What is the Process Behind Gummy Vitamin Manufacturing?

This blog post explores the intricate process of gummy vitamin manufacturing, detailing essential ingredients, production techniques, quality control measures, and emerging trends shaping the industry. Learn how to create effective and appealing gummy vitamins.

How to Start Your Gummy Manufacturing Business in Greece for Nutraceutical and CBD Gummies?

Starting a gummy manufacturing business for nutraceutical and CBD gummies in Greece requires understanding compliance regulations, sourcing quality ingredients, optimizing production processes, and implementing effective marketing strategies to succeed.

How Can You Set Up a Supplements and OTC Gummies Factory in Argentina in 6 Easy Steps?

Setting up a supplements and OTC gummies factory in Argentina involves six essential steps: regulatory compliance, location selection, equipment choice, quality control, packaging logistics, and sustainability practices for market success.

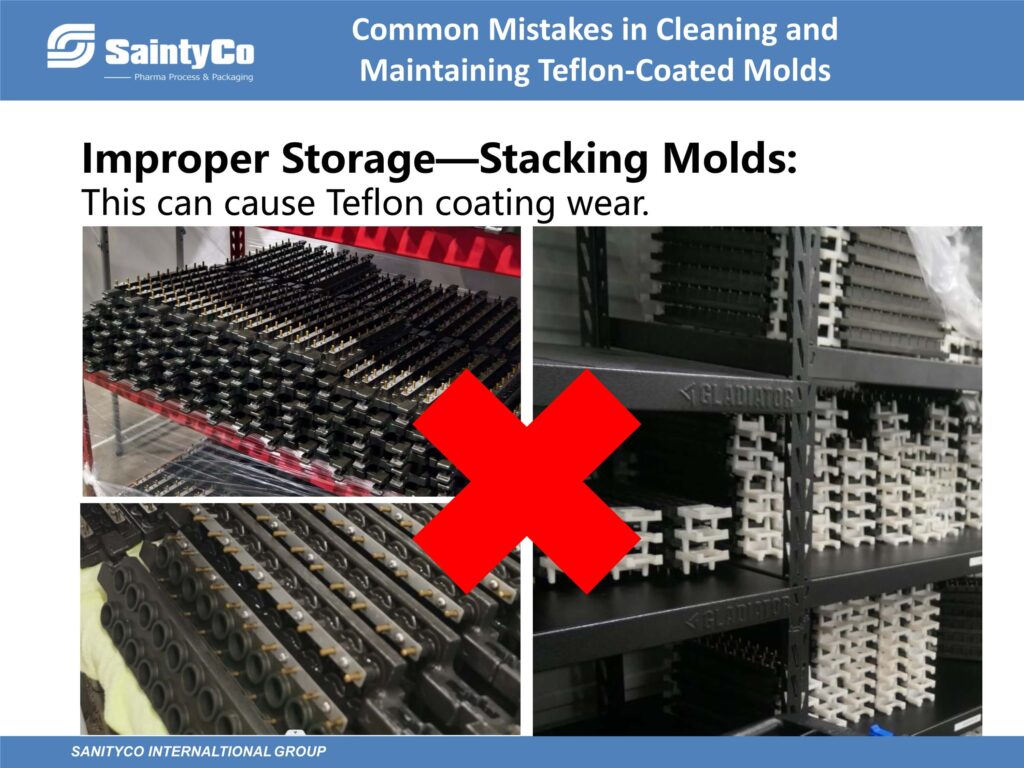

Teflon-Coated Metal Gummy Molds: Best Tips for Cleaning and Maintaining

To maintain Teflon-coated molds for gummies and candies, clean immediately after use with mild detergents, avoid harsh chemicals, dry thoroughly, and store properly to extend their lifespan and effectiveness.

Silicone Molds vs. Metal Candy Molds: Which is Better for Gummy Making?

This article compares silicone and metal molds for gummy production, highlighting their differences in texture consistency, production speed, ease of use, cleaning, and overall cost-effectiveness to help manufacturers choose the best option.

How to Coat Gummy Candy: Methdods & Equipment Explained

Explore the best coating methods for gummies, including sugar, oil, sour, spray, gel, powder, and carnauba wax. Each method enhances texture, flavor, and shelf life for improved gummy production.

How to Make Sour Gummy Candies?

Learn expert tips for making sour gummies, focusing on ingredient balance, timing, and production techniques. Discover how to troubleshoot common issues and create delicious, consistent treats with automation.

How Many Operators for Your Gummy Production Line?

Optimizing gummy production requires understanding the ideal number of operators based on automation levels. Semi-automated lines need 2-3 operators, while fully automated setups require 3-4 for efficiency and quality control.

How Are Sour Gummy Worms Made: Which Production Method Is Best, Starch Mogul or Starchless Depositing?

This blog post explores the production methods for sour gummy worms, comparing Mogul lines and starchless depositing. It highlights their advantages, challenges, and key considerations for manufacturers to make informed decisions.

How to Choose Small Gummy-Making Machines for Your Restaurant?

This ultimate guide helps restaurants choose the right small gummy-making machines by considering production volume, space, customization options, ease of use, budget, and after-sales support for optimal operations.