Are you looking to extend the lifespan of your Teflon-coated molds for gummy production?

To effectively clean and maintain Teflon-coated metal molds for gummies and candies, always clean immediately after use with mild detergents, employ gentle cleaning techniques, and ensure proper drying and storage. Avoid aggressive cleaning methods and improper storage practices to preserve the integrity of your molds.

By following these best practices, you can ensure that your molds remain in optimal condition, thereby enhancing the quality of your gummy products. Let’s delve deeper into each aspect of mold maintenance to unlock their full potential.

Cleaning Teflon molds immediately after use is essential.True

Immediate cleaning prevents residue buildup, ensuring the longevity and performance of Teflon-coated molds for gummies.

Aggressive cleaning methods extend the life of Teflon molds.False

Aggressive cleaning can damage Teflon coatings, reducing mold effectiveness and lifespan.

What Cleaning Products Should You Use for Teflon-Coated Metal Molds for Gummy Bears?

Are you unsure about how to properly clean your Teflon-coated metal gummy molds? Choosing the right products is vital to maintain their nonstick properties while ensuring a thorough clean.

To clean Teflon-coated metal gummy molds for gummies effectively, use mild detergents and non-abrasive scrubbers. Avoid strong acids and aggressive scrubbing tools to protect the coating's integrity.

Understanding Teflon Coating

Teflon is a popular nonstick coating used in many molds. It provides easy release and makes cleaning simpler. However, improper care can damage this coating. Thus, knowing the right products for cleaning is essential.

Recommended Cleaning Products

When it comes to cleaning Teflon-coated molds, select products that are gentle yet effective. Here are some recommendations:

| Product Type | Examples | Why Use |

|---|---|---|

| Mild Detergents | Dawn, Seventh Generation | These detergents clean without harming the Teflon. |

| Non-Abrasive Scrubbers | Soft sponges, microfiber cloths | Prevent scratches while cleaning. |

| Non-Metallic Scrapers | Plastic or silicone scrapers | Remove stubborn residue without damage. |

Utilizing mild detergents1 specifically designed for Teflon surfaces is crucial. Strong acids or alkalis should be avoided as they can degrade the coating over time.

Cleaning Techniques

Effective cleaning isn't just about the right products; it's also about technique:

- Immediate Cleaning: Always clean molds right after use. Delaying can cause residues to harden, making them tougher to clean.

- Gentle Manual Cleaning: Use warm water with a soft brush to clean your molds. For tougher residues, a non-metallic scraper works well.

- Machine Cleaning Options: Employ a steamer or dishwasher for deep cleaning. This is particularly effective for removing stubborn grease and residues.

For more insights on cleaning techniques, visit cleaning techniques2.

Maintenance Tips for Longevity

Maintaining your Teflon-coated molds extends their life. Here are some key maintenance practices:

- Avoid Physical Damage: Stiff brushes can scratch Teflon surfaces. Use soft brushes instead.

- Proper Storage: Store molds in a dry, ventilated space away from direct sunlight to prevent damage.

- Regular Inspections: Check for wear and tear. If the Teflon coating shows signs of degradation, it may be time to replace the mold.

By following these tips and using the right products, you can ensure that your Teflon-coated molds remain effective and last longer in your kitchen operations. For more information on maintaining kitchen equipment, check out equipment maintenance3.

Mild detergents are safe for Teflon-coated molds.True

Using mild detergents like Dawn is essential to clean without damaging the Teflon coating.

Metal scrubbers can be used on Teflon surfaces.False

Metal scrubbers can scratch and damage Teflon coatings, so they should be avoided.

How Can You Prevent Damage to Teflon Coatings of Gummy Molds?

Maintaining Teflon coatings is essential for ensuring their longevity and effectiveness. Here are practical steps you can take to prevent damage during cleaning.

To prevent damage to Teflon coatings during cleaning, always use mild detergents, avoid harsh chemicals, and employ gentle cleaning techniques. Thoroughly dry your items after washing to maintain their effectiveness.

Immediate Cleaning

Cleaning Teflon-coated surfaces immediately after use is crucial. This prevents residues from hardening, which can lead to more complicated cleaning processes later on. For example, if syrup or gel is left to dry, it becomes much tougher to remove.

Use of Mild Detergents

When cleaning Teflon surfaces, it’s essential to use mild detergents specifically formulated for nonstick materials. Harsh acids or alkaline cleaners can degrade the Teflon coating.

| Cleaner Type | Safe for Teflon | Note |

|---|---|---|

| Mild Detergent | Yes | Best for routine cleaning |

| Strong Acid | No | Can damage the coating |

| Alkaline Cleaner | No | Reduces effectiveness |

Gentle Cleaning Techniques

Manual Cleaning: A soft brush and warm water should be used for general cleaning.

For tougher residues, a non-metallic scraper can be employed carefully to avoid scratches.

Machine Cleaning: Dishwashers and steamers are excellent for deep cleaning Teflon surfaces, especially for stubborn grease.

Drying Properly

After cleaning, ensure that the molds or cookware are thoroughly dried. Wipe them with a soft cloth or use an air gun to remove any moisture.

Moisture can lead to corrosion or damage the Teflon coating, affecting its longevity.

Avoid Physical Damage

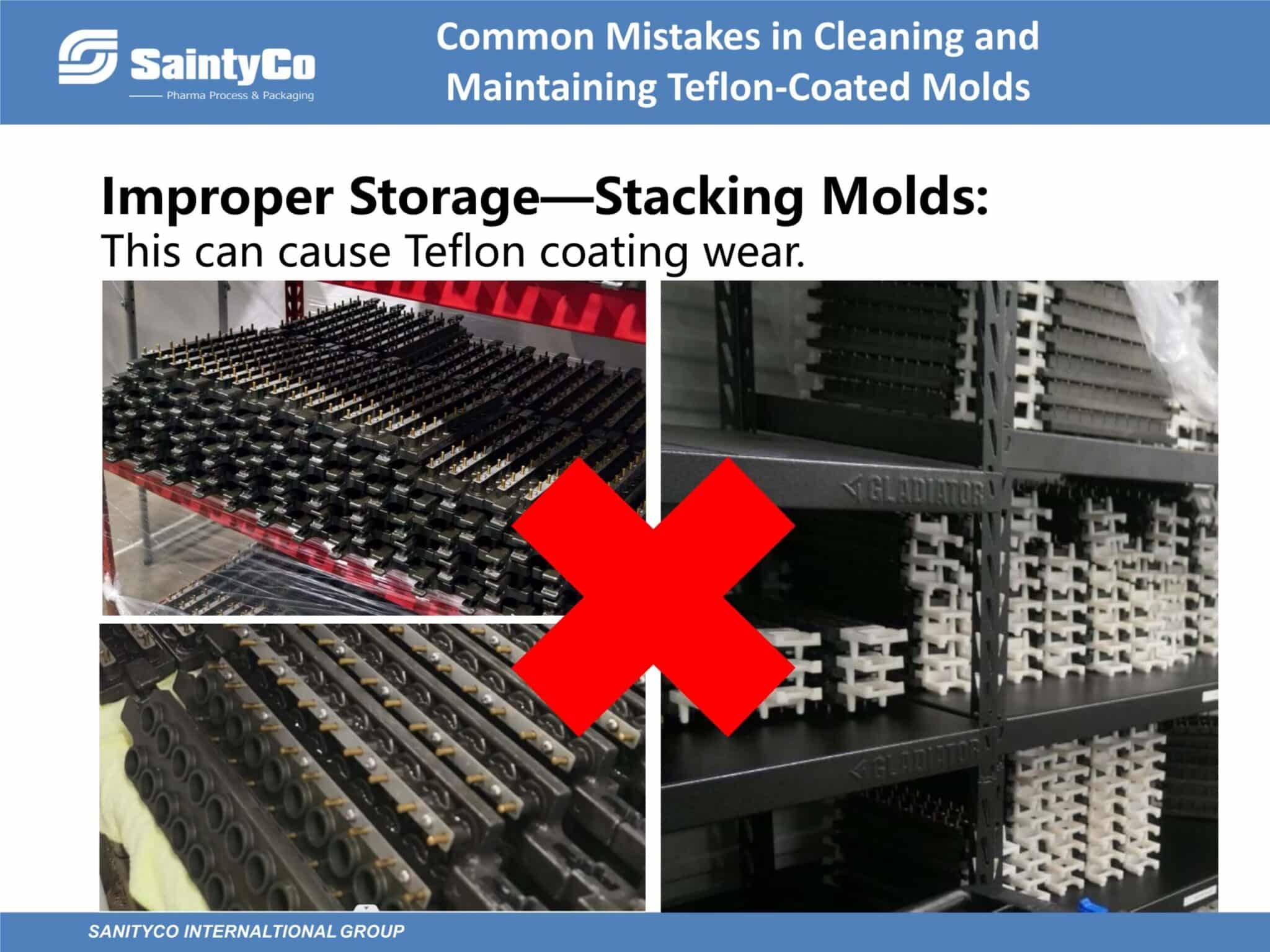

Avoid using stiff brushes or hard objects during cleaning to protect the Teflon surface. Stacking molds directly on top of each other can also cause friction wear. When necessary, use protective materials like pearl cotton between them to prevent damage.

Storage Conditions

Storing Teflon-coated items in a dry and well-ventilated area away from direct sunlight is vital.

Avoid damp environments to maintain the integrity of the Teflon coating and prevent moisture-related damage.

Periodic Checks

Regular inspections of Teflon coatings for wear and tear are essential. If any compromise is noticed, consider replacing the affected parts to ensure continued effectiveness. For instance, upgrading ejector pins to stainless steel can extend their usability significantly.

For more tips on maintaining your Teflon items, check out cleaning strategies4 that can enhance your cleaning routines!

Immediate cleaning prevents tough residue buildup on Teflon.True

Cleaning Teflon surfaces right after use stops residues from hardening, making future cleaning easier and more effective.

Harsh cleaners can safely be used on Teflon coatings.False

Using harsh acids or alkaline cleaners can damage Teflon coatings, so mild detergents are recommended instead.

What Are the Key Maintenance Practices for Metal Gummy Molds?

Teflon molds are essential in many manufacturing processes, but proper maintenance is key to their performance and longevity. What are the best practices for keeping them in top shape?

Key maintenance practices for Teflon-coated metal gummy molds include immediate cleaning after use, using mild detergents, avoiding physical damage during storage, and regular inspections for wear. Proper storage conditions are also critical.

|

|

|---|

Guide for Cleaning and Maintaining SaintyCo Teflon-Coated Metal Molds | Brand: SaintyCo

Cleaning Teflon-Coated Metal Molds

To maintain the longevity of Teflon molds, immediate cleaning is crucial. Cleaning right after use prevents residues from hardening, which can affect future production cycles.

Mild Detergents: Always opt for detergents specifically designed for Teflon surfaces. This helps remove residues effectively without harming the coating.

| Cleaning Method | Description |

|---|---|

| Manual Cleaning | Use a soft brush with warm water. For tougher spots, utilize a non-metallic scraper carefully to avoid scratches. |

| Machine Cleaning | Employ a dishwasher or steamer for deep cleaning to remove stubborn grease. |

Drying and Storage

After cleaning, ensure that molds are thoroughly dried using a soft cloth or air gun. Moisture can lead to corrosion and damage the coating.

Storage Conditions

Proper storage is vital. Store molds in a dry, ventilated area away from sunlight and humidity to prevent moisture-related damage.

- Avoid stacking: If you need to stack molds, use protective materials like pearl cotton between them to minimize friction.

Maintenance Practices

Regular checks are essential to ensure Teflon mold integrity. Focus on the condition of the coating and ejector pins. Upgrading to stainless steel ejector pins can enhance durability and resist corrosion.

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Replace Worn Parts | As Needed |

For more information on effective Teflon maintenance practices, check out best practices for mold cleaning5 and storage solutions for manufacturing6.

Immediate cleaning of Teflon molds prevents residue buildup.True

Cleaning Teflon molds right after use stops residues from hardening, ensuring optimal performance in future cycles.

Storing Teflon molds in humid areas is acceptable.False

Teflon molds should be stored in dry, ventilated areas to prevent moisture-related damage and prolong their lifespan.

What Common Mistakes Should Be Avoided in Mold Care?

Understanding the common mistakes in mold care can help you prevent costly damage and ensure efficient production cycles.

Avoiding common mistakes in mold care, such as improper cleaning and storage techniques, is essential for maintaining mold integrity and production quality. Proper maintenance practices can significantly extend the lifespan of your molds.

Common Mistakes in Mold Maintenance

When it comes to mold care, avoiding mistakes can save both time and resources. Here are some of the most common pitfalls to be aware of:

-

Delaying Cleaning: Cleaning molds immediately after use is crucial.

Delays allow residues to harden, complicating cleaning efforts and affecting production cycles. For effective cleaning strategies, check cleaning techniques7. -

Using Harsh Cleaners: Many people opt for strong detergents or acid cleaners, thinking they will do a better job. However, these can damage Teflon coatings, reducing effectiveness. Stick to mild detergents specifically formulated for Teflon surfaces.

-

Neglecting Drying: Post-cleaning drying is often overlooked. Molds must be thoroughly dried to prevent corrosion. Use a soft cloth or air gun to eliminate moisture. Learn more about drying methods in moisture control8.

-

Aggressive Cleaning Techniques: Scrubbing too hard with stiff brushes can scratch the mold surfaces, leading to product quality issues over time. Use gentle methods such as a soft brush with warm water.

-

Improper Storage: Molds should not be stacked without protective materials. If space is limited, placing protective materials like pearl cotton between molds can prevent friction damage. For storage tips, see storage best practices9.

Maintenance Oversights

Regular maintenance is key to mold longevity:

-

Ignoring Periodic Checks: Regularly inspect molds for wear, especially the Teflon coating and ejector pins. Many newer molds have stainless steel pins that resist corrosion better than older brass options.

-

Overlooking Coating Integrity: If the Teflon coating shows wear, it’s often best to replace the molds to maintain quality. Consider upgrading parts like ejector pins to extend mold usability.

| Maintenance Tip | Importance |

|---|---|

| Regular Inspection | Catch wear before it impacts production |

| Use Protective Materials | Prevent friction damage during storage |

| Upgrade Parts When Needed | Extend mold lifespan and maintain quality |

Conclusion on Common Mistakes

Being aware of these common mistakes in mold care can significantly enhance your production quality and mold lifespan. The goal is to maintain molds in the best possible condition for optimal performance. For a deeper understanding of mold care practices, visit our detailed guide on mold maintenance10.

Delaying mold cleaning can complicate future maintenance.True

Immediate cleaning prevents residue hardening, simplifying maintenance and ensuring efficient production cycles.

Using harsh cleaners is safe for Teflon-coated molds.False

Harsh cleaners can damage Teflon surfaces, reducing mold effectiveness and quality over time.

Conclusion

Learn essential tips for cleaning and maintaining Teflon-coated gummy candy molds to enhance their longevity and performance through proper cleaning techniques and storage practices.

Additional Resources

For more information on mold cleaning and maintenance, refer to the detailed PDF guide provided by SaintyCo. (Fill out the right-hand inquiry form for a digital copy.)

At GummyGenix by SaintyCo, we're here to support your journey with cutting-edge, GMP-compliant gummy manufacturing equipment designed for efficiency, precision, and adaptability. Our machines are fully compatible with regulatory standards, and we offer reliable after-sales support to keep your operations running smoothly.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality gummy products to life—together.

Gummy Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Discover the best cleaning products for Teflon-coated molds to maintain their quality and longevity. ↩

-

Learn effective cleaning techniques specifically designed for maintaining Teflon-coated kitchenware. ↩

-

Understand how to properly maintain Teflon-coated molds to enhance their lifespan and performance. ↩

-

Discover effective cleaning methods tailored specifically for Teflon surfaces that will prolong their life and maintain their nonstick properties. ↩

-

Explore this link for expert advice on maintaining Teflon molds effectively, ensuring they last longer and perform better in your operations. ↩

-

This resource offers insights on optimal storage solutions that can enhance the lifespan of your Teflon molds significantly. ↩

-

Discover effective cleaning and storage methods that ensure mold longevity and quality production. ↩

-

Learn how to properly dry molds after cleaning to prevent corrosion and damage. ↩

-

Get insights into proper storage practices that protect your molds from damage. ↩

-

Understand the importance of regular checks and maintenance for mold integrity. ↩