Are you looking to enhance your gummy candies?

The best coating methods for gummies include sugar, oil, sour, spray, gel, powder, and carnauba wax coatings. Each method serves unique purposes, such as improving texture, adding flavor, or extending shelf life. Understanding these options can help you elevate your gummy production.

In this post, we'll delve deeper into each coating method, discussing their processes, benefits, and challenges. This knowledge is invaluable for anyone looking to improve gummy quality, whether for personal use or commercial production.

Sugar coating enhances the flavor of gummy candies.True

Sugar coating adds sweetness and improves the overall taste profile of gummies, making them more appealing to consumers.

Carnauba wax is used solely for aesthetic purposes in gummies.False

While carnauba wax provides shine, it also helps extend shelf life by creating a protective barrier.

What Are the Key Benefits of Coating Gummies?

Gummy coatings are more than just decoration; they serve multiple purposes that enhance both product quality and consumer appeal.

Coating gummies offers key benefits including improved aesthetic appeal, extended shelf life, enhanced texture, flavor protection, and the ability to customize nutritional content. Each method has unique advantages that can elevate your product's marketability.

Enhancing Aesthetic Appeal

One of the most immediate benefits of coating gummies is the enhancement of their visual appeal. A shiny, well-coated gummy is more attractive to consumers.

Sugar coatings provide a glossy finish, creating a classic candy look that appeals to both children and adults. The right coating can significantly increase shelf appeal, impacting purchasing decisions. Explore more about gummy aesthetics1.

Improving Texture and Mouthfeel

Coatings can modify the texture of gummies, providing a smoother or crunchier experience depending on the method used.

- Sugar Coating: Creates a slightly crunchy exterior, enhancing the overall mouthfeel.

- Oil Coating: Offers a sleek, soft finish that can be preferable for premium gummies.

Consumers often associate texture with quality; thus, the right coating can elevate the product's perception. Learn about different textures in gummies2.

Extending Shelf Life

Properly coated gummies can have improved shelf life due to better moisture control and protection against environmental factors.

| Coating Type | Shelf Life Impact | Key Benefits |

|---|---|---|

| Sugar Coating | Moderate | Glossy finish, sweetness |

| Oil Coating | High | Moisture resistance |

| Carnauba Wax | Very High | Extended shelf life |

For instance, carnauba wax provides a robust barrier against air and moisture, significantly extending shelf life. Find out how to extend gummy shelf life3.

Protecting Flavor Integrity

Different coatings can also help protect the flavor integrity of gummies. By encapsulating flavoring agents, coatings can preserve taste over time.

- Gel Coatings: Help maintain flavors while adding a chewy texture.

- Powder Coatings: Can enhance flavor without adding additional sugars.

This is particularly crucial in functional gummies where the active ingredients need protection from degradation. Read about preserving flavors in gummies4.

Customizing Nutritional Benefits

Coating methods can also be leveraged to add nutritional benefits to gummies. This is especially relevant in the nutraceutical sector, where added vitamins and minerals can be coated onto the gummies.

- Powder Coating: Ideal for adding proteins and fibers.

- Spray Coating: Allows for the application of nutrient powders evenly across the surface.

Such enhancements not only improve health benefits but also marketability, appealing to health-conscious consumers. Discover nutritional enhancements in gummy production5.

Final Considerations

While each coating method offers unique benefits, it's crucial to select a technique that aligns with your product goals. Factors such as target audience, desired texture, and shelf life should guide your choice. For manufacturers, understanding these benefits is key to optimizing production processes and achieving product excellence. Get insights on manufacturing processes6.

Coating gummies enhances their visual appeal significantly.True

A shiny, well-coated gummy attracts consumers, boosting shelf appeal and purchase likelihood.

Oil coatings provide a crunchy texture to gummies.False

Oil coatings create a sleek, soft finish, not a crunchy texture, enhancing mouthfeel.

How Can You Customize Coatings for Different Gummy Types?

Customizing coatings for different gummy types is essential for enhancing their appearance, texture, and flavor. This guide explores various coating methods tailored for specific gummy applications.

To customize coatings for different gummy types, understand each method's unique requirements: sugar coating for shine, oil coating for smoothness, sour coating for tanginess, spray coating for nutrients, gel coating for softness, powder coating for nutrition, and carnauba wax for durability.

Understanding Gummy Coating Types

Coating is essential for enhancing the appearance and texture of gummy candies. Different methods serve various gummy types, each with unique requirements and characteristics. Let’s explore how you can customize coatings based on the type of gummies you are producing.

Sugar Coating for Classic Gummies

Sugar coating is ideal for classic gummies and confectioneries, offering a shiny finish. The process involves applying hot sugar syrup to the gummies, which crystallizes to create a glossy surface. Here’s a brief overview:

| Aspect | Details |

|---|---|

| Ideal For | Classic gummies |

| Process | Hot sugar syrup applied using a polishing pan |

| Challenges | Time-consuming, requires precise temperature control |

To achieve optimal results, maintain humidity control to prevent stickiness and ensure consistent crystallization by adjusting the syrup’s temperature.

Oil Coating for Premium Gummies

Oil coatings are preferred for functional gummies, providing a smooth finish without adding sugar. A thin layer of vegetable or mineral oil is applied using a coating drum. Key considerations include:

| Aspect | Details |

|---|---|

| Ideal For | Premium and functional gummies (e.g., CBD) |

| Moisture Sensitivity | Less protective against moisture than sugar coatings |

| Challenges | Requires careful temperature control |

Applying a controlled layer of oil is crucial to avoid a greasy appearance, maintaining the gummy's integrity.

Sour Coating for Tangy Gummies

Sour coatings add a zesty flavor to gummies like sour bears. A mixture of citric and tartaric acid with sugar is applied to enhance taste. Important aspects include:

| Aspect | Details |

|---|---|

| Ideal For | Sour gummies |

| Application | Spraying or rolling in a pan |

| Post-Coating Drying | Essential to avoid clumping |

Ensure even distribution of the sour powder to maintain texture without compromising flavor. Adjust acidity levels to tailor the sourness based on your product line.

Spray Coating for Nutrient-Enhanced Gummies

Spray coating is perfect for gummies needing a precise application, such as those enriched with nutrients or probiotics. This method uses specialized nozzles for uniformity:

| Aspect | Details |

|---|---|

| Ideal For | Nutrient-enriched gummies |

| Process | Thin layer sprayed onto gummies |

| Spray Thickness Control | Calibration is key to prevent uneven coatings |

Maintain compatibility between the coating material and gummy base to ensure adhesion and prevent separation during storage.

Gel Coating for Soft Texture Maintenance

Gel coatings provide a soft, chewy texture ideal for premium or functional gummies. Here’s what you need to know:

| Aspect | Details |

|---|---|

| Ideal For | CBD gummies, nutraceuticals |

| Application Method | Spraying or dipping |

| Temperature Control | Critical to prevent premature solidification |

Proper humidity control during storage is vital to preserve softness and avoid melting of the gel coating.

Powder Coating for Nutritional Benefits

Powder coatings are utilized mainly for nutritional gummies, allowing fortification with fibers or proteins. Key points include:

| Aspect | Details |

|---|---|

| Ideal For | Nutritional gummies |

| Drying Post-Coating | Essential to prevent clumping |

| Moisture Control | Critical to maintain coating integrity |

Handle powder applications carefully to avoid lumps, ensuring that they enhance rather than hinder the gummy's texture.

Carnauba Wax Coating for Durability

Carnauba wax provides a glossy finish while enhancing shelf life. Here’s a snapshot:

| Aspect | Details |

|---|---|

| Ideal For | High-end gummies |

| Application Method | Sprayed or drum polished |

| Durability Benefits | Excellent moisture resistance |

Ensure an even wax application to achieve the right gloss without compromising the gummy surface.

By understanding these coating methods, you can customize your production process effectively, catering to various consumer preferences and market trends. For more insights into specific techniques or recipes, consider exploring gummy coating techniques7.

Sugar coating is best for premium gummy types.False

This claim is false; sugar coating is ideal for classic gummies, not premium types.

Gel coatings maintain the softness of functional gummies.True

This claim is true; gel coatings provide a soft texture ideal for premium or functional gummies.

How Does Humidity Affect Gummy Coatings?

Humidity significantly impacts the quality of gummy coatings, affecting everything from texture to shelf life. Understanding these effects is crucial for manufacturers aiming for consistent results.

Humidity affects gummy coatings by influencing crystallization and texture. High humidity can cause stickiness and uneven coating, while controlled environments help maintain desired quality and appearance.

The Impact of Humidity on Gummy Coating Quality

Humidity levels play a significant role in the production of gummy coatings. High humidity can cause gummy candies to become sticky, leading to issues during packaging and distribution.

To mitigate this, manufacturers must maintain controlled air circulation and temperature during the coating process.

For example, sugar coatings require specific humidity levels to ensure proper crystallization. If the humidity is too high, the syrup may not set correctly, resulting in an uneven finish. This can also lead to clumping or incomplete coating.

Utilizing dehumidifiers and monitoring humidity with hygrometers can help maintain optimal conditions.

Different Coating Methods and Humidity Sensitivity

Different coating methods exhibit varying degrees of sensitivity to humidity:

| Coating Method | Humidity Sensitivity | Key Considerations |

|---|---|---|

| Sugar Coating | High | Requires precise temperature control |

| Oil Coating | Moderate | Less affected but needs controlled storage |

| Sour Coating | High | Post-coating drying is crucial |

| Spray Coating | Moderate | Spray drying can help avoid moisture buildup |

| Gel Coating | High | Sensitive to excess moisture |

| Powder Coating | Very High | Immediate drying needed post-application |

| Carnauba Wax Coating | Low | Provides moisture resistance |

As seen in the table, sugar and sour coatings are particularly vulnerable to humidity. In contrast, carnauba wax coatings provide better moisture resistance, making them suitable for more humid environments.

Best Practices for Managing Humidity in Production

To ensure the best outcomes for gummy coatings, consider the following practices:

- Regular Monitoring: Use hygrometers to keep track of humidity levels in production areas.

- Environmental Control: Implement dehumidification systems to maintain optimal humidity.

- Batch Size Management: Smaller batches allow for better control over environmental factors, including humidity.

- Storage Solutions: Store gummies in climate-controlled environments to prevent moisture-related issues.

By applying these practices, manufacturers can enhance the quality and consistency of their gummy coatings, leading to a superior product that stands out in the market. For further insights on best practices, explore best practices for gummy production8.

High humidity causes gummy candies to become sticky.True

Excess moisture during production leads to stickiness in gummy candies, affecting packaging and distribution.

Carnauba wax coatings are highly sensitive to humidity.False

Unlike sugar and sour coatings, carnauba wax coatings resist moisture, making them suitable for humid environments.

What Challenges Do Gummy Manufacturers Face with Each Coating Method?

Manufacturers face various challenges with different coating methods in gummy production. Each method presents unique difficulties that can impact product quality and production efficiency.

Manufacturers encounter specific challenges with each coating method in gummy production. Key issues include time consumption with sugar coatings, moisture sensitivity with oil coatings, and achieving flavor balance with sour coatings.

1. Sugar Coating Challenges

Sugar coating is often favored for its classic appeal but poses several hurdles:

-

Time Consumption: The process can be slow, especially for larger batches. This can impact production timelines and efficiency.

-

Energy Intensity: Significant energy is required to maintain the correct temperatures for syrup preparation and crystallization. This adds to operational costs.

-

Humidity Sensitivity: High humidity can lead to sticky gummies, requiring manufacturers to manage environmental conditions closely. Controlled air circulation is essential.

For more on the sugar coating method, check out How to Sugar Coat Gummies: The Complete Guide to Gummy Sugar Coating9.

2. Oil Coating Challenges

While oil coating offers a non-sticky finish, it brings specific issues:

-

Moisture Sensitivity: Oil coatings are less effective at moisture protection compared to sugar coatings. This necessitates extra care during storage.

-

Texture Compromise: Too much oil can result in a greasy texture, which may detract from the product appeal.

-

Temperature Control: Maintaining the right temperature during application is crucial to prevent uneven coating or solidification issues.

Learn more about moisture control in manufacturing by visiting moisture management techniques10.

3. Sour Coating Challenges

Sour coating enhances flavor but introduces complexities:

-

Flavor Balance: Achieving the right level of tartness is critical. Too much citric acid can affect gummy adhesion and overall flavor.

-

Even Distribution: Ensuring uniform application of sour powder can be challenging, leading to clumping if not managed properly.

-

Post-Coating Issues: Gummies must be adequately dried post-coating to prevent the sour powder from sticking or clumping together.

For insights into flavor optimization, explore flavor balancing techniques11.

4. Spray Coating Challenges

Spray coating allows for precision but requires high standards:

-

Equipment Precision: Spray nozzles must be calibrated precisely; any deviation can lead to uneven coatings.

-

Drying Techniques: Quick drying is needed to avoid moisture buildup, requiring additional equipment and monitoring.

-

Compatibility Concerns: Selecting the right coating materials that adhere properly to gummy bases is essential for quality.

Discover more about advanced spray techniques in our guide on spray technology in food production12.

5. Gel Coating Challenges

Gel coatings provide softness but come with their own set of difficulties:

-

Temperature Sensitivity: The gel must be maintained at specific temperatures to avoid premature solidification.

-

Environmental Factors: Humidity can affect the gel's integrity, potentially altering the texture of the gummy.

-

Adhesion Issues: Proper application is necessary to ensure that the coating remains intact without compromising texture.

For detailed strategies on gel coating, see gel application best practices13.

6. Powder Coating Challenges

Powder coatings add functionality but require careful handling:

-

Immediate Drying Needs: Powders must be dried quickly after application to avoid clumping, requiring efficient processes.

-

Moisture Control: Extreme sensitivity to moisture necessitates strict environmental controls during storage and processing.

-

Texture Alteration Risks: Improper application can change the chewiness of the gummies, affecting consumer experience.

To learn more about controlling powder applications, check out powder coating techniques14.

7. Challenges of Coating Gummies with Carnauba Wax

Carnauba wax provides a glossy finish but has challenges of its own:

-

Application Consistency: Ensuring an even layer of wax is vital; too much can create a greasy appearance.

-

Durability vs. Texture: Finding the right balance between durability and maintaining the gummy's texture can be tricky.

-

Shelf Life Management: While wax extends shelf life, it requires careful monitoring of application processes to avoid excessive buildup.

For insights into managing shelf life, read our article on shelf life extension strategies15.

Sugar coating requires significant time and energy to apply.True

The sugar coating process is slow and energy-intensive, impacting production efficiency and costs.

Oil coatings provide better moisture protection than sugar coatings.False

Oil coatings are less effective at moisture protection compared to sugar coatings, requiring careful storage measures.

What Equipment Is Needed for Gummy Coating Processes?

Understanding the equipment needed for gummy coating processes is crucial for manufacturers aiming to enhance product quality and efficiency.

To successfully coat gummies, essential ancillary equipment for perfectly shaped & finished gummies equipment includes polishing pans for sugar coating, coating drums for oil applications, and specialized spray nozzles for precise coatings. Additionally, humidity and temperature control systems play a vital role in maintaining quality during production.

Ancillary Equipment for Coating Gummies | Machine Brand:SaintyCo | Click to Know More

Key Equipment for Gummy Coating Processes

To ensure a successful gummy coating process, specific equipment is essential. Each type of coating method requires tailored machinery to achieve optimal results. Here's a breakdown of the key equipment needed for various gummy coating techniques.

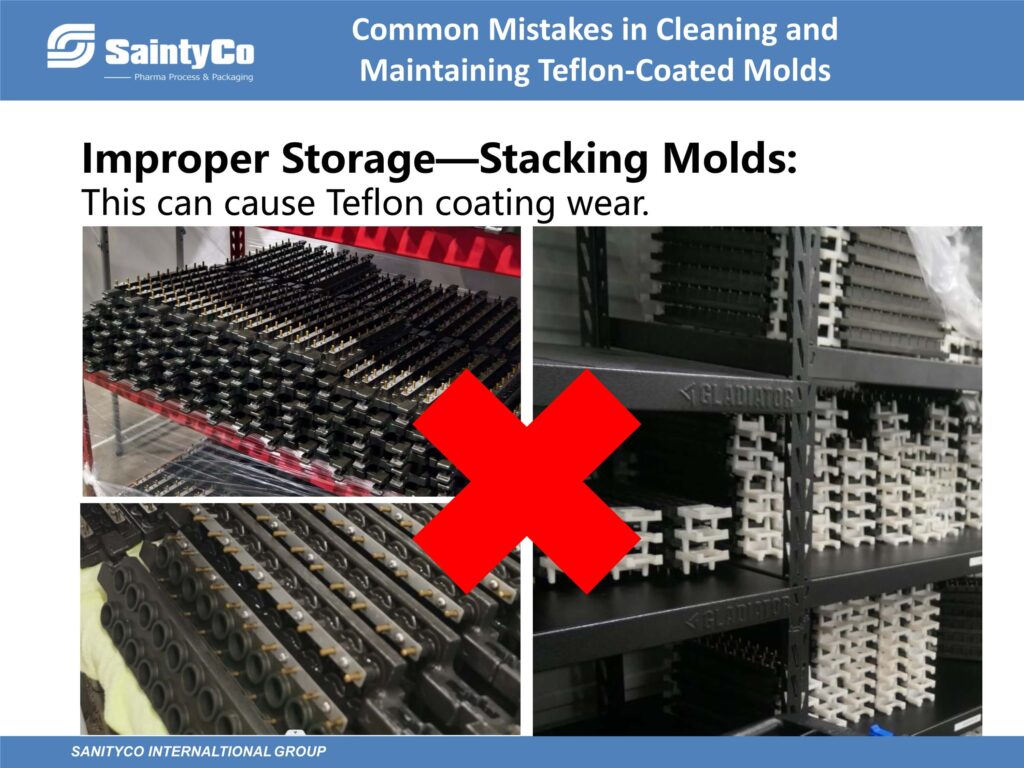

1. Sugar Coating/Sanding Equipment

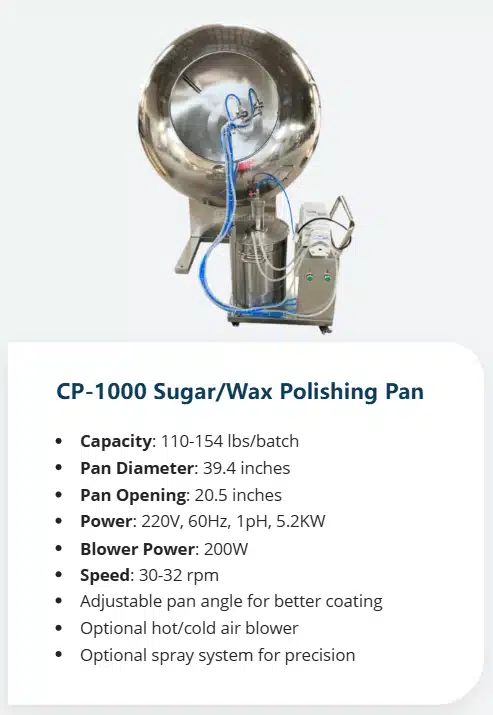

- Sugar Polishing Pan (e.g., CP-1000): This machine applies hot sugar syrup to gummies while they rotate to promote even coating. It’s vital for achieving that glossy finish.

- Temperature Control System: Maintains syrup temperature to avoid crystallization issues.

- Humidity Control System: Essential for preventing gummies from becoming sticky due to high humidity.

Ancillary Equipment for Coating Gummies | Machine Brand:SaintyCo | Click to Know More

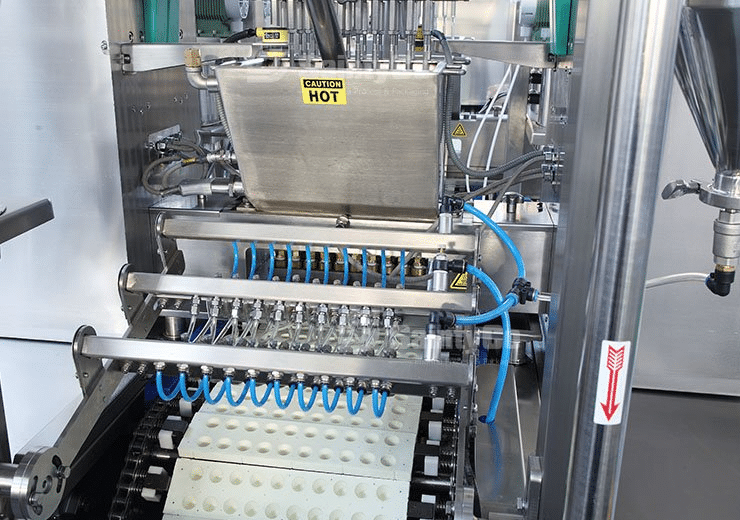

2. Oil Coating Equipment

- Oil Coating Drum (e.g., CW-600): This machine applies a thin layer of oil, ensuring a smooth finish without stickiness.

- Oil Pumping System: Regulates the amount of oil applied, preventing over-coating.

3. Sour Coating Equipment

- Coating Pan or Spraying System: Allows for even application of sour powders like citric and tartaric acid mixed with sugar.

- Drying Oven: Ensures that gummies dry properly after sour coating, preventing clumping.

4. Spray Coating Equipment

- Specialized Spray Nozzles: These nozzles apply a thin, uniform layer of coating material, crucial for encapsulation.

- Calibration System: Ensures nozzle speed and pressure are set correctly for even coverage.

5. Gel Coating Equipment

- Spray or Dipping Machines: Used to apply gelatin or pectin-based coatings while preserving the gummy's texture.

- Temperature Control Unit: Keeps gel materials at optimal temperatures to prevent solidification.

6. Powder Coating Equipment

- Dusting Machine: Dusters or rollers apply powder coatings evenly onto gummies.

- Drying System: Quickly dries coated gummies to prevent moisture-related issues.

7. Carnauba Wax Coating Equipment

- Spraying or Drum Polishing Machines: These machines apply carnauba wax for a glossy finish and extended shelf life.

- Application Control System: Monitors the wax layer to ensure consistency without excessive glossiness.

Summary Table of Key Equipment Needs

| Coating Type | Key Equipment | Purpose |

|---|---|---|

| Sugar Coating | Polishing Pan | Applies hot sugar syrup |

| Temperature Control System | Maintains syrup temperature | |

| Humidity Control System | Prevents stickiness | |

| Oil Coating | Coating Drum | Applies oil layer |

| Oil Pumping System | Controls oil application | |

| Sour Coating | Coating Pan/Spraying System | Applies sour powder |

| Drying Oven | Dries gummies post-coating | |

| Spray Coating | Specialized Spray Nozzles | Uniformly applies coatings |

| Calibration System | Ensures consistent spray coverage | |

| Gel Coating | Spray/Dipping Machines | Applies gel coatings |

| Temperature Control Unit | Maintains gel temperature | |

| Powder Coating | Dusting Machine | Evenly applies powder |

| Drying System | Prevents moisture accumulation | |

| Carnauba Wax Coating | Spraying/Polishing Machines | Applies wax for glossiness |

| Application Control System | Monitors wax application |

Additional Considerations

When selecting equipment for gummy coating processes, consider the following:

- Production Volume: Higher volumes may require more automated systems to maintain efficiency.

- Quality Control Devices: Implementing quality control measures ensures that coatings meet desired specifications and standards.

For further insights into optimizing your gummy production line and selecting the right machinery, explore advanced gummy production automation options16.

Polishing pans are essential for sugar coating gummies.True

Polishing pans apply hot sugar syrup to rotating gummies for an even, glossy finish, making them crucial in the sugar coating process.

Humidity control is unnecessary for gummy coating processes.False

Humidity control systems are vital to prevent gummies from becoming sticky, especially during the coating process, making it essential equipment.

What Trends Are Emerging in Gummy Coating Techniques?

Gummy coating techniques are evolving rapidly in response to consumer demands and technological advancements. Discover the latest trends shaping this vital aspect of gummy production.

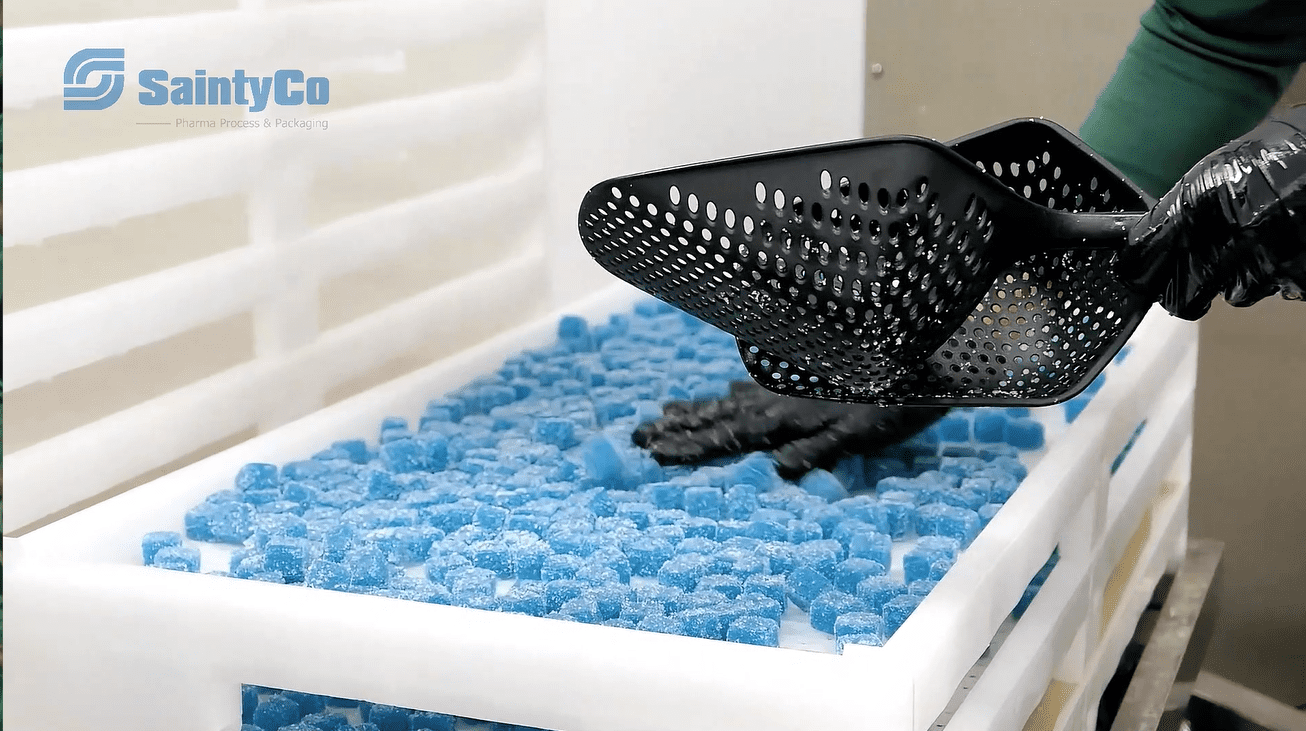

Emerging trends in gummy coating techniques include the rise of functional coatings, an emphasis on shelf life through innovative materials like carnauba wax, sustainability efforts, and enhancements in flavor and texture.

The Rise of Functional Coatings

With the increasing demand for functional gummies, particularly those infused with health benefits like CBD and vitamins, coating techniques have evolved to accommodate these specialized needs.

For instance, oil coatings are gaining traction due to their ability to maintain the softness of gummies while providing a non-sticky finish. This has been crucial for products targeting health-conscious consumers.

Moreover, spray coating methods are now widely used for precise application, ensuring that active ingredients are evenly distributed. This technique allows for encapsulation of nutrients, enhancing the gummy’s appeal without compromising texture.

Emphasis on Shelf Life and Quality

Another emerging trend is the focus on extending shelf life through innovative coating materials like carnauba wax.

Carnauba wax not only provides a glossy finish but also offers excellent moisture resistance. This is particularly beneficial for gummies stored in humid environments. It acts as a barrier against air and moisture, prolonging product freshness.

| Coating Type | Benefits | Challenges |

|---|---|---|

| Sugar Coating | Glossy finish | Time-consuming |

| Oil Coating | Softness retention | Moisture sensitivity |

| Spray Coating | Precise application | High precision required |

| Carnauba Wax | Extended shelf life | Application control needed |

Sustainability in Gummy Coatings

As consumers become more environmentally conscious, manufacturers are exploring sustainable coating options. Biodegradable materials and natural extracts are being incorporated into gummy coatings, appealing to eco-friendly consumers. This shift not only meets market demands but also enhances brand image.

Additionally, manufacturers are researching plant-based coatings that can replace traditional synthetic materials. Such innovations could lead to a new standard in gummy production, aligning with global sustainability goals.

Innovations in Texture and Flavor Enhancement

Gummy manufacturers are increasingly experimenting with texture and flavor through innovative coating techniques. For instance, sour coatings have become popular, adding a tangy twist to traditional gummies. This method involves using a mix of citric and tartaric acids, which can significantly enhance flavor profiles.

Furthermore, powder coatings are being utilized to incorporate additional nutritional value, such as fibers or proteins, without altering the gummy's chewiness too much. These trends indicate a shift towards more flavorful and nutritious options that cater to evolving consumer preferences.

Oil coatings maintain gummy softness without stickiness.True

Oil coatings are preferred for their ability to keep gummies soft while preventing a sticky texture, catering to health-conscious consumers.

Carnauba wax extends shelf life of gummy products.True

Carnauba wax is effective in enhancing the shelf life of gummies by providing moisture resistance and a protective barrier against air.

Conclusion

Discover various gummy coating methods that enhance texture, flavor, and shelf life. Learn about sugar, oil, sour, spray coatings and more to elevate your gummy production.

Choosing the right coating method is critical for ensuring that your gummies not only look appealing but also meet the desired quality and functionality standards. Whether you are aiming for a classic sugar-coated finish or a high-performance coating like carnauba wax, each method requires careful attention to detail and precise control over environmental conditions, coating materials, and equipment.

At GummyGenix by SaintyCo, we're here to support your journey with cutting-edge, GMP-compliant gummy manufacturing equipment designed for efficiency, precision, and adaptability. Our machines are fully compatible with regulatory standards, and we offer reliable after-sales support to keep your operations running smoothly.

Would you like more specific guidance on choosing the right coating equipment or methods for your gummy production line?

Contact GummyGenix by SaintyCo Today I can provide tailored recommendations based on your product goals, coating preferences, and production scale.

Gummy Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

This link provides detailed insights into the visual appeal of gummies and how coatings enhance their attractiveness. ↩

-

Explore how different textures influence consumer preferences and how coatings can achieve desired mouthfeel. ↩

-

Learn methods to extend shelf life through effective coating techniques. ↩

-

Understand how to protect flavors in gummies during production with various coating techniques. ↩

-

Find out how nutritional benefits can be enhanced in gummy products through specific coating methods. ↩

-

This link discusses essential manufacturing processes for optimizing gummy production. ↩

-

Clicking this link will provide you with detailed techniques and recipes tailored specifically for gummy coatings, enhancing your production efficiency. ↩

-

Discover practical strategies to optimize gummy production and coating techniques while managing humidity levels effectively. ↩

-

Explore this link for a deeper understanding of the challenges in gummy production sugar coatings and how to overcome them effectively. ↩

-

Find strategies to manage moisture issues effectively in gummy production and enhance product quality. ↩

-

Learn about flavor optimization techniques that ensure balance and quality in sour coated gummies. ↩

-

Read about advanced spray techniques that improve coating precision in gummy manufacturing. ↩

-

Understand best practices for gel application to maintain quality and texture in gummies. ↩

-

Get insights into powder coating techniques that help avoid common pitfalls in gummy production. ↩

-

Discover how to extend shelf life while maintaining quality through effective carnauba wax application. ↩

-

Click here to discover diverse gummy production automation options that can enhance your coating process efficiency and product quality. ↩