Ever tried making gummy bears without the right tools? It’s like baking without an oven!

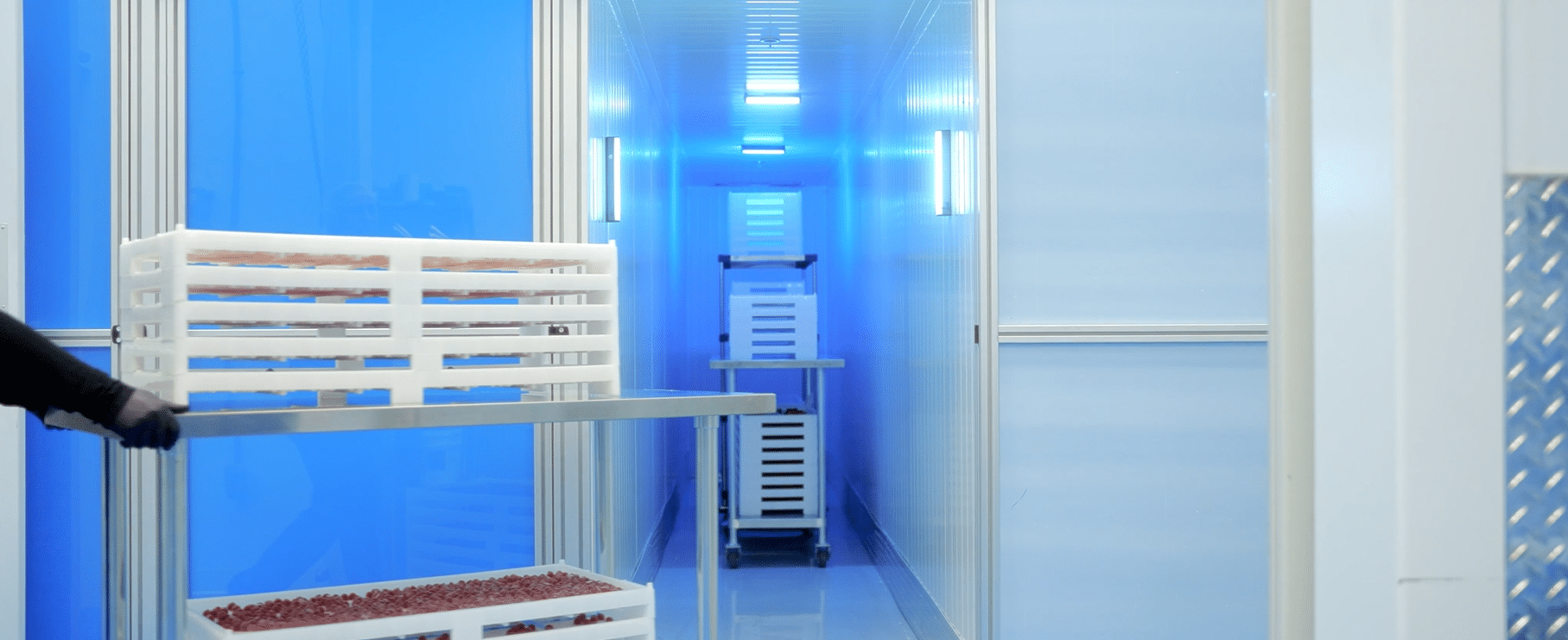

Drying trays and dollies are essential in gummy manufacturing because they ensure efficient space utilization, uniform drying, and easy handling of products. These tools contribute significantly to maintaining the quality and consistency of gummy candies during production.

Stick around as we explore how these unsung heroes of gummy manufacturing can transform your production line. From space-saving designs to enhancing drying efficiency, there's more to these trays and dollies than meets the eye.

Drying trays save 80% of floor space in gummy production.True

Self-stacking trays optimize storage, reducing space by up to 80%.

What Makes SaintyCo's Slot-Vent Drying Trays a Game-Changer?

SaintyCo’s Slot-Vent Drying Trays with Dollies are revolutionizing gummy production, but how exactly does it stand out?

SaintyCo's Slot-Vent technology transforms gummy manufacturing by enhancing drying efficiency and ensuring consistent quality across batches.

Revolutionary Drying Efficiency

Imagine baking cookies without a timer—some might end up crispy, others gooey. The same principle applies to gummy manufacturing. SaintyCo's1 Slot-Vent technology features unique slot-vent bottoms in drying trays, promoting faster and more uniform drying. This ensures each gummy reaches the perfect moisture level, crucial for texture and flavor consistency. In fact, it's like having a personal coach for each batch, guiding them to perfection.

Consistency Across Batches

For manufacturers, consistency is king. The Slot-Vent technology maintains uniform airflow across trays, akin to a gentle breeze evenly drying clothes on a line. This uniformity means no more unexpected surprises when opening a batch. Every gummy emerges with the same delightful chewiness and flavor, keeping your customers coming back for more.

Space-Saving Design

Space in production facilities is as precious as the chocolate coating on a truffle. SaintyCo's self-stacking trays use Slot-Vent technology to save up to 80% of floor space compared to traditional racks. Think of it as the Marie Kondo of gummy manufacturing—keeping operations tidy and efficient.

Built to Last

These trays aren't just smart; they're tough. Constructed from impact-resistant materials, they withstand the demands of high-output lines. Whether you're working in tight spaces or moving stacks as tall as a giraffe, these trays handle it all with ease. It's like having an unyielding assistant by your side, day in and day out.

Adaptable to Your Needs

Whether you're running a boutique operation or a large-scale factory, SaintyCo’s trays integrate seamlessly with existing setups. They're as flexible as a gymnast at the Olympics, ready to fit into semi-automated or fully automated lines, always ensuring the highest efficiency without missing a beat.

Slot-Vent technology enhances gummy drying efficiency.True

Slot-Vent trays promote faster, uniform drying, improving gummy quality.

SaintyCo's trays save 80% of production floor space.True

The self-stacking design reduces space usage compared to traditional racks.

How Do Drying Trays Improve Production Efficiency?

Discover how drying trays can boost your gummy production like never before!

Drying trays enhance production efficiency by optimizing space usage, ensuring uniform drying, and simplifying handling processes, leading to improved gummy quality and consistency.

Space Optimization: More Gummies, Less Room

Picture a city skyline—tall buildings stretching upwards rather than sprawling outward. SaintyCo's drying trays do just that for your gummy operation. By stacking vertically, these trays save up to 80% of floor space compared to traditional racks. Imagine cramming 1000 gummies per tray on a dolly stacked 50 trays high—that's efficiency! This space-saving trick is a boon for factories where every square foot counts. Check out how other space-saving industrial solutions2 can transform your production floor.

Uniform Drying: Consistency is King

No one likes a chewy gummy that's dry on one side and sticky on the other. Enter SaintyCo's slot-vent technology, the unsung hero ensuring each gummy is perfectly cured. The unique vented design allows air to circulate evenly across the tray, reducing drying time and achieving consistent moisture levels. This is crucial for maintaining quality across batches, making every gummy a delightful chew. Learn more about the science behind drying uniformity3 in food production.

Streamlined Handling: Less Lift, More Shift

Anyone who's played Tetris knows the value of efficient stacking. With heavy-duty swivel wheels, SaintyCo's dollies make moving stacks of trays a breeze, even in tight factory spaces. This system reduces labor costs and minimizes the risk of damaging gummies during transport. It's like having a conveyor belt on wheels! Explore how ergonomic equipment4 can reduce workplace strain and improve productivity.

Integration with Automation: Seamless Workflow

Whether you're running a boutique operation or a full-scale factory, these trays adapt to your needs. They slot seamlessly into automated lines, working in tandem with other machinery like cooling tunnels and depositors. This integration ensures a smooth flow from mixing to packaging, reducing downtime and boosting output. Find out how automation solutions5 are revolutionizing manufacturing processes.

Drying trays save up to 80% of floor space.True

Stacking trays vertically reduces the required floor space by 80%.

Slot-vent technology causes uneven gummy drying.False

Slot-vent technology ensures even air circulation for uniform drying.

Why Is Durable Equipment Vital in Gummy Manufacturing?

In gummy manufacturing, reliable equipment is the backbone of efficient production.

Durable equipment is vital in gummy manufacturing as it ensures consistent product quality, reduces downtime, and improves overall operational efficiency. High-quality machinery and tools withstand the demands of continuous use, maintaining optimal performance and minimizing disruptions.

Ensuring Consistent Product Quality

In the world of gummy manufacturing, maintaining consistent quality is paramount. Using durable equipment, like SaintyCo's trays and dollies, ensures that every batch of gummies achieves the same texture, moisture levels, and taste. This consistency keeps customers satisfied and maintains a brand's reputation. Imagine trying to bake cookies without a sturdy baking sheet—your results would vary wildly!

Reducing Downtime and Maintenance Costs

Investing in high-quality, durable equipment means less time and money spent on repairs and replacements. When machinery fails, it halts production and can cause significant delays. With robust materials and engineering, durable equipment like SaintyCo's can handle the rigors of constant use. It's like having a reliable old truck that just keeps on trucking without a hitch.

Enhancing Operational Efficiency

Durable equipment is designed for seamless integration into production lines, enhancing efficiency. With features like slot-vent technology in drying trays, operations can maximize throughput without compromising quality. This means more gummies on the shelf and happier customers. Efficiency doesn't just happen; it's engineered with precision tools that stand the test of time.

Supporting Diverse Production Needs

Whether you're running a small boutique gummy shop or a large-scale operation, durable equipment can adapt to various production needs. From semi-automated to fully automated systems, these tools are versatile. They integrate smoothly with other machinery like cooling tunnels and depositor machines. Think of them as the Swiss Army knife of your production line—ready for any challenge.

To truly grasp the impact of durable equipment on gummy manufacturing, consider this table highlighting key benefits:

| Feature | Benefit |

|---|---|

| Impact-resistant materials | Withstands industrial rigors |

| Heavy-duty swivel wheels | Easy maneuverability in tight spaces |

| Slot-vent technology | Faster, uniform drying for quality control |

| Space-efficient design | Maximizes factory floor usage |

Want to dive deeper into how these components play a pivotal role in gummy manufacturing? Check out these insightful sources6. You'll find a wealth of knowledge on maximizing production efficiency and quality with durable equipment.

Durable equipment reduces gummy production downtime.True

Durable equipment minimizes repairs, maintaining continuous production.

Inconsistent gummy quality results from durable equipment use.False

Durable equipment ensures consistent texture and taste in gummies.

Can Trays and Dollies Adapt to Different Production Scales?

In the gummy world, flexibility is key. Can trays and dollies keep up with changing production demands?

Yes, trays and dollies can adapt to different production scales, from small batches to large-scale operations, by offering versatile design features like adjustable stacking, durable materials, and efficient space utilization. These qualities make them indispensable tools for varying production needs.

The Versatile Design of Trays and Dollies

When it comes to scaling your gummy production, having equipment that adapts as you grow is essential. Trays and dollies offer just that. With features like adjustable stacking heights and compact designs, they easily cater to small artisanal setups or massive industrial lines.

Think of them as the Swiss Army knives of gummy manufacturing! They're engineered to work seamlessly7 with everything from depositor machines to cooling tunnels.

Durable Materials for Long-Term Use

Durability is crucial whether you're making 1,000 or 100,000 gummies a day. Made from impact-resistant materials, these trays and dollies are built to last. Their robust construction ensures they withstand the hustle and bustle of any production line.

Imagine them as the trusty workhorses in your factory, capable of handling rough and tumble with ease.

Efficient Space Utilization

Space is always at a premium in manufacturing settings. Self-stacking drying trays can reduce space requirements by up to 80% compared to traditional racks. This compact design is a godsend for operations where every square inch counts.

Picture this: instead of sprawling racks cluttering your floor, you have neat stacks reaching skyward, leaving ample room for other essential equipment.

Adapting to Diverse Production Needs

From semi-automated to fully automated systems, trays and dollies can be the unsung heroes that tie it all together. They're like the glue holding different parts of your production line in harmony, ensuring smooth transitions from one stage to the next.

Whether it's helping you achieve uniform drying8 or providing easy transport across the factory floor, these tools are indispensable.

In a nutshell, trays and dollies are the adaptable chameleons of gummy production. They shift and change to meet your needs, making them invaluable assets regardless of how large or small your operation may be.

Trays adapt to small and large-scale production.True

Trays feature adjustable stacking for different scales.

Dollies are unsuitable for automated systems.False

Dollies integrate well with both semi- and fully automated systems.

Conclusion

Understanding the role of drying trays and dollies can significantly boost your gummy production's efficiency and quality. Reflect on how these tools can fit into your process to maximize output while minimizing waste.

At GummyGenix by SaintyCo, we're here to support your journey with cutting-edge, GMP-compliant gummy manufacturing equipment designed for efficiency, precision, and adaptability. Our machines are fully compatible with regulatory standards, and we offer reliable after-sales support to keep your operations running smoothly.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality gummy products to life—together.

-

Discover the unique features that enhance drying efficiency and product quality.: Titon manufactures and supplies window ventilators – also known as fresh air vents, air inlets and trickle vents – to aid thermal comfort. ↩

-

Explore other methods to maximize factory floor space efficiently.: From heavy duty pallet racking to small parts bin storage, we have industrial storage solutions designed to save space. ↩

-

Understand how even drying improves product consistency.: Drying is known as the best method to preserve fruits, vegetables, and herbs, decreasing not only the raw material volume but also its weight. ↩

-

Discover tools that enhance comfort and efficiency in the workplace.: Some examples of industrial ergonomic equipment include electric lifting columns and electric hydraulic positioners. These tools lift and position equipment and ... ↩

-

Learn about the latest trends in manufacturing automation.: Robotic process automation (RPA) is one of the most adopted technologies to automate tasks such as supplier communications, invoicing and payment processing, ... ↩

-

Gain insights into maximizing efficiency and quality in gummy production.: ... machines, allowing for a comprehensive production process. Durability and Support: Offers a 2-year warranty for parts and provides ... ↩

-

Discover how trays and dollies sync with your entire production line.: Trays and Dollies: Whether you're scaling up production or managing smaller runs, our selection of drying trays adapts to your needs. Packaging: Ensure ... ↩

-

Learn about the technology behind consistent drying for perfect gummies.: Ensure uniform drying and easy handling. The drying trays and dollys from CandyPros offer a specialized approach to efficiently dry and set gummy candy. Made ... ↩