Curious about how to make CBD gummies?

To create high-quality CBD gummies, start by choosing the right CBD extract and ensuring compliance with local regulations. Pay attention to ingredient selection and dosage precision, and utilize proper infusion techniques for the best results.

In this blog post, we’ll delve deeper into each step of the process, providing you with expert tips and essential knowledge to elevate your gummy-making experience. Let's explore the details that can make or break your homemade CBD gummies.

Choosing the right CBD extract is crucial for gummies.True

The type of CBD extract affects the quality and effectiveness of the gummies, making it essential for optimal results.

Ingredient selection does not impact gummy quality.False

The ingredients used in making CBD gummies directly influence their taste, texture, and overall quality, making careful selection important.

What are the best CBD extracts for gummies?

Exploring the best CBD extracts for gummies can be crucial for both manufacturers and consumers looking for effective options. Let's dive into what makes a quality CBD extract.

The best CBD extracts for gummies include full-spectrum, broad-spectrum, and isolate options. Each offers distinct benefits tailored to user needs, influencing factors like potency and desired effects.

Understanding CBD Extracts for Gummies

CBD extracts play a pivotal role in the effectiveness of gummies. The main types available include full-spectrum, broad-spectrum, and isolate. Each type has unique properties and benefits that cater to different user needs.

- Full-Spectrum CBD: This extract contains all cannabinoids found in the hemp plant, including trace amounts of THC. Users often report enhanced effects due to the entourage effect, where various cannabinoids work synergistically.

- Broad-Spectrum CBD: Similar to full-spectrum but without THC. This option is ideal for those seeking the benefits of multiple cannabinoids without the psychoactive effects of THC.

- CBD Isolate: This is the purest form of CBD, containing no other cannabinoids or THC. It is perfect for users who want to avoid any other compounds altogether.

By selecting the right extract, manufacturers can cater to specific health benefits, such as pain relief or anxiety reduction. Consider conducting market research to understand your target audience's preferences regarding these extracts.

Key Factors in Choosing CBD Extracts

When choosing the best CBD extracts for gummies, several factors come into play:

- Source of Hemp: Ensure the hemp used for extraction is organically grown. This guarantees that it’s free from harmful pesticides and other chemicals.

- Extraction Method: CO2 extraction is preferred for its ability to preserve the purity and potency of CBD while eliminating unwanted compounds.

- Third-Party Testing: Look for products that have been tested by independent labs. This adds credibility and ensures product quality.

- Label Transparency: Clear labeling with dosage information and extraction methods helps consumers make informed decisions.

Top Brands Offering Quality CBD Extracts

| Brand Name | Type of Extract | Key Features | Rating |

|---|---|---|---|

| Brand A | Full-Spectrum | Organically grown, lab-tested, diverse cannabinoid profile | 4.8/5 |

| Brand B | Broad-Spectrum | No THC, strong anti-inflammatory properties | 4.5/5 |

| Brand C | Isolate | Pure CBD, great for those avoiding THC | 4.7/5 |

This table highlights some reputable brands that provide high-quality CBD extracts suitable for gummies. Researching and comparing such brands will help you select the best options for your production needs.

Consumer Preferences and Trends

Understanding consumer preferences is vital when selecting CBD extracts for gummies. Many consumers are leaning towards products that emphasize:

- Health Benefits: Popular claims include pain relief, anxiety reduction, and sleep aid. Align your extracts with these demands to attract buyers.

- Taste and Texture: Gummies should taste good and have a pleasant texture. Combining quality extracts with tasty flavors can enhance consumer satisfaction.

- Sustainability: Eco-friendly packaging and sustainably sourced ingredients are becoming increasingly important to consumers. Explore ways to integrate sustainability into your product line.

For more insights on selecting extracts that resonate with consumer trends, check out consumer preferences in CBD1.

Full-spectrum CBD enhances effects due to the entourage effect.True

Full-spectrum CBD contains all cannabinoids, including THC, which can enhance overall effectiveness through synergistic interaction among compounds.

CBD isolate is the purest form of CBD available.True

CBD isolate contains only CBD without any other cannabinoids or THC, making it the purest option for consumers wanting to avoid other compounds.

How can I enhance the flavor of my CBD gummies?

Discover effective ways to elevate the taste of your CBD gummies! From natural sweeteners to unique flavoring agents, learn how to make your gummies more enjoyable.

To enhance the flavor of your CBD gummies, consider using natural sweeteners, fruit extracts, and flavoring agents like essential oils or spices. Experimenting with high-quality ingredients also contributes significantly to taste improvement.

Experiment with Natural Sweeteners

Natural sweeteners can transform the flavor profile of your CBD gummies. Consider using honey, maple syrup, or agave nectar to provide a pleasant sweetness without the aftertaste of artificial options.

These sweeteners not only improve flavor but also add unique health benefits. For example, honey is known for its antioxidant properties.

| Sweetener Type | Flavor Profile | Health Benefits |

|---|---|---|

| Honey | Floral, sweet | Antioxidant |

| Maple Syrup | Caramel-like | Rich in minerals |

| Agave Nectar | Mild, sweet | Low glycemic |

Try combining different natural sweeteners for a custom taste that suits your preferences!

Infuse with Fruit Extracts

Fruit extracts can enhance the flavor and aroma of your CBD gummies significantly. Using concentrated extracts from berries or citrus fruits can introduce a refreshing twist.

Incorporating fruit juices or purees during production can also create a vibrant flavor experience. Consider using:

- Strawberry extract for a berry burst

- Lemon juice for a zesty kick

- Mango puree for tropical sweetness

Optimize Your Gummy Base

The base of your gummy is just as important as its flavoring agents. Using gelatin or pectin can influence texture and taste. Experimenting with different ratios can lead to a more enjoyable product.

Consider the following when selecting your gummy base:

- Gelatin: Provides a firmer texture; ideal for traditional gummies.

- Pectin: Vegan alternative; results in a softer chew.

Both options can be flavored differently depending on the additional ingredients you choose to use.

Add Flavoring Agents

In addition to sweeteners and fruit extracts, incorporating various flavoring agents can elevate your gummies. Options include:

- Citric acid: Adds tartness and enhances fruit flavors.

- Essential oils: Use food-grade oils like peppermint or orange for an aromatic experience.

- Spices: A hint of cinnamon or ginger can introduce warmth and depth to the flavor.

Using these agents in moderation ensures you do not overpower the natural essence of CBD while enhancing the overall taste. For best practices on adding flavor, explore these tips2 on optimizing taste profiles.

Use Flavor Masking Techniques

If your CBD extract has a strong or bitter taste, consider using masking techniques to improve palatability. Techniques may involve:

- Balancing flavors: Combine sweet and sour to counteract bitterness.

- Layering flavors: Introduce multiple flavors that complement each other, such as mixing berry with citrus.

- Temperature control: Heating certain ingredients can mellow out strong flavors before infusion.

Experimentation is key here; find what works best for your specific formulation.

Quality Ingredients Matter

Lastly, the quality of your ingredients will directly affect the flavor of your CBD gummies. Always opt for high-quality, organic ingredients whenever possible.

By investing in quality raw materials, you not only enhance flavor but also improve the overall health profile of your gummies. Consider sourcing local ingredients for freshness and potential cost savings. You can learn more about ingredient sourcing strategies here3.

Natural sweeteners can improve CBD gummy flavor.True

Using honey, maple syrup, or agave nectar enhances taste and adds health benefits to CBD gummies.

Pectin is a firmer base for CBD gummies than gelatin.False

Gelatin provides a firmer texture, while pectin results in a softer chew for gummies.

What equipment do I need for making CBD gummies?

Are you ready to dive into the world of CBD gummy production? Discover the essential equipment you'll need to create delicious and compliant gummies.

To make CBD gummies, you need specialized equipment including cooking vessels, depositors, molds, cooling systems, coaters (optional), and packaging machinery. Each plays a vital role in ensuring quality and consistency.

Essential Equipment for Making CBD Gummies

To create CBD gummies, a variety of equipment is necessary, whether you're starting on a small scale or venturing into larger production. Here’s a breakdown of the essential tools and machines required:

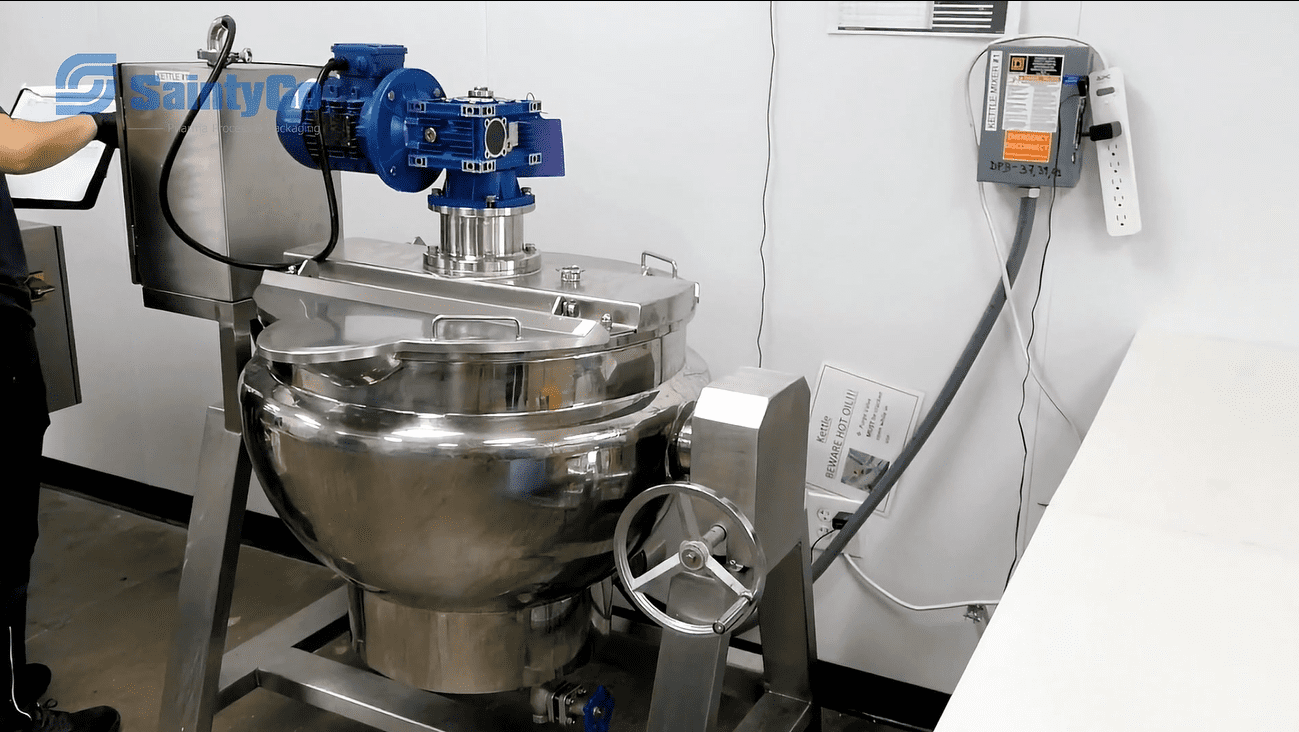

1. Cooking Equipment

Cooking equipment is vital for precise ingredient preparation and ensuring consistent quality in gummy production:

- Jacketed Kettles: Designed for controlled heating and mixing, these kettles evenly dissolve ingredients like gelatin or pectin while preventing overheating. Essential for creating a smooth and homogenous mixture.

- High-Shear Mixers: Ideal for blending active ingredients such as CBD with other components, ensuring uniform infusion and reducing processing time.

- Stirring and Scraping Tools: Automated stirring systems with Teflon scrapers maintain even mixing and prevent residue buildup, enhancing the efficiency of your cooking process.

|

|

|---|

Jacket Cooker with High-Shear Mixer blending vibrant gummy candy mixture in a modern facility | Machine Brand: SaintyCo

2. Depositing Units

Depositing units are essential for pouring the mixture into molds accurately, ensuring consistent gummy sizes:

- Automatic Depositor: Provides precision and speed, ideal for larger batches.

- Manual Depositor: A good option for small-scale production where flexibility is needed.

3. Molds

Molds shape your gummies and come in various designs and sizes:

- Silicone Molds: Flexible and easy to release gummies, available in various shapes.

- Metal Molds: More durable but can require additional lubrication to release gummies easily.

4. Cooling Systems

Cooling systems are vital after depositing to ensure gummies set properly:

- Refrigeration Unit: Helps accelerate cooling, ensuring gummies achieve the desired texture quickly.

- Cooling Tunnel: For larger operations, a cooling tunnel can streamline the process, allowing continuous production.

5. Packaging Equipment

Once your gummies are made, packaging them correctly preserves their quality:

- Bottling Machines: Automated bottling systems ensure precise filling of gummies into bottles, maintaining hygiene and consistency. They streamline operations, especially in high-output production lines.

- Bagging Machines: Ideal for flexible packaging needs, these machines efficiently pack gummies into bags, catering to a wide range of pouch sizes and materials.

- Sealing Machines: Ensure your gummies are airtight, protecting them from moisture and light.

- Labeling Machines: Essential for compliance with regulations; labels must include dosage and ingredient information.

Summary Table of Equipment Needed

| Equipment Type | Purpose | Recommended Type | |

|---|---|---|---|

| Cooking Equipment | Melting and mixing ingredients | Electric Jacket Kettle with a high shear mixer | |

| Depositing Units | Accurate gummy shaping | Automatic/manual depositor | |

| Molds | Shaping gummies | Silicone/metal molds | |

| Cooling Systems | Setting gummies | Refrigeration unit/cooling tunnel | |

| Packaging Equipment | Preserving quality | Bottling/Bagging/Sealing/labeling machines |

Each piece of equipment plays a vital role in the gummy-making process. Investing in quality machinery ensures that you produce high-quality CBD gummies that meet regulatory standards. For more detailed insights into each category of equipment, check out our guide on choosing the right gummy machinery4.

A double boiler is essential for making CBD gummies.True

A double boiler prevents burning while melting ingredients, crucial for proper CBD infusion.

Metal molds are the best option for gummy production.False

While durable, metal molds require lubrication and can be less flexible than silicone molds, which are easier to use.

How do I ensure consistent dosage in my gummies?

Achieving consistent dosage in your gummies is essential for safety and effectiveness. Here’s how you can ensure precision every step of the way.

To ensure consistent dosage in your gummies, accurately measure ingredients, use automated gummy production equipment, apply proper mixing techniques, and conduct lab tests on batches to verify content. Proper packaging also plays a critical role in maintaining potency.

Watch this client video showcasing gummy production with SaintyCo's DM-50X Gummy Depositor in action!

Understanding Dosage Consistency

To ensure that each gummy has a consistent dosage, it's critical to understand the measurement of ingredients. The accuracy in measuring your CBD or THC extract is paramount.

Using a digital scale for weighing ingredients can greatly improve your precision. For example, if you're making a batch of 100 gummies and want each gummy to contain 10mg of CBD, you should start with 1000mg of CBD extract. This calculation is simple but crucial. Calculate your dosage5.

Equipment for Consistent Production

Investing in automated production equipment can significantly enhance dosage consistency. SaintyCo Gummy Making Machines like the DM-50X or G300 are designed to ensure uniformity and accuracy during the production process.

Here's a comparison table of common equipment:

| Equipment | Type | Benefits |

|---|---|---|

| DM-50X Depositor | Semi-automatic | Cost-effective for small and R&D batches |

| G300 Gummy Production Line | Fully automatic | High precision and ideal for large scale |

| Manual mixers | Traditional | Low cost but less accuracy in dosing |

Mixing Techniques

Proper mixing techniques are also essential. When combining your ingredients, ensure that the CBD is evenly distributed throughout the mixture. This can be achieved by using a high-shear mixer or even a simple kitchen blender, depending on your scale.

Tip: Allow the mixture to sit for a few minutes after mixing, as this helps to reduce air bubbles and allows the CBD to settle evenly.

Testing for Dosage Accuracy

Before going into full production, test a small batch for dosage accuracy. After producing a sample, test several gummies in a lab to ensure that they contain the desired amount of CBD or THC. If discrepancies are found, adjust your mixing or weighing methods accordingly.

Packaging Considerations

Once gummies are made, packaging plays a role in maintaining their consistency. Airtight, opaque containers help protect from moisture and light, which can degrade potency and lead to inconsistent dosing over time.

For more on how packaging affects potency, check out packaging best practices6.

Using a digital scale improves dosage accuracy in gummies.True

A digital scale provides precise measurements of ingredients, ensuring each gummy contains the correct dosage of CBD or THC for consistent results.

Automated equipment guarantees perfect dosage every time.False

While automated equipment enhances consistency, perfect dosage is not guaranteed; proper measurement and mixing techniques are still crucial for accuracy.

Conclusion

This guide provides expert tips on making CBD gummies, focusing on extract selection, ingredient quality, dosage accuracy, and necessary equipment for optimal results.

At GummyGenix by SaintyCo, we don’t just provide equipment—we empower your gummy business with solutions tailored to your success. Here’s what makes us the ideal partner for your venture:

- Competitive Pricing: Top-tier machinery at affordable rates, ensuring a strong return on investment.

- High-Quality Machinery: GMP-compliant, precision-engineered equipment designed to meet evolving industry standards.

- Equipment Financing & Referral Support: Access flexible payment options and financing resources through our trusted partners, helping you secure affordable payments and potential tax advantages.

- Quick Startup SOPs: Basic recipes and production workflows for a fast, hassle-free start. Additionally, we can connect you with leading formulation consultants and global ingredient suppliers for more advanced product development.

- Custom Molds & Recipes: Stand out in the market with bespoke gummy shapes and innovative recipes tailored to your brand.

- Comprehensive After-Sales Support: From setup and training to troubleshooting, we provide the guidance needed to ensure smooth operations and sustained success.

Contact GummyGenix by SaintyCo, you’ll gain the expertise, resources, and support to build a thriving gummy production business. Let’s succeed together.

Gummy Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Discovering reliable information on CBD extracts can help you choose the right product for your gummy production needs. ↩

-

Explore effective methods to elevate the flavor of your CBD gummies, ensuring a more enjoyable consumption experience. ↩

-

Discover sourcing strategies that can help you select high-quality ingredients for improved flavor in your CBD products. ↩

-

Clicking this link provides comprehensive insights into the best equipment options available for gummy making, ensuring you invest wisely in your production setup. ↩

-

Discover effective methods to maintain dosage consistency in your homemade gummies for better results. ↩

-

Explore the best equipment options to improve your gummy production process for consistent results. ↩