How to Launch a Supplements & OTC Gummies Factory in Indonesia: Compliance & Equipment Guide

Thinking of launching a supplements and OTC gummies factory in Indonesia? You’re in for an exciting ride! To succeed, you’ll need to navigate regulatory requirements, secure essential certifications like GMP and Halal, and choose the right machinery to keep your production seamless and compliant. Let’s dive into the details!

Gummy Production Line Maintenance: Daily & Deep Cleaning Tips

Maintaining hygiene in gummy production is crucial. This guide outlines effective daily and weekly cleaning methods, safety protocols, and best practices to ensure optimal machine performance and product quality.

Healthy Gummy Candy Manufacturing: Gelatin vs. Pectin, and Sugar-Free Options

This article delves into the healthiest gummy options available today, focusing on the differences between gelatin and pectin as gelling agents. Gelatin offers a chewy texture derived from animal collagen, making it ideal for traditional gummies and CBD/THC applications. In contrast, pectin is plant-based and suitable for vegan diets, providing a firmer texture preferred in health-focused products. Additionally, sugar-free gummies are gaining popularity due to lower calorie content and reduced cavity risk but may cause digestive issues for some. The piece also highlights production considerations for low-sugar gummies while addressing consumer preferences towards healthier snacks. Understanding these elements can help manufacturers cater to evolving market demands effectively.

Gummy Bear Business: How to Secure Funding and Plan Finances?

Starting a gummy making business requires careful financial planning. This guide outlines essential steps including estimating costs for raw materials, machinery, labor, packaging, and marketing. Explore various funding options such as self-funding, loans, angel investors, venture capital, and crowdfunding. Additionally, learn effective pricing strategies to ensure profitability while considering competitor analysis and unique value propositions. Consulting a financial advisor can further enhance your strategy by providing tailored budgeting and risk management insights. Equip yourself with the necessary tools to build a financially sustainable gummy business.

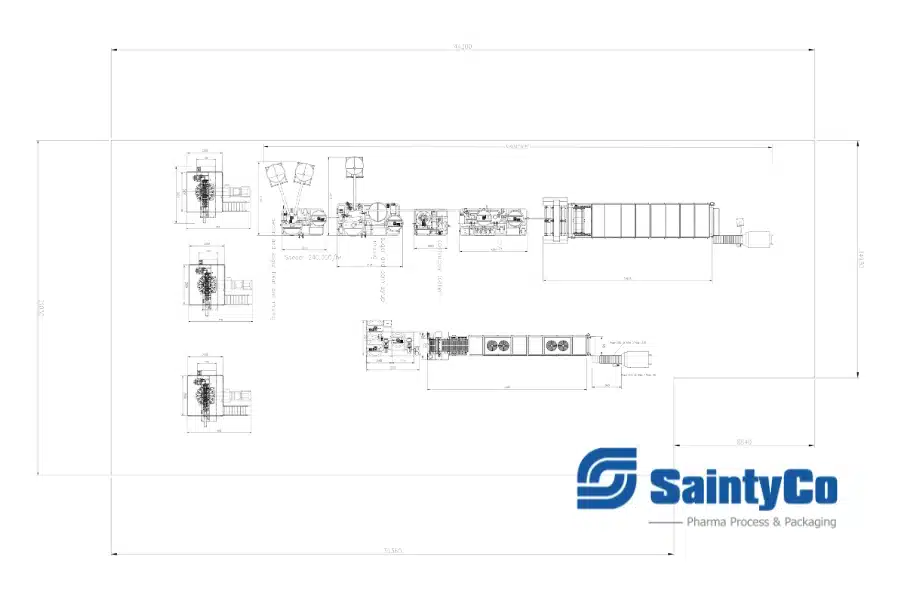

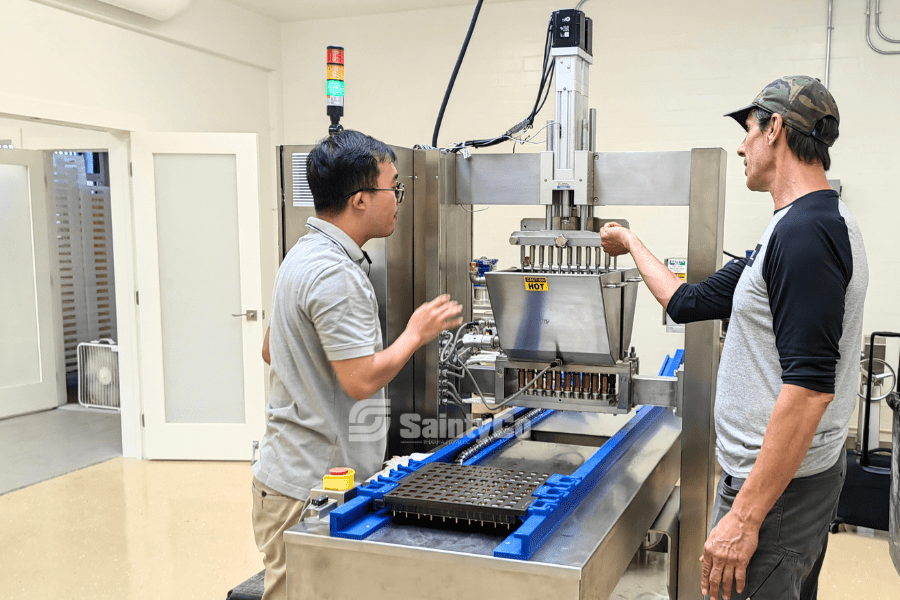

Gummy Production Line Layout: How to Optimize Machine Placement and Integration?

This blog explores how to optimize gummy production layouts and machine integration for enhanced efficiency. Key strategies include selecting compatible equipment, optimizing workflows, ensuring safety compliance, and maximizing space utilization.

Making Sugar-Free Gummies: Challenges and Solutions for Manufacturers at Different Scales

Sugar-free gummies are increasingly popular among health-conscious consumers, but their production involves unique challenges. Key issues include maintaining texture and flavor balance without sugar, as well as navigating regulatory compliance. Manufacturers must choose appropriate sweeteners like Maltitol or Stevia while utilizing specialized machinery to optimize production at different scales. Small-scale producers can benefit from compact depositors for experimentation, while medium to large-scale operations require advanced lines that ensure consistency and quality. Understanding the impact of sweeteners on taste and texture is crucial for creating appealing products that meet consumer expectations. This guide explores effective strategies for overcoming manufacturing obstacles and achieving success in the sugar-free gummy market.

What Are the Key Steps to Set Up an OTC Gummies and Supplements Factory in the UK?

Setting up a supplements and OTC gummies factory in the UK requires regulatory compliance, equipment selection, ingredient sourcing, quality control, and financial planning to ensure successful operations and product safety.

Semi-Automatic vs. Fully-Automatic Gummy Machines: What Are the Key Differences?

This blog post explores the key differences between semi-automatic and fully-automatic gummy machines, focusing on automation levels, operational efficiency, cost implications, production speed, and maintenance needs to guide your investment decision.

Sugar-Free Gummies: Solutions for Manufacturing Challenges and Business Growth

Sugar-free gummies are gaining popularity, but their production presents unique challenges. Key areas of focus include improving taste and texture with alternative sweeteners, ensuring formulation stability, maintaining shelf life without sugar’s preservative qualities, and optimizing production processes. Advanced packaging solutions are essential for extending shelf life by protecting against moisture and oxygen. Quality assurance throughout the manufacturing process ensures safety and consistency while adhering to regulatory standards. Strategic marketing targeting health-conscious consumers can enhance brand visibility and drive sales. By addressing these aspects effectively, manufacturers can successfully position their sugar-free gummies in a competitive market.

Sugar-Free Vitamin Gummies for Kids: Key Production Insights for Manufacturers

In the competitive market of children’s nutrition, gummy manufacturers face the challenge of producing sugar-free and vitamin gummies that appeal to both parents and kids. Parents prioritize safety, seeking allergen-free options without artificial additives while ensuring nutritional value with essential vitamins like A, D, and zinc. Manufacturers must balance taste with health benefits using advanced machinery for precise ingredient mixing and quality control. Innovative flavors, fun shapes, and eco-friendly practices can enhance product appeal. Understanding regulatory standards is crucial for compliance. This guide explores strategies for creating successful sugar-free gummies that satisfy both parental concerns and children’s preferences.