Creatine gummies are revolutionizing the supplement industry with their convenience and appeal. These chewy powerhouses offer athletes and fitness enthusiasts a delightful way to incorporate essential nutrients into their routines.

Creatine gummies are made through a meticulous process involving specialized gummy manufacturing equipment that ensures precise dosing and stability. Key machinery include jecket cookers, gummy depositors, coaters, and packaging systems, all designed to maintain the efficacy of creatine while producing high-quality, tasty gummies.

But what makes these machines indispensable to gummy production? Dive into the details of each stage of the process and discover how innovative equipment is transforming the way we consume supplements today. Explore the benefits, challenges, and solutions involved in making creatine gummies efficiently and effectively.

Creatine gummies are made using gummy depositors.True

Gummy depositors are crucial in shaping and dosing creatine gummies accurately.

Cooling tunnels are unnecessary in gummy production.False

Cooling tunnels stabilize gummies by setting them, ensuring quality and texture.

What Makes Creatine Gummies So Popular Among Consumers?

Creatine gummies are gaining traction for their convenience and taste, appealing to both athletes and everyday consumers. With easy consumption and precise dosing, they cater to modern lifestyle demands, making them a trendy supplement choice.

Creatine gummies are popular due to their convenient, chewable form and pleasant taste, making them an appealing alternative to traditional powders or pills. They offer precise dosing and can be consumed on-the-go, fitting well into busy lifestyles.

A Shift in Consumer Preferences

The rise in popularity of creatine gummies can largely be attributed to the consumer shift towards more convenient supplement formats. Modern consumers, particularly those leading active lifestyles, prefer products that are not only effective but also easy to incorporate into their daily routines. Gummies offer this convenience by eliminating the need for mixing or measuring, unlike traditional creatine powders1.

Taste and Appeal

Another significant factor in the rise of creatine gummies is their taste. Unlike the often bland or unpleasant taste associated with creatine powders, gummies are available in a variety of flavors, making them a more enjoyable option for many users. This taste appeal makes it easier for individuals to maintain consistent use, which is crucial for experiencing the full benefits of creatine supplementation2.

| Benefit | Gummies | Powders |

|---|---|---|

| Taste | Flavorful | Bland |

| Convenience | High | Low |

| Portability | Easy | Requires Mixing |

Precise Dosing

Gummies also provide precise dosing, which is especially beneficial for athletes who need specific creatine intake levels. This precision allows both beginners and advanced users to tailor their intake according to their needs. Some brands offer varying dosages per gummy, making it easier to adjust intake without additional calculations or measurements3.

Market Trend Insights

The nutraceutical market has seen a significant trend towards personalized nutrition. Gummies can be customized to meet diverse consumer needs, from vegan options to sugar-free varieties. This versatility has broadened their appeal and made them a staple in sports nutrition.

For more detailed information on current market trends4 in dietary supplements, manufacturers are constantly innovating to meet evolving consumer preferences.

Creatine gummies offer more precise dosing than powders.True

Gummies provide specific dosages per unit, unlike powders that require measuring.

Creatine gummies are less portable than creatine powders.False

Gummies are more portable as they don't require mixing or measuring.

What Are the Key Challenges in Formulating Creatine Gummies?

Crafting creatine gummies poses unique challenges, from maintaining stability to ensuring taste. These hurdles require innovative solutions to produce a consistent and appealing product.

The primary challenges in formulating creatine gummies include managing hygroscopic properties of creatine, ensuring even distribution of ingredients, and maintaining flavor and texture over time. These factors are crucial for quality and consumer satisfaction.

Understanding Hygroscopic Nature

Creatine is inherently hygroscopic, which means it naturally attracts moisture. This characteristic can lead to gummy texture issues5, such as stickiness or hardening, which affects consumer acceptance. Controlling humidity during production and storage is vital to combat these issues.

Achieving Even Distribution

Ensuring that creatine is uniformly distributed within each gummy is challenging yet essential. Production techniques must be refined to prevent clumping, which can cause variability in dosage. Utilizing advanced mixing technology is crucial to achieve this consistency.

Maintaining Flavor and Texture

Balancing the natural taste of creatine with desirable flavors can be tricky. The formulation process must incorporate flavor enhancers or maskers while preserving the gummy's intended texture. This balance is crucial for consumer satisfaction and repeat purchases.

Equipment Compatibility and Innovation

To address these challenges, selecting the right equipment is key. Machines like the G300 gummy line6 offer precise temperature and mixing controls that help maintain ingredient integrity. The use of such equipment ensures high-quality output.

Table: Equipment Features Comparison

| Equipment Model | Capacity (gummies/hour) | Key Features |

|---|---|---|

| DM-20S | 10,000 | Compact, versatile for small-scale |

| G150 | 60,000 | Dual-hopper, multi-color capability |

| G800 | 240,000 | Fully automated, high efficiency |

Regulatory Considerations

Compliance with regulations is imperative in gummy production. Manufacturers must adhere to FDA guidelines to ensure safety and efficacy of their products. Understanding these regulatory requirements7 helps mitigate risks associated with production.

By exploring these challenges and addressing them through innovation and precision equipment, the production of creatine gummies can meet consumer demands effectively.

Creatine gummies are prone to moisture-related issues.True

Creatine's hygroscopic nature attracts moisture, causing texture problems.

All gummy production equipment can handle creatine's challenges.False

Specialized equipment is needed to maintain creatine gummy quality.

How Does Advanced Gummy Machinery Enhance Product Quality?

Advanced gummy machinery revolutionizes production, enhancing quality and consistency. Discover how this technology impacts taste, texture, and efficiency, offering an edge in the competitive gummy market.

Advanced gummy machinery enhances product quality by providing precise control over production parameters such as temperature, mixing, and formulation. This ensures consistent taste and texture, while maintaining ingredient efficacy and minimizing contamination risks.

The Role of Precision in Gummy Production

Advanced machinery allows for unparalleled precision in controlling critical parameters like temperature and mixing speed. For example, maintaining an optimal temperature8 ensures that the active ingredients are evenly distributed without degradation. This leads to consistent taste and

texture, vital for meeting consumer expectations.

Hygienic Production Processes

The starchless production process utilized by modern machines minimizes contamination risks. This method not only enhances hygiene but also appeals to health-conscious consumers9. Moreover, it reduces cleaning time and maintenance, further improving operational efficiency.

Customization Capabilities

With advanced machinery, manufacturers can easily customize gummies in terms of shape, size, and color. The dual-hopper system in machines like the G150 allows for the creation of multi-color gummies, adding visual appeal to the product line. This customization ability helps brands stand out10 in a crowded market.

| Feature | Benefit |

|---|---|

| Precise Temperature Control | Consistent texture and taste |

| Starchless Process | Enhanced hygiene |

| Dual-Hopper System | Multi-color gummies |

Scalability and Efficiency

From small-scale to large-scale production, advanced machinery offers solutions that grow with your business. For startups, compact machines like DM-20S are perfect for R&D, while larger lines like the G300 offer automated high-speed solutions suitable for established businesses. These scalable systems ensure efficiency while maintaining high

quality standards.

Support Services and Value Additions

Beyond machinery, consulting services for recipe optimization ensure that formulations are both effective and enjoyable. Training for equipment installation and maintenance is also provided to minimize downtime and maximize productivity, ensuring a seamless production experience for businesses of all sizes11.

Advanced gummy machinery ensures consistent taste and texture.True

Precision control of temperature and mixing maintains product consistency.

Starchless production increases contamination risks in gummy making.False

Starchless methods minimize contamination, enhancing hygiene in production.

Which Machines Are Essential for Small-Scale Creatine Gummy Production?

Small-scale creatine gummy production requires specific equipment to ensure efficiency and product quality. These machines include mixers, depositors, and cooling tunnels, which play crucial roles in the manufacturing process.

Essential machines for small-scale creatine gummy production include mixing tanks, gummy depositors, and demolders. These machines ensure consistent quality, precise dosing, and efficient production, catering to market demands for convenience and taste.

Mixing Tanks: The Foundation of Gummy Production

Mixing tanks are vital for preparing the gummy base. They ensure that ingredients like gelatin and flavorings are well-combined with creatine. Tanks with precise temperature controls prevent overheating, maintaining the integrity of sensitive ingredients12.

| Feature | Importance |

|---|---|

| Temperature Control | Maintains ingredient integrity |

| Agitation Speed | Ensures uniform mixing |

| Capacity | Suitable for small-batch production |

Depositors: Precision in Gummy Shaping

Depositors inject the prepared gummy mixture into molds. This step is critical for dosage accuracy, especially with creatine's specific intake requirements. Machines like the DM-20S offer flexibility in shape and size, perfect for startups looking to innovate with shapes13.

- Flexibility: Supports different shapes and sizes.

- Accuracy: Ensures consistent dosages.

Cooling Tunnels: Setting the Gummies Right

After deposition, gummies must be cooled to solidify. This is essential for preserving both the aesthetic appeal and structural integrity14 of the gummies.

- Rapid Cooling: Reduces setting time.

- Hygiene: Ensures a contaminant-free process.

Gummy Demolder: Smooth and Efficient Demolding

Demolders are integral in ensuring seamless extraction of gummies from their molds without damage, maintaining both productivity and product quality.

- Wide Compatibility: Works efficiently with both metal and silicone molds, adapting to diverse production requirements.

- Enhanced Efficiency: Reduces time and labor involved in demolding, contributing to a faster production cycle.

Compact Production Lines: Efficiency at Small Scale

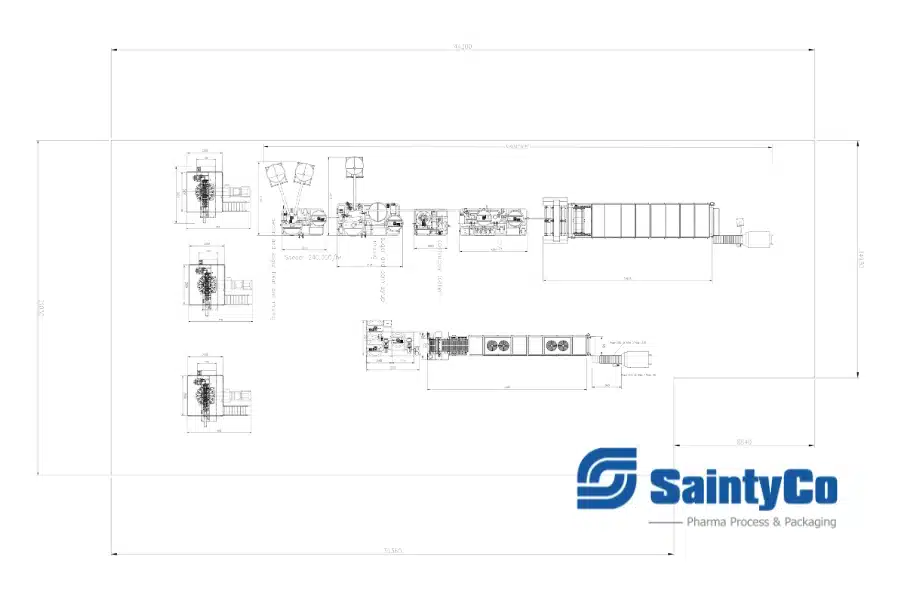

For small-scale operations, individual gummy depositors for R&D like DM-50X model or compact gummy production lines like the GummyGenix by SaintyCo G40 integrate mixing, depositing, and cooling in one streamlined system. These machines save space and optimize productivity15, making them ideal for businesses venturing into the gummy market.

Combining these machines ensures a seamless production line, allowing small businesses to meet market demands efficiently.

Mixing tanks prevent overheating of gummy ingredients.True

Mixing tanks with temperature controls maintain ingredient integrity.

Cooling tunnels increase gummy stickiness and deformation.False

Cooling tunnels reduce temperature to prevent stickiness and deformation.

How Can Brands Customize Enegery Chews to Stand Out?

Creatine gummies are gaining traction among athletes and casual users alike. Customizing these supplements can make a brand stand out in a crowded market, offering unique flavors, shapes, and dosages.

Brands can customize creatine gummies by focusing on unique flavors, creative shapes, and tailored dosages to meet diverse consumer needs. This approach enhances appeal and differentiates products in the competitive supplement market.

Innovating with Flavor Profiles

One of the simplest yet most effective ways to customize creatine gummies is through unique flavor combinations. While traditional flavors like berry or citrus are popular, experimenting with exotic options such as passion fruit or lychee can intrigue consumers.

Creative Shapes for Brand Recognition

Visual appeal plays a crucial role in product differentiation. Offering creatine gummies in creative shapes like dumbbells or running shoes can strengthen brand association with fitness. By using advanced mold technology, brands can create intricate designs that appeal to target audiences.

| Shape | Target Audience |

|---|---|

| Dumbbell | Gym-goers |

| Runner | Endurance athletes |

| Kettlebell | CrossFit enthusiasts |

Custom Dosage for Niche Markets

Tailoring creatine gummy dosages to specific user needs can cater to different segments. Beginners might prefer lower dosages, while seasoned athletes could seek higher concentrations. Offering a range of options within a product line can attract a broader customer base.

Packaging and Branding Strategies

Eye-catching packaging not only protects the product but also serves as a marketing tool. Eco-friendly packaging options can appeal to environmentally conscious consumers. Combining vibrant designs with informative labels helps convey the benefits of creatine gummies effectively.

Collaborations and Co-Branding Opportunities

Partnering with well-known fitness personalities or brands can enhance credibility and reach. Co-branding opportunities create a sense of trust among consumers, encouraging them to try new products. Exploring partnerships16 with influencers or gym chains can expand market presence effectively.

Educational Content and User Engagement

Educating consumers about the benefits of creatine through engaging content like infographics, blog posts, or videos can enhance brand loyalty. Interactive platforms for user feedback can also provide insights into consumer preferences and areas for improvement.

Discover why educational content matters17 for enhancing brand loyalty and engaging your audience in meaningful ways.

Creative gummy shapes enhance brand recognition.True

Unique shapes like dumbbells or runners strengthen brand association with fitness.

All creatine gummies should have the same dosage.False

Customizing dosages caters to different user needs, from beginners to athletes.

Conclusion

Creatine gummies are produced using advanced machinery that ensures precise dosing, stability, and quality. Their convenience and taste cater to modern consumers seeking effective supplement options.

At GummyGenix by SaintyCo, we're here to support your journey with cutting-edge, GMP-compliant gummy manufacturing equipment designed for efficiency, precision, and adaptability. Our machines are fully compatible with regulatory standards, and we offer reliable after-sales support to keep your operations running smoothly.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality gummy products to life—together.

-

Explore the differences between creatine powders and gummies to understand why gummies might be more suitable for your lifestyle. ↩

-

Learn about the advantages of using creatine gummies over other forms of creatine. ↩

-

Discover how creatine gummies ensure accurate dosing and why this matters for users. ↩

-

Stay updated with the latest trends in dietary supplements to make informed purchasing decisions. ↩

-

Learn techniques for controlling moisture during production to prevent gummy stickiness or hardening. ↩

-

Discover the advanced features of the G300 line that enhance gummy production quality. ↩

-

Understand FDA guidelines crucial for ensuring the safety and compliance of creatine gummies. ↩

-

Learn how temperature control impacts ingredient distribution and product consistency. ↩

-

Discover why starchless production is crucial for hygiene and appeal. ↩

-

Explore how unique gummy shapes enhance brand visibility. ↩

-

Find scalable machinery options for growing gummy businesses. ↩

-

Understanding temperature control helps in maintaining ingredient quality during the gummy production process. ↩

-

Exploring depositor capabilities can inspire creative product designs and improve market appeal. ↩

-

Cooling tunnels ensure gummies set correctly, maintaining quality and preventing defects. ↩

-

Compact lines improve efficiency by integrating multiple processes, ideal for small businesses. ↩

-

Discover how partnerships with fitness influencers can increase brand credibility and market reach. ↩

-

Learn why creating educational content helps in building trust and loyalty among consumers. ↩