Are you curious about what gives popping boba its signature burst and appealing texture? The secret lies in a process known as reverse spherification that uses precise interactions between sodium alginate and calcium lactate to form the perfect popping pearls.

Popping boba is typically produced through reverse spherification, where a calcium-rich liquid is introduced into a sodium alginate bath, creating a gel-like outer shell. The interior is filled with flavored juices, providing the iconic burst of taste. Specialized machines ensure precision in size, consistency, and production efficiency.

While this gives you a basic understanding, the detailed process behind popping boba production involves sophisticated machinery and techniques that optimize quality and efficiency. Let’s dive deeper into the science and practical applications of popping boba manufacturing.

Popping boba is made using reverse spherification.True

Reverse spherification uses sodium alginate and calcium lactate to form boba.

Popping boba contains artificial flavors only.False

Popping boba can be filled with natural or artificial flavored juices.

What Role Do Ingredients Like Sodium Alginate and Calcium Lactate Play in Reverse Spherification for Popping Boba?

Understanding the roles of sodium alginate and calcium lactate is key to mastering the reverse spherification process that creates popping boba pearls. These ingredients interact to form seamless, flavorful spheres with a unique burst-in-your-mouth effect.

Sodium alginate, derived from seaweed, reacts with calcium ions to create a gel-like shell around the liquid core. This is essential for reverse spherification, which stabilizes the boba’s structure during production and storage.

Demonstration of Reverse Spherification - Youtube: ChefStep

Sodium Alginate: The Gel-Forming Agent

Sodium alginate, derived from brown seaweed, is a thickening agent that forms a gel-like shell when exposed to calcium ions. In reverse spherification, it plays a crucial role in forming the outer membrane of popping boba.

| Property | Impact on Popping Boba Production |

|---|---|

| Viscosity | Determines the thickness of the shell |

| Gel Formation | Controls the encapsulation process |

- Concentration Control: The viscosity of sodium alginate must be carefully controlled. Too low, and the shell will be thin and prone to breaking. Too high, and the solution becomes difficult to work with.

- Recyclability: Sodium alginate solutions can be reused during production, improving cost efficiency without quality loss sodium alginate.

Calcium Lactate: The Cross-Linking Agent

Calcium lactate provides the calcium ions necessary to trigger the gelation reaction with sodium alginate. It is preferred over calcium chloride due to its neutral flavor profile, making it ideal for food applications.

| Ingredient | Role |

|---|---|

| Sodium Alginate Bath | Creates the outer gel membrane |

| Calcium Solution | Forms the liquid core of the bursting popping boba |

- Calcium Source: Provides calcium ions required for gel formation.

- Flavor Neutrality: Ensures no unwanted taste is imparted to food.

Key Tip: Maintaining the right balance between sodium alginate and calcium lactate ensures that the popping boba’s outer shell is durable and consistent.

What are Practical Steps in Reverse Spherification for Popping Boba Production?

In commercial popping boba production[^wrdilsaaclp-1], reverse spherification is widely used due to its ability to create stable, flavorful spheres. Here’s how the process works:

Step 1: Prepare the Calcium Solution

Mix calcium lactate with flavored juice to form the liquid core of the boba. The juice can be natural or artificial, depending on flavor preferences.

- Calcium Source: Use calcium lactate to ensure a neutral taste.

- Flavoring: Add desired juices and colorants to enhance the taste and visual appeal.

Step 2: Create the Sodium Alginate Bath

Dissolve sodium alginate in water to prepare the bath. This solution will form the outer shell when the calcium solution is introduced.

- Concentration Control: The alginate concentration impacts the thickness of the boba’s shell.

- Temperature Maintenance: Keep the bath at a consistent temperature to ensure optimal gelling.

Step 3: Droplet Formation

Using a depositing machine, introduce droplets of the calcium-rich liquid into the sodium alginate bath. The interaction between the two solutions causes the formation of a gel-like membrane around the liquid core.

- Multi-Nozzle Hopper: Ensures consistent droplet size.

- Servo-Driven Systems: Controls flow rate to reduce waste and improve precision.

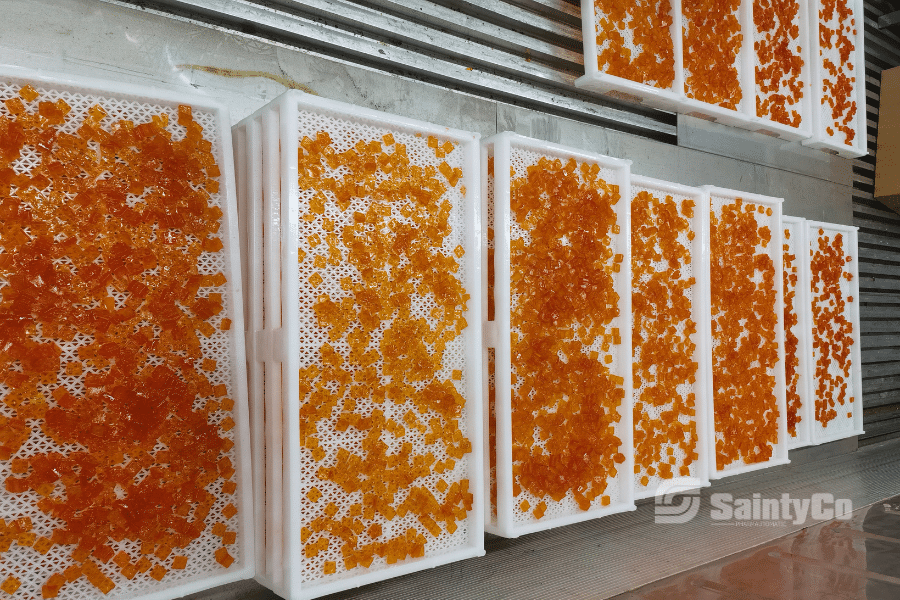

Step 4: Rinsing and Curing

After formation, rinse the boba to remove any excess sodium alginate. Then, cure the pearls in a controlled environment to achieve the desired texture and firmness.

- Rinsing: Removes residual alginate to prevent off-flavors.

- Curing: Ensures that the boba maintains its structure during storage and transport.

Industrial Insights: Why Reverse Spherification Matters?

Reverse spherification creates a thicker, more resilient shell, which is crucial for commercial popping boba production. It allows the boba to withstand storage and transportation while maintaining its burst-in-the-mouth texture.

Key Advantages for Popping Boba Manufacturers:

Customizable Sizes: Adjust alginate and calcium levels to create popping boba in sizes ranging from 4mm to 20mm.

Flavor Versatility: Use various juices and colorants to meet market preferences.

Long Shelf Life: Proper sterilization and packaging extend product lifespan.

By mastering the use of sodium alginate and calcium lactate, businesses can innovate across various sectors, offering unique products and experiences.

Sodium alginate is derived from brown seaweed.True

Sodium alginate is extracted from brown seaweed, used as a thickener.

Calcium lactate imparts a strong taste to food.False

Calcium lactate is flavor neutral, ideal for culinary use.

What Are Process and Machines for Popping Boba Production?

Crafting popping boba involves a precise dance of ingredients and equipment. From forming the delicate outer shell to ensuring the burst of flavor inside, each step is crucial for perfection.

Popping boba production involves reverse spherification, where sodium alginate and calcium lactate create the boba shell, followed by filling with flavored liquids. Proper machinery ensures consistent quality and texture.

Watch this video showcasing popping boba production process with SaintyCo's 100kg popping boba production line in action!

Essential Popping Boba Making Machines

-

Mixing and Cooking Systems:

- Use jacketed cookers and high-efficiency mixers for uniform ingredient mixing.

- Maintain optimal temperatures (60-80°C cooking, 15°C cooling) mixing systems1.

-

Depositing Machines:

- Multi-nozzle hoppers dispense droplets into Sodium Alginate bath, ensuring size consistency.

- Servo-driven systems optimize flow rates depositing machines2.

-

Filtration Systems:

- Remove impurities to prevent clogging and maintain smooth textures.

- Automated cleaning cycles reduce downtime and ensure hygiene standards.

Sodium alginate forms the outer shell of popping boba.True

Sodium alginate reacts with calcium to create the gel-like shell.

Calcium lactate is used for a sour flavor in popping boba.False

Calcium lactate is preferred for its neutral flavor profile.

How Does the Machinery Influence Popping Boba Quality?

Explore how machinery impacts the texture, flavor, and overall quality of popping boba. Discover the critical role that technology plays in crafting the perfect popping pearls.

High-quality machinery ensures consistent popping boba by maintaining precise temperature control, uniform droplet size, and optimal ingredient mixing. This results in a product with ideal texture, flavor, and longevity.

1. Preparation Stage: The Role of Mixing and Cooking Systems for Making Popping Boba

Machinery used in mixing and cooking is pivotal for consistency in popping boba production. Jacketed cookers and high-efficiency mixers guarantee even distribution of sodium alginate and filling ingredients. Maintaining the correct temperature during this stage prevents premature gelling and ensures uniform texture and flavor3.

Popping Boba Production Line Components:

| Machine Type | Function | Benefit |

|---|---|---|

| Mixing Systems | Uniform Ingredient Blending | Ensures consistency in recipes |

| Jacketed Cookers | Cooking and Mixing of Juices and Alginate | Prevents air bubbles, ensures uniform cooking |

2. Forming Stage: Precision with Depositing Machines for Popping Boba Production

Depositing machines are vital in controlling the droplet size. These machines use servo-driven systems to dispense alginate solution accurately into calcium baths. This precision maintains consistent sizes, usually ranging from 4mm to 20mm, which is essential for ensuring that each piece of boba pops satisfactorily when consumed. Explore more about multi-nozzle hoppers4.

Popping Boba Production Line Components:

| Machine Type | Function | Benefit |

|---|---|---|

| Depositing Machines | Droplet Precision | Guarantees size consistency |

| Buffer Conveyors | Transports Formed Boba to Rinsing Stations | Minimizes handling, ensures continuity |

3. Rinsing and Cleaning Stage: Filtration and Rinsing Systems Impact for Popping Boba Pearls

Filtration systems remove impurities, ensuring the purity of the popping boba. Automated cleaning cycles reduce downtime while adhering to hygiene standards. After forming, rinsing units eliminate residual calcium, preventing unwanted flavors and improving the overall taste. Learn about filtration systems5.

Popping Boba Production Line Components:

| Machine Type | Function | Benefit |

|---|---|---|

| Rinsing Systems | Washes Formed Boba to Remove Excess Alginate | Improves taste by removing residues |

| Filtration Systems | Removes Impurities and Residual Chemicals | Enhances taste and hygiene |

| Cleaning Systems | Automated Cleaning of Equipment | Maintains hygiene and reduces downtime |

4. Packaging Stage: Curing and Packaging Equipment Efficiency for Finished Bursting Boba

Curing chambers finalize the firmness of popping boba by controlling temperature and time. Packaging machines, including filling and sealing units, ensure airtight seals that preserve freshness.

Popping Boba Production Line Components:

| Machine Type | Function | Benefit |

|---|---|---|

| Weighing & Packing Machines | Automatically Weighs and Packs Boba | Ensures accurate portioning and packaging |

| Labeling and Sealing Systems | Finalizes Packaging with Labels and Seals | Enhances product presentation and security |

5. Post-Processing Stage: Sterilization Systems for Extended Shelf Life of Popping Boba

Water bath sterilizers further extend shelf life without altering the product's taste or texture6. Understanding these processes is crucial for maintaining high-quality standards.

| Machine Type | Function | Benefit |

|---|---|---|

| Retort Sterilizers | Post-Packing Sterilization | Extends shelf life and ensures food safety |

| Cooling Systems | Rapid Cooling of Packaged Products | Prevents overcooking, preserves texture |

Sustainability and Food Safety

Investing in popping boba machinery that incorporates recycling mechanisms for alginate and water can significantly reduce operational costs. Utilizing food-grade stainless steel machines adheres to global hygiene standards, ensuring safe production of popping boba. This not only enhances efficiency but also supports sustainable practices.

The choice of machinery can transform production processes, meeting consumer demands for diverse textures and flavors while maintaining product integrity.

Mixers ensure even distribution of ingredients in boba.True

Mixers distribute sodium alginate and fillings evenly, ensuring consistency.

Depositing machines determine the popping boba's droplet size.True

These machines use precision to control droplet size, impacting quality.

How Can Businesses Optimize Their Popping Boba Manufacturing Process?

In the competitive world of popping boba production, optimizing the manufacturing process can significantly boost efficiency, reduce costs, and enhance product quality. Here's how businesses can achieve these goals effectively.

Businesses can optimize popping boba manufacturing by using high-quality ingredients, investing in advanced popping boba making machines, and implementing sustainable practices. These steps improve efficiency, consistency, and reduce waste, ensuring high-quality output.

Leveraging High-Quality Ingredients

The foundation of a great popping boba lies in the ingredients. High-viscosity sodium alginate ensures a robust outer shell, while premium fruit juices create delightful flavors.

| Ingredient | Role | Key Factor |

|---|---|---|

| Sodium Alginate | Outer Shell Formation | Concentration & Recyclability |

| Fruit Juices | Flavor & Texture | Viscosity Optimization |

Using a preservative solution that matches the filling concentration is crucial to maintaining taste and appearance.

Investing in Advanced Popping Boba Prodution Lines

State-of-the-art machines like multi-nozzle hoppers ensure precise droplet sizes, enhancing consistency. Mixing and cooking systems allow uniformity in alginate solutions. Automated systems help maintain optimal temperatures, preventing premature gelling.

For businesses, selecting machines with servo-driven systems7 enhances control over flow rates.

Check out the Standard Popping Boba Production Line by SaintyCo, delivering up to 340K popping boba per hour with precision and efficiency. Perfect for scaling your boba production!

Implementing Sustainable Practices

Implementing sustainable practices in popping boba production can significantly reduce costs and environmental impact.

Key Sustainable Practices

Recycling alginate and water reduces waste and operational costs. This is crucial for large-scale production.

| Practice | Impact |

|---|---|

| Recycling Alginate | Reduces Waste |

| Efficient Water Use | Lowers Costs |

Food Safety Standards

Compliance: Use food-grade stainless steel equipment to meet global hygiene standards (cGMP, ISO, CE, FDA).

Enhancing Popping Boba Production Through Automation

Automation can significantly streamline production. Automated cleaning cycles reduce downtime and ensure hygiene. Consistent droplet size and ingredient ratios improve flavor uniformity. Businesses benefit from machines designed for quick setup8 and changeovers for diverse recipes.

By examining these strategies, businesses can enhance their popping boba manufacturing process effectively, ensuring high-quality output while maintaining efficiency and reducing costs. Incorporating these changes allows adaptation to consumer preferences with customizable textures, flavors, and colors.

High-viscosity sodium alginate ensures a robust boba shell.True

Sodium alginate's viscosity is crucial for forming a strong outer shell.

Automated systems reduce downtime in boba production.True

Automation streamlines cleaning cycles, minimizing production interruptions.

Conclusion

Reverse spherification is the key to producing high-quality popping boba with a burst-in-your-mouth effect. By mastering the balance of sodium alginate and calcium lactate and investing in advanced machinery, businesses can achieve consistent results and meet growing consumer demands.

At SaintyCo, we don’t just provide pharmaceutical and confectionary equipment—we empower your popping boba manufacturing business with solutions tailored to your success.

Why Choose SaintyCo for Your Popping Boba Business?

- Competitive Pricing: Get high-performance popping boba machines without breaking the bank. Our cost-effective solutions maximize your ROI.

- High-Quality Machinery: Food-grade, hygienic equipment engineered for precision, ensuring your production aligns with global standards.

- Flexible Financing Options: Partner with us to access flexible payment plans and financing support, reducing upfront costs while unlocking potential tax benefits.

- Quick Startup SOPs & Recipes: Begin production faster with starter recipes and workflows included. For advanced development, we connect you with top-tier consultants and suppliers worldwide.

- Comprehensive After-Sales Support: Enjoy peace of mind with our full-service assistance—from installation and training to troubleshooting and maintenance.

Popping Boba Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Explore the machinery that ensures uniform mixing in popping boba creation. ↩

-

Find out how multi-nozzle machines improve popping boba consistency. ↩

-

Find detailed insights on how temperature impacts flavor and texture during production. ↩

-

Learn about the technology behind multi-nozzle hoppers that ensures consistent droplet formation. ↩

-

Discover how filtration systems maintain quality by removing impurities in food production. ↩

-

Explore how effective packaging can preserve the texture and taste of popping boba. ↩

-

Discover how servo-driven systems enhance precision in droplet formation, leading to consistent popping boba sizes. ↩

-

Learn about machines offering quick setup capabilities, enabling efficient recipe changes and faster production cycles. ↩