Looking to automate your gummy production, fine alternatives and tools can help streamline the process without breaking the bank? You're in the right place!

For affordable gummy production automation, consider starting with manual tools like handheld depositors, squeeze bottles or confectionery funnels, progressing to semi-automatic options like the SaintyCo DM series, and finally exploring fully-automated lines such as the G40. Each option caters to different production needs and budgets.

But wait—this is just the tip of the iceberg! Keep reading to uncover the unique benefits and applications of each solution that can supercharge your production.

Handheld gummy depositors cost around $29.True

Handheld gummy depositors are priced at about $29, making them affordable.

What Are Basic Manual Tools for Gummy Production?

Small-scale gummy producers often face challenges balancing quality and costs. Manual tools offer a practical solution.

Manual tools like handheld gummy depositors, squeeze bottles or confectionery funnels allow small-scale gummy producers to maintain quality and flexibility while minimizing costs. These tools provide precise control over the production process, enabling producers to experiment with new recipes and batch sizes efficiently without significant investment in automated machinery.

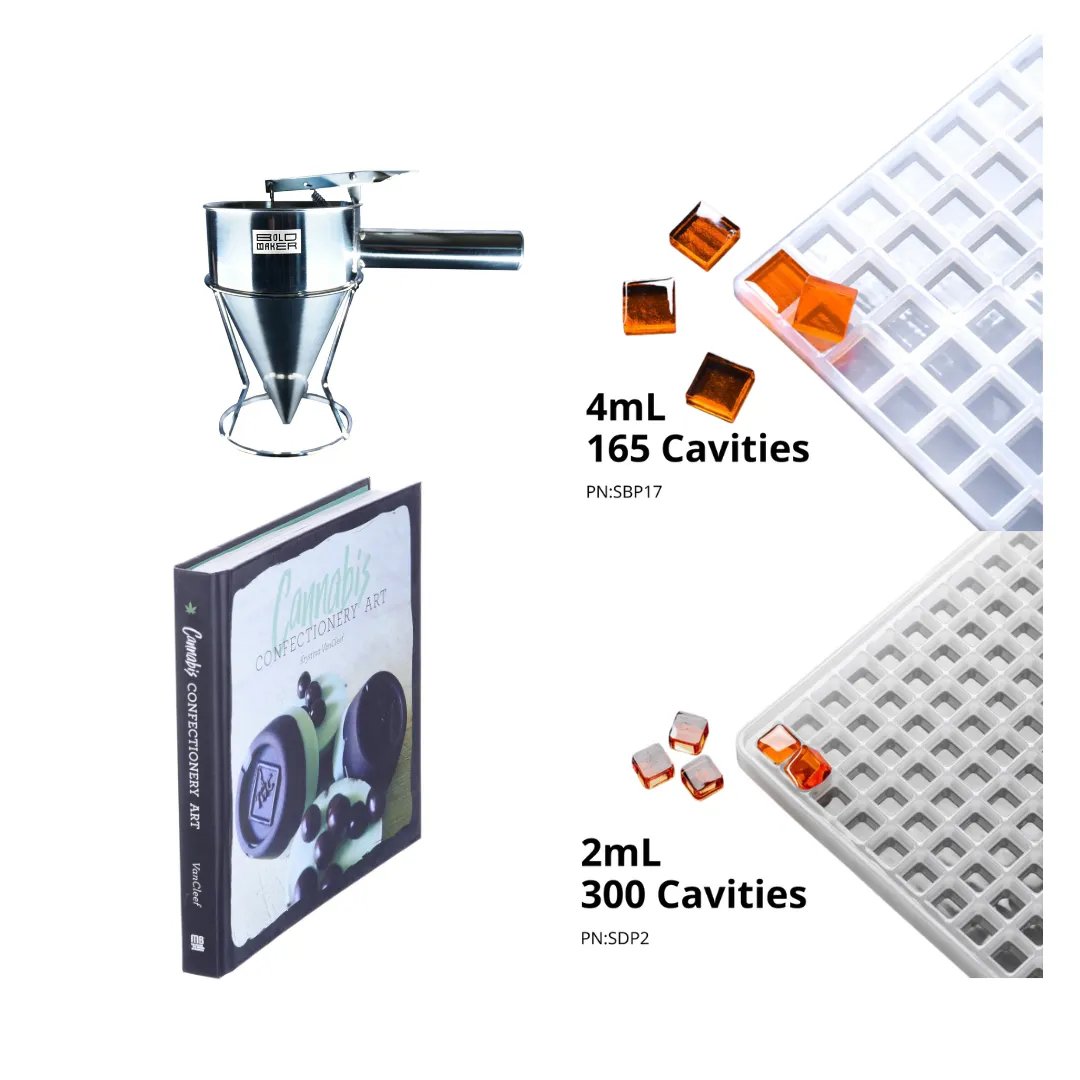

Handheld Gummy Depositors: Your First Step

Begin your gummy production journey with handheld gummy depositors. These nifty tools, such as the Bold Maker Stainless Handheld Depositor, allow for precise filling of molds without the need for large machinery. Priced at around $29, they're affordable and reusable. Many users appreciate their ease of cleaning and the control they offer when working with small-scale or trial productions. This tool is a great starting point if you're new to the world of gummy manufacturing.

Squeeze Bottles: Simple yet Effective

Another excellent manual tool is the humble squeeze bottle. Fill it with your prepared gummy mixture and keep it warm using a sous vide bath to maintain consistency. This method is not only economical but also allows for hands-on control over the dispensing process, making it ideal for small batches or experimental flavors.

For those curious about the different types of squeeze bottles available, check out squeeze bottle options1. They come in various sizes and materials, catering to diverse needs in gummy production.

Confectionery Funnels: Speed and Neatness Combined

If you're looking to enhance speed and precision further, consider adding confectionery funnels to your toolkit. Available on platforms like Amazon, these funnels are praised for their efficiency in filling molds quickly and neatly. They work well in conjunction with squeeze bottles or can be used directly with the gummy mixture.

For a more detailed look at confectionery funnel options and where to purchase them, take a look at confectionery funnel products2.

Challenges and Considerations

While manual tools offer many benefits, they also come with challenges. Time and labor are required to manage each batch manually, which may limit output as demand grows. However, for those who prioritize quality and flexibility, manual tools remain an invaluable part of the production toolkit.

Exploring these aspects helps gummy producers make informed decisions about when and how to transition from manual to automated systems as their business evolves.

Squeeze bottles cannot maintain gummy mixture consistency.False

Squeeze bottles keep the gummy mixture warm with a sous vide bath.

How Do Semi-Automatic Solutions Enhance Efficiency?

Semi-automatic solutions strike a perfect balance between manual labor and full automation, offering a cost-effective path to boost production efficiency.

Semi-automatic gummy machines, like the SaintyCo DM-20S and DM-50X, enhance efficiency by automating repetitive tasks, improving consistency, and reducing manual labor. These systems often include features like automated depositing and precise dosing, making them ideal for businesses transitioning from manual to more scalable production methods.

Automation Meets Flexibility in Gummy Production

Semi-automatic gummy making systems are designed to fill the gap between manual methods and full automation. They offer a flexible approach to increasing productivity without the hefty price tag of fully-automated lines. This makes them an attractive option for businesses ready to scale their operations.

One notable example is the GummyGenix by DM-20S Depositor. Capable of producing up to 10,000 gummies per hour, it automates the depositing process, which is crucial for maintaining product consistency. The machine's user-friendly interface3 allows operators to quickly adjust settings according to batch size and recipe requirements.

Reducing Labor Costs

By minimizing manual involvement, semi-automatic solutions significantly cut down labor costs. Employees can focus on quality control and other value-added tasks rather than repetitive depositing or dosing. The SaintyCo DM-50X, for example, supports up to 15,000 gummies per hour and requires minimal supervision once set up.

This reduction in manual labor not only saves time but also decreases the likelihood of errors common in manual processes. The consistency these machines bring means fewer defects and a higher-quality product reaching the market.

Enhancing Consistency and Quality

The precise dosing mechanisms within semi-automatic systems ensure each gummy is consistent in size and shape. This uniformity is crucial for maintaining brand reputation and meeting regulatory standards. Systems like the DM series include features such as programmable logic controllers (PLCs) that allow for fine-tuned control over the production process.

Moreover, the transition from manual to semi-automatic can be gradual. Businesses can start with smaller investments like the DM-20S and progress to more advanced models as demand increases.

Scalability Options for Growing Gummy Businesses

As production needs grow, semi-automatic solutions provide a scalable pathway. Adding more units or upgrading to higher-capacity machines can be done incrementally, offering financial flexibility. This approach aligns well with long-term business strategies focused on sustainable growth.

For businesses contemplating this transition, exploring scalable automation solutions4 offers insights into how semi-automatic systems can be integrated into existing workflows without disrupting current operations. This method ensures efficiency improvements are realized without overhauling the entire production line.

Semi-automatic solutions reduce labor costs significantly.True

They minimize manual involvement, allowing focus on quality control.

Why Consider Fully-Automated Lines for Expansion?

Are fully-automated production lines the key to maximizing efficiency in gummy manufacturing? Let's find out!

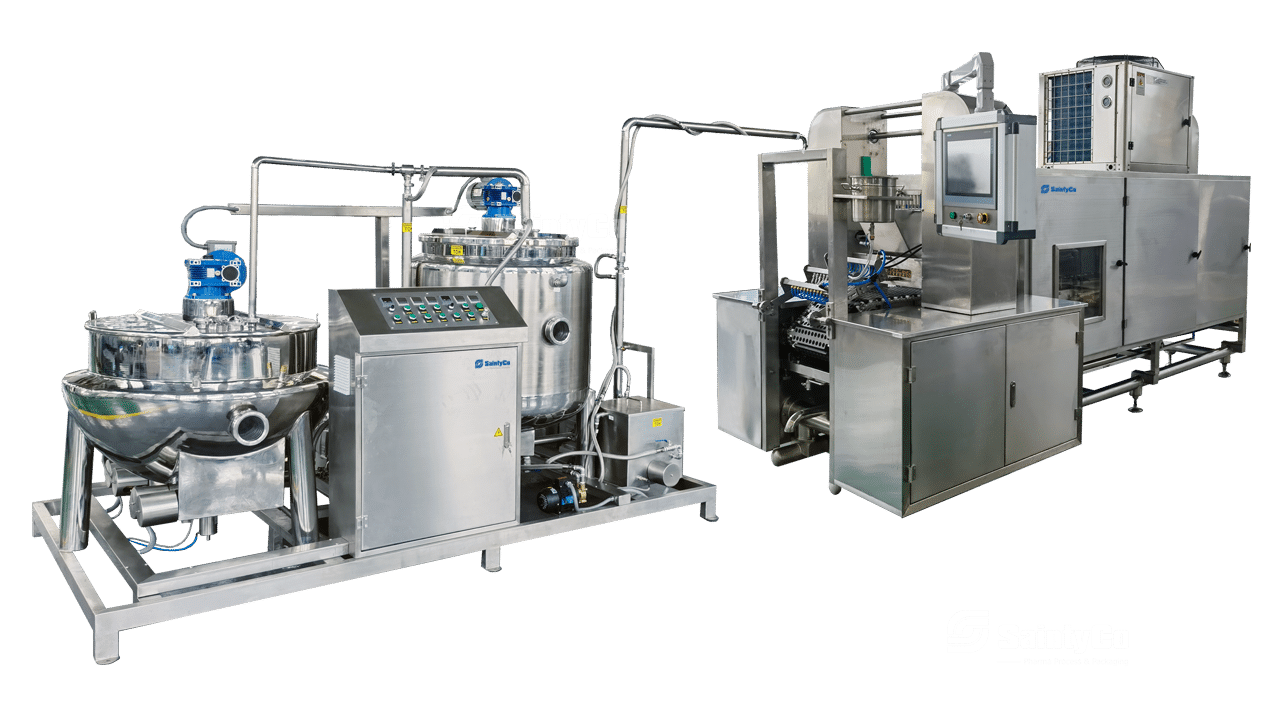

Yes, fully-automated gummy production lines like the SaintyCo G40 can significantly enhance production efficiency by reducing manual labor, increasing output, and ensuring consistent product quality. These systems streamline processes from mixing, cooking, depositing, cooling, demolding to packaging finished gummies, allowing businesses to meet high demand efficiently.

The Advantages of Full Automation

Fully-automated gummy production lines, such as the SaintyCo G40 model, provide several compelling advantages for expanding gummy production. These systems ensure consistent quality and high-speed output, producing up to 15,000 gummies per hour. This efficiency is essential for meeting growing market demands without the need for proportional increases in labor.

Moreover, fully-automated lines can significantly reduce human error, a common issue in manual and semi-automatic systems. The integration of advanced technology ensures precision in every batch, maintaining the taste, texture, and appearance customers expect.

Cost Efficiency and Labor Savings

While the initial investment in a fully-automated line might seem steep, the long-term savings are considerable. By reducing manual labor requirements, these systems lower operational costs and free up your workforce to focus on other strategic areas of your business.

Consider this example:

| Manual Production | Fully-Automated Line |

|---|---|

| Labor Intensive | Minimal Labor Required |

| Variable Quality | Consistent Output |

| Limited Scale | High-Speed Production |

Versatility and Scalability

Many fully-automated systems are designed with versatility in mind. For instance, the SaintyCo G40 supports dual-color capabilities, allowing you to diversify your product offerings without additional machinery. This feature is invaluable for businesses looking to innovate and adapt to changing consumer preferences.

Moreover, fully-automated lines are scalable solutions. As your business grows, these systems can be integrated with other automated processes, such as packaging solutions5, to create a seamless production line.

Challenges and Considerations

While fully-automated lines offer numerous benefits, there are challenges to consider:

- Initial Investment: High upfront costs can be a barrier for small businesses. However, the return on investment through increased efficiency often justifies this expense.

- Maintenance and Training: Regular maintenance and operator training are essential to keep automated systems running smoothly.

- Technical Issues: Reliance on technology means that any technical failures could halt production entirely. Having a robust support system is crucial.

By understanding these aspects, businesses can better assess whether transitioning to fully-automated lines aligns with their operational goals and resources. Interested in exploring further? Learn more about automation impacts4.

Fully-automated lines reduce labor costs significantly.True

Automation requires fewer workers, lowering labor expenses.

Automated lines always eliminate human error entirely.False

While reducing errors, automation cannot eliminate them completely.

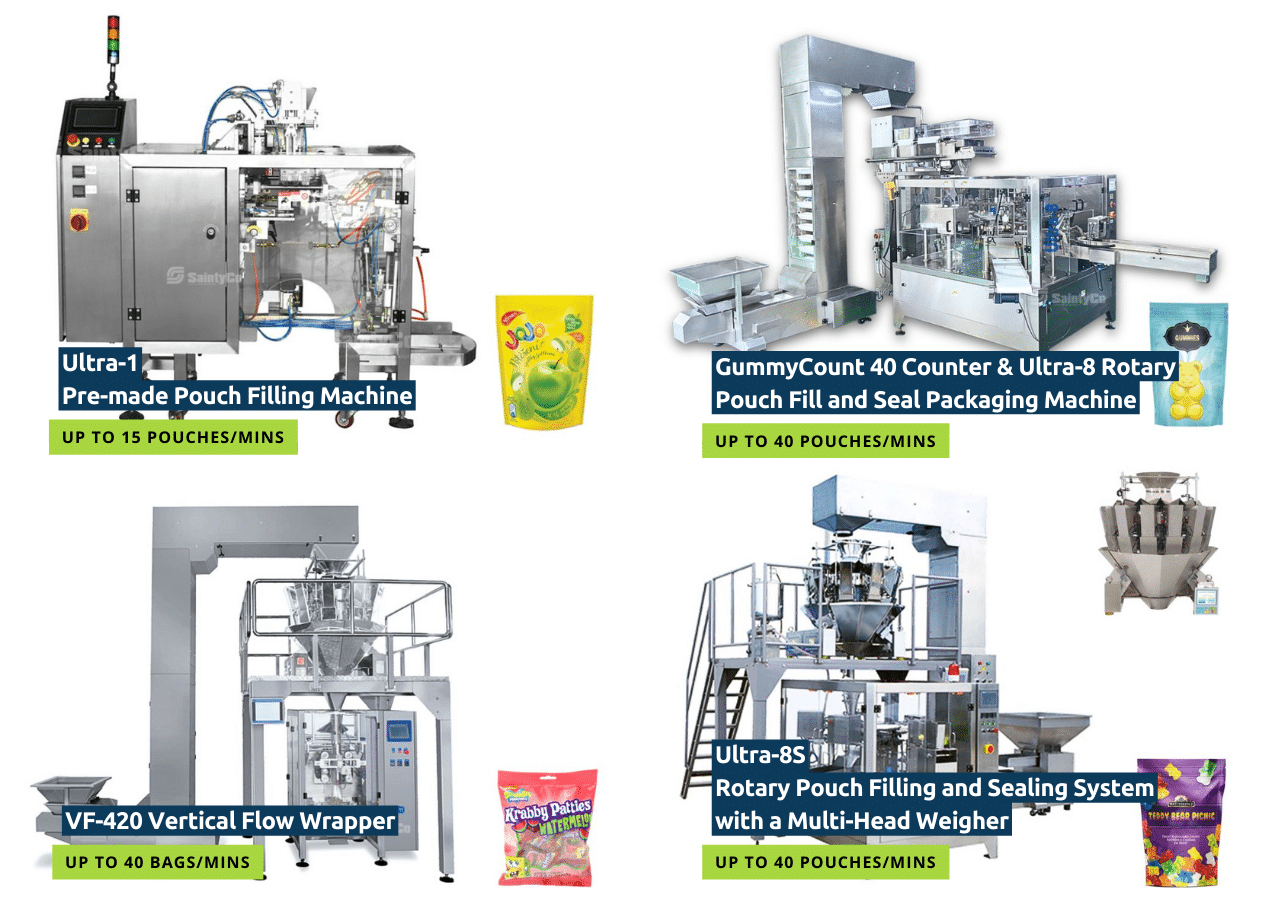

What Are Cost-Effective Packaging Automation Options?

Exploring packaging automation's role in cost management can reveal significant financial benefits for producers.

Packaging automation can significantly reduce overall costs by increasing efficiency, decreasing labor expenses, and minimizing errors. Automated systems streamline packaging processes, leading to faster production times and reduced waste. While initial investments may be high, long-term savings make automation a cost-effective choice.

Entry-Level Automation: A Practical Starting Point

For businesses dipping their toes into automation, starting small can lead to significant improvements without the steep costs. TACH-IT labeling solutions, priced around $500, are an excellent choice for businesses just beginning to automate their labeling processes. These machines streamline labeling tasks, reducing the time and effort spent on manual labeling, thereby improving consistency and appearance.

Scaling Up with Integrated Solutions

As your business grows, so does the need for more comprehensive packaging solutions. Enter SaintyCo GummyGenix Packaging Systems6, which offer a flexible setup for filling, sealing, and labeling. These systems are designed to scale alongside your production demands, ensuring that as you increase output, your packaging keeps pace without sacrificing quality or efficiency. By integrating multiple packaging stages into a cohesive workflow, these systems minimize bottlenecks and enhance overall productivity.

Balancing Cost and Efficiency

While initial investments in automation equipment may seem daunting, the long-term savings in labor costs and increased production speeds often justify the expense. It's crucial to assess your current production volume and future goals to select the right level of automation. A phased approach, starting with basic solutions and gradually moving to more advanced systems, allows businesses to adapt as their needs evolve.

Here's a quick overview:

| Automation Level | Equipment Options | Approximate Cost | Benefits |

|---|---|---|---|

| Entry-Level | TACH-IT Labelers | $500+ | Consistent labeling, cost-effective |

| Advanced | Tailored GummyGenix by SaintyCo Packaging Solutions | Scalable Pricing | Integrated packaging solutions |

Adopting automation doesn't have to be a one-size-fits-all approach. By evaluating your specific needs and growth projections, you can invest in the right tools that provide flexibility and scalability.

TACH-IT labelers cost around $500.True

Entry-level TACH-IT labeling solutions start at approximately $500.

SaintyCo GummyGenix is only for small businesses.False

SaintyCo GummyGenix scales with production demands, suitable for growing businesses.

Conclusion

By exploring these affordable automation options, you can efficiently scale your gummy production to meet growing demands while keeping costs in check. Dive deeper into each solution to find the best fit for your needs.

GummyGenix by SaintyCo is here to support your promising gummy making journey. With over 23 years of experience, we specialize in end-to-end gummy production solutions—from innovative, industry-compliant machinery to expert guidance at every step. Whether you're a new business or expanding production, our customized solutions, efficient equipment, and dedicated after-sales support can help you meet your goals.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality gummy products to life—together.

-

Discover various squeeze bottle options tailored for different gummy production needs.: The Tablecraft 12 oz Clear Heavy Duty Squeeze Bottle was our favorite squeeze bottle. It works especially well with thinner liquids and doesn't leak. ↩

-

Explore a variety of confectionery funnels to enhance your gummy production.: Our pastry collection has an extensive line of world-class professional products from pastry and ice cream molds, disposable and metal bakeware. ↩

-

Explore how easy it is to adjust settings for batch variations.: Gummy depositor comprises of user interface which the operator uses to control how the gummy depositor operates. You will also find a touch ... ↩

-

Discover how scalable options support growth in gummy production.: Automated packaging machines sort the gummies, fill packages, seal them, and even label them. These systems are designed to operate at high ... ↩ ↩

-

Explore how integrating automated packaging enhances production efficiency and reduces costs.: Improved speed and efficiency. The most obvious benefit from automated packaging is achieving a greater production rate than manual packaging. ↩

-

Learn how SaintyCo's systems integrate filling, sealing, and labeling seamlessly.: Twin packs; Gusseted bags; Counter displays; Flexible packages; Multi-packs; PTE and HDPE bottles; Sachets; Club store trays. What Safety ... ↩