Automatic Popping Boba Machines & Production Lines

Your Popping Boba Line Starts Here — Production, Packaging, Pasteurization Equipment and Support All in One Place

Join hundreds of businesses—from tea brands to export-focused factories—relying on SaintyCo’s popping boba machines for cleaner production, precise control, and scalable growth. All from one source for a streamlined experience.

Pharma-Inspired. Food-Focused

Built to meet higher hygiene and precision standards—ideal for functional foods, clean-label SKUs, and export markets.

Built to Fit Your Process

From small batch setups to fully automated lines—our modular design adapts to your space, scale, and recipes.

Competitive Pricing & Certified

CE, ISO 9001, and GMP compliant—delivering global-standard performance at better value than local suppliers.

Support That Actually Shows Up

Real-time help via call, video, or on-site. Fast, responsive, and timezone-friendly.

Get help solving your biggest automation problems

Increase Your Return on Investment on Every Dollar Spent on Popping Boba Production & Packaging Machines.

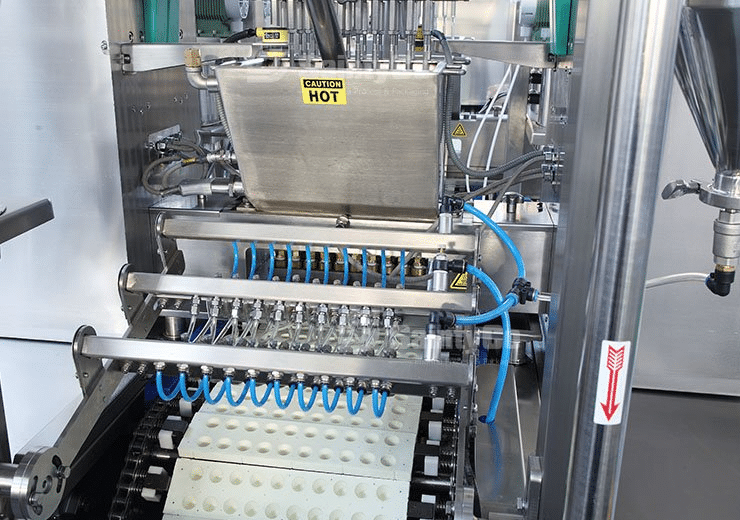

Automatic Popping Boba Depositors

Ideal for new recipe testing, pilot production, or training, this compact popping boba pouring machine produces up to 24,000 popping boba/hour with consistent size and shape.

Equipped with a pneumatic filling system, servo-driven conveyor, and PLC control, it ensures stable dosing and easy operation. The 30L hopper and 20-piston system deliver smooth flow, while the buffer boards minimize splash and waste.

Built with a SUS304 stainless frame and food-grade contact parts, it’s easy to clean, fast to install, and fits perfectly in labs or tight spaces.

Exploring new flavors or prepping for scale-up? This is your go-to starting point.

Compact Solution for Small-Scale Popping Boba Production

Mini Lab Popping Boba Depositor

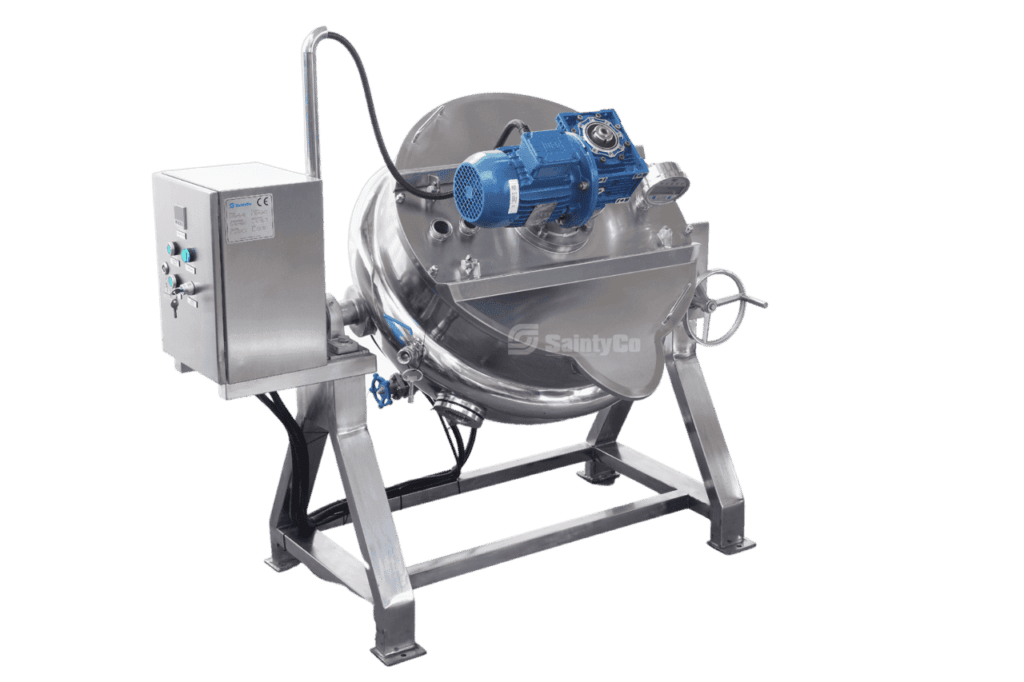

100L Tilt Cooker

Popping Boba Production Lines

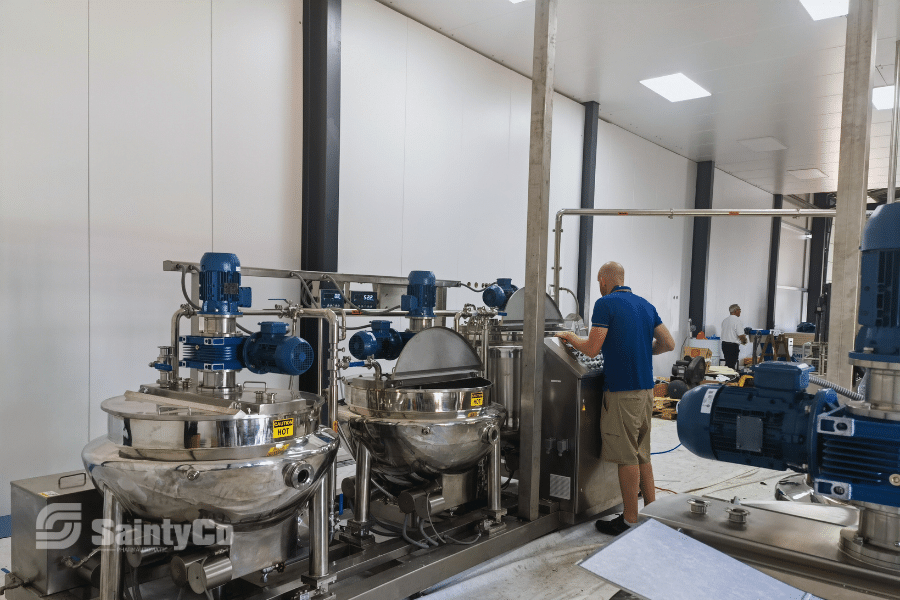

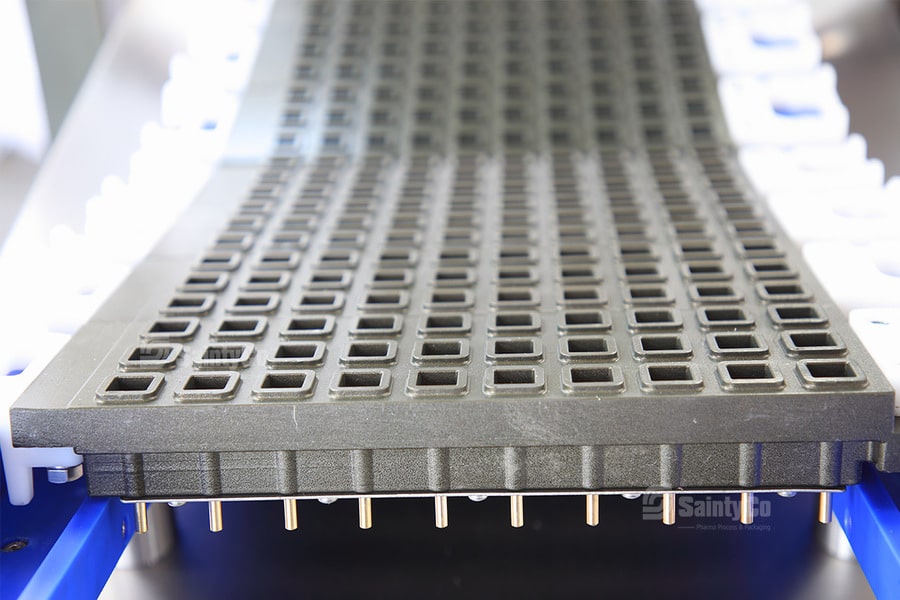

The X-Series of SaintyCo Popping Boba Machines delivers 50–1500kg/hr of popping boba through a fully automated process — from independent cooking and transfer of juice and alginate to precise depositing, pearl forming, and cleaning. Suitable for both startups (X50/X100 model) and industrial-scale producers (X200 and above) looking to expand OEM or private-label capacity.

Precision and Control

Runs on a smart PLC + HMI setup for easy control, real-time tracking, and quick recipe recall. Quick-change nozzles support fast SKU shifts, while its modular stainless steel design ensures easy cleaning and aligns with global food-grade standards.

Customizable to Drive Your Success

Tell us your needs. You can also choose from options such as- Adjustable layout to fit your facility.

- Servo-driven or rotary valve depositors for accurate drops.

- Custom nozzles for 4–20mm, micro to large boba.

- SS316L material upgrades for acidic formulations.

- Built-in CIP systems for faster, hygienic cleaning.

Over 200 clients worldwide have scaled their output, improved consistency, and accelerated time-to-market with our food and nutraceutical processing lines. Let us help you achieve the same success.

Popping Boba Production Lines for Faster, Smarter Output

*All capacities are based on standard 8–10mm popping boba (approx. 1g per bead). Actual output may vary depending on size, recipe, and operation conditions.

Boba-X50/X100 Popping Boba Production Line

Capacity: up to 50kg/hour (X50) | up to 100kg/hour (X100)

Depositing Speed: 30 times/min

Dimension: 3100 × 950 × 2150 mm (10.2 ft × 3.1 ft × 7.1 ft)

Boba-X200 Popping Boba Production Line

Capacity: 200-300kg/hour

Depositing Speed: 15-25 times/min

Dimension: 5400 × 2200 × 2250 mm (17.7 ft × 7.2 ft × 7.4 ft)

Boba-X400 Popping Boba Production Line

Capacity: 500-600kg/hour

Depositing Speed: 15-25 times/min

Dimension: 6400 × 3000 × 2250 mm (21.0 ft × 9.8 ft × 7.4 ft)

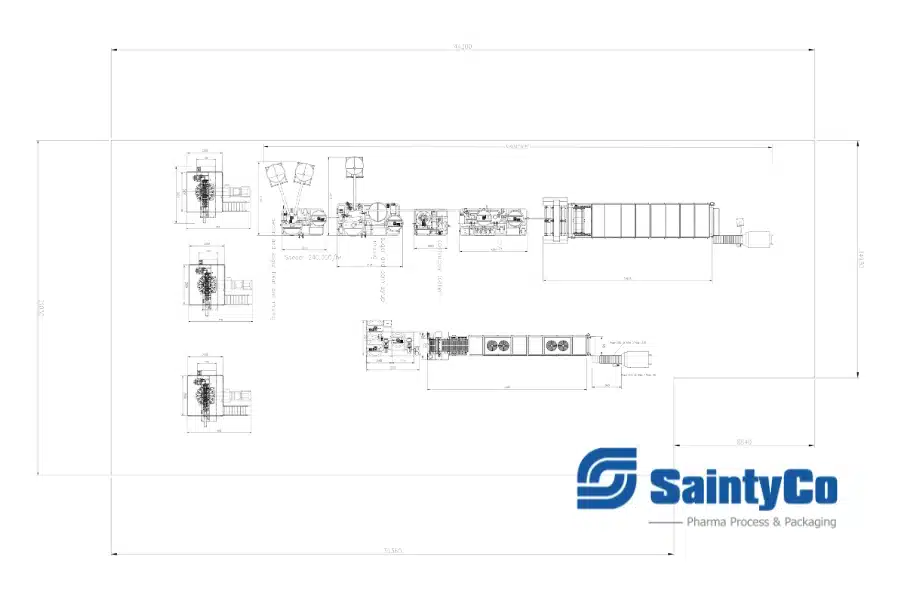

Boba-Ultra Popping Boba Production Line

Capacity: 1000-1500kg/hour

Depositing Speed: 25-35 times/min

Dimension: 13m line length (42.6 ft) – full layout customizable

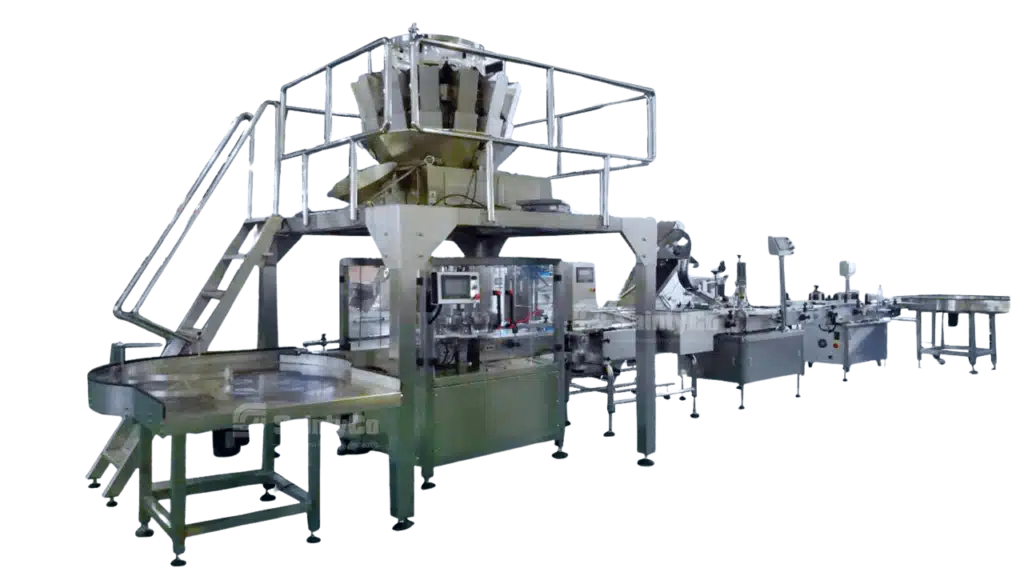

Automated Packaging Machines for Popping Boba

SaintyCo’s automated packaging systems are built specifically for the delicate nature of popping boba — whether you are filling bottles, pouches, buckets, or custom containers.

Boba-Safe Filling

Designed to protect fragile boba from crushing or leaking

High Accuracy

Weighing precision up to ±1–3g, reducing giveaway

Easy Cleaning

Food-grade SS304 design, quick disassembly, easy wash

Low Labor Need

Efficient output with only 1–3 operators required

Multi-SKU Ready

Fast changeovers between pouch sizes or flavor SKUs

Flexible Popping Boba Packaging Lines for Diverse Formats

PBP-12 Popping Boba Bottling Line

KL-420 Pouch Packing Machine for Popping Pearls

- Output: 30–35 packs/min for popping boba (10g–2000g per pouch)

- Weighing Accuracy: ±1–3g via multihead weighing system

- Power Supply: 220/380V, 3 Phase, 8.5kW

- Operator Requirement: 1–2 persons per shift

- Footprint: 79" × 79" × 79" / 2000 × 2000 × 2000 mm (L × W × H)

Popping Boba Pasteurization Equipment

SaintyCo offers two pasteurization equipment and systems tailored for popping boba — designed to extend shelf life without compromising texture, flavor, or color. Whether you’re packing in bottles, pouches, buckets, or jars, our solutions preserve product quality across every format.

From small batches to full-scale production, we help you choose the right systemto match your workflow, packaging process, and regulatory requirements.

Advanced Pasteurization Machines for Popping Boba Products

Polypropylene Plate Pasteurizer for Bottled or Bucketed Boba

RS-6300 Automatic Water Bath Autoclave for Popping Boba

Get the support needed for Popping Boba success

At GummyGenix, we offer more than machines—we provide the support you need to buy with confidence, run smoothly, and grow your profits. You’re building your business, but with GummyGenix, you’re never alone. Let’s see how we can help you succeed.

SOP Development

Guidance is available for building safe, hygienic, and efficient processes. This includes cleaning protocols, accurate dosing, and gentle product handling to help improve yield.

We also offer SOPs for filling, sealing, and sterilization, based on your packaging setup and project scope.

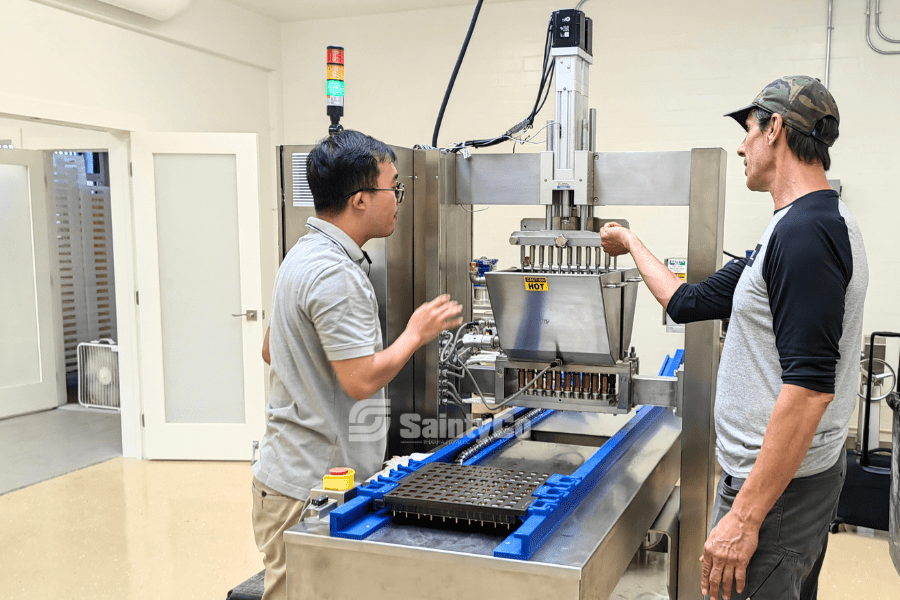

Installation & Batch Production

Lines are fully assembled and tested in our factory before shipment.

Our crew can handle on-site installation, utility connections, and commissioning to meet your product specs and capacity goals. Pilot runs are available to help you launch faster with lower startup risk.

Unlock More Possibilities with Popping Boba Machines

- 4–14 mm pearl sizes for beverages, desserts, and packaged snacks

- Handles juice, syrup, or functional ingredient fillings

- Built for quick flavor changeovers and high-volume runs

- Suits both dedicated lines and multi-product setups

Expand your product line across drinks, desserts, and functional snacks — with consistent output and market-ready quality.

Where Our Popping Boba Machines Deliver Results

Beverages & RTD

Add texture-rich boba to milk teas, smoothies, or bottled drinks with consistent size and shelf stability.

Frozen & Chilled Desserts

Top or fill ice cream, yogurt, and jellies with colorful boba to boost visual appeal and product value.

OEM & Private Label

Run multi-flavor batches with flexible SKUs for brands, co-packers, and global retail channels.

Functional & Clean-Label

Produce low-sugar, vitamin-infused boba for wellness drinks and better-for-you snack products.

Why ChooseGummyGenix by SaintyCo

At GummyGenix, a sub-brand of SaintyCo (Sainty International Group), we apply 25+ years of pharmaceutical and nutraceutical engineering to popping boba—bringing together food-grade safety, dosing accuracy, and automation.

We adapt proven cooking, depositing, and packaging technologies—refined through gummy production in nutraceutical and cannabis applications—to meet the specific needs of boba manufacturing.

Rely on GummyGenix to launch faster, stay compliant, and scale smarter—with certified systems and expert support built for your boba line.

countries SERVED

Happy Clients

Avg. Production Growth

Installed depositing lines

Your success is our priority

See how we simplify every stage

Tailored Consultation for Your Popping Boba Line

Your formulation, capacity, layout, and budget drive every solution we design. Our automation experts—skilled in startup lines, scaling, and packaging integration—combine proven know-how from food and pharmaceutical systems with on-site insights to deliver efficient, food-grade systems tailored to your needs.

Schedule a free consultation anytime via call, email, or WhatsApp—whichever works best for you.

International Standards Organization (ISO) 9001:2015

CE Electrical Certification

Food and Drug Administration (FDA) Quality Standard & Certification

UL Certification (US)

SGS-CSTC Testing Inspection Certification

Certified quality, customized machinery, built for compliance.

Our popping boba machines are built for hygiene, dosing precision, and gentle product handling—designed to meet global standards like CE, GMP, and cGMP. With SS304 stainless steel, modular design, and lean production systems, we ensure faster delivery, cost efficiency, and full food-grade compliance.

Drawing from decades in pharmaceutical and nutraceutical equipment, our R&D and manufacturing teams deliver customized, scalable systems for every stage of your production.

You can be sure of the quality you receive

All GummyGenix equipment undergoes a thorough Factory Acceptance Test (FAT), including visual inspection, functions, controls, and safety checks. We test all components for accuracy and calibration—covering temperature, pressure, speed, rotations, dosage, and safety—and document every step to ensure full traceability.

Delivery Right to Your Doorstep, Worry-Free

Purchasing equipment abroad involves securing favorable freight rates, choosing the right ports, and handling customs efficiently. With over 20 years of export experience, we streamline these processes for a seamless acquisition. All machinery is shipped in export-compliant wooden crates, ensuring protection that meets national standards.

By collaborating with top-tier logistics providers, we ensure your machinery arrives safely and on time, enabling a swift transition to production.

Passionate about customer care, supporting you anywhere needed

Our Technical Support offers detailed manuals, quick installation, spare parts, and continuous assistance from factory-trained techs and a global network of independent technicians, ensuring smooth operations with minimal downtime.

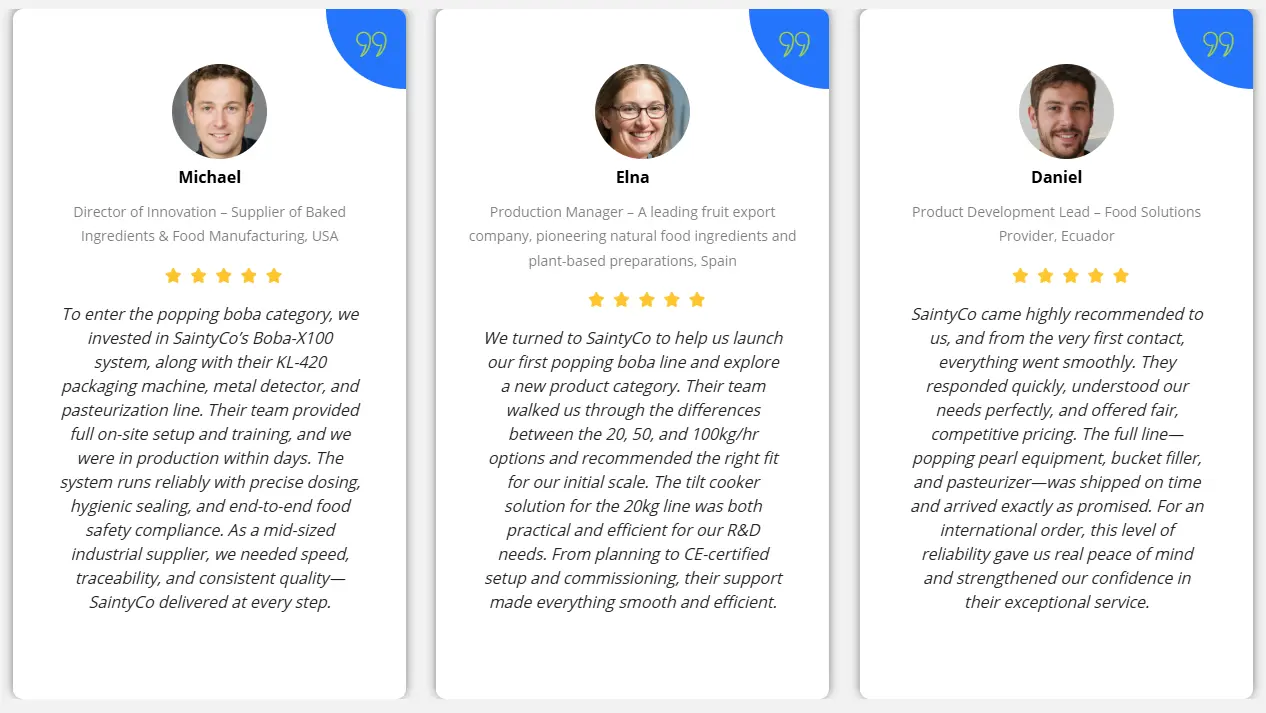

Our biggest achievement is a "Happy Customer"

At GummyGenix, our customers’ success stories are the heart of what we do. Hear firsthand how we solve our customers‘ tough challenges.

Join hundreds of companies experiencing production success with us.

Request a Quote for Your Popping Boba Line

Leverage Global Expertise for Customized Automation That Works

- Awareness of your needs

- Recommend solutions for your reference and comparison

- Reasonable Pricing

- 360° After-Sales Support

Popping Boba Machine Form

Note: Once all the fields are completed and the submit button is clicked, you will be redirected to a form submission confirmation page. If this does not happen, the form was not submitted successfully. Double check ALL fields are filled out correctly to submit successfully.

Frequently Asked questions

Still can’t find the information you want? Don’t hesitate to contact us.

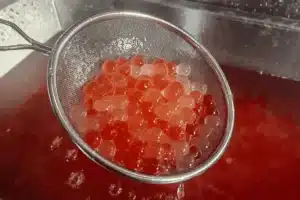

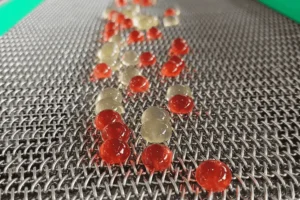

Popping boba are juice-filled spheres with a soft outer shell that bursts with flavor when bitten. Unlike chewy tapioca boba, they offer a light, juicy pop — no chewing required.

They’re made through reverse spherification, where a flavored liquid containing calcium is dropped into a sodium alginate solution. This triggers a reaction that forms a thin, flexible membrane around each droplet — creating uniform, poppable pearls.

Modern production lines automate the entire process — from cooking and droplet formation to rinsing, packaging, and sterilization — ensuring consistency, hygiene, and high output.

We offer popping boba production and packaging lines for all scales — from 20kg/hr lab setups to 1.5 tons per hour for large-scale factories. Whether you're just launching or scaling up, we have a line to match your capacity, container type, and automation needs.

Continuous cooking is essential for keeping the juice and alginate materials at a stable temperature and texture throughout the production process. This helps ensure smooth droplet formation, prevents clumping or premature gelling, and maintains the right viscosity for consistent boba shape and size. It also reduces waste and avoids machine blockages. Overall, it keeps production steady and product quality high.

No special ingredients are required. Our system works with standard popping boba formulations based on sodium alginate, calcium solutions, and fruit juice cores. We can also support with recipe R&D if needed.

Absolutely. We provide layout drawings, equipment footprints, and utility specs so you can plan plumbing, electrical, and HVAC needs in advance.

Sure, we will send you machine demos. And we provide comprehensive information, specifications, and customer service to help you make the best decision.

The order process at GummyGenix involves several steps:

- Confirmation of requirements

Issuing of Proforma Invoice (PI) outlining business terms, prices, services, guarantees - Payment of 50% deposit

- Creation of CAD layout design

- Machine Manufacturing

- Inspection of your machines before shipping

- Balance payment

- Shipment

- Installation at your facility

- Training of your staff

Reach out to us via our website's contact form or email us directly via [email protected], and one of our team members will assist you promptly. We'll walk you through the process and ensure a seamless experience.

Our payment terms involve a 50% initial deposit, followed by the remaining 50% before shipping. We always strive for flexibility to accommodate our customers' financial needs.

Typically, our lead time ranges between 30-40 working days for manufacturing, depending on the machine and customization details. We always strive to deliver within the agreed-upon timeline.