Fibre gummies are more than just a sweet treat; they're a burgeoning segment in the health supplement market.

To successfully manufacture fibre gummies, focus on key aspects like ingredient selection, temperature control, moulding, and packaging. Soluble fibres such as inulin and pectin are essential, but managing their solubility and viscosity is critical for achieving the desired texture and health benefits. Proper temperature and humidity control further ensure quality.

While this gives a brief overview, each stage in the fibre gummy production process presents unique challenges and opportunities. Delve deeper into each aspect to understand how you can optimize your production line for efficiency and quality.

Inulin is a key ingredient in fibre gummies.True

Inulin is used for its soluble fibre properties, aiding texture.

Temperature control is unnecessary in gummy production.False

Temperature control is crucial for maintaining gummy quality and texture.

Fiber Gummies Ingredients: What Are Fiber Gummies Made Of?

Discover what makes fibre gummies not just tasty, but also beneficial for your health. We'll explore the key ingredients that give these gummies their unique properties and nutritional value.

Fibre gummies primarily contain soluble fibres like inulin, pectin, and agar, which are crucial for digestive health. They also include gelling agents, sweeteners, and flavourings to enhance taste and texture.

Key Ingredients Overview

Fibre gummies are crafted from several essential ingredients that work together to provide their health benefits. The main component is soluble fibre, such as inulin1, which aids digestion and promotes gut health. Pectin and agar are commonly used gelling agents that give gummies their chewy texture while also offering dietary fibre.

| Ingredient | Role | Benefits |

|---|---|---|

| Inulin | Soluble Fibre | Aids digestion, improves gut health |

| Pectin | Gelling Agent | Provides texture, adds dietary fibre |

| Agar | Gelling Agent | Offers plant-based fibre |

Balancing Sweetness and Health

Sweeteners are vital for making fibre gummies palatable. Most manufacturers use natural sweeteners like erythritol2 or stevia to keep sugar content low while maintaining taste. These options help in reducing calorie intake without sacrificing flavour.

Flavour and Colour Enhancements

To appeal to different palates, fibre gummies often include natural flavourings such as fruit extracts. Colorants, preferably natural ones, like beet juice or turmeric, are used to make the gummies visually appealing. Ensuring these additives are natural is crucial for maintaining the product's health benefits.

Quality Control and Consistency

Right ratio of fibres and other ingredients (like sugars and gelling agents) is key. Achieving the right balance of these ingredients is critical for both texture and effectiveness. Excessive fibre can make gummies too firm, while insufficient amounts can reduce their health benefits. Manufacturers must carefully control the ratios to maintain consistent quality across batches.

Challenges in Fibre Gummy Production

Producing fibre gummies comes with challenges such as managing the high viscosity of fibre mixtures during production. Equipment used must be capable of handling this without affecting the flow or consistency of the mixture. Innovative gummy machines with precise controls are essential for overcoming these hurdles.

Inulin is the only soluble fibre in gummies.False

Other soluble fibres, like pectin, are also used in gummies.

Agar provides plant-based fibre in gummies.True

Agar is a gelling agent that offers plant-based fibre.

How Does Temperature Control Affect Manufacturing Fibre Gummies?

Understanding temperature's impact on fibre gummies is crucial for maintaining their quality. Temperature control influences texture, shelf life, and safety, ensuring these chewy supplements remain effective and enjoyable.

Temperature control in fibre gummies affects their texture and stability. Proper temperature management prevents issues like melting, hardening, or stickiness, ensuring consistent quality and shelf life.

Importance of Temperature in Gummy Production

Temperature plays a vital role in the production and quality of fibre gummies. These gummies require precise control to maintain desired texture and consistency. Incorrect temperatures can lead to gel breakdown3 or improper setting, negatively impacting product quality.

Texture and Stability

Fibre gummies are particularly sensitive to temperature variations. Too high a temperature during production can cause them to melt or lose their shape, while too low a temperature might lead to hardening. These effects compromise both the texture and the consumer's experience.

Table: Effects of Temperature on Fibre Gummies

| Temperature | Effect on Gummies |

|---|---|

| High | Melting, stickiness |

| Low | Hardening, brittleness |

Impact on Storage and Shelf Life

Proper storage conditions, including temperature control, are essential to prevent moisture absorption, which can lead to gummies becoming overly soft or sticky. Ensuring a consistent environment helps maintain their shelf life.

Gummy Manufacturing Equipment Considerations

Not all gummy production equipment can handle the specific needs of fibre gummies. Machines must be capable of precise temperature4 control and support higher viscosity mixtures to avoid clogs and ensure uniform mould filling. This is particularly important during the cooking and cooling processes, which requires delicate handling to achieve optimal texture.

|

|

|---|

Vacuum Cooker with pump enabling low-temp cooking for fiber-sensitive gummies, paired with precise temperature control panel for consistent, high-quality gummy production in a hygienic setup. | Machine Brand: SaintyCo

Best Practices for Temperature Management

Implementing precise temperature controls throughout the manufacturing process is vital. This includes:

- Monitoring: Continuous monitoring of cooking and depositing temperatures.

- Cooling: Controlled cooling processes tailored for fibre gummies.

- Storage: Keeping a stable storage environment to prolong shelf life.

By adhering to these practices, manufacturers can maintain the quality of fibre gummies, ensuring they meet consumer expectations and regulatory standards.

For more insights on gummy production, explore how different ingredients affect gummy texture5.

High temperatures cause gummy melting.True

Excessive heat during production causes gummies to melt, affecting texture.

Low temperatures improve gummy texture.False

Low temperatures lead to hardening, compromising the gummies' texture.

What Role Does Moulding Play in Maintaining Gummy Quality?

Moulding is crucial in gummy production, ensuring the right shape, texture, and consistency. Explore how the choice of moulds influences gummy quality, affecting everything from appearance to shelf life.

Moulding plays a vital role in maintaining gummy quality by determining shape, texture, and consistency. The choice of mould material and design impacts how gummies set, retain moisture, and their overall shelf life.

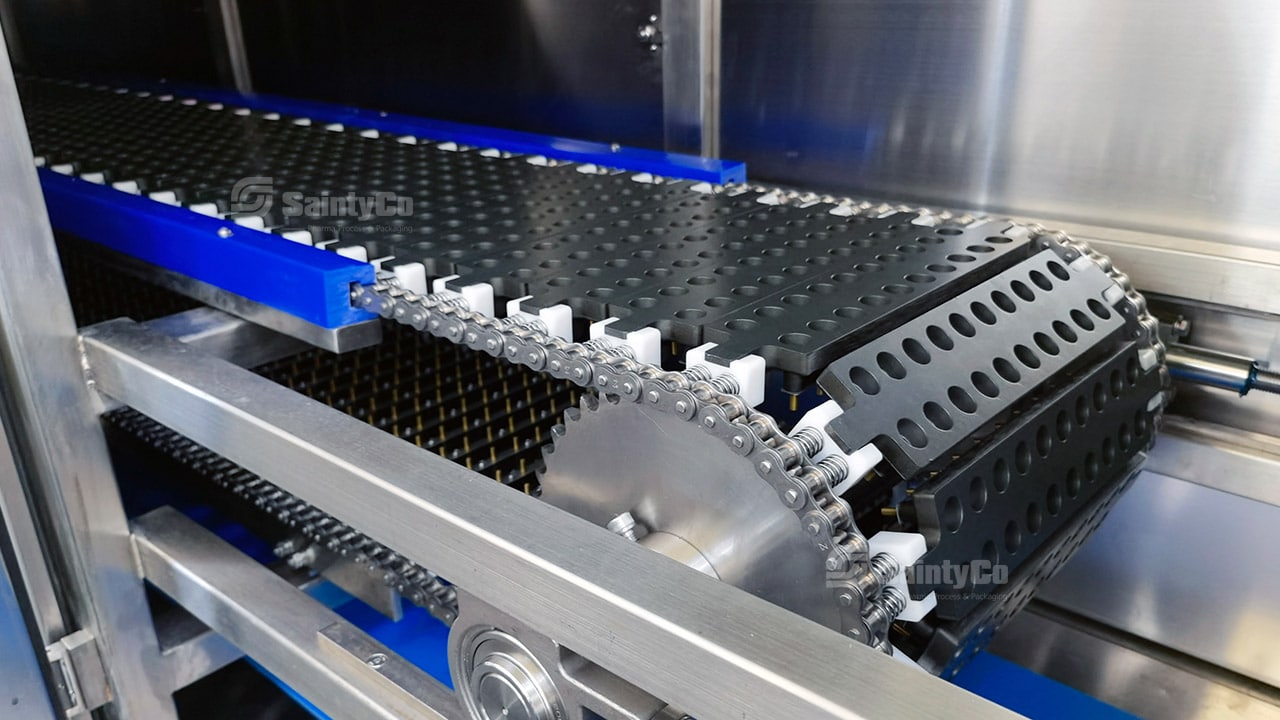

|

|

|---|

Gummy production equipment by SaintyCo ensuring seamless compatibility with both silicone and metal molds, enhancing production efficiency and flexibility for diverse gummy shapes and sizes in a high-performance manufacturing setting | Machine Brand: SaintyCo

Mould Material and Design

Choosing the right mould material is essential for ensuring gummy quality6. Silicon and polycarbonate moulds are popular due to their flexibility and durability. These materials prevent sticking and aid in easy demoulding without damaging the gummies.

Different mould designs can influence the final shape and size of gummies, affecting consumer appeal. A well-designed mould ensures even distribution of the mixture, crucial for maintaining uniformity in texture and taste.

| Mould Material | Benefits | Challenges |

|---|---|---|

| Silicone | Flexible, non-stick | Limited durability over time |

| Polycarbonate | Durable, high precision | Requires more maintenance |

Impact on Texture and Consistency

The texture of gummies is directly influenced by moulding. Proper moulding techniques ensure that gummies have a consistent texture, balancing softness with chewiness. Issues like air bubbles can be minimized by using precision moulds7.

Inconsistent mould filling can lead to varied textures within the same batch, which can affect consumer perception and satisfaction. It’s crucial to maintain a precise depositing speed to avoid these inconsistencies.

Moisture Retention and Shelf Life

Moulding also impacts the moisture retention capacity of gummies. A well-sealed mould helps in controlling the moisture content within each gummy, which is critical for shelf life and taste.

Improper moulding can lead to issues like uneven moisture distribution, resulting in a shorter shelf life or altered taste. Understanding the role of moisture control8 in moulding helps manufacturers produce gummies with longer shelf lives.

By considering these aspects, manufacturers can enhance the quality of their gummies, ensuring they meet consumer expectations for both taste and texture.

Silicone moulds improve gummy texture consistency.True

Silicone's flexibility aids in even distribution, enhancing texture.

Polycarbonate moulds reduce gummy shelf life.False

Polycarbonate moulds enhance precision, not directly affecting shelf life.

Why Is the Drying and Cooling Process Crucial for Texture of Fibre Gummies?

Understanding the drying and cooling process is vital for achieving the desired texture in food products, particularly in fibre gummies. This phase affects how gummies set and maintain their shape, impacting consumer satisfaction.

The drying and cooling process ensures that fibre gummies achieve optimal texture by controlling moisture content and firmness. Proper management during these stages prevents gummies from becoming too hard or sticky, enhancing their chewiness.

How Does Drying Impact Texture?

The drying phase is essential for removing excess moisture from fibre gummies. This step controls the moisture content9, which directly affects the gummy's firmness and chewiness. Too much moisture can lead

to a sticky texture, while too little can make them hard and brittle. Managing drying times and conditions, such as temperature and airflow, is crucial to maintaining product quality.

| Drying Condition | Impact on Texture |

|---|---|

| High Temperature | Rapid moisture loss; potential hardness |

| Low Temperature | Gradual drying; optimal chewiness |

Importance of Cooling in Texture Development

Cooling allows gummies to set and stabilize their structure post-drying. This stage is vital for achieving the desired firmness and preventing the product from becoming overly soft or losing shape. A controlled

cooling process also helps retain the flavour profile10 by preventing volatile compounds from evaporating.

The Role of Equipment in Drying and Cooling

Utilizing specialized equipment can enhance the efficiency of both drying and cooling processes. Machines designed for precise temperature control can manage fibre-rich formulations better, reducing issues like over-drying11 or insufficient setting. Investing in quality machinery with robust capabilities ensures consistent results and high-quality end products.

Understanding these processes is vital for manufacturers aiming to produce superior fibre gummies that meet consumer expectations. Each stage, from drying to cooling, plays a critical role in defining the final product's texture.

High temperature drying makes gummies harder.True

High temperatures cause rapid moisture loss, leading to hardness.

Cooling has no effect on gummy texture.False

Cooling stabilizes structure and prevents gummies from becoming soft.

How Can Packaging Improve the Shelf Life of Fibre Gummies?

Packaging plays a crucial role in extending the shelf life of fibre gummies by controlling moisture and preserving their texture. Understanding effective packaging techniques can significantly enhance product longevity.

To improve the shelf life of fibre gummies, packaging must control moisture and oxygen exposure. Vacuum-sealed bags or foil pouches are ideal as they provide a barrier against environmental factors that degrade quality.

The Role of Moisture Control

Fibre gummies are particularly susceptible to moisture due to their high fiber content. This sensitivity necessitates packaging that minimizes moisture absorption to maintain the gummies' texture and integrity. One effective solution is using vacuum-sealed packaging12, which removes air and creates a tight seal, significantly reducing moisture exposure.

Oxygen Barriers for Longevity

Oxygen can cause oxidation, leading to changes in taste and nutritional value. Packaging that acts as an oxygen barrier, such as foil-based pouches13, can help preserve the freshness of fibre gummies. These pouches are designed to block out air, thus preventing oxidation and prolonging shelf life.

| Packaging Type | Benefits |

|---|---|

| Vacuum-sealed Bags | Minimizes moisture |

| Foil Pouches | Prevents oxidation |

| Resealable Zipper Bags | Convenient for consumers |

The Importance of Storage Conditions

Optimal storage conditions also play a significant role in maintaining the quality of fibre gummies. Storing these products in a controlled environment14 with consistent temperature and humidity levels can prevent them from becoming sticky or hard.

Innovative Packaging Solutions

Emerging technologies in packaging offer novel solutions to extend the shelf life of fibre gummies. For example, incorporating active packaging15 that releases preservatives or absorbs excess moisture is gaining popularity. This technology actively interacts with the product, providing an additional layer of protection against environmental factors.

Vacuum-sealed bags reduce moisture in fibre gummies.True

Vacuum-sealing removes air, limiting moisture exposure, preserving texture.

Foil pouches allow oxygen to enter, causing oxidation.False

Foil pouches block air, preventing oxidation and extending shelf life.

What Regulatory Standards Must Fibre Gummies Meet?

Navigating the regulatory landscape for fibre gummies is crucial to ensure compliance and consumer trust. Understanding these standards helps manufacturers align with health and safety regulations, ensuring product quality and marketability.

Fibre gummies must meet regulatory standards set by authorities like the FDA, covering ingredient safety, labeling, and manufacturing practices. Compliance ensures product safety and consumer confidence, vital for market success.

Regulatory Frameworks for Fibre Gummies

Fibre gummies, often marketed as dietary supplements, are subject to regulatory scrutiny to ensure they meet health and safety standards. In the USA, the Food and Drug Administration16 oversees these products, focusing on key areas like ingredient safety, labeling requirements, and manufacturing practices.

Ingredient Safety

To comply with regulations, fibre gummies must use ingredients recognized as safe. This involves adhering to the Generally Recognized as Safe (GRAS) guidelines or obtaining approval for new ingredients. Manufacturers need to ensure that fibres like inulin or pectin are sourced from certified suppliers.

| Ingredient | Status |

|---|---|

| Inulin | GRAS |

| Pectin | GRAS |

| New Additives | Approval required |

Sourcing high-quality materials helps avoid issues related to compliance and product recalls. Transparency in ingredient sourcing builds consumer trust, especially in the nutraceutical sector.

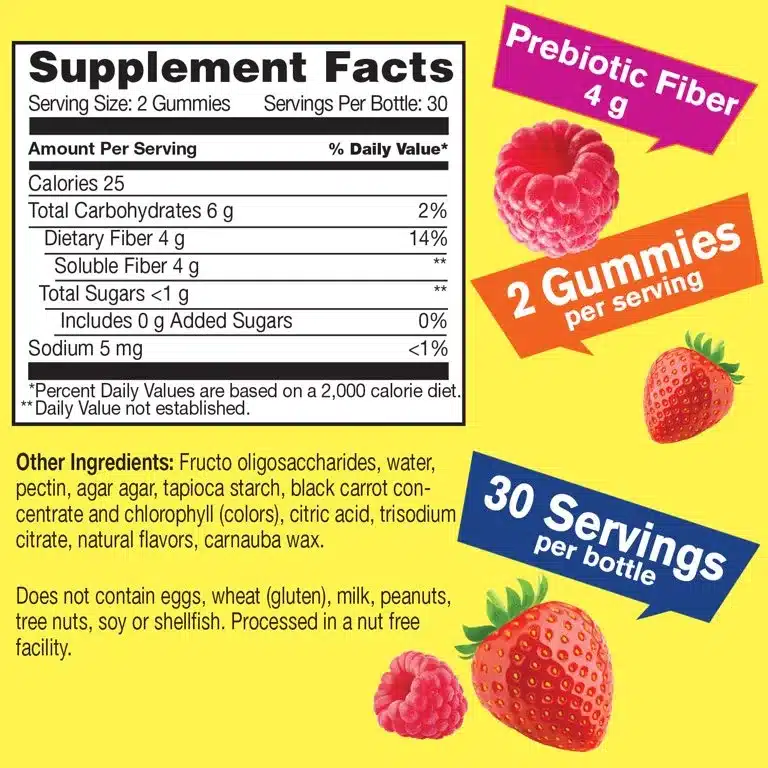

Labeling Requirements

Correct labeling is essential to meet regulatory standards. The label should clearly state:

- Nutritional Information

- Daily Value Percentage

- Warning Statements, if necessary

For fibre gummies marketed as dietary supplements, additional information like serving sizes and health claims must be precise. Misleading claims can lead to regulatory actions and damage brand reputation.

Manufacturing Standards for Fibre Gummies

Adhering to Current Good Manufacturing Practices (CGMP) is mandatory for ensuring the quality of fibre gummies. This includes:

- Facility Cleanliness

- Employee Training

- Consistent Quality Checks

Implementing robust quality control measures minimizes risks and ensures that the final product meets both regulatory standards and consumer expectations.

International Regulations

For businesses operating globally, understanding different countries' regulations is essential. The European Food Safety Authority17 sets similar guidelines, emphasizing ingredient verification and consumer safety.

Manufacturers need to tailor their processes to align with diverse regulatory landscapes, ensuring seamless market entry and sustained compliance across regions.

Challenges in Compliance

Maintaining compliance with evolving standards can be challenging. Continuous monitoring of regulatory changes and integrating them into manufacturing practices is necessary to stay ahead.

Utilizing technology for quality checks and documentation can streamline compliance efforts, ensuring that fibre gummies meet all required standards effortlessly. Additionally, industry partnerships18 offer valuable insights into best practices and regulatory updates.

Understanding these standards not only helps in legal compliance but also enhances brand reliability in a competitive market. By prioritizing quality and transparency, manufacturers can build lasting consumer relationships, fostering brand loyalty and growth in the fibre gummy sector.

Fibre gummies must meet FDA standards for ingredient safety.True

The FDA regulates ingredient safety in dietary supplements like fibre gummies.

Pectin in fibre gummies requires special approval from the FDA.False

Pectin is generally recognized as safe (GRAS) and doesn't need special approval.

Conclusion

Successful fibre gummies manufacturing hinges on ingredient selection, temperature control, moulding, and packaging to ensure quality, texture, and compliance with health regulations for optimal consumer satisfaction.

SaintyCo’s Solution for Fibre Gummy Production

At GummyGenix by SaintyCo, we provide innovative solutions to help you succeed in fibre gummy production. With machinery designed to handle the unique challenges of high-viscosity mixtures and precise temperature control, we ensure consistent, high-quality results.

Key Features of SaintyCo Equipment for Fibre Gummy Production

-

Advanced Temperature Control

Our machines offer precise cooking and depositing temperature regulation, perfectly suited for sensitive fibre mixtures. This ensures optimal texture and proper setting of the gummies. -

High Viscosity Management

Designed to handle the high viscosity of fibre-based ingredients, our depositing machines feature adjustable speed and flow control, preventing clogging and ensuring accurate mould filling. -

Customizable Moulding Options

We provide versatile moulding solutions tailored to the sticky and viscous nature of fibre gummies, ensuring they maintain their desired shape and texture. -

Efficient Cooling Systems

Our cooling tunnels, equipped with humidity and temperature controls, optimally set the gummies for a perfect balance of firmness and chewiness. -

Packaging Solutions

Automated packaging machines designed for moisture-sensitive products extend the shelf life of fibre gummies, ensuring proper sealing and reliable packaging.

Full Production Line Integration

Our fully integrated production lines streamline every step, from mixing and depositing to cooling and packaging, improving efficiency and minimizing downtime.

Why Choose GummyGenix by SaintyCo?

- Competitive Pricing: Affordable, top-tier equipment for a strong return on investment.

- GMP-Compliant Machinery: Precision-engineered to meet evolving industry standards.

- Flexible Financing: Partnered payment options and financing resources with potential tax benefits.

- Quick Startup SOPs: Basic recipes and workflows for a seamless start, with access to advanced formulation consultants and ingredient suppliers.

- Custom Molds & Recipes: Stand out with unique gummy shapes and tailored recipes.

- Comprehensive Support: From setup and training to troubleshooting, our team ensures smooth operations and lasting success.

Support for Your Growth

Whether you’re starting out or scaling up, SaintyCo offers:

- Initial setup and installation

- Team training

- Ongoing technical assistance

Partner with SaintyCo to excel in the fibre gummy market with confidence and efficiency.

Contact GummyGenix by SaintyCo, you’ll gain the expertise, resources, and support to build a thriving gummy production business. Let’s succeed together.

Gummy Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Inulin is a prebiotic that supports digestive health by fostering beneficial gut bacteria. Learn more about its advantages. ↩

-

Erythritol is a low-calorie sweetener that doesn't spike blood sugar levels, making it ideal for health-conscious consumers. ↩

-

Learn about how gel breakdown affects gummy quality and consistency. ↩

-

Understand why precise temperature control is critical in gummy production for consistency. ↩

-

Discover how various ingredients can influence the texture of gummies. ↩

-

Explore the benefits of using silicon and polycarbonate moulds to ensure high-quality gummy production with reduced sticking and easier demoulding. ↩

-

Discover how precision moulds minimize air bubbles, ensuring consistent texture and enhancing overall gummy quality. ↩

-

Learn why controlling moisture during moulding is vital for extending gummy shelf life and maintaining their taste and texture. ↩

-

Exploring this link reveals how moisture levels influence gummy texture, helping manufacturers achieve optimal chewiness. ↩

-

This link discusses how cooling impacts flavor retention, ensuring your gummies maintain their intended taste. ↩

-

Discover the consequences of over-drying on food texture to prevent common pitfalls in gummy production. ↩

-

Learn how vacuum-sealed packaging keeps food fresh by minimizing air exposure, enhancing product longevity. ↩

-

Explore how foil pouches act as a barrier to oxygen, preserving the taste and quality of food. ↩

-

Discover why maintaining specific temperature and humidity levels is crucial for gummy preservation. ↩

-

Find out how active packaging technology can extend the shelf life of food products by interacting with their environment. ↩

-

Explore FDA guidelines for dietary supplements to understand necessary compliance measures for fibre gummies. ↩

-

Learn about European regulations to ensure international compliance for fibre gummy products. ↩

-

Discover how partnerships can aid in staying updated with regulatory changes and best practices. ↩