Empowering CBD Startups

A Comprehensive Machinery Solution Enhances Gummy Production for a Texas Entrepreneur

Working with GummyGenix by SaintyCo, Mr. Jason launched his gummy business and hit multiple milestones. This partnership prioritized refining the startup’s production process, enhancing machinery efficiency, cutting costs, and connecting Mr. Jason to top industry resources. Consequently, there was a marked enhancement in production efficacy and a notable increase in market visibility.

Mr. Jason, leveraging his decade-long expertise in the CBD sector, aimed to produce 800,000 monthly broad-spectrum CBD gummies in flavors such as Strawberry and Tropical Fruit, ensuring they are gluten-free, vegan, and pectin-based. Facing a $45,000 budget and setbacks from two failed batches that cost $4,000, Mr. Jason’s limited expertise in gummy production highlighted the pressing need for a reliable machinery partner.

After evaluating multiple suppliers, Mr. Jason chose GummyGenix by SaintyCo, not just for our proven track record, but because we truly understood the unique challenges faced by North American startups. Our comprehensive machinery offerings and commitment to client success were pivotal in his decision.

SOLUTIONS PROVIDED

- Tailored Equipment Solutions

- Recipe Consultation

- Setup Guidance

- Operator Training

GUMMY MANUFACTURING EQUIPMENT PROCURED

- DM-20S Gummy Depositor

- Custom Gummy Molds

- 100L Electric Tilt Sugar Dissolving Kettle

- Drying Trays & Dollies

- Sugar/Wax Polishing Pan

KEY WINS

- Kickstarted gummy production within 2 months on a $45k budget

- Avoided expanding the facility

- Operated without adding new labor

- Rolled out vegan CBD gummies praised for their genuine flavor without bitterness

Client Profile: Mr. Jason's Foray into CBD Gummies Production

Name: Mr. Jason

Industry: CBD Production & Gummy Manufacturing

Team: a dedicated team of 5 members

Location: Texas, USA

Prior Endeavors: Mr. Jason’s expertise spanned a range of CBD products, from prerolls and cartridges to a curated selection tailored for health-food aficionados, functional beverage enthusiasts, and the cosmetics sector.

Challenge Faced: Financial Limitations and Gummy Production Intricacies

As Mr. Jason’s team ventured into the dynamic functional gummies market, they navigated challenges from budgetary constraints to maintaining product quality.

- Budget Constraints: Balancing funds between machinery investment, training, and product quality.

- Space Efficiency: Maximizing limited space for machinery and storage.

- Employee Training: Ensuring machinery is user-friendly for efficient staff training.

- Hygiene & Quality: Prioritizing top-notch hygiene, especially for health-centric products.

- Precision & Consistency: Guaranteeing accurate dosage in each gummy to uphold consumer trust and ensure product reliability.

Mr. Jason’s ambition was to establish a strong foothold in the functional gummies market. He envisioned starting on a smaller scale and then expanding, ensuring consistent business growth and consumer trust. Addressing these challenges was crucial, and GummyGenix by SaintyCo was poised to assist.

Our Solution: Tailored Machinery Suite and Support for Startup Success

Understanding the Vision

Recognizing Mr. Jason’s business goals, Leo, our seasoned global sales director, embarked on comprehensive consultations to ensure alignment with his strategic vision.

Customized Machinery Solutions for Streamlined Gummy Production

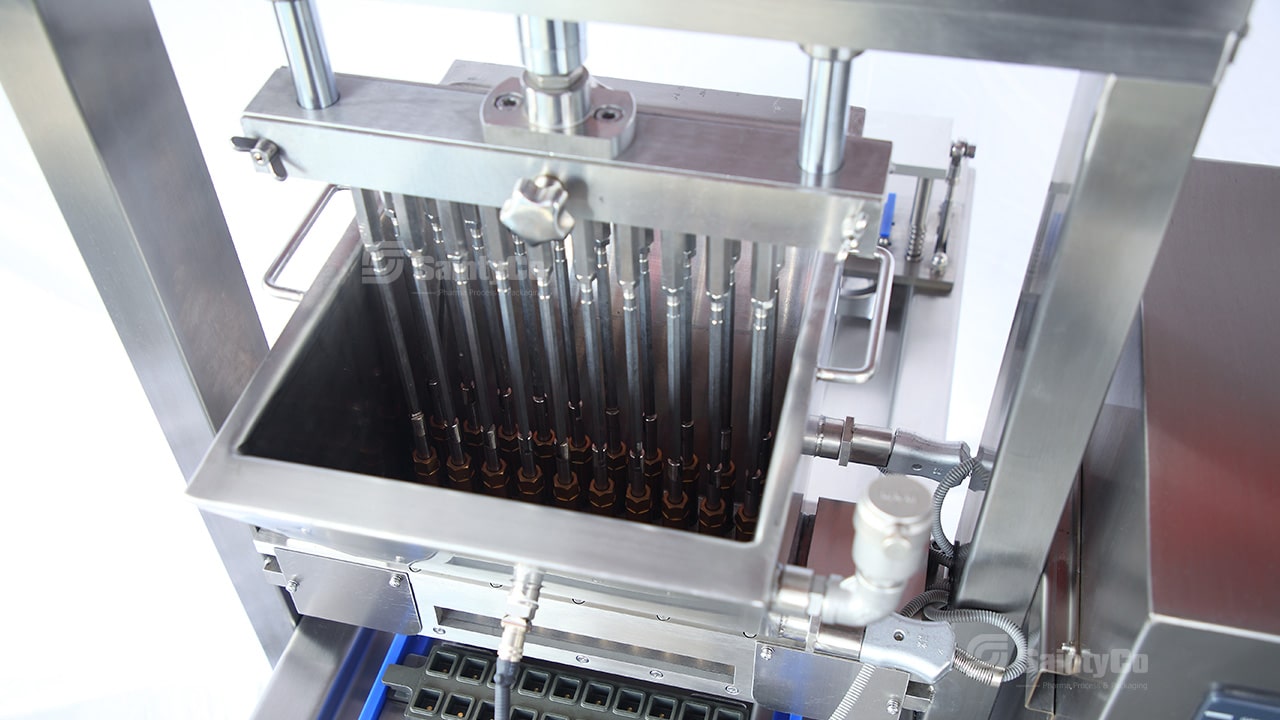

1. DM-20S Gummy Depositing Machine:

- Purpose: Designed for adaptability in producing both pectin and gelatin-based CBD/THC gummies, offering cost-effective solutions.

- Key Features:

- Efficiency: Produces up to 10,000 gummies/hr, making it ideal for startups and R&D.

- Space-Efficient: Just 120 sq ft, inclusive of an integrated demolding device.

- Quality & Hygiene: Constructed using pharma-grade stainless steel, ensuring product safety.

- Quick Setup: Its plug-and-pull design ensured Mr. Jason’s team, with only one trained operator, could set it up within an hour, minimizing downtime.

- Ease of Use: Full training completed in just 30 minutes.

- Certifications: Meets top industry standards.

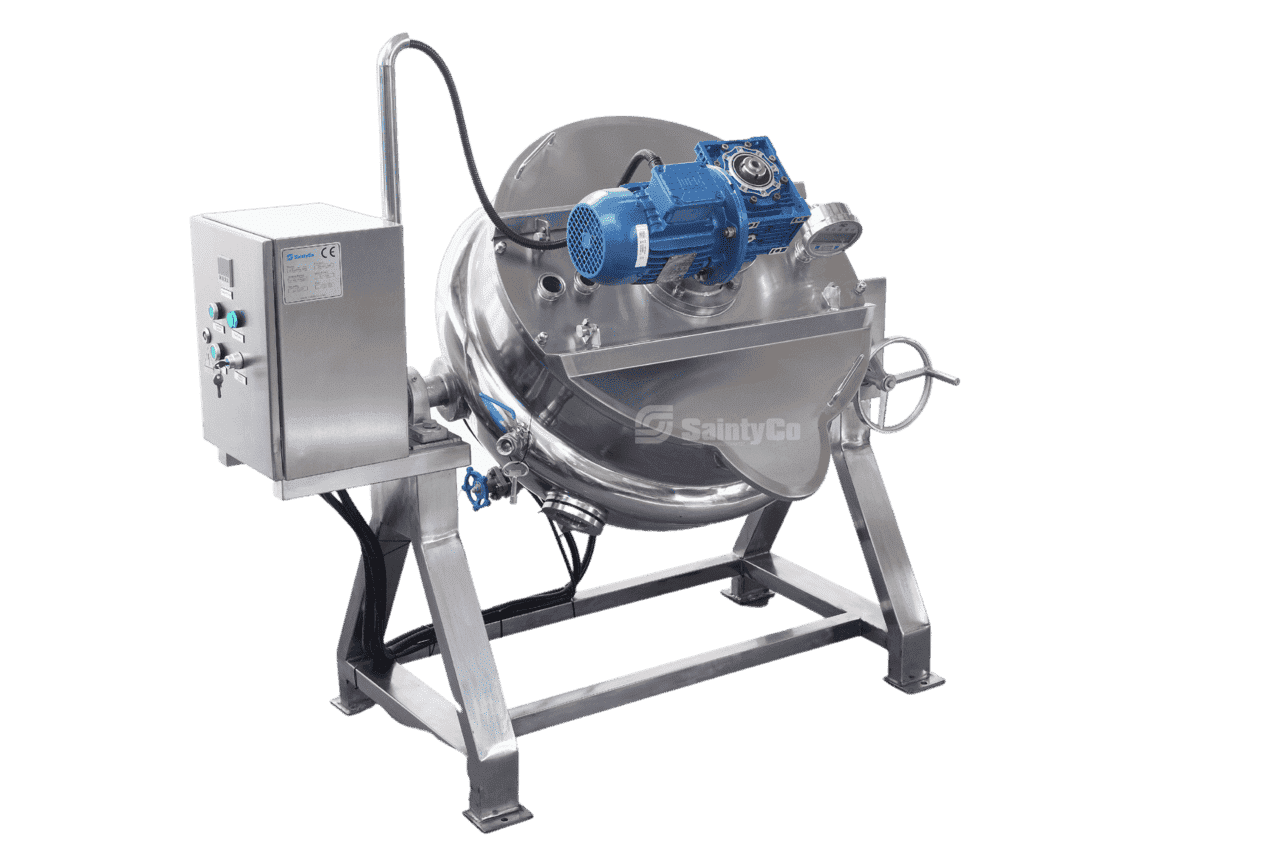

2. 100L Electric Tilt Sugar Dissolving Jacketed Kettle:

- Purpose: Delivers consistent syrup texture for premium gummies.

- Key Features:

- Precision: Accurate temperature and mixing controls.

- Efficiency: Reduces prep time by 20% with advanced heating.

- Safety: Uses SS 316-grade for food-contact components.

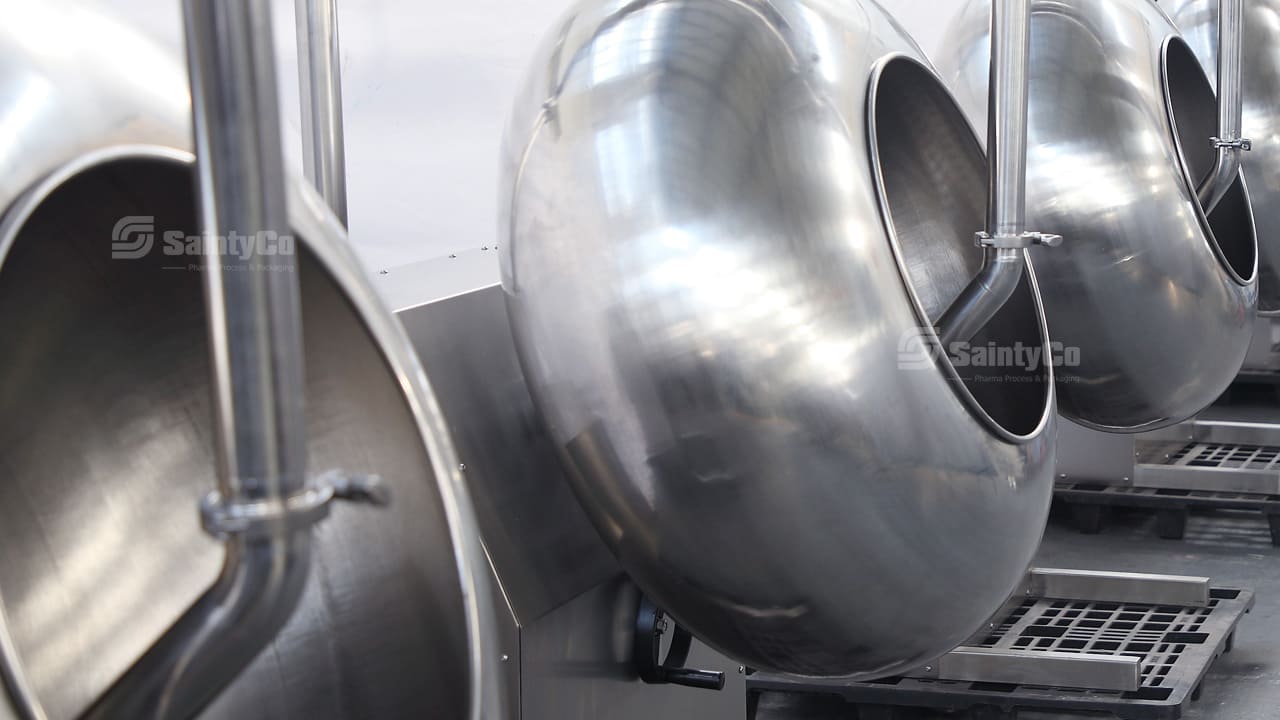

3. Sugar/Wax Polishing Pan:

- Purpose: Imparts a professional finish to gummies.

- Key Features:

- Labor-Saving: Handles 70-90kg/hour.

- Accuracy: Speed inverter and control panel for accurate adjustments.

- Clump-Free: Designed for smooth, consistent mixing.

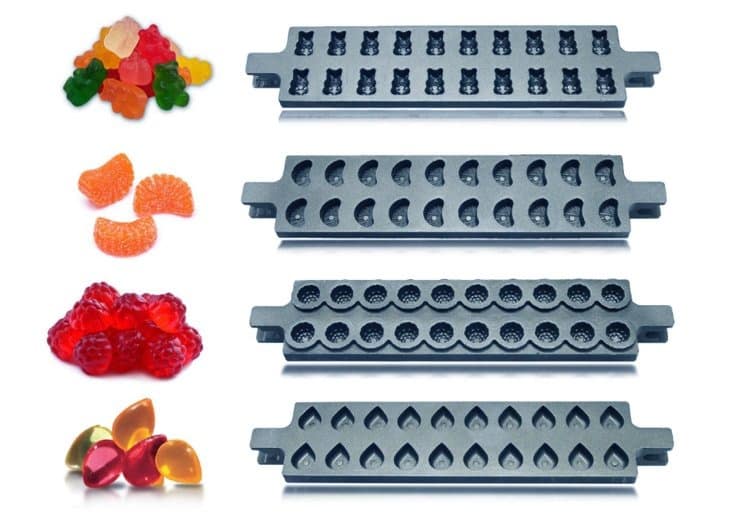

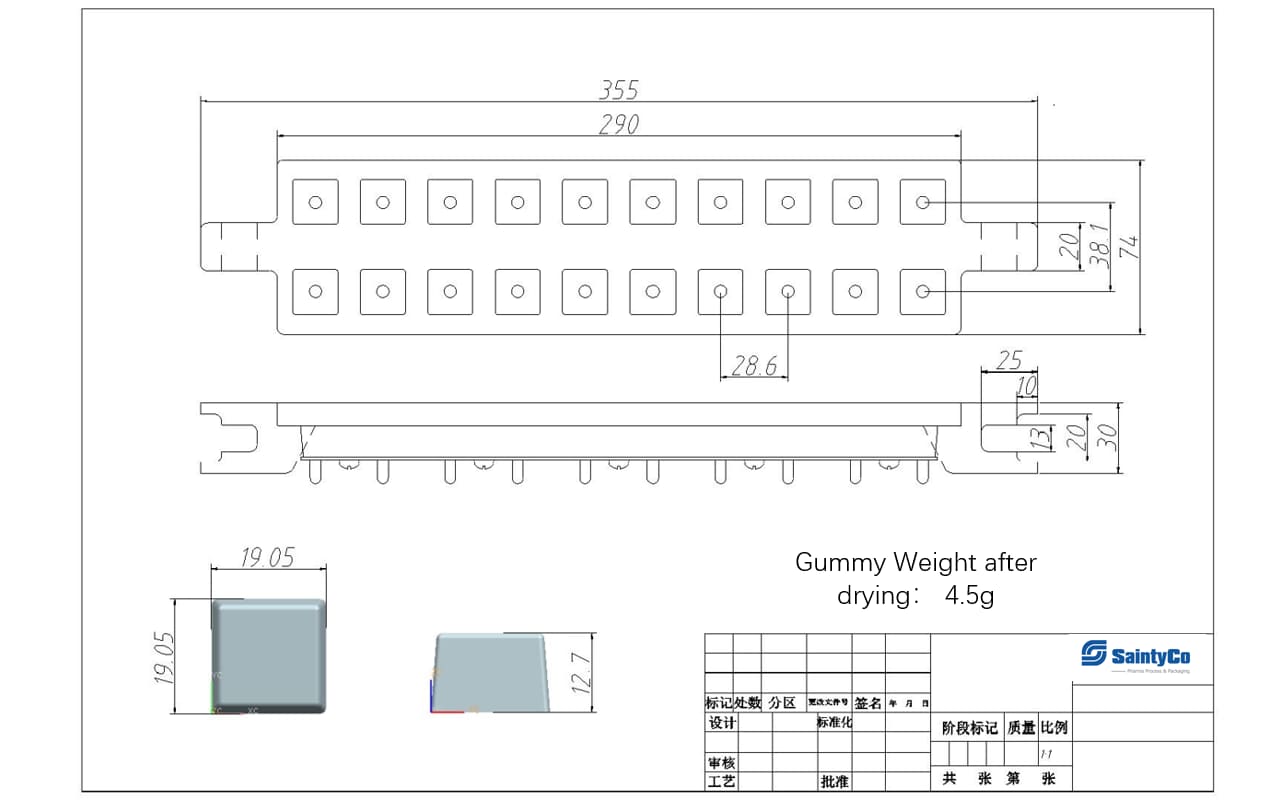

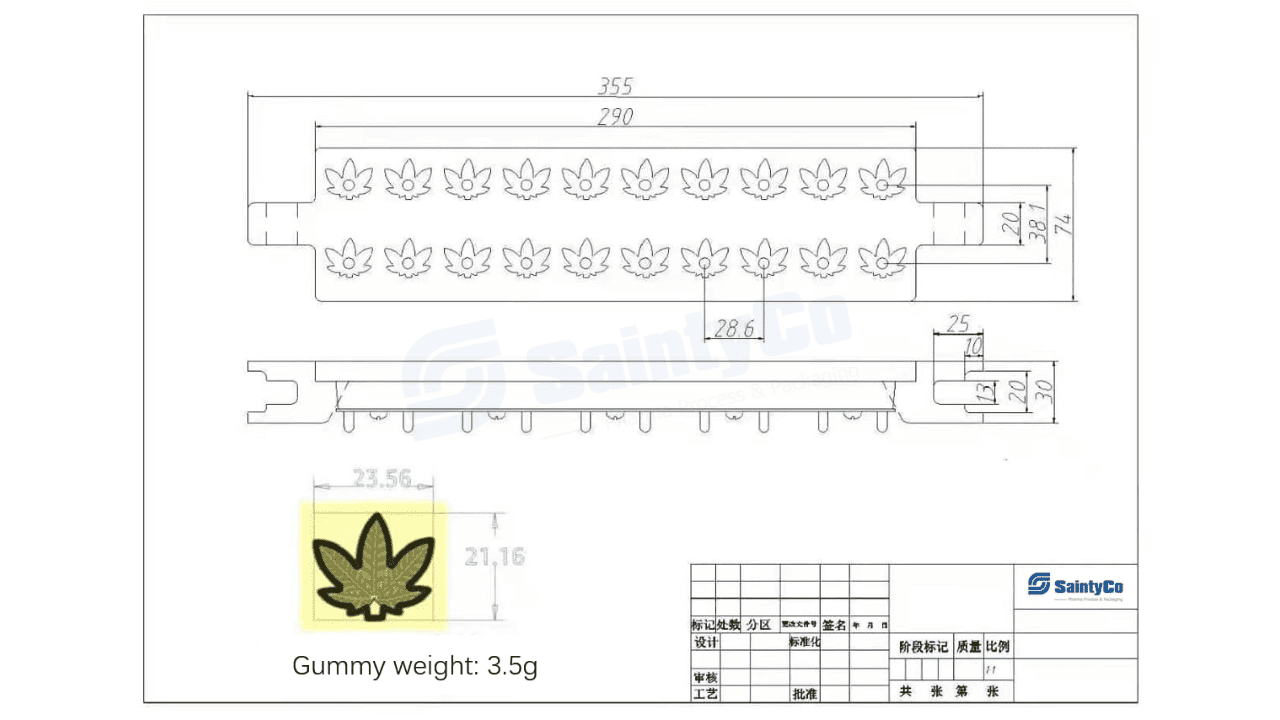

4. Gummy Metal Molds (100 pieces):

- Purpose: Precision molding for gummies.

- Key Features:

- Hygiene: Teflon-coated with stainless-steel ejection.

- Branding: Detailed logo imprinting capability.

- Consistency: 20 cavities per mold ensure uniform output.

- Versatility: Variety of shapes, from standard to custom.

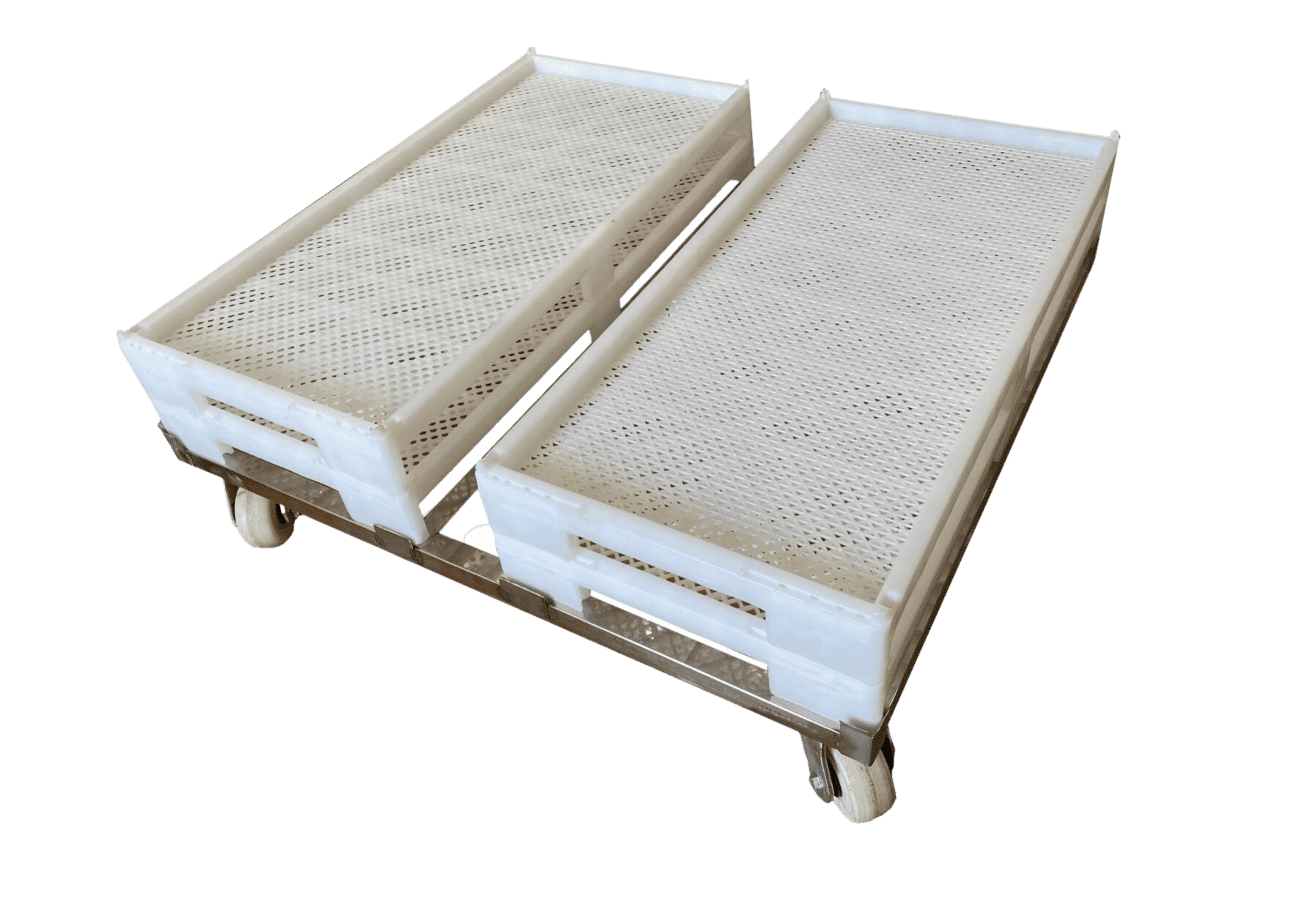

5. Drying Trays (60 pieces) & Dry Tray Dollies (2 pieces):

- Purpose: A cost-effective solution for optimal gummy drying.

- Key Features:

- Capacity: Each tray holds 2-3kg of gummies.

- Material: Durable PE+PP blend.

- Space-Saving: Stackable design saves 40% storage space.

- Efficiency: Mobile dollies support up to 50 trays, enhancing workflow by 25%.

Customer Support

More than just providing machinery, we empowered Mr. Jason with our proven gummy formulations, laying the foundation for superior product quality. We also connected him with vetted ingredient sources and ensured ongoing support.

Regulatory Assurance

SaintyCo’s machinery is designed to meet international standards such as FDA, cGMP, GMP, and ISO 9001, ensuring startups in the CBD sector uphold the high quality benchmarks.

Result: Maximizing ROI with Cost-Effective Production Solutions

In November 2022, Mr. Jason onboarded GummyGenix by SaintyCo’s advanced machinery. By February 2023, this investment resulted in a 30% surge in production output. This progression exemplifies the real-world advantages startups can harness with machinery that melds fiscal prudence with operational excellence.

With SaintyCo, Mr. Jason didn’t merely procure equipment; he invested in a high-performance solution that respects financial constraints.

As Mr. Jason’s gummies gain market traction, our commitment at GummyGenix by SaintyCo is unwavering. Aware of the pivotal decisions startups grapple with, we focus on offering solutions that align with budgetary considerations while fueling business expansion. With us, it’s not just about machinery; it’s about ensuring every investment decision contributes directly to the bottom line.

What Our Clients Say:

Venturing into the gummy sector presented its set of challenges. Yet, our collaboration with GummyGenix by SaintyCo turned these challenges into growth opportunities. Beyond just supplying machinery, GummyGenix empowered us with essential knowledge and connected us with key industry contacts. Their total support, clear communication, and expertise have been instrumental in the success of our gummies. With GummyGenix, it wasn't merely a supplier-client relationship; it felt like a genuine partnership, with both parties invested in mutual success.

Are you looking for an expert in gummy machine solutions who truly understands your startup’s challenges? Let’s talk today >

GummyGenix, a dynamic arm of SaintyCo International Group, leverages its parent company’s pharmaceutical machinery expertise to provide cutting-edge automated gummy production and packaging solutions worldwide, tailored for the confectionery, cannabis, and nutraceutical industries. Our genuine commitment lies in helping you to be more successful.

From compact R&D gummy depositor units to versatile gummy production lines covering kitchen setups and packaging machinery for finished gummies, our solutions are designed to save time and resources, boosting your profitability.

Our value goes beyond machinery. We offer comprehensive support, including customized gummy formulations, facility layout design, manufacturing operations, and training. With two decades of partnership-building, we are dedicated to bringing innovation, one-stop solutions, and proactive customer service to you. Schedule a call to learn more.

Let's start the conversation

How can we help you succeed?

Partnering with GummyGenix, you will benefit from:

Expertise: Over 20 years in confectionery and pharmaceutical machinery design.

Custom Solutions: Tailored, cost-effective gummy machinery solutions.

Support: Financing, custom gummy formula, facility layout design, SOP optimization, installment, training, and more reliable after-sales service.

Productivity: Seamless operations for peak productivity.