Popping boba adds a delightful pop of flavor to drinks and desserts, making it a favorite among culinary enthusiasts.

Unopened popping boba doesn't require refrigeration due to its protective syrup, which prevents spoilage. However, once opened, it should be refrigerated at 4°C (39°F) to maintain freshness for up to 14 days.

While this quick guide covers the basics, there's more to know about storing popping boba efficiently. From packaging solutions to cost-effective logistics, we'll explore how to make the most of your popping boba investment.

Unopened popping boba requires refrigeration.False

Unopened popping boba does not need refrigeration due to its syrup.

Opened popping boba stays fresh for 14 days in the fridge.True

Refrigerating opened popping boba at 4°C keeps it fresh for 14 days.

What Makes Popping Boba Shelf-Stable Before Opening?

Popping boba, the vibrant bursts of flavor that brighten any beverage, remain shelf-stable due to smart packaging and preservation methods. Understanding these techniques can enhance your appreciation and usage of this delightful treat.

Popping boba is shelf-stable before opening thanks to protective liquid solutions, vacuum-sealed or nitrogen-flushed packaging, and sterilization processes that prevent microbial growth and spoilage.

Protective Liquid Solutions

The key to popping boba's shelf-stability lies in the protective liquid used in its packaging. This liquid often contains preservatives like potassium sorbate, which inhibit microbial growth. Potassium sorbate1 is a common food preservative that extends shelf life without altering flavor.

Innovative Packaging Techniques

Packaging plays a crucial role in maintaining freshness. Vacuum-sealed or nitrogen-flushed methods help remove oxygen, reducing the risk of spoilage.

A comparison table below highlights the benefits of each method:

| Packaging Method | Benefits |

|---|---|

| Vacuum-Sealed | Reduces oxygen exposure, prevents spoilage |

| Nitrogen-Flushed | Extends shelf life, maintains flavor integrity |

By utilizing these packaging innovations, manufacturers ensure popping boba remains safe for consumption over extended periods.

Sterilization Processes for Popping Boba Pearls

Sterilization techniques such as retort or water bath sterilization ensure the product is commercially sterile. These methods are crucial in eliminating bacteria and extending the shelf life further. Retort sterilization2 is especially effective, allowing popping boba to remain unrefrigerated until opened.

Storage Guidelines Pre-Opening

For optimal shelf stability, store popping boba in a cool, dry place, away from direct sunlight. This minimizes the risk of heat or light-induced degradation.

These strategies make popping boba a convenient and long-lasting option for cafes and retailers looking to reduce costs associated with refrigerated products. The combination of protective liquids, advanced packaging, and effective sterilization processes allows for extended storage without compromising quality or safety. Explore further3 to see how these methods compare across different food products.

Potassium sorbate alters the flavor of popping boba.False

Potassium sorbate extends shelf life without altering flavor.

Vacuum-sealed packaging reduces oxygen exposure in popping boba.True

Vacuum-sealing removes oxygen, preventing spoilage and maintaining freshness.

How Does the Protective Liquid Preserve Popping Boba after Production?

Popping boba, those delightful juice-filled spheres, owe their longevity and freshness to a special protective liquid. But how does this magic potion work to preserve these tasty treats?

The protective liquid in popping boba serves as a preservative, maintaining freshness by preventing microbial growth. It typically contains ingredients like potassium sorbate and sugar syrup, extending shelf life without refrigeration.

Role of Ingredients in Protective Liquid

The protective liquid often comprises sugar syrup and preservatives like potassium sorbate. This combination not only enhances flavor but also creates an environment that inhibits microbial activity, which is essential for prolonging the shelf life of popping boba4. By creating an osmotic barrier, the liquid reduces the water activity, making it difficult for microorganisms to thrive.

Advantages of Non-Refrigerated Storage

The ability to store popping boba at room temperature is a significant advantage. For businesses, this means reduced costs associated with refrigeration during distribution. This cost-efficiency makes popping boba an attractive option for cafes and retailers looking to streamline logistics without compromising on quality.

| Benefit | Description |

|---|---|

| Cost-Efficiency | Eliminates refrigeration expenses during transport and storage. |

| Extended Shelf Life | Can last up to 12 months unopened, thanks to the protective liquid. |

| Logistics Simplification | Easier handling and transportation due to non-refrigerated storage capabilities. |

Impact of Packaging & Sterilization Technologies

Proper packaging complements the protective liquid's role by maintaining an airtight environment. Vacuum-sealed or nitrogen-flushed packaging further prevents oxidation and spoilage, ensuring that the product's freshness5 is retained for longer periods.

After packaging, sterilization solutions like water retort sterilization ensure commercial sterility, providing a robust defense against potential spoilage. For businesses dealing with large volumes, this translates into fewer losses and a consistent quality product reaching the end consumer.

Popping boba requires refrigeration for preservation.False

The protective liquid allows popping boba to be stored at room temperature.

Potassium sorbate inhibits microbial activity in popping boba.True

Potassium sorbate is a preservative that prevents microbial growth.

What Are the Best Practices for Storing Opened Popping Boba?

Storing opened popping boba correctly is crucial to maintain its taste and texture. Whether you're a business owner or a home enthusiast, here are the best practices you should follow.

To store opened popping boba, refrigerate it at 4°C (39°F) and use within 7 to 14 days. Keep it in an airtight container submerged in its syrup to preserve freshness and flavor.

Storage Temperature and Duration

After opening, popping boba should be stored in the refrigerator at 4°C (39°F). This temperature helps maintain its texture and prolongs freshness. The general rule is to consume the boba within 7 to 14 days. Keeping it beyond this period could result in changes to texture and flavor.

Use of Airtight Containers

An airtight container is vital for storing opened popping boba. This prevents air exposure, which can lead to oxidation and spoilage. Submerge the boba fully in its preservative syrup to further protect it from drying out. Consider these airtight storage options6 for optimal freshness.

| Container Type | Pros | Cons |

|---|---|---|

| Glass Jars | Non-reactive, clear visibility | Heavier, breakable |

| Plastic Containers | Lightweight, durable | May stain or absorb odors |

Avoid Cross-Contamination

Ensure utensils and hands are clean before handling popping boba. Cross-contamination can introduce bacteria that accelerate spoilage. Explore our guide on safe food handling7 for more insights.

Impact of Protective Syrup

The syrup in which popping boba is stored acts as a preservative by preventing microbial growth. It contains stabilizers like potassium sorbate. Without the syrup, popping boba is more prone to spoilage, emphasizing the importance of keeping it submerged.

Monitoring Storage Conditions

Regularly check the boba's condition during storage. If you notice any off smells or changes in texture, it might be time to discard it. Maintaining optimal storage conditions ensures you enjoy popping boba at its best.

For more tips on food storage8, explore our comprehensive guides.

Opened popping boba should be stored at room temperature.False

Popping boba should be refrigerated at 4°C (39°F) after opening.

Airtight containers prevent popping boba spoilage.True

Airtight containers reduce air exposure, preventing oxidation and spoilage.

Can Packaging Techniques Extend the Shelf Life of Popping Boba after Production?

Popping boba, those delightful juice-filled spheres, owe their shelf life to advanced packaging techniques. But how exactly do these methods work to keep your boba fresh? Let's uncover the secrets behind packaging innovation.

Packaging techniques like vacuum-sealing and nitrogen flushing help extend popping boba's shelf life by preventing oxidation and microbial growth. These methods maintain freshness without refrigeration, ideal for storage and transportation.

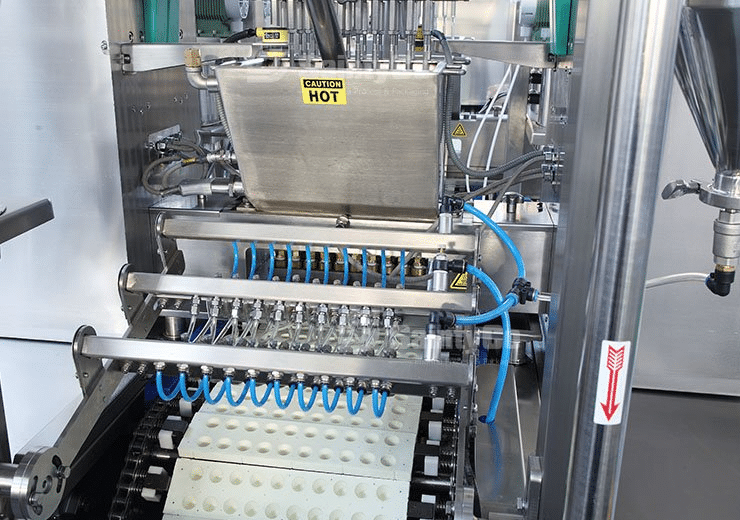

Watch this video showcasing how to pack popping boba into plastic containers with SaintyCo's popping boba production line in action!

Understanding Packaging Techniques

The longevity of popping boba is significantly influenced by the packaging techniques9 used. Among the most effective methods are vacuum-sealing with protective liquid and nitrogen flushing.

| Packaging Method | Benefits |

|---|---|

| Vacuum-Sealing | Reduces oxygen exposure, inhibits spoilage |

| Nitrogen Flushing | Prevents oxidation, maintains flavor & texture |

| Protective Liquid | Provides microbial barrier, ensures shelf stability |

-

Vacuum-Sealing: This process removes air, reducing oxygen exposure which can lead to spoilage. By eliminating air pockets, vacuum-sealing inhibits microbial growth, keeping popping boba fresher longer.

-

Nitrogen Flushing: Nitrogen, an inert gas, replaces oxygen in packaging. This prevents oxidation, which is crucial for maintaining flavor and texture. Products packaged with nitrogen remain stable without needing refrigeration.

The Role of Protective Liquids

A key element in popping boba preservation is the protective liquid surrounding each pearl. This syrup, often containing stabilizers like potassium sorbate, acts as a barrier against spoilage10. Its efficacy means popping boba can be stored at room temperature if unopened.

How it works in popping boba packaging lines:

• Filling: Containers (bottles, plastic bags, or metal cans) are initially filled with 70% of the prepared boba pearls. This ensures that there is enough space left for the protective liquid.

• Adding Protective Liquid: After filling the containers with boba pearls, the remaining 30% of the container volume is filled with a protective solution that helps maintain the freshness of the pearls and prevents them from sticking together.

Industrial Applications

For businesses, adopting these techniques means extended product shelf life and easier logistics. Non-refrigerated storage reduces distribution costs and enhances efficiency.

Moreover, investing in popping boba machines capable of applying these methods can optimize production lines. Companies offering popping boba solutions11 often provide integrated systems that streamline both production and packaging processes.

Ensuring your popping boba products meet consumer expectations requires understanding these preservation techniques and leveraging them to your advantage.

Vacuum-sealing reduces oxygen exposure in popping boba packaging.True

Vacuum-sealing removes air, reducing oxygen exposure, which inhibits spoilage.

Nitrogen flushing requires refrigeration to maintain popping boba freshness.False

Nitrogen flushing prevents oxidation, allowing non-refrigerated storage.

What Sterilization Processes Enhance Popping Boba's Longevity?

Popping boba is a delightful addition to beverages and desserts, but ensuring its longevity is crucial for businesses. Discover the sterilization processes that extend its shelf life.

Sterilization processes like water bath pasteurization and retort sterilization can significantly enhance popping boba's longevity by ensuring commercial sterility and minimizing microbial growth, thereby extending shelf life without refrigeration.

The Science of Sterilization

Sterilization is critical for prolonging the shelf life of popping boba. It involves eliminating harmful microorganisms that can spoil food. Common methods include water bath pasteurization12 and retort sterilization. These techniques heat the product to a temperature that destroys pathogens while preserving quality.

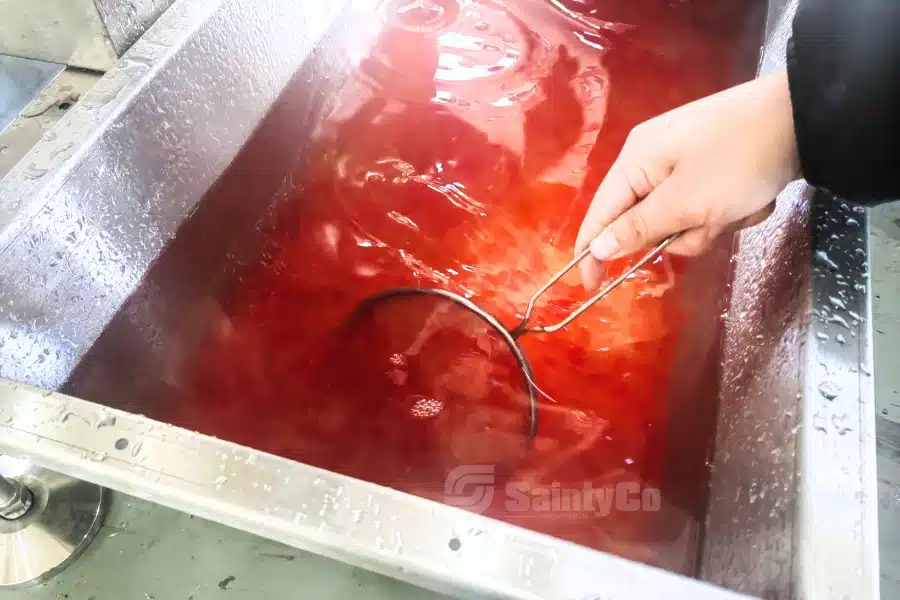

Water Bath Pasteurization

This method involves submerging sealed packages of popping boba in hot water. The heat eliminates harmful bacteria without affecting the texture or flavor. A major advantage is its simplicity and cost-effectiveness, making it ideal for large-scale production.

| Process | Temperature | Duration |

|---|---|---|

| Pasteurization | 60-85°C | 30-60 minutes |

Retort Sterilization

Retort sterilization uses pressurized steam to achieve higher temperatures than pasteurization. This ensures complete sterility, extending the shelf life considerably. It's effective for products intended for long-term storage without refrigeration.

| Process | Temperature | Pressure | Duration |

|---|---|---|---|

| Retort | 121°C | 15 PSI | 15-20 minutes |

Benefits and Considerations

By adopting these sterilization methods, manufacturers can produce shelf-stable popping boba, reducing the need for preservatives and refrigeration. However, it's essential to maintain strict controls over temperature13 and time to avoid compromising product quality.

Example: A company using retort sterilization can offer popping boba with a shelf life of up to 12 months, appealing to retailers seeking cost-efficient storage solutions.

Understanding these processes can help businesses optimize production, ensure food safety, and meet consumer demand efficiently. Explore more about these sterilization techniques14 to enhance your product's longevity.

Water bath pasteurization extends popping boba's shelf life.True

This method kills bacteria without affecting texture, enhancing longevity.

Retort sterilization requires lower temperatures than pasteurization.False

Retort sterilization uses higher temperatures for complete sterility.

How Do Non-Refrigerated Options Benefit Businesses?

Non-refrigerated solutions are revolutionizing business operations by reducing costs, simplifying logistics, and enhancing sustainability. Let's explore how these options offer strategic advantages over traditional refrigerated methods.

Non-refrigerated options benefit businesses by cutting energy costs, simplifying logistics, and reducing environmental impact. They ensure product longevity without refrigeration, offering a sustainable and cost-effective alternative for various industries.

Energy Cost Reduction

Non-refrigerated options drastically cut energy expenses. Businesses save on electricity and maintenance costs associated with refrigeration. For instance, products like shelf-stable popping boba15 eliminate the need for costly cold storage facilities.

Simplified Logistics

Non-refrigerated products simplify supply chain logistics. Businesses can store and transport items without special temperature controls, reducing logistical complexities16. This flexibility often leads to faster delivery times and broader market reach.

Enhanced Sustainability

These options contribute to environmental sustainability17 by lowering energy consumption and reducing carbon footprints. Using eco-friendly packaging further enhances the green appeal of non-refrigerated products.

Table: Comparing Refrigerated vs. Non-Refrigerated

| Aspect | Refrigerated | Non-Refrigerated |

|---|---|---|

| Energy Consumption | High | Low |

| Logistics | Complex | Simple |

| Shelf Life | Variable, requires continuous cooling | Stable, no refrigeration needed |

| Environmental Impact | Higher carbon footprint | Reduced carbon footprint |

Broader Market Reach

With no refrigeration constraints, businesses can expand to regions lacking cold chain infrastructure. This opens new business opportunities18 and markets previously untapped by refrigerated goods.

Exploring non-refrigerated options not only optimizes operational efficiency but also aligns with modern business strategies focusing on sustainability and cost-effectiveness. Business leaders should consider these benefits when strategizing for future growth.

Non-refrigerated options reduce energy costs for businesses.True

Non-refrigerated products eliminate the need for costly refrigeration, cutting energy expenses.

Non-refrigerated products complicate supply chain logistics.False

They simplify logistics by removing the need for temperature-controlled storage and transport.

Conclusion

Popping boba remains shelf-stable unopened due to protective syrup. Once opened, refrigerate at 4°C for up to 14 days to maintain freshness and flavor.

At SaintyCo, we don’t just provide pharmaceutical and confectionary equipment—we empower your popping boba manufacturing business with solutions tailored to your success.

Why Choose SaintyCo for Your Popping Boba Business?

- Competitive Pricing: Get high-performance popping boba machines without breaking the bank. Our cost-effective solutions maximize your ROI.

- High-Quality Machinery: Food-grade, hygienic equipment engineered for precision, ensuring your production aligns with global standards.

- Flexible Financing Options: Partner with us to access flexible payment plans and financing support, reducing upfront costs while unlocking potential tax benefits.

- Quick Startup SOPs & Recipes: Begin production faster with starter recipes and workflows included. For advanced development, we connect you with top-tier consultants and suppliers worldwide.

- Comprehensive After-Sales Support: Enjoy peace of mind with our full-service assistance—from installation and training to troubleshooting and maintenance.

Popping Boba Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Learn about the benefits of potassium sorbate in food preservation and how it helps maintain popping boba's freshness. ↩

-

Discover how retort sterilization ensures popping boba remains shelf-stable by eliminating bacteria effectively. ↩

-

Understand how different packaging methods contribute to shelf stability across various food products. ↩

-

Explore what ingredients make up the protective liquid and their preservation roles. ↩

-

Learn how advanced packaging techniques help maintain popping boba's freshness. ↩

-

Discover different airtight storage options to maintain the freshness of your popping boba. ↩

-

Learn essential food handling techniques to prevent cross-contamination and spoilage. ↩

-

Explore a variety of tips on storing foods effectively to maintain their quality. ↩

-

Discover how vacuum-sealing can enhance food preservation by eliminating air and prolonging freshness. ↩

-

Explore why potassium sorbate is a popular choice for extending food shelf life and its role in microbial inhibition. ↩

-

Find top solutions for integrating advanced packaging techniques into your popping boba production line. ↩

-

Learn about water bath pasteurization, a gentle method to extend shelf life without affecting taste. ↩

-

Discover why maintaining precise temperatures during sterilization is vital for food safety. ↩

-

Explore various sterilization methods used in popping boba production to enhance product longevity. ↩

-

Learn how shelf-stable popping boba eliminates refrigeration needs, cutting costs and simplifying logistics. ↩

-

Discover how non-refrigerated products ease supply chain complexities and enhance distribution efficiency. ↩

-

Explore how non-refrigerated solutions contribute to sustainability by reducing energy use and emissions. ↩

-

Find out how these products allow businesses to access new markets without cold chain limitations. ↩