What Are the Key Steps to Commercially Manufacturing Mushroom Gummies?

Mushroom gummies are gaining popularity due to their health benefits and ease of consumption. The commercial manufacturing process includes selecting functional mushrooms like Chaga and Reishi, using gelling agents such as gelatin or agar-agar, and employing advanced machinery for precision. Key steps involve grinding mushrooms into powder, mixing ingredients thoroughly, and utilizing automated depositors for uniform gummy shapes. Understanding the specific health benefits of various mushrooms enhances product appeal. Additionally, manufacturers must adhere to strict quality control measures throughout the production process to ensure safety and efficacy. As consumer demand grows for innovative health products, mushroom gummies stand out as a convenient supplement option that combines taste with nutritional value.

What Ingredients Are Commonly Used by Private Label Gummy Manufacturers?

In the burgeoning world of private label gummy manufacturing, understanding the core ingredients is essential for creating successful products. This article explores the most common ingredients, their impacts on texture and flavor, and important manufacturing considerations.

How Are Drying Trays and Dollies Essential in Gummy Manufacturing?

Ever tried making gummy bears without the right tools? It’s like baking without an oven! Drying trays and dollies are crucial in gummy production, enhancing efficiency, space management, and product quality. Let’s dive into how these unsung heroes make a difference in the manufacturing process!

How to Set Up an OTC & Supplements Gummy Factory in Colombia?

Setting up a supplements and OTC gummies factory in Colombia can be a rewarding venture, but it requires careful planning and understanding of local regulations. From navigating INVIMA approvals to designing an efficient production process and marketing your products effectively, this guide outlines essential steps to help you succeed in this booming industry.

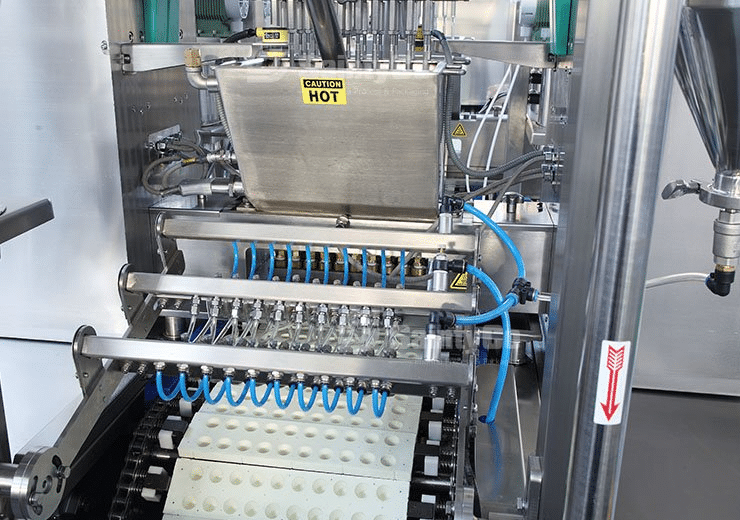

Gummy Depositors: Common Clogging Issues and How to Prevent Gummy Clogs?

Gummy depositors can experience clogs due to various factors such as thick mixtures, temperature changes, and residual build-up. To prevent these issues, it’s crucial to select appropriate ingredients and maintain consistent temperatures. Regular cleaning and inspections are essential for optimal performance. Implementing strategies like using vacuum degassing systems can help minimize air entrapment while ensuring smooth operations. By understanding the causes of clogs and taking proactive measures, manufacturers can enhance production efficiency and product quality in gummy candy manufacturing.

What Are the Best Strategies to Optimize a Gummies Production Line?

This article outlines effective strategies for optimizing gummy production lines. Key approaches include streamlining workflows through task segmentation and continuous flow operations, investing in reliable automated equipment, ensuring precise ingredient measurements, and maintaining high hygiene standards. By implementing these practices, manufacturers can boost efficiency, reduce waste, and enhance product consistency. Data-driven optimization further aids in identifying bottlenecks and improving resource allocation. Regular maintenance and calibration of equipment are essential for consistent performance. Overall, these strategies contribute to a more efficient gummy manufacturing process that meets market demands while maintaining quality.

What Are the Most Important Gummy Manufacturing Equipment for Scaling Production?

Gummy candies have taken the confectionery world by storm, and scaling production to meet demand requires the right equipment. From depositors to packaging machines, each piece plays a vital role. In this article, we’ll dive into the key equipment necessary for a successful gummy manufacturing process.

How Can I Stop My Gummies from Curing Too Quickly in a Gummy Depositor?

Are you tired of your gummies setting too fast, leaving them with an undesirable texture? You’re not alone! This guide dives into the intricacies of gummy production, offering you expert tips to control temperature, Brix levels, acid timing, and humidity, ensuring your gummies achieve that perfect chewiness every time.

Gummy Depositors: What Are the Most Common Issues When Using Them?

Gummy depositors are vital in the confectionery industry, but they can encounter several issues. This article explores the most common problems such as inconsistent filling, clogging, and temperature sensitivity, while providing actionable insights to overcome these challenges. By understanding and addressing these issues, manufacturers can optimize their production processes and ensure high-quality gummy products.

Gummy Production Tips: How to Maintain Your Gummy Depositor Effectively?

Maintaining a gummy depositor is essential for efficient production and high-quality output. By focusing on regular cleaning, inspections, and operator training, I can ensure smooth operations and minimize downtime. Let’s dive into the key components and innovative technologies that can help enhance maintenance practices.