Ever had that moment when a gummy depositor decides to throw a fit and clog up? Frustrating, right?

Clogs in gummy depositors often stem from thick mixtures, temperature changes, leftover build-up, trapped air, foreign debris, and worn-out parts. To prevent these clogs, it's essential to choose the right ingredients, maintain steady temperatures, clean regularly, and use filters to catch unwanted particles.

I still remember a time during a test batch of gummies when everything seemed to be running smoothly—until the depositor suddenly clogged. Production came to a halt, leaving a sticky mess to clean up. After some troubleshooting, I realized the issue was due to a mixture that was too viscous and a drop in temperature I hadn't noticed.

This experience taught me how critical it is to maintain consistent temperatures and ensure the mixture's viscosity is within the optimal range. These lessons have since helped me and many of my clients optimize their gummy production processes. Let’s explore some common causes of clogs in gummy depositors and, more importantly, how you can prevent them to keep your production running seamlessly.

Viscosity issues can lead to depositor clogs.True

Overly thick gummy mixtures are harder to process, causing clogs.

Air bubbles improve gummy flow consistency.False

Air bubbles create inconsistent flow; degassing systems are needed.

How Does Viscosity Affect Gummy Depositor Functionality?

Remember that time when your favorite gummy got stuck in the mold? It all boils down to one thing: viscosity.

Viscosity affects gummy depositor functionality by controlling how smoothly the gummy mixture flows, impacting both the consistency and quality of the final product. A well-balanced viscosity ensures smooth operations and prevents blockages, making your gummy-making process a breeze.

Understanding Viscosity in Gummy Production

When I first dove into gummy production, I quickly realized that viscosity isn't just a fancy term—it’s a game-changer. Picture this: you’re trying to pour syrup that's as thick as honey through a tiny funnel. That’s what happens if the viscosity is too high in gummy mixtures. It can lead to clogs and inconsistencies that can drive anyone up the wall. On the flip side, if it’s too thin, your gummies might end up as shapeless blobs instead of cute bears or worms.

The Role of Temperature Control

One mistake I made early on was neglecting how temperature affects viscosity. I remember one batch where the heating system was off, and everything solidified—a nightmare! Now, I always ensure the temperature is just right using thermostatically controlled systems1. It keeps the gummy mixture fluid enough to flow but not so much that it won't set.

Importance of Ingredient Preparation

Once, I thought I could just toss all ingredients into the mixer and call it a day. But let me tell you, well-dissolved pectin or gelatin makes all the difference. Using high-shear mixing tanks was a lifesaver for me—it keeps everything nice and even, reducing the chances of clogging.

Influence on Equipment Wear and Maintenance

High viscosity doesn’t just mess with your gummies; it can be brutal on your equipment. I learned this after having to replace some worn-out parts on my depositor. Now, I regularly inspect everything—from nozzles to seals—to catch wear and tear before it becomes a costly problem. Plus, implementing routine cleaning protocols2 has been crucial to keep things running smoothly.

Strategies for Optimal Viscosity Management to Prevent Gummy Clogs

Monitoring and adjusting the flow rate is critical for achieving consistent results, especially during batch production or testing. With depositors equipped with PLC-enabled systems, real-time monitoring becomes seamless. It's like having a reliable co-pilot ensuring a smooth, consistent flow, minimizing the risk of air pockets that can compromise product quality.

Thick mixtures are harder to process in gummy depositors.True

Overly thick gummy mixtures can cause clogging, requiring recipe adjustments.

Air bubbles improve the flow of gummies in depositors.False

Air bubbles create inconsistent flow, necessitating degassing systems.

How Does Temperature Prevent Gummy Depositor Clogs?

Have you ever wondered why your depositor suddenly clogs? The secret lies in managing temperature effectively.

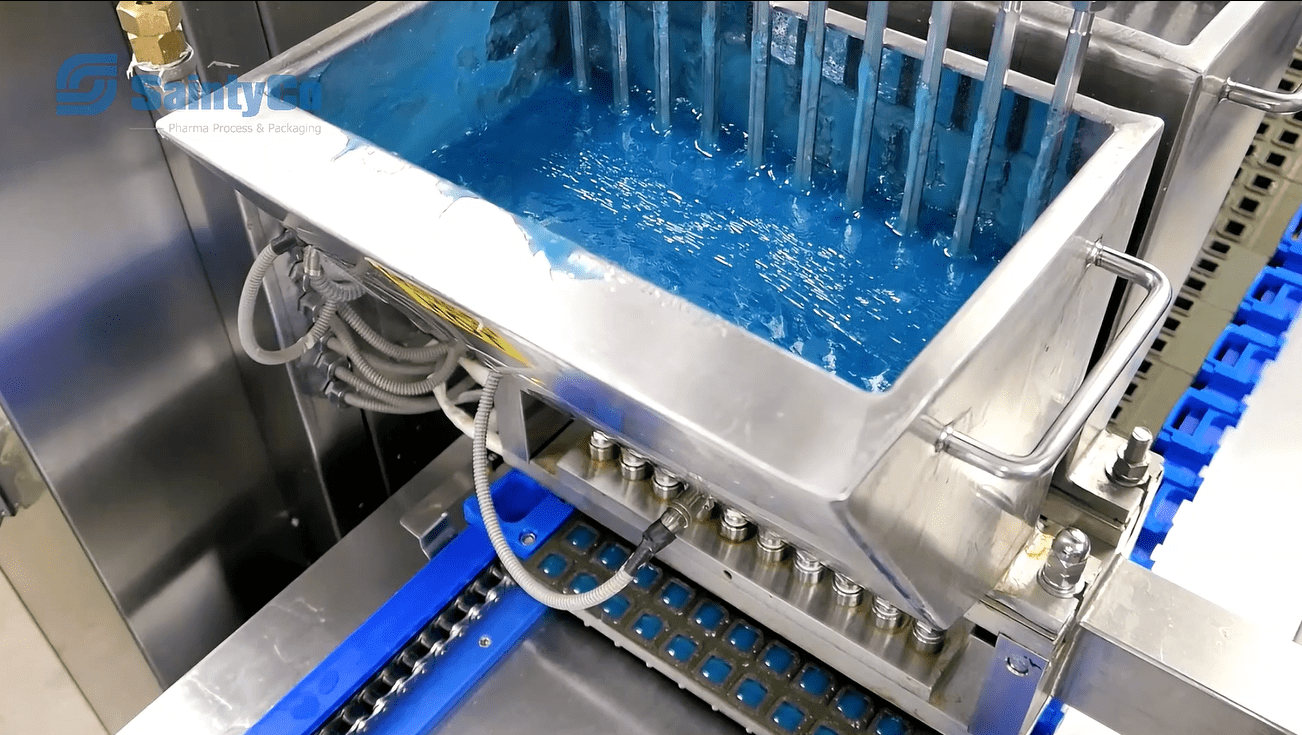

Temperature management is essential in preventing depositor clogs. By keeping materials at a consistent heat, they remain fluid, avoiding premature solidification and ensuring smooth flow through nozzles and pathways.

Understanding Temperature's Impact on Material Viscosity

Imagine trying to pour honey on a cold winter morning—it thickens and resists every move. Similarly, when gummy mixtures drop below the ideal temperature, they thicken and lose their smooth flow. This can lead to clogs in critical areas like nozzles and hoppers, disrupting production and wasting valuable materials.

Consistent temperature control3 isn’t just a preference; it’s essential for ensuring efficiency and preventing costly downtime in both batch and full-scale production runs. It ensures that mixtures maintain the perfect viscosity for smooth depositing, whether you're testing a new batch or scaling up for high-volume production.

The Importance of Consistent Heating

Inadequate heating can be a nightmare—believe me, I've been there! Imagine trying to maintain a steady flow of material only to have it solidify mid-process. Advanced systems with thermostatic controls help keep materials within the right temperature range, ensuring they don't turn into an unmanageable mass. This not only prevents solidification but also maintains the material's quality and texture throughout the production process. Using thermostatic systems4 can make all the difference in modern manufacturing setups.

Real-Time Monitoring and Adjustments

Having real-time temperature monitoring feels like having a guardian angel watching over your production line. These advanced depositors allow operators to make quick adjustments when needed, minimizing clogs and enhancing efficiency. Systems with PLC-enabled monitoring provide precise control over the depositing environment.

Effects on Equipment Longevity

Keeping everything flowing smoothly not only prevents clogs but also prolongs the life of your equipment. When materials glide through without a hitch, there’s less wear and tear on parts like hoses and nozzles. With regular maintenance and optimal temperature control5, you can significantly cut down on downtime and extend the lifespan of your production gear.

Proper temperature prevents gummy solidification in depositors.True

Maintaining recommended temperatures ensures fluidity, avoiding clogs.

Air bubbles do not affect gummy flow in depositors.False

Air bubbles create inconsistencies, necessitating degassing systems.

Why Is Regular Maintenance Crucial for Gummy Depositors?

Ever had your gummy production line grind to a halt? I know the frustration firsthand. Let's dive into why regular maintenance of gummy depositors is your best friend in the confectionery world.

Regular maintenance of gummy depositors is crucial to prevent clogs, ensure efficient production, and prolong equipment lifespan. It involves cleaning, inspecting for wear, and adjusting settings to maintain optimal performance. Neglecting maintenance can lead to costly downtimes and compromised product quality.

Prevent Gummy Clogs and Ensure Smooth Operations

Regular cleaning, including system flushing6 with approved solutions, now feels like second nature to me. Disassembling nozzles for a good rinse is something I never skip. Trust me, it makes all the difference.

Enhance Production Efficiency

A well-maintained machine is a happy machine. By keeping a close eye on flow rates and adjusting depositing speeds, You can manage to keep your gummies consistently top-notch.

Extend Equipment Lifespan

It’s incredible how a simple inspection can make all the difference in preventing unexpected breakdowns. Regularly checking for wear in hoses and seals allows you to replace parts before they cause disruptions, saving both time and costly repairs. In batch production for testing or smaller runs, this becomes even more critical—minimizing downtime ensures seamless trials and accurate results.

Additionally, applying the right amount of lubrication to key components not only keeps the machine running smoothly but also extends its lifespan significantly. A little attention to maintenance today can lead to big savings and consistent performance in the long run.

Adapt to Ingredient Variability

Every batch is an adventure with its own quirks. Regular maintenance means checking how I prepare ingredients, ensuring syrup viscosity is just right using vacuum cookers7. It's all about finding that sweet spot to avoid caramelization disasters.

Implement Advanced Monitoring Systems for Gummy Production Maintanence

Our clients love using upgraded PLC-enabled systems for real-time tweaks. These digital helpers mean they can keep their depositing machines finely tuned without having to micromanage every little detail. It’s like having an extra set of eyes on the production line, always ready to step in if something goes off track.

Overly viscous mixtures increase clog risk.True

Thick gummy mixtures are harder to process, leading to clogs.

Regular cleaning reduces depositor efficiency.False

Regular cleaning prevents blockages, maintaining depositor efficiency.

How Can I Minimize Air Entrapment in Gummy Production?

Ever wondered why some gummies are smooth and others... not so much? It all boils down to avoiding those pesky air bubbles during production.

To keep air entrapment at bay while making gummies, try using vacuum degassing systems, tweak mixing speeds, and keep an eye on ingredient temperatures. These steps can help create a flawless gummy texture and boost overall quality.

Understanding the Causes of Air Entrapment in Gummy Production

Air entrapment is a common challenge during the mixing and depositing stages of gummy production. Picture this: as you mix the ingredients, over-agitation introduces air into the syrup. Or, if the ingredients aren’t properly pre-heated, the viscosity increases, making it easier for air to become trapped. The result? Imperfections that affect both the aesthetics and texture of your gummies.

To effectively address this issue, it’s crucial to understand its root causes:

- Over-Aggressive Mixing: High-speed mixing can introduce excess air into the mixture.

- Temperature Variations: Improperly heated ingredients are more likely to trap air due to increased viscosity.

- Inadequate Equipment: Standard mixing systems without air extraction mechanisms may not handle the gummy syrup’s unique characteristics effectively.

Implementing Vacuum Degassing Systems

One day, a fellow gummy enthusiast shared a game-changing tip with me: vacuum degassing systems. These clever devices help suck out the air from your gummy mix before it hits the depositor, leading to a more uniform and smoother final product. Devices like the G300 vacuum degasser8 are fantastic for maintaining efficiency while handling high volumes.

Mixing Speed: A Key Factor in Achieving Perfect Gummy Consistency

High speeds can introduce unwanted air bubbles into the mixture, while excessively slow speeds may result in uneven ingredient integration and inconsistent textures.

To achieve optimal results, producers should aim for a balanced mixing speed that ensures thorough blending of ingredients while minimizing air incorporation. Our machines are designed with adjustable mixing speeds to help you consistently achieve the ideal texture and quality for your gummies.

Maintaining Optimal Ingredient Temperatures

Temperature control is another trick of the trade I've come to appreciate. Mixing ingredients at just the right temperature ensures everything dissolves properly, minimizing air entrapment. For instance, heating your gelatin solutions to their ideal temperature range can prevent solubility issues and help maintain a consistent gummy texture.

Ensuring that all components are at the correct temperature before mixing can significantly reduce air bubbles. Regular monitoring and adjustment of ingredient temperatures can lead to a more consistent gummy texture.

Regular Equipment Maintenance

Finally, keeping your gummy equipment in top shape has been a game-changer. Worn-out machines can introduce more air than you might think. Regular check-ups and servicing ensure everything runs smoothly, keeping those unwanted air bubbles at bay.

Routine inspections and servicing of mixers and depositors ensure they operate smoothly and efficiently.

Air bubbles in gummies cause inconsistent texture.True

Air bubbles disrupt gummy flow, affecting texture and quality.

Regular cleaning prevents depositor clogs.True

Frequent cleaning removes residual build-up, preventing nozzle blockage.

Conclusion

Clogs in gummy depositors arise from viscosity, temperature fluctuations, residual build-up, air entrapment, foreign debris, and equipment wear. Preventive measures include proper ingredient selection and regular maintenance.

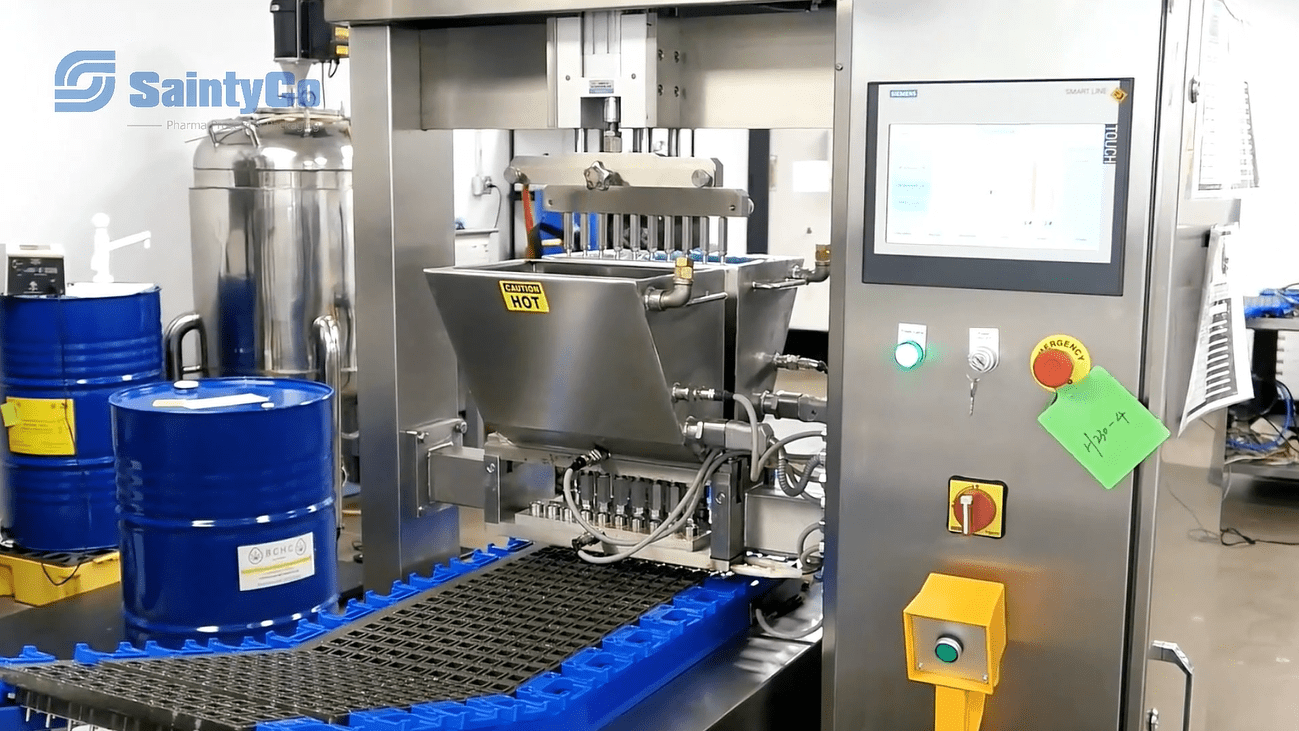

Whether you’re producing traditional gummies or specialized formulations, GummyGenix by SaintyCo is the perfect solution for achieving consistent, high-quality results.

Want to see the GummyGenix Depositor in action?

Contact us now for a personalized consultation or schedule a demo to learn more about how GummyGenix can benefit your business!

-

Explore how controlled systems help maintain optimal gummy consistency. ↩

-

Learn about cleaning practices that prevent depositor clogs. ↩

-

Explore how temperature influences viscosity in production settings. ↩

-

Learn why thermostatic systems are crucial for consistent heating. ↩

-

Understand how temperature control affects equipment longevity. ↩

-

Discover effective flushing techniques for maintaining depositor cleanliness. ↩

-

Explore how vacuum cookers ensure consistent syrup viscosity. ↩

-

Learn about high-efficiency vacuum degassing systems for large-scale gummy production. ↩