Commercial Hard Candy Making Machines

From cooking to packing, depositing and die-forming solutions for functional/medicated hard candies and lollipops—pilot to high-volume.

Join OEMs, brands, and startups choosing SaintyCo hard candy machines — depositors, fully-automatic depositing or die-forming lines. Get precise forming, fast cycles and stable output with batch accuracy. Handle multi-flavor runs and produce clear, striped, layered, center-filled, sugar-free, or lollipops (stick insertion) with quick changeovers, up to 600 kg/h.

Get help solving your biggest automation problems

Increase Your Return on Investment on Every Dollar Spent on Hard Candy Production & Packaging Machines.

Pilot-Scale & Laboratory

Hard Candy Depositors

Ideal for lozenges, lollipops*, or small-batch hard candy runs. Outputs up to 15,000 pcs/hr (DM-50X) and 6,000–10,000 pcs/hr (DM-20S) with consistent dosing, less scrap, and fewer steps than traditional forming; typical piece weight 2–8 g. Works with metal or silicone molds, and molds can scale to future full-auto lines.

Quick mold changeovers, index conveyor (DM-50X) for automatic mold advance, and integrated demolding (DM-20S) keep runs smooth and repeatable; 1–2 people can run it easily.

Built in food-grade stainless steel, on wheels, with a simple touchscreen HMI — ideal for labs, pilot lines, or first automation.

*Lollipops require a lollipop former plus stick insertion unit.

Reliable Choice for Entry-Level Hard Candy Machine

DM-50X Servodose Mini Depositor

DM-20S 2-in-1 Lab Scale Depositor

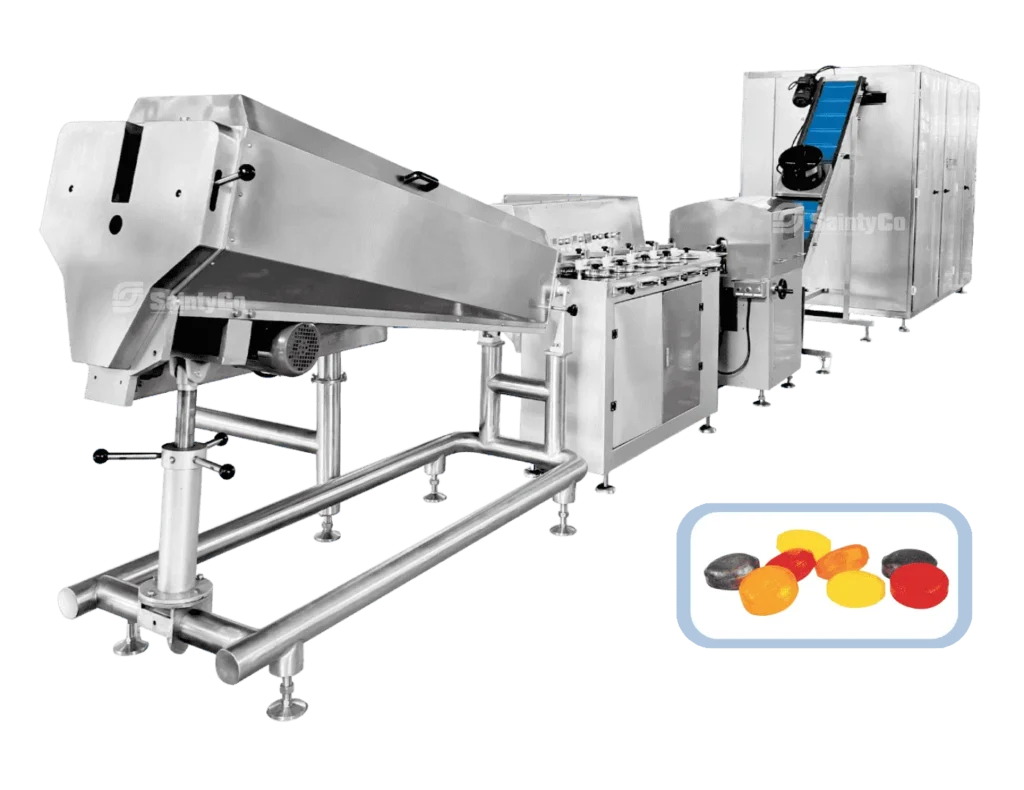

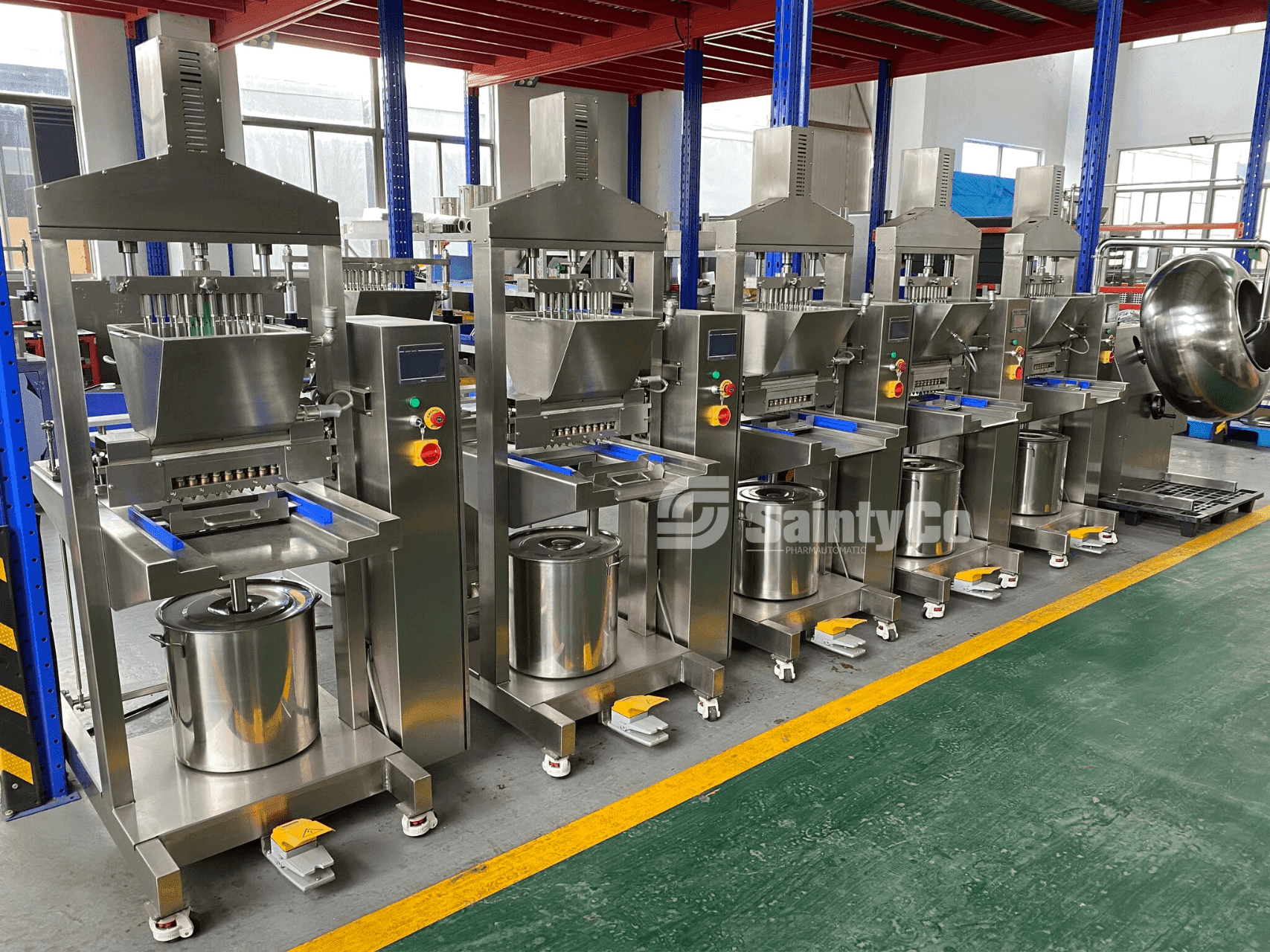

Continuous & Mid to Large-Batch Hard Candy Manufacturing

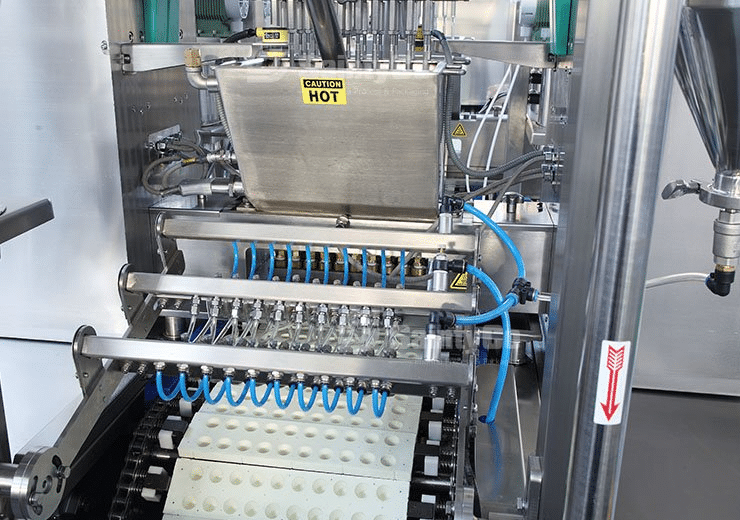

Hard Candy depositing making machines

Precision and Control

Equipped with PLC and an LED touch panel, the system ensures stable syrup flow and precise dosing. Servo systems and dosing pumps handle color, flavor, and acid injection. Quick mold changeovers support versatile formats.Customizable to Drive Your Success

Tell us your goals. You can also choose from options such as- Design L-, U-, or straight-line layouts to fit factory space.

- Control steam automatically for stable microfilm cooking.

- Use center-filling or two-color striping nozzles to expand product variety.

- Integrate in-line pre-mixing and dosing for smoother production flow.

200+ candy brands and OEMs clients worldwide trust SaintyCo for reliable hard candy production — batch after batch.

Hard Candy making machine That Scale With You

HC-150 Hard Candy Making Machine

Power Supply: 30kw

Steam Consumption: 250kg/h

Air Consumption: 0.2m³/min | Air Pressure: 0.4~0.6MPa

Length: 15m | Weight: 3500kg

HC-300 Hard Candy Making Machine

Power Supply: 40kw (Steam heating), 260kw (Electric heating)

Steam Consumption: 500kg/h

Air Consumption: 0.2m³/min | Air Pressure: 0.4~0.6MPa

Length: 18m | Weight: 5500kg

HC-600 Hard Candy Making Machine

Power Supply: 40kw (Steam heating), 260kw (Electric heating)

Steam Consumption: 500kg/h

Air Consumption: 0.2m³/min | Air Pressure: 0.4~0.6MPa

Length: 18m | Weight: 5500kg

Ancillary Equipment for Precise Shaping and Efficient Handling

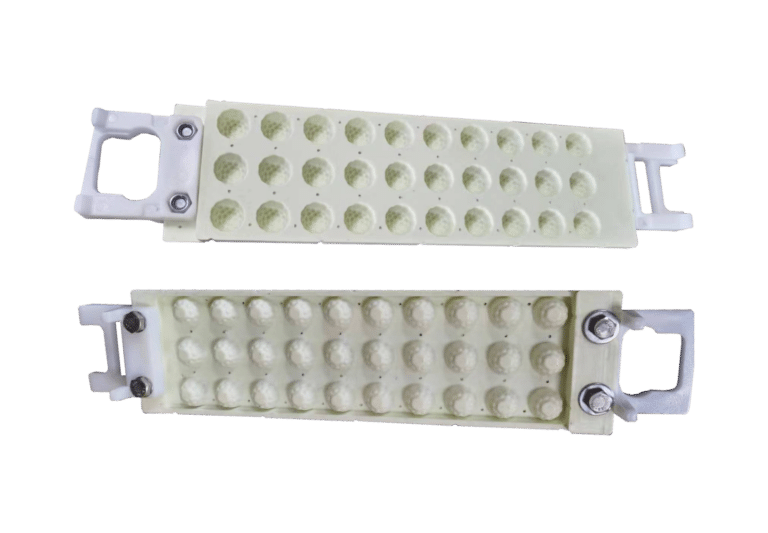

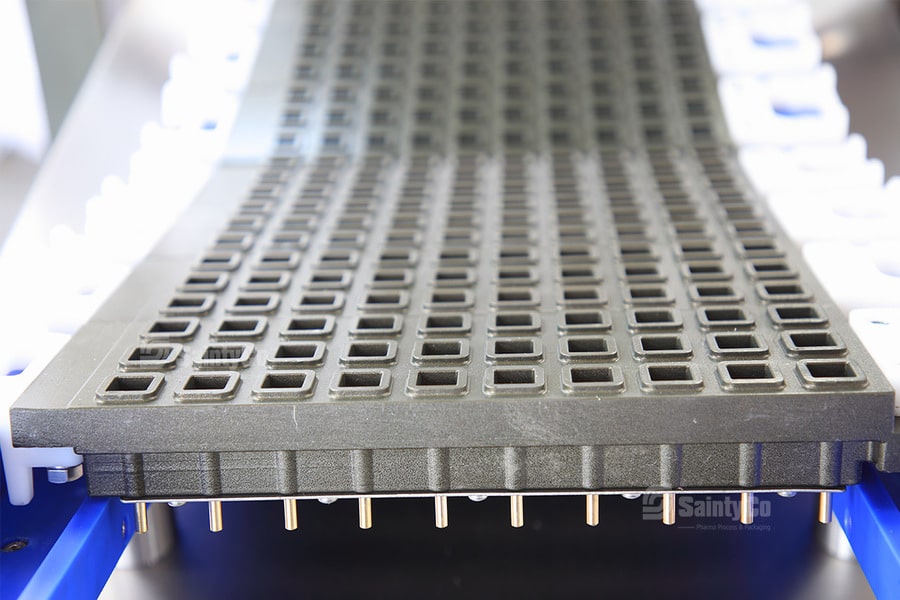

Metal Hard Candy Molds

Silicone Hard Candy Molds

Drying Tray & Dolly

Shape Hard Candy Faster — With Precision, Output & Consistency

Hard Candy Die Forming making machines

Start trials on the SaintyCo HC-200 drop roller candy machine – a compact, low-cost solution for small batches, featuring quick die swaps to run multiple shapes on a single unit.

When demand grows, move to the DF-Series automatic die-forming line that integrates an auto-weighing system, a candy cooking machine, a candy batch roller, a candy rope sizer, a candy forming machine, and a cooling/vibration tunnel for consistent shapes and smooth release at 100–400 kg/h. Swap dies for new shapes or add a lollipop former; central-fill available. Hygienic stainless and a simple HMI keep cleaning fast and output steady shift after shift.

Starter Machine for Die-Formed Candy Projects

HC-200 candy Drop Roller

- Siemens motor + Siemens inverter for precise speed control

- CNC custom rollers for rope-formed candies and dragees

- Specialised tabletop equipment for small-format candy industries, laboratories, and pilot developments

- Capacity: 10-20kg/hr

- Power Supply: 220V/1KW

- Gross weight: 80kg

Hard Candy Die Forming making machines for Smooth, Steady & Scalable Output

| Model | DF-150 | DF-200 | DF-300 | DF-400 |

|---|---|---|---|---|

| Capacity | 100kg/h | 200kg/h | 300kg/h | 400kg/h |

| Power | 20kw | 18kw/380V | 38kw/380V | 38kw/380V |

| Steam Consumption | 100 kg/h | 200 kg/h | 400 kg/h | 400 kg/h |

| Steam Pressure | 0.5-0.8 Mpa | 0.5-0.8 Mpa | 0.5-0.8 Mpa | 0.5-0.8 Mpa |

| Air Consumption | 0.25 m³/min | 0.25 m³/min | 0.25 m³/min | 0.25 m³/min |

| Air Pressure | 0.4-0.6 MPa | 0.4-0.6 MPa | 0.4-0.6 MPa | 0.4-0.6 MPa |

| Length | 14m | 16m | 18m | 22m |

| Weight | 3000kg | 4500kg | 8000kg | 8000kg |

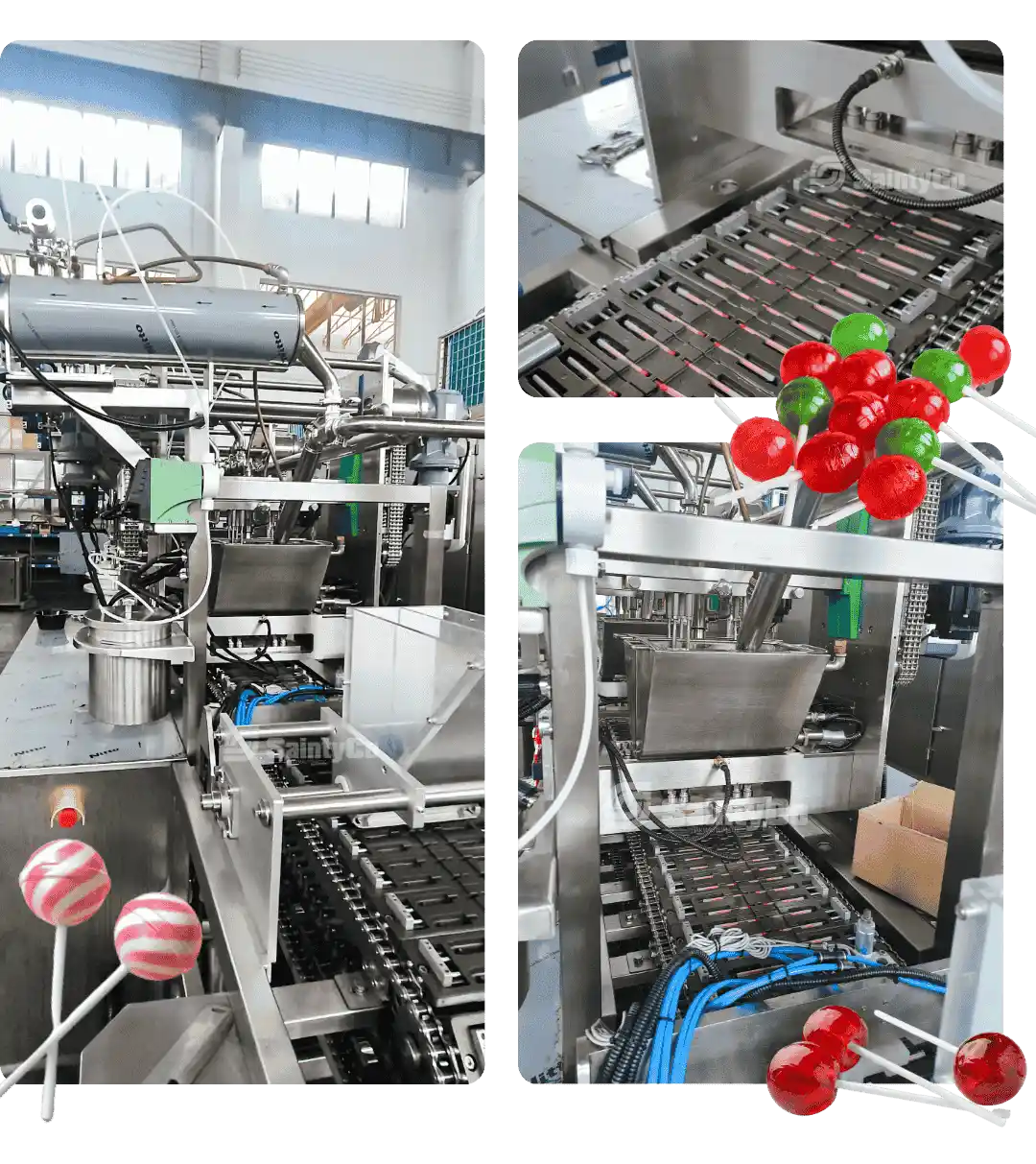

Make Lollipops on Your Hard Candy Production Line

Die-Forming Lines — Quick Change to Lollipops

- Swap to a lollipop forming die; enable the automatic stick feeder.

- Set rope diameter to the die and sync the cutter to stick pitch.

- Match stick length/Ø to the die; tune cooling speed.

- Output round or flat pops with consistent weight and smooth finish.

Depositing Lines — Lollipop Stick Insertion System

- Ball pops: deposit first; unit inserts sticks, keeps alignment during cooling.

- Flat pops: sticks load into molds first; the servo depositor fills each cavity.

- Per-mold control for alignment, clean release, and repeatable weight

- Quick mold changeovers; supports sugar-free and multi-color.

Efficient Output with Stable Flavor and Shape

Continuous forming enables high-speed production with minimal waste while maintaining hygiene and quality. Output ranges from 100 to 300kg/h, ready to scale with your production needs.Join 200+ candy manufacturers who trust SaintyCo to deliver consistent, high-quality hard candy — stick by stick.

Hard Candy Making Equipment Backed by Service That Delivers

Applications & Industries

Choose The Right Candy Machinery by Product Type

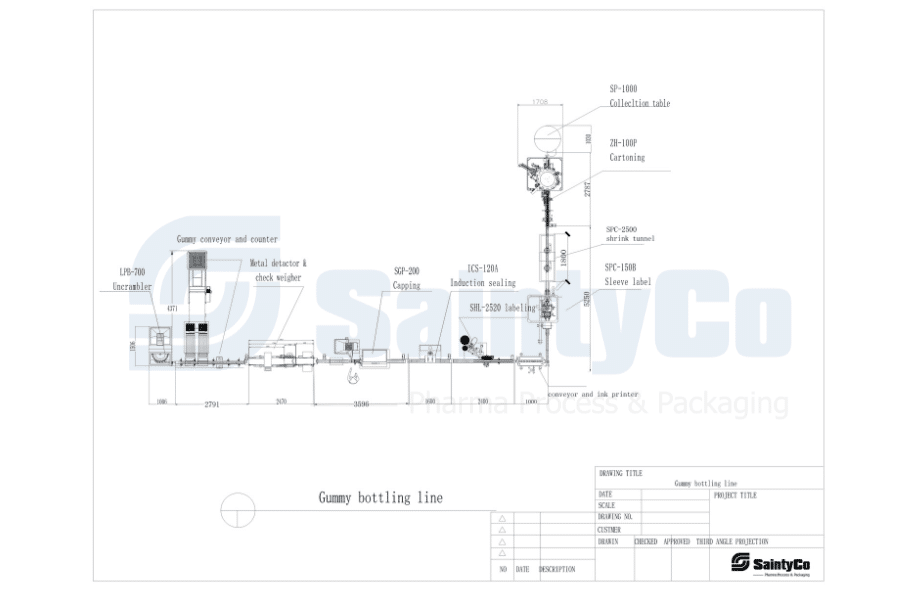

GummyGenix by SaintyCo provides hard candy making equipment and packaging systems built for yield, uptime, and food-grade compliance.

Our technology helps you develop new products quickly. Supported formats include one–four color, striped, layered, center-filled, and multi-component—via simple configuration changes.

Who wins with GummyGenix — and how it boosts your line

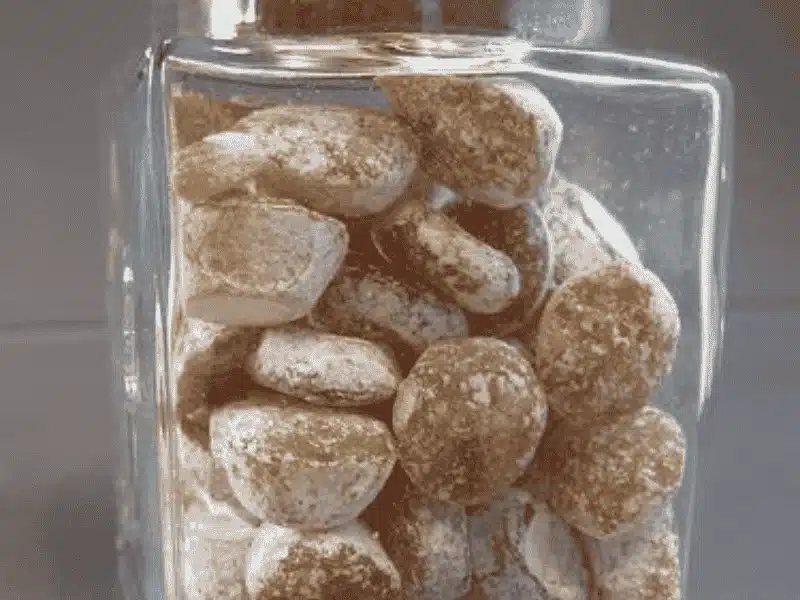

- Food & confectionery brands – Mint · Fruit · Sugar-free · Two-color · Lollipop-ready.

- Nutraceutical & OTC – Herbal/Throat · Vitamin · In-line dosing.

- Lollipop producers – Flat/Die-formed · Stick insertion · Single/Double-twist · Flow-wrap.

- Contract manufacturers & co-packers – Fast changeover · Multi-product lines · 150–600 kg/h · Die-forming.

- Pilot & R&D labs – Compact · Trials · Quick molds · Small footprint.

Trusted Supplier of Candy & Gummy Machinery

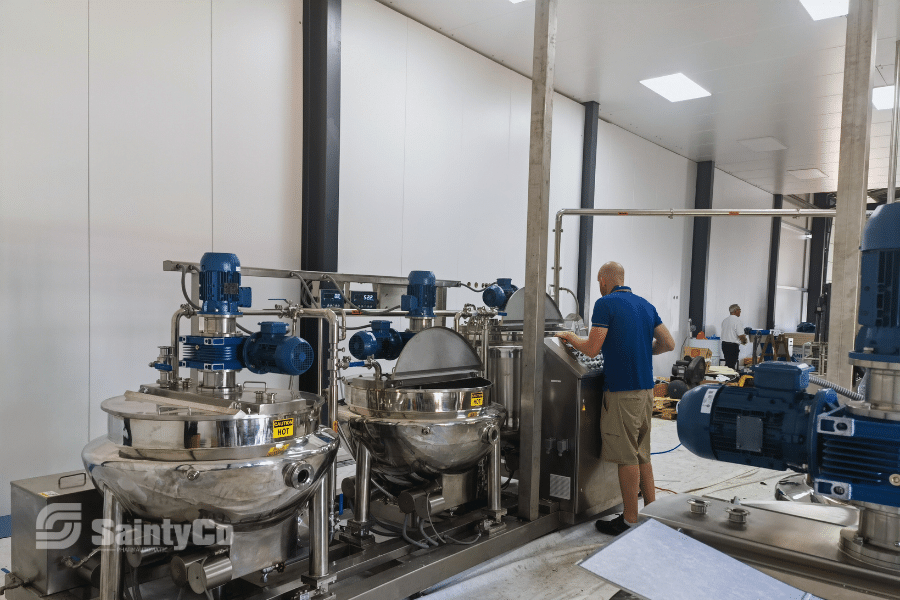

GummyGenix, powered by SaintyCo, supplies candy, gummy, and popping boba machinery to manufacturers of functional and medicated products worldwide — SaintyCo International Group has even deeper roots, with 25+ years of designing, developing, and manufacturing advanced pharmaceutical machinery.

We build CE- and cGMP-compliant commercial candy making equipment across scales — from cooking and depositing to packaging — for hygienic production of hard candies, flat lollipops, and medicated lozenges.

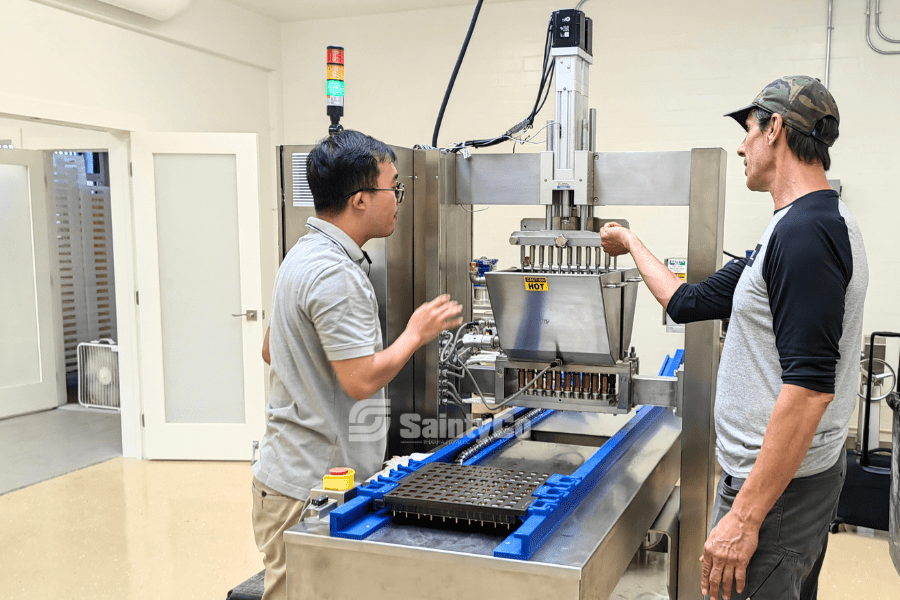

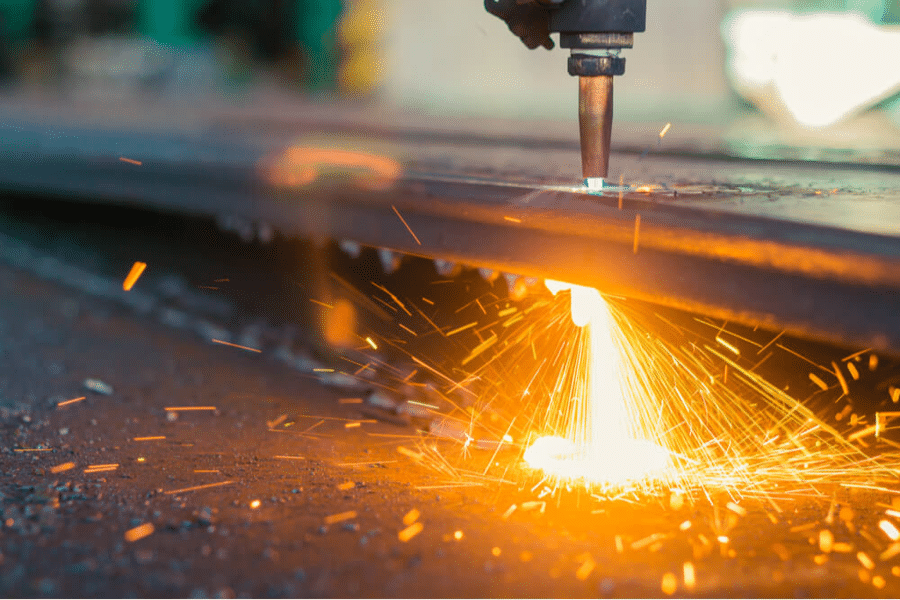

With in-house R&D, CNC machining, and full FAT before shipment, we ensure quality and innovation — helping clients across confectionery, nutraceutical, and pharma, from private-label brands to contract manufacturers, keep production lines delivering day after day.

countries SERVED

Happy Clients

Avg. Production Growth

Installed depositing lines

Your success is our priority and we'll be there every step of the way

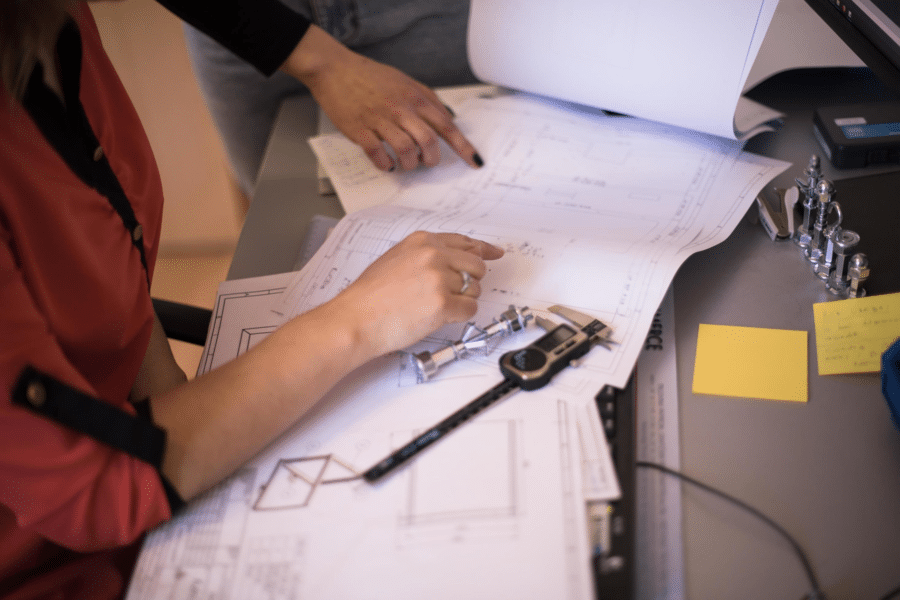

Tailored Consultation for Your Production Goals

Your plant layout, capacity goal, candy type, and budget guide how we customize your hard-candy production line. Our automation team — experienced in confectionery manufacturing — applies field know-how and years of system design to deliver hard candy making equipment that runs at high efficiency and fits your process.

Book a free consultation anytime via WhatsApp, call, or email — whatever’s easiest for you. No pressure, just practical advice.

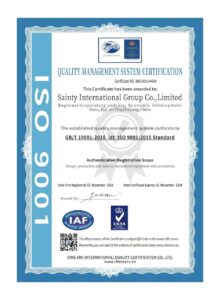

International Standards Organization (ISO) 9001:2015

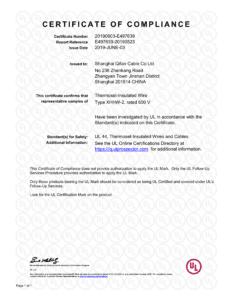

CE Electrical Certification

Food and Drug Administration (FDA) Quality Standard & Certification

UL Certification (US)

SGS-CSTC Testing Inspection Certification

Certified quality, customized machinery, built for compliance.

SaintyCo’s hard candy production solutions meet international compliance standards, including cGMP, GMP, 21CFR part II, and CE. Our decades of R&D and manufacturing expertise in confectionery and pharma-grade automation support global factories with reliable, high-quality equipment, from die-forming or depositing lines to fully integrated production systems.

You can be sure of the quality you receive

All GummyGenix equipment undergoes a thorough Factory Acceptance Test (FAT), including visual inspection, functions, controls, and safety checks. We test all components for accuracy and calibration—covering temperature, pressure, speed, rotations, dosage, and safety—and document every step to ensure full traceability.

Delivery Right to Your Doorstep, Worry-Free

Purchasing equipment abroad involves securing favorable freight rates, choosing the right ports, and handling customs efficiently. With over 20 years of export experience, we streamline these processes for a seamless acquisition. All machinery is shipped in export-compliant wooden crates, ensuring protection that meets national standards.

By collaborating with top-tier logistics providers, we ensure your machinery arrives safely and on time, enabling a swift transition to production.

Passionate about customer care, supporting you anywhere needed

Our Technical Support offers detailed manuals, quick installation, spare parts, and continuous assistance from factory-trained techs and a global network of independent technicians, ensuring smooth operations with minimal downtime.

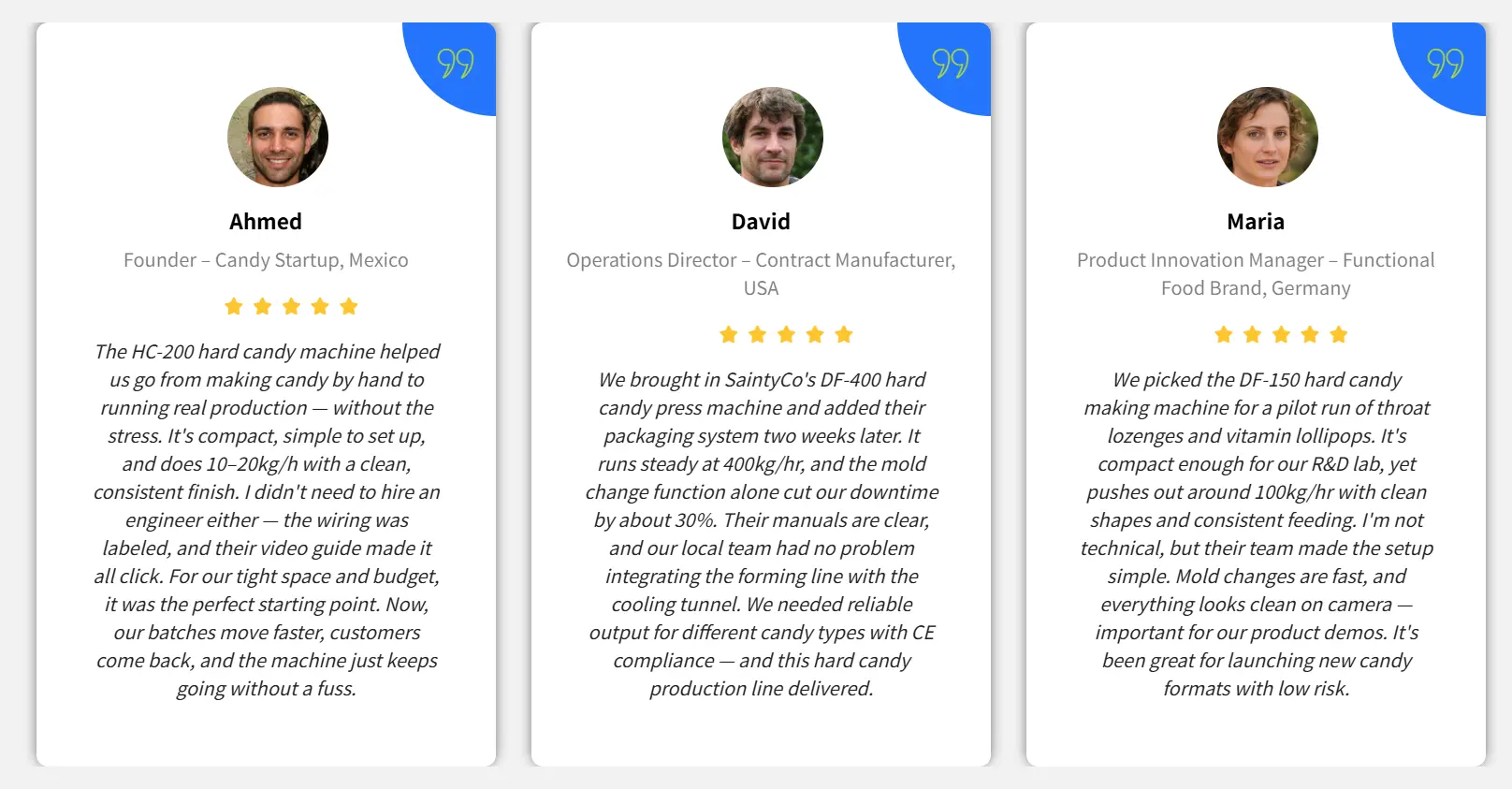

Our biggest achievement is a "Happy Customer"

Join hundreds of companies experiencing production success with us.

Boost Output & Efficiency with Proven Hard Candy Equipment

Leverage Global Know-How for Automation Built Around Your Needs

- Awareness of your needs

- Recommend solutions for your reference and comparison

- Reasonable Pricing

- 360° After-Sales Support

- HARD CANDY MACHINE FORM

- HARD CANDY PACKAGING SOLUTION FORM

- CUSTOM HARD CANDY MOLD FORM

- service support form

Hard Candy Making Machine Form

Note: Once all the fields are completed and the submit button is clicked, you will be redirected to a form submission confirmation page. If this does not happen, the form was not submitted successfully. Double check ALL fields are filled out correctly to submit successfully.

Hard Candy Packaging Solution Form

Note: Once all the fields are completed and the submit button is clicked, you will be redirected to a form submission confirmation page. If this does not happen, the form was not submitted successfully. Double check ALL fields are filled out correctly to submit successfully.

Custom Hard Candy Mold Form

Note: Once all the fields are completed and the submit button is clicked, you will be redirected to a form submission confirmation page. If this does not happen, the form was not submitted successfully. Double check ALL fields are filled out correctly to submit successfully.

Service & Parts Request Form

Note: Once all the fields are completed and the submit button is clicked, you will be redirected to a form submission confirmation page. If this does not happen, the form was not submitted successfully. Double check ALL fields are filled out correctly to submit successfully.

Frequently Asked questions

Still can’t find the information you want? Don’t hesitate to contact us.

To purchase SaintyCo's hard candy equipment, simply contact us today to request a quote. Share your production specifications, and our experts will guide you in selecting the Professional Confectionery Machine for Lollipop, Hard Candy, Gummy, etc for your needs. We ensure a seamless and tailored solution for your candy production endeavors.

Yes. SaintyCo provides customized hard candy machines that can switch between lozenges, striped candies, center-filled candies, and flat or round lollipops by changing molds and adjusting depositing settings — all in one line.