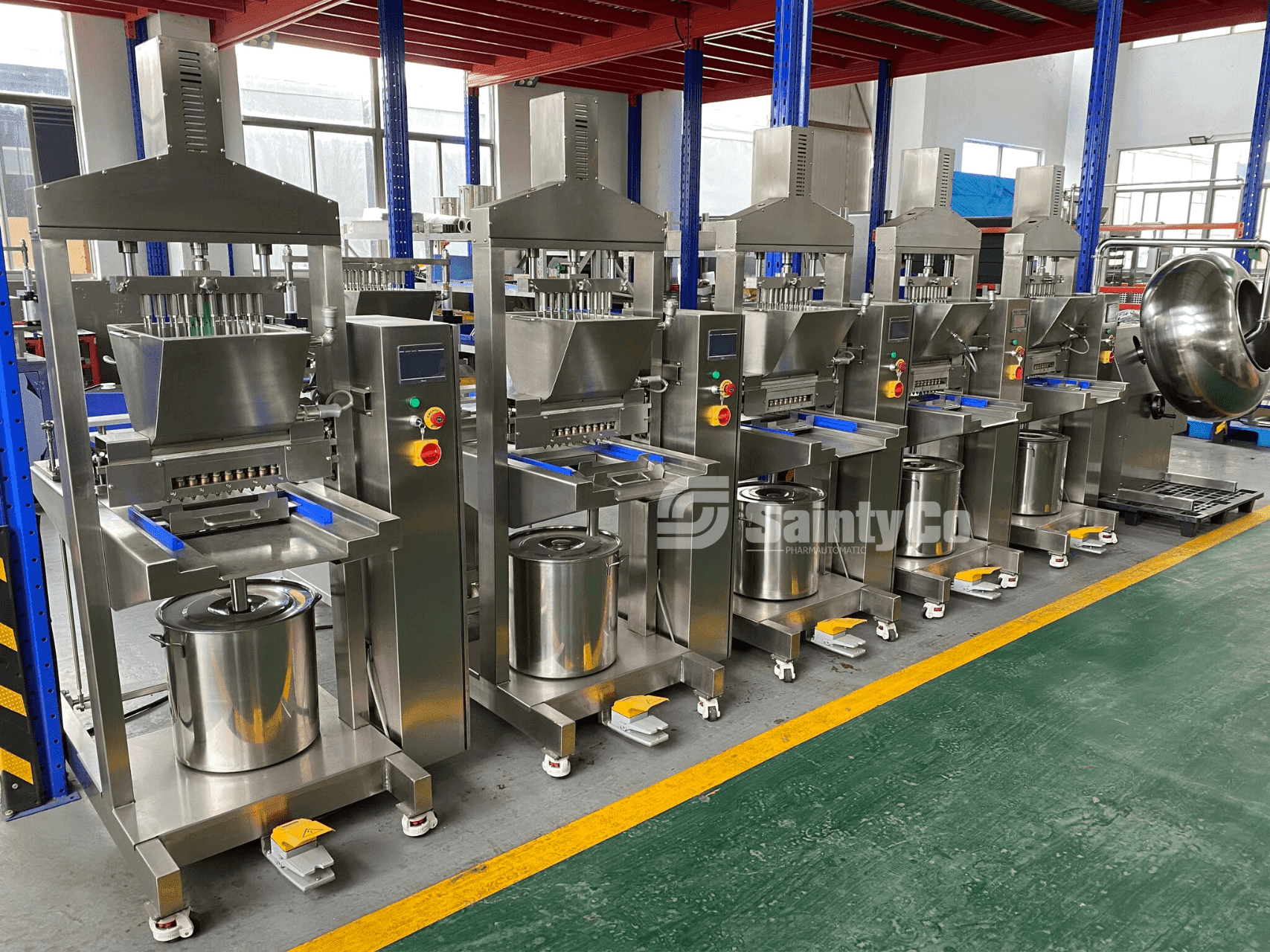

Join hundreds of businesses—startups to industry giants—choosing SaintyCo’s starchless gummy equipment for top-quality gelatin and pectin gummies. Elevate your OTC and functional gummies with active ingredients, unique shapes, and vibrant colors, all enabled by our advanced machinery. Streamline your production with a single trusted partner.

Get help solving your biggest automation problems

Increase Your Return on Investment on Every Dollar Spent on Gummy Production & Packaging Machines.

Experimental & Laboratory-Scale

Gummy Depositors

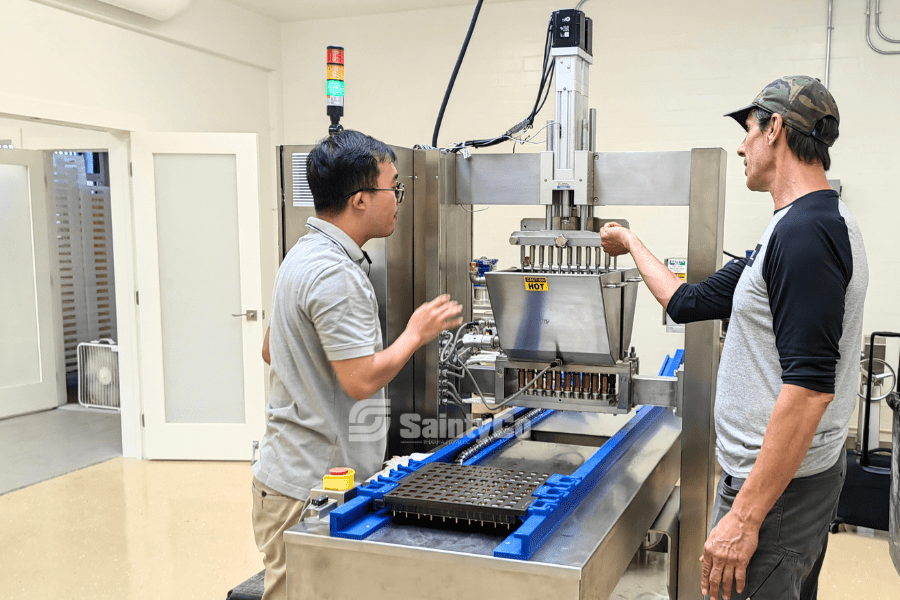

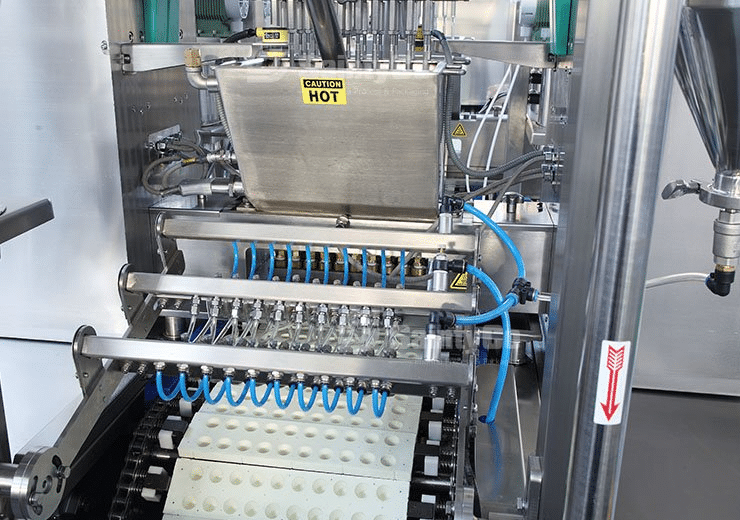

Experience the accuracy and flexibility of these automatic gummy depositor machines, ideal for nutraceutical and confectionery production, with the ability to deposit up to 15,000 gummies per hour.

With precise dosing, quick changeovers, and user-friendly controls, they are perfect for research, product development, and test marketing of gummies, jellies, hard candies, and more.

The compact design optimizes space, while the SUS316 contact surfaces and SUS304 frame guarantee hygiene and durability.

Easily scale your production with consistent results and minimal setup effort.

Top-Selling Gummy Depositors to Launch or Expand Production

DM-50X Servodose Mini Depositor

DM-20S 2-in-1 Lab Scale Depositor

MINI DP-10S Table Top Depositor

Add-On Equipment to Stream and Improve Every Step

100L Tilt Cooker

Pneumatic Gummy Demolder

CP-1000 Sugar/Wax Polishing Pan

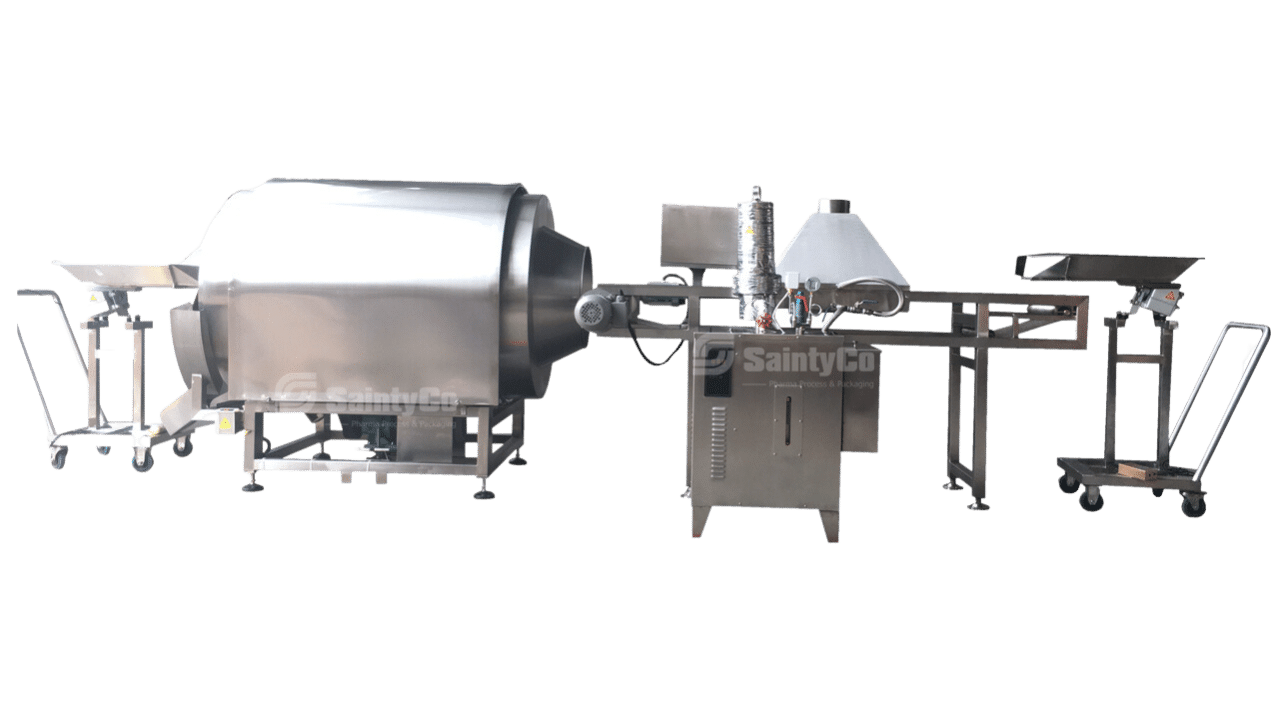

Continuous & Starch-Free, Mid to High-Batch Gummy Manufacturing

Gummy Production Lines

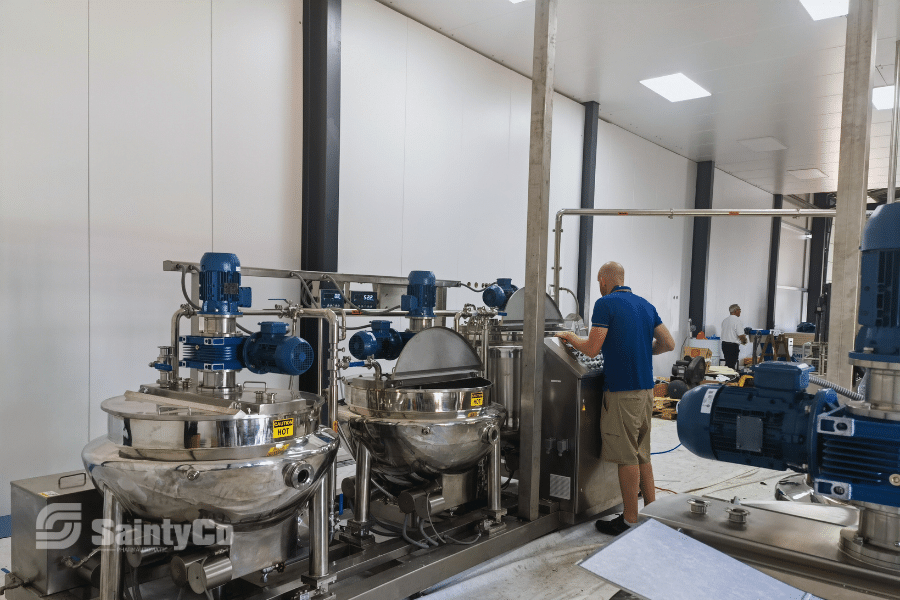

The G-Series empowers pectin and gelatin gummy manufacturers efficiently produce 15,000 to 240,000 gummies per hour. It covers every stage—mixing, cooking, dosing, depositing, cooling, and demolding—while integrating coating seamlessly. Ideal for scaling private-label and white-label operations.

Precision and Control

Powered by PLC controls and an HMI touch panel, the G-Series offers easy, precise operation. Heated hoppers and servo-driven depositing ensure consistent, quality gummies. Quick-change molds allow easy SKU shifts.

Customizable to Drive Your Success

Tell us your needs. You can also choose from options such as

- Flexible U- or L-shaped layout to fit your facility.

- Inline batch weighing systems for precise dosing.

- Continuous vacuum cookers to reduce bubbles.

- Dual depositing stations for multi-layer or dual-color gummies.

- CIP systems for faster cleaning and reduced downtime.

200+ clients worldwide have boosted their efficiency, quality, and growth with our gummy machinery. We’re here to help you do the same.

Gummy Production Lines for Faster, Smarter, and Bigger Output

Ancillary Equipment for Perfectly Shaped & Finished Gummies

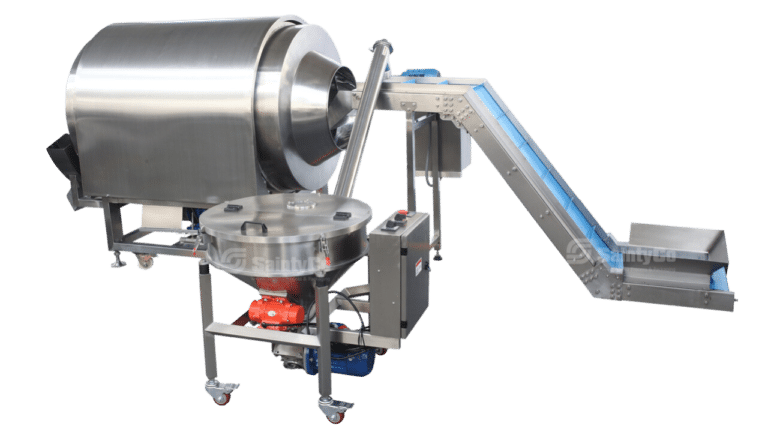

CW-600 Oil Coating Drum

SW-600 Sugar Sanding Drum

SOW-100 Multi Coater for Gummies

SW-600A Turbo Sugar Coater

Drying Tray & Dolly

TW-600S Tray Washer & Spin Dryer

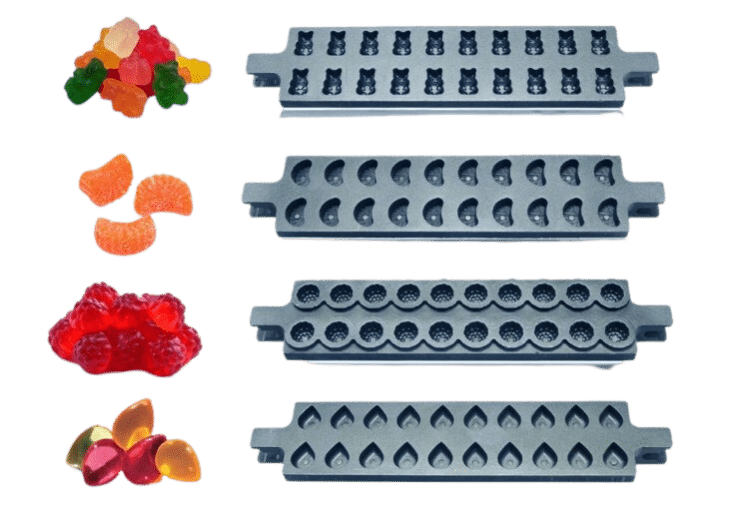

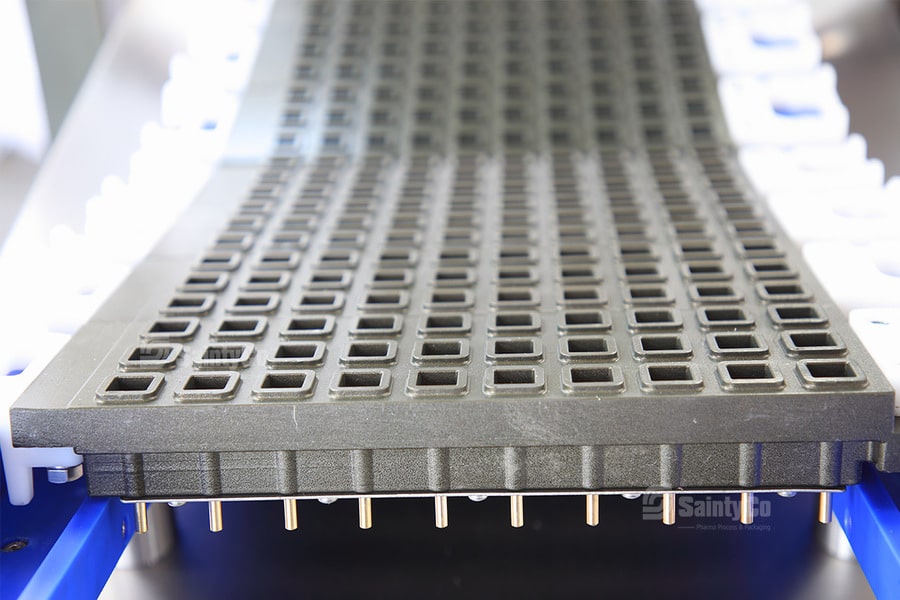

Custom Gummy Molds for Unique Candy Shapes

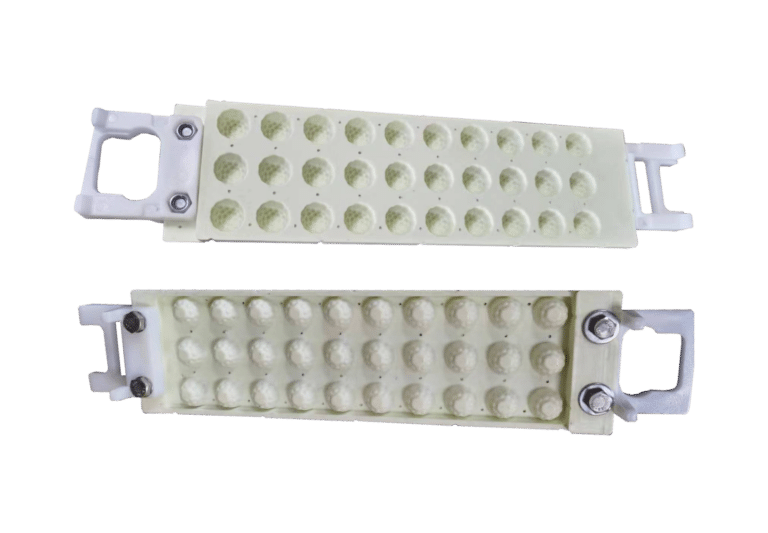

Silicone Gummy Molds

Metal Gummy Molds

3D Gummy Molds

- High-precision 3D molds for sharp gummy shapes

- Fully customizable—logos, letters, characters, or symbols

- Quick-change design—no tools, no downtime

- Smooth surface for clean release and extended mold life

Comprehensive Support Services for Optimal Production

At GummyGenix, we offer more than machines—we provide the support you need to buy with confidence, run smoothly, and grow your profits. You’re building your business, but with GummyGenix, you’re never alone. Let’s see how we can help you succeed.

Choose the Right Gummy Machinery for Your Product Type

Whether it’s timeless gummy classics or innovative jelly designs, from mono- to double-layered, center filled to side-by-side, we bring your confectionery dreams to life. Discover the possibilities, and create your next gummy masterpiece.

Gummy Production Solutions for Every Industry

GUMMYGENIX by SaintyCo provides smart gummy production & packaging solutions by industry, setting the standard for yield, efficiency, and safety across various industries and applications. Whatever your product needs, we can meet it with precision and passion.

Confectionery

Pharmaceutical

Customized Gummy Products

CBD & Cannabis Edibles

Nutraceuticals & Supplements

Trusted Gummy Manufacturing Equipment Supplier– Your Success Partner

At GummyGenix, a sub-brand of SaintyCo (Sainty International Group), we leverage over 20 years of SaintyCo’s expertise in advanced pharmaceutical machinery. This foundation drives our automated gummy production and packaging solutions for industries like confectionery, cannabis, and nutraceuticals.

We’re committed to empowering entrepreneurs with innovative solutions, comprehensive support, and a proven track record in building lasting partnerships.

countries SERVED

Happy Clients

Avg. Production Growth

Installed depositing lines

Your success is our priority

and we’ll be there every step of the way

Tailored Consultation for Your Production Goals

Your production goals, budget, layout, and processes drive our customized solutions. Our automation experts, specialized in gummy manufacturing, use years of experience and on-site insights to design systems that are highly efficient and tailored to your needs.

Enjoy a free, no-obligation consultation. Easily schedule a meeting or reach us by call, email, or WhatsApp at your convenience.

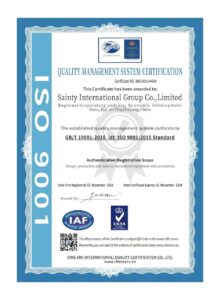

International Standards Organization (ISO) 9001:2015

CE Electrical Certification

Food and Drug Administration (FDA) Quality Standard & Certification

UL Certification (US)

SGS-CSTC Testing Inspection Certification

Certified quality, customized machinery, built for compliance.

Our gummy machines prioritize safety, reliability, and advanced technology to meet global standards like WHO, cGMP, GMP, 21CFR part II, and CE. Benefit from premium materials, streamlined processes, and Lean systems that reduce delivery times and optimize costs for smooth international operations.

Our R&D and Manufacturing teams, with over 100 successful custom projects, deliver advanced machinery tailored to your needs.

You can be sure of the quality you receive

All GummyGenix equipment undergoes a thorough Factory Acceptance Test (FAT), including visual inspection, functions, controls, and safety checks. We test all components for accuracy and calibration—covering temperature, pressure, speed, rotations, dosage, and safety—and document every step to ensure full traceability.

Delivery Right to Your Doorstep, Worry-Free

Purchasing equipment abroad involves securing favorable freight rates, choosing the right ports, and handling customs efficiently. With over 20 years of export experience, we streamline these processes for a seamless acquisition. All machinery is shipped in export-compliant wooden crates, ensuring protection that meets national standards.

By collaborating with top-tier logistics providers, we ensure your machinery arrives safely and on time, enabling a swift transition to production.

Passionate about customer care, supporting you anywhere needed

Our Technical Support offers detailed manuals, quick installation, spare parts, and continuous assistance from factory-trained techs and a global network of independent technicians, ensuring smooth operations with minimal downtime.

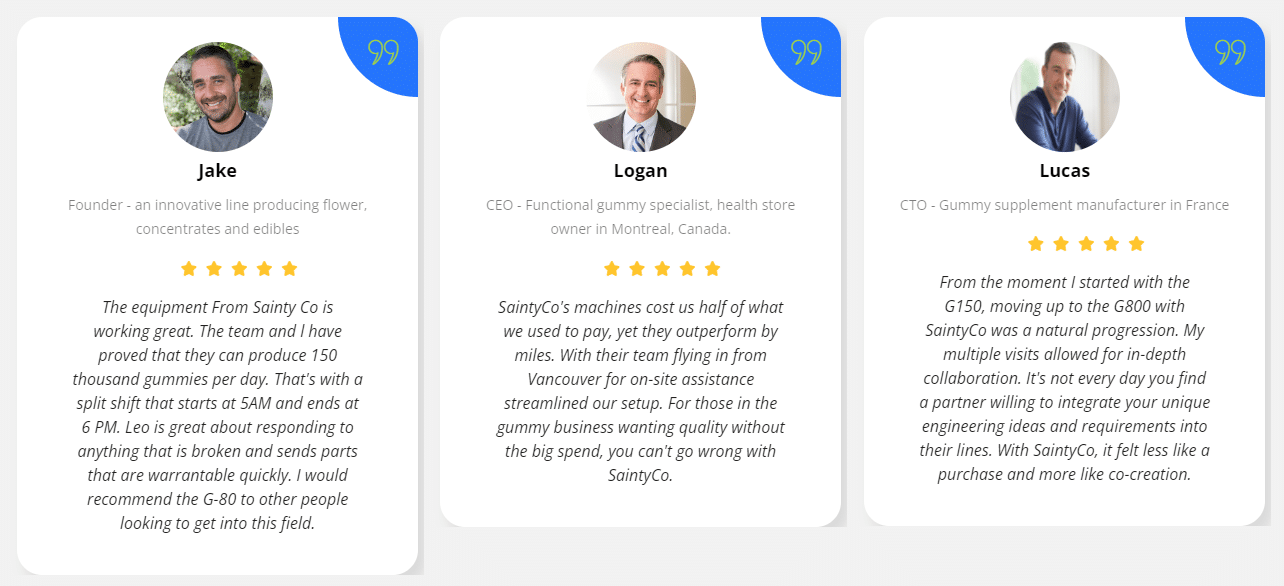

Our biggest achievement is a “Happy Customer”

At GummyGenix, our customers’ success stories are the heart of what we do. Hear firsthand how we solve our customers‘ tough challenges.

Join hundreds of companies experiencing production success with us.

Maximize Profits in the Booming Gummy Industry with Our Machines!

Tap Into Global Experience for Tailored Automation Solutions

- Awareness of your needs

- Recommend solutions for your reference and comparison

- Reasonable Pricing

- 360° After-Sales Support

Gummy Making Machine Form

Note: Once all the fields are completed and the submit button is clicked, you will be redirected to a form submission confirmation page. If this does not happen, the form was not submitted successfully. Double check ALL fields are filled out correctly to submit successfully.

Gummy Packaging Solution Form

Note: Once all the fields are completed and the submit button is clicked, you will be redirected to a form submission confirmation page. If this does not happen, the form was not submitted successfully. Double check ALL fields are filled out correctly to submit successfully.

Custom Gummy Mold Form

Note: Once all the fields are completed and the submit button is clicked, you will be redirected to a form submission confirmation page. If this does not happen, the form was not submitted successfully. Double check ALL fields are filled out correctly to submit successfully.

Service & Parts Request Form

Note: Once all the fields are completed and the submit button is clicked, you will be redirected to a form submission confirmation page. If this does not happen, the form was not submitted successfully. Double check ALL fields are filled out correctly to submit successfully.

Frequently Asked questions

Still can’t find the information you want? Don’t hesitate to contact us.

Our gummy making equipment is designed for the production of various types of gummies and jellies. One thing to consider when purchasing a machine is the type of ingredients you'll be working with. Certain materials can be too harsh for your machine and may cause damage. At GummyGenix, we ensure the quality and durability of our machines, using only the highest grade materials that are designed to withstand various ingredient types.

With our gummy manufacturing equipment, you have the flexibility to produce a diverse range of products. This includes traditional gummies like gummy bears, to chewy nutraceutical sweets, and various jelly or gummy-based confectionery. Our equipment is designed to handle a broad array of recipes, allowing you to expand your product offering and meet market demands.

For gummy bear production, we recommend our starch-free depositing machines that guarantee hygiene and prevent cross-contamination.

Our gummy making machines are made of Stainless Steel 316, complying with cGMP standards.

Depending on your requirements, our production lines can handle varying capacities. You provide your conditions and requirements, and we'll equip you with the ideal production line.

The choice between automated and non-automated systems depends on various factors like production volume, budget, and specific requirements. Our experts can guide you to choose the best system for your situation.

Continuous cooking is integral for maintaining the ideal moisture content in your product, which is critical for the right texture and stability. At GummyGenix, we offer a selection of continuous cooking systems engineered for precise moisture control, such as coil cookers and jet cookers, among others. We are always available to assist you in choosing the most suitable system for your needs. For more information on this, you can consult with one of our experts.

GummyGenix, under the umbrella of SaintyCo International Group, leverages its parent company's 20 years of expertise in the pharmaceutical and nutraceutical sectors, delivering high-quality production and packaging solutions in the gummy equipment industry. Our strengths range from crafting top-tier machinery to providing excellent post-sales services, solidifying our role as a dependable partner in your comprehensive gummy production journey.

GummyGenix offers comprehensive consultation, implementation, and after-sales service. We walk with you through every stage of the process, from understanding your requirements, testing in our innovation center, to assisting you in the launch. Our commitment doesn't end with installation. We are always available for training services and optimization of your machines.

Sure, we will send you machine demos. And we provide comprehensive information, specifications, and customer service to help you make the best decision.

The order process at GummyGenix involves several steps:

- Confirmation of requirements

Issuing of Proforma Invoice (PI) outlining business terms, prices, services, guarantees - Payment of 30% deposit

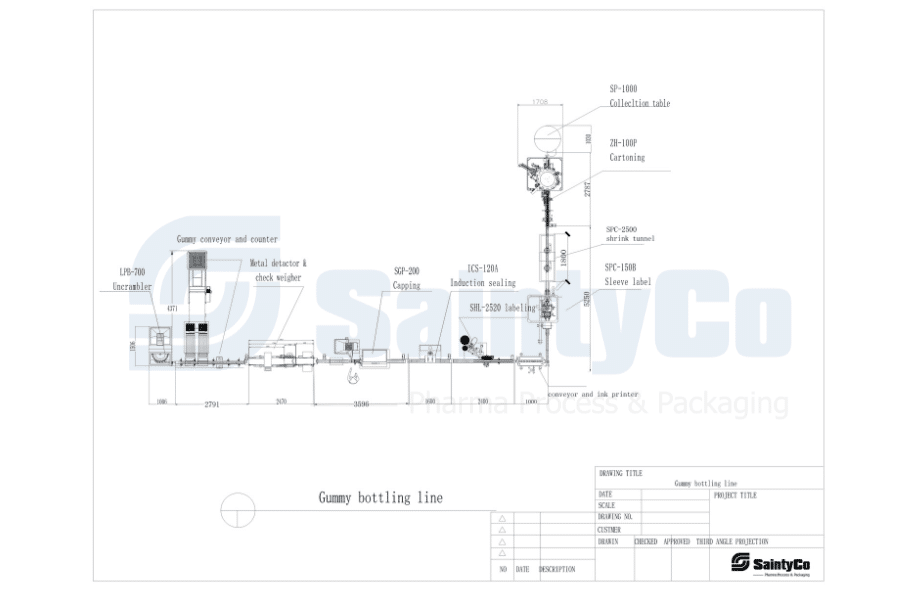

- Creation of CAD layout design

- Designing of molds

- Production

Inspection of your machines before shipping - Balance payment

- Shipment

- Installation at your facility

- Training of your staff

Reach out to us via our website's contact form or email us directly via [email protected], and one of our team members will assist you promptly. We'll walk you through the process and ensure a seamless experience.

Our payment terms involve a 50% initial deposit, followed by the remaining 50% before shipping. We always strive for flexibility to accommodate our customers' financial needs.

Typically, our lead time ranges between 30-40 working days for manufacturing, depending on the machine and customization details. We always strive to deliver within the agreed-upon timeline.

Absolutely! We welcome dealers to join us in spreading our services. The commission structure can be discussed upon application.