Choosing the right gummy making machine is a big decision for any gummy business owner. The right machine can help you make your gummies faster, make better gummies, and make more money. This guide will help you choose the best industrial gummy making machine for your business.

Determining the production capacity of a gummy-making machine is essential before making a purchase. It's typically measured in weight per hour and depends on your gummies' desired size and weight. Keep in mind that the automation level and size of the machine also influence production capacity.

.

Choosing the best gummy machinery involves several considerations, which we will explore in detail.

.

How to Choose the Best Gummy Making Machine for Sale in the USA?

When selecting a gummy making machine in the USA, it's crucial to consider several market-specific factors.

Firstly, assess your production scale. Are you aiming for small-scale production, or do you need a machine designed for large-scale operations?

Regulatory compliance is paramount in the USA. Ensure the machine adheres to local standards, including ISO 9001:2015, cGMP Regulations, and FDA Quality Standards. This compliance guarantees that your machine is safe, reliable, and meets stringent industry requirements. Furthermore, many of our clients also require machines that are cGMP certified and conform to FDA CFR 21 Part 11. Defined by the Food and Drug Administration, cGMP—current Good Manufacturing Practice—outlines essential guidelines that manufacturers must follow to ensure their products are safe, pure, and effective. Adherence to these standards is mandatory for gummy manufacturers and their machinery suppliers to ensure they meet our industry-leading specifications.

.

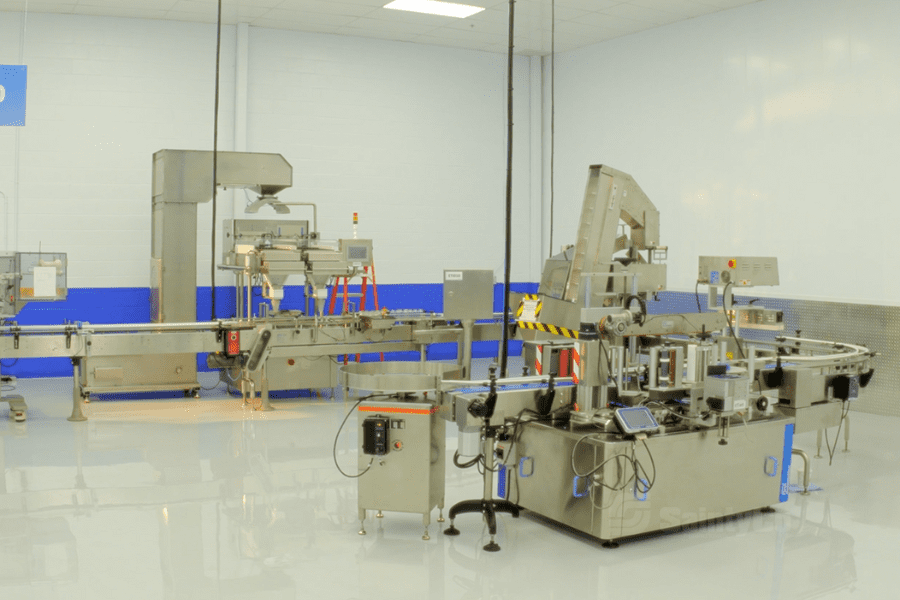

Consider the availability of local support and service. Choosing a supplier with a robust local presence is essential as it helps minimize downtime related to maintenance and repairs. Additionally, the US market prioritizes efficiency and advanced automation. Opt for machines with enhanced automation capabilities to streamline production processes and minimize labor costs.

.

.

Understanding the Gummies Manufacturing Process

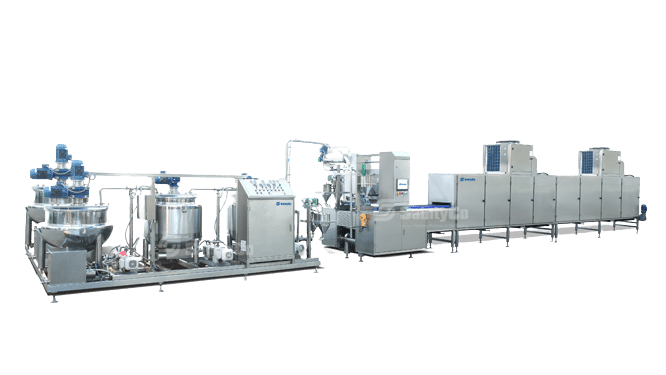

To choose the best gummy making machine, you need to understand the gummy manufacturing process. The process typically involves cooking, depositing, cooling, demolding, and sometimes coating. Each stage requires specific machinery designed to handle the tasks efficiently.

- Cooking: This stage involves heating and mixing the ingredients to create the gummy base. A good cooking machine will offer precise temperature control to ensure consistency.

- Depositing: This is where the gummy mixture is poured into molds. Servo dosing systems are ideal for this stage as they offer high accuracy, which is especially important for cannabis, pharma, and medicated gummies.

- Cooling: After depositing, the gummies need to be cooled to set properly. Cooling tunnels are used to bring the gummies to the desired temperature quickly.

- Demolding: Once cooled, the gummies are removed from the molds. This step must be handled carefully to avoid damaging the gummies.

- Coating: Some gummies, such as sour gummies, require an additional coating step. Coating machines apply a uniform layer of sugar or other substances to the gummies.

- Packaging: The final stage involves packaging the gummies for sale. Gummy packaging equipment is automated systems that use weight or count, packing your candies to perfection. Packaging machines should offer flexibility and efficiency to handle different packaging formats. This can involve weighing, bagging, wrapping, and boxing machines.

.

.

Commercial Gummy Making Machine Features to Consider

When choosing a gummy making machine, several features should be top of mind:

- Servo Dosing: Crucial for high-precision dosing, servo systems are essential in cannabis, pharmaceutical, and medicated gummy production where exact dosing is required. These systems outperform pneumatic options by delivering consistent, accurate control across various viscosities with minimal waste, ideal for precise formulations.

- Hygienic Design: Ensures the machine is easy to clean and meets sanitary standards.

- Quality Certifications: Look for machines certified with ISO 9001:2015, CE Electrical Certification, FDA Quality Standards, and cGMP compliance. Additionally, the machine should be part of a manufacturing facility that meets FDA CFR 21 Part 11.

- Automation Level: Depending on your production needs, you may require a fully automatic machine or a semi-automatic one.

- Customization Options: The ability to customize the machine to meet specific production requirements can be a significant advantage.

.

.

Top Brands in Gummy Machine Manufacturing

Several brands stand out in the gummy machine manufacturing industry, each with its own unique strengths that are suited to different sectors. Here are a few to consider:

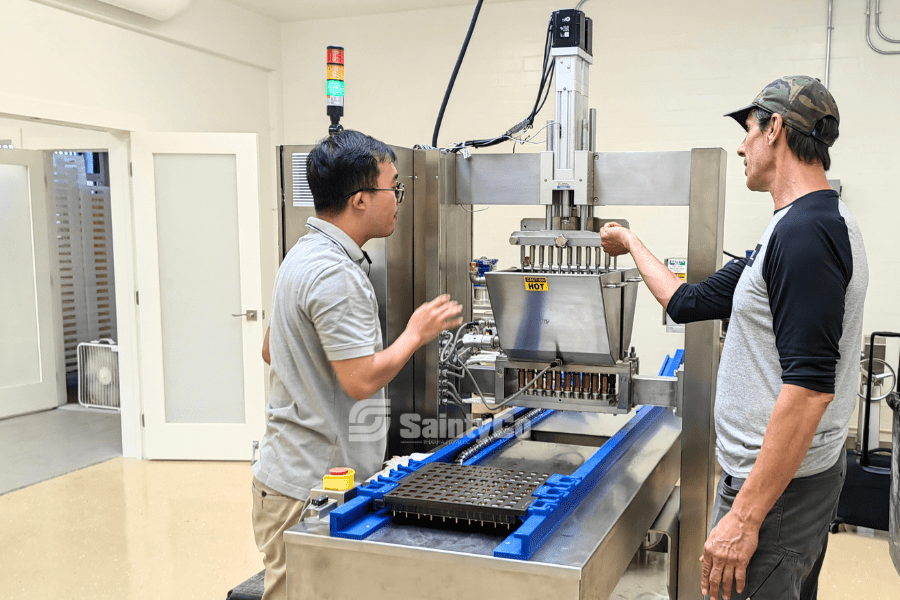

- SaintyCo: Renowned for its innovative, hygienic designs and comprehensive certifications, SaintyCo offers semi-automatic and fully automatic gummy manufacturing machines. With global sales support and competitive pricing, they are a preferred choice for many gummy manufacturers. Their machines are celebrated for robust design, customization options, and ease of cleaning and maintenance, crucial for the cannabis industry’s regulatory environment. SaintyCo is a premier pharmaceutical machine manufacturer, cGMP compliant, providing IQ/OQ Documentation Protocols for qualification and validation. They have also developed advanced dosing and mixing solutions for the cannabis sector, ensuring uniformity and potency in CBD/THC infused gummies.

.

.

- Baker Perkins: Known for high-quality food processing machines, Baker Perkins specializes in large-scale candy production. Their machines feature advanced automation, streamlining production and reducing labor costs. With strong customer support and extensive confectionery sector experience, Baker Perkins is a top choice for traditional gummy and candy production.

.

- Tanis: Tanis offers a range of candy production machines tailored to various needs, known for durability and precision. They provide options from small-scale to large-scale production, making them versatile for different business sizes. Tanis's innovative technology ensures consistent high-quality gums and jellies, making them ideal for the confectionary and OTC sectors.

.

Customization and Support for Unique Client Needs

Customization is a crucial factor when selecting a gummy making machine. Each business has unique needs, and having the ability to customize the machine to meet those needs can be a significant advantage.

Here are some specific customization options and support needs:

- Facility Layout: Different facilities have varying layouts, and a customizable machine can fit seamlessly into your production space. This includes considerations for space constraints and workflow optimization.

- Ingredients: Depending on the type of gummies you produce, whether gelatin-based, pectin-based or another formulation, the machine must be able to handle these ingredients effectively.

- Gummy Types: Businesses producing a variety of gummies, such as cannabis, pharmaceutical, or nutraceutical gummies, need machines with adjustable settings and interchangeable parts to accommodate different recipes and production methods.

- Production Scale: From small-batch to large-scale production, scaling the machine's capacity to match production needs can help manage costs and efficiency.

- Advanced Features: Options like servo dosing for precision, double-head depositing stations for multiple layered or center-filled gummies, and integrated cooling systems can be tailored to enhance specific production requirements.

- UL Certification: Machine manufacturers should also be able to customize machines or parts to meet UL certification standards, ensuring safety and compliance with local regulations.

.

Support is just as important as the machine itself. A reliable supplier should offer comprehensive after-sales service, including installation, training, and ongoing maintenance. This level of support guarantees smooth operation and quick resolution of any issues. Opt for suppliers who provide local support to reduce downtime and resolve technical problems swiftly.

.

.

Summary

Selecting the ideal gummy making machine requires a thorough assessment of production capacity, machine features, brand reputation, and the availability of customization and support. By understanding your specific needs and exploring available options, you can choose a machine that boosts your production and contributes to your business’s success.

.

Remember, the right machine is a crucial investment in your business's future. Invest the time to research and make a well-informed choice to ensure you achieve the best return on your investment.

.

.

This information is provided as guidance only; users must conduct their application tests. GummyGenix by SaintyCo does not assume any responsibility for using this information. Our seasoned team can assist you with any questions concerning machine use. For more detailed information on our gummy production solutions and equipment, visit GummyGenix or SaintyCo’s website or contact me at [email protected].