In 2024, the global gummy candy market is booming. The Grand View Research says that the gummy market size is projected to grow at an 11.8% compound annual growth rate by 2030. Whether you're a hobbyist or looking to enter the gummy business, this guide will explain how gummies are made at home and on an industrial scale.

.

What Are the Main Differences Between Homemade and Commercial Gummy Making?

Homemade and commercial methods share the goal of making tasty gummies, but they differ in scale, complexity, and purpose. Here’s a quick comparison:

| Aspect | Homemade Gummy Making | Commercial Gummy Making |

| Ingredients | Basic ingredients: gelatin, sugar, flavorings, water. | Some uses additional ingredients like starch, acids, preservatives for shelf life. |

| Equipment | Simple tools: stove, saucepan, silicone molds. | Specialized machines: cookers, mixers, depositors, cooling tunnels. |

| Batch Size | Small batches for personal use or gatherings. | Large-scale production, thousands per hour. |

| Customization | Highly customizable: flavors, shapes, ingredients. | Limited customization; standardized for consistency. |

| Time to Make | 1-2 hours per batch. | Fast production with industrial machines. |

| Cost | Low initial cost, but time-consuming. | High machinery cost, but low per-unit cost. |

| Additives & Preservatives | No preservatives, short shelf life. | Preservatives added for long shelf life and transport. |

| Shelf Life | 1-2 weeks in good storage. | Months or years due to preservatives and packaging. |

| Health & Nutritional Control | Full control, can make organic or sugar-free. | Often includes artificial ingredients, but health-focused options are growing. |

| Regulation & Quality Control | Informal, based on personal standards. | Strict control with lab testing for safety and compliance. |

.

How to Make Gummy at Home: Step-by-Step Process

Creating your own gummy candies at home gives you complete control over the ingredients and customization of the chewy treat. The best part is that you can try out unique flavors and shapes to craft personalized gummies that suit your preferences. They are a fun, easy project for both kids and adults, making them excellent gifts or party treats!

Key Gummy Ingredients for Homemade Gummy Candy

| Ingredients | Source | Role |

| Gatin | Sourced from animal collagen (pork or beef). Vegan alternatives include agar-agar or pectin. | Creates the chewy, jelly-like texture by forming a gel when dissolved in water and cooled. |

| Sweeteners | Common options: sugar, honey, corn syrup. Healthier options: stevia or erythritol. | Adds sweetness, balances acidity, and affects the final texture. |

| Flavorings | Fruit juices, extracts (vanilla, mint), or concentrated flavor oils. | Provides the gummies' signature taste. Natural fruit flavors are great for healthier gummies. |

| Colorings | Natural powders like beetroot (red) or spirulina (green). | Adds visual appeal. Natural colors help avoid artificial additives. |

.

Essential Equipment For At-Home Gummy Production

| Tool Name | Function | Example |

| Saucepan | It is used to heat and combine the gummy ingredients. Choose a size that fits your recipe. |  |

| Whisk | Ensures thorough mixing of gelatin and sweeteners, preventing clumps in the gummy mixture. |  |

| Candy Thermometer | Accurately monitors the gummy mixture’s temperature to ensure proper gelatin activation. |  |

| Gummy Molds | Shape the final gummies. | |

| Dropper or Small Spoon | Helps fill molds precisely without spilling. |

|

| Brix Refractometer | Measures sugar content easily and accurately. |

|

.

Step-By-Step Instructions For Making Gummy Candy At Home

1. Prepare the Gelatin

- Sprinkle gelatin powder over cold water or fruit juice in a saucepan or bowl.

- Let it sit for 5 to 10 minutes to allow the gelatin to absorb the liquid and dissolve evenly.

2. Heat the Sweetener

- In a separate saucepan, combine your sweetener (sugar, honey, or corn syrup) with water.

- Heat gently over medium heat.

- Use a thermometer to ensure the mixture reaches 220°F while stirring constantly until the sweetener melts and dissolves completely.

3. Combine the Mixtures

- Gradually add the bloomed gelatin to the hot sweetener mixture.

- Whisk continuously and heat until the gelatin dissolves completely, and the mixture becomes smooth.

- Tip: Avoid overheating, as this can weaken the gelatin's ability to set.

4. Add Flavor and Color

- Remove the mixture from the heat.

- Add your desired flavorings and colorings.

- Stir until the flavor and color are fully combined.

- Tip: You can adjust flavors and colors according to your taste preferences at this stage.

5. Mold the Gummies

- Pour the mixture into gummy molds.

- For intricate molds, use a dropper or small spoon to fill each cavity precisely without spilling.

6. Set the Gummies

- Refrigerate the filled molds for 30 minutes to 1 hour to allow the gummies to fully set and firm up.

7. Unmold and Store

- Gently pop the gummies out of the molds once they are set.

- Store the gummies in an airtight container at room temperature.

- Tip: If you live in a humid climate, store your gummies in the refrigerator to maintain their texture.

.

.

Pro Tips for Homemade Gummy Makers

- Experiment with flavors and colors: Try different combinations to create unique gummies. Use natural fruit juices or plant-based colorings to avoid artificial additives.

- Adjust for high altitudes: Increase water slightly and lower the cooking temperature by 2-5°F to ensure gummies set properly without drying out.

- Store for long-term freshness: Keep gummies in an airtight container at room temperature for up to a week. In humid areas, refrigerate them with a silica gel packet to prevent stickiness and preserve texture.

- Fix soft gummies: Add more gelatin next time to improve the texture if they’re too soft.

- Fix hard gummies: Reduce the gelatin or add more liquid in the next batch if the gummies are too hard.

- Prevent sticking: Dust gummies with cornstarch or powdered sugar, especially in warm climates, to keep them from sticking together.

- Vegan alternatives: When using agar-agar or pectin, remember pectin needs a higher boiling point, and agar-agar sets quickly at room temperature. Pour the mixture into molds quickly to avoid premature setting.

.

How To Make Gummies On An Industrial Scale

Commercial gummy production vastly differs from homemade methods. It focuses on efficiency, consistency, and mass production with tighter measures for precision and hygiene. Moreover, it uses automated systems and highly specialized machinery. You can partner with GummyGenix to get state-of-the-art equipment for the entire gummy production line.

Key Ingredients For Commercial Gummy Production

| Ingredient | Source | Role |

| Gelling agent | Most commercial gummies use gelatin derived from pork or beef collagen. Vegan options include pectin or agar-agar. | Gelatin gives gummies their chewy texture and is crucial for forming the gel structure that holds the candy together. |

| Sweeteners | Common sweeteners include glucose syrup, sucrose, and corn syrup. They can also be blended. | Sweeteners add flavor and help to balance the acidity of other ingredients while also affecting the texture. |

| Water | Find clean, filtered water to use in the gummy-making process. | Water acts as a solvent to dissolve the gelatin, sweeteners, and other ingredients. It also facilitates the cooking process. |

| Flavorings | Flavorings are typically natural or artificial extracts, such as fruit juices or oils. | They give the gummies their distinct taste, which can range from fruity to sour or sweet. |

| Colors | Commercial gummies use both artificial and natural food colorings (e.g., beetroot extract for red, turmeric for yellow). | Coloring enhances the visual appeal of the gummies, making them more marketable. |

| Acids | Commonly used acids include citric acid and malic acid, sourced from citrus fruits or apples. | Acids balance sweetness, enhance flavors to give the gummies a tangy or sour taste and improve shelf life. |

| Optional vitamins and minerals | Many commercial gummies are fortified with vitamins (e.g., vitamins C, D) and minerals for functional benefits. | These additions turn gummies into nutraceuticals, offering health benefits along with flavor. |

Pro Tips for Commercial Gummy Manufacturers

- Prevent hard gummies in large batches: In mass production, gummies can become too hard if gelling agent ratios are off or if the cooking temperature is too high. Use precise temperature control on GummyGenix equipment to maintain consistency.

- Ensure flavor uniformity: Add flavorings after the gelatin mixture is fully dissolved, and mix thoroughly to ensure even distribution. Automated GummyGenix mixers can help with achieving uniform taste in large batches.

- Avoid crystallization in sugar-free gummies: To prevent crystallization in sugar-free recipes, use non-crystallizing sugar substitutes like maltitol and ensure your GummyGenix mixing equipment is calibrated for sugar-free formulations.

- Extend shelf life: Add a small amount of citric acid or sodium citrate as preservatives, and use airtight packaging to maintain freshness. GummyGenix packaging systems can provide vacuum-sealed, tamper-proof containers for maximum shelf stability.

.

What Gummy Manufacturing Equipment Do I Need To Make Gummies On A Large Scale?

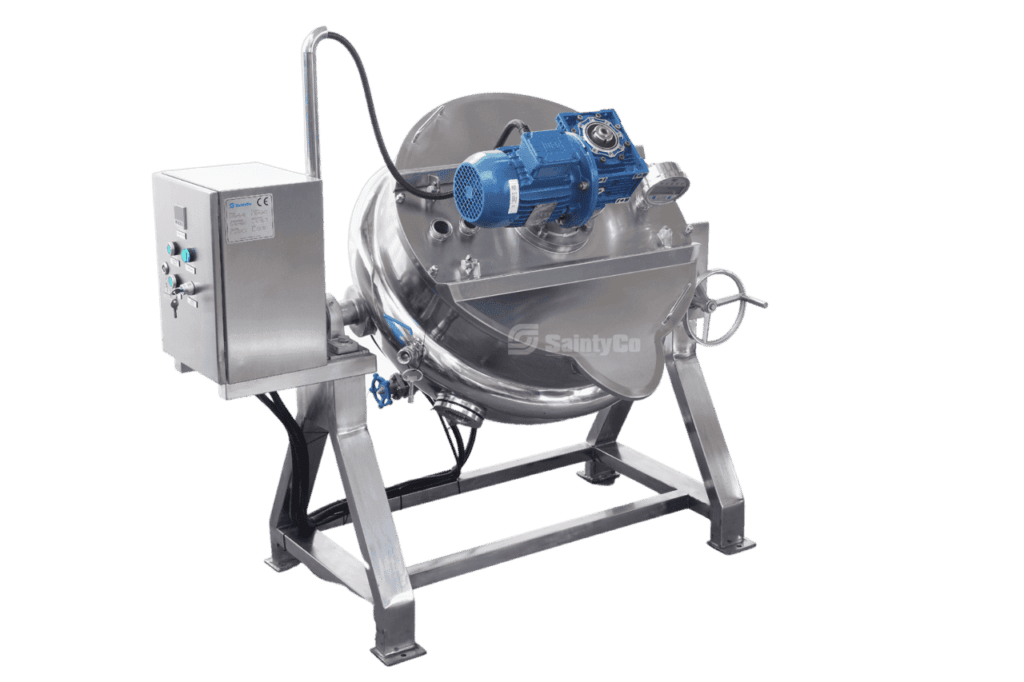

1. Cooking Equipment for Gummies Production

Purpose:

Cooking and mixing are critical for achieving the perfect texture, flavor, and uniformity in ingredients. Industrial cookers precisely heat sweeteners and gelling agents, ensuring consistency across batches.

Small-Scale Production:

- Batch mixers, like the GummyGenix 100L Dissolving Tank, are ideal for artisan or specialty gummies, such as CBD or nutraceutical products.

- Specifications:

- Capacity: 100L

- Temperature range: 0-200°C, adjustable

- Heating type: Electrical, with 300°C heat conduction oil for precise temperature control.

- This equipment is ideal for small-batch artisan gummies, ensuring even mixing of gelatin and other gelling agents with accurate temperature control.

- Specifications:

.

.

Large-Scale Production:

- For larger production volumes, the G150 Fully Automatic Gummy Production Line as an example of G-series lines by GummyGenix is an ideal solution.

- Specifications:

- Output: 60,000 gummies per hour

- Cooking system: Advanced jacketed cooking kettles with precise temperature control to prevent crystallization and ensure a uniform mixture

- Temperature control: Automated control panels maintain cooking temperatures between 0-200°C, perfect for complex formulations like sugar-free or vegan gummies

- The G150 system ensures uniform texture and quality across large batches, with automated features that reduce human error, especially for sensitive products like vegan or sugar-free gummies.

- Specifications:

.

.

Why Temperature Control Matters:

- Preserves texture by preventing overcooking.

- Ensures consistent flavor by avoiding burning or uneven cooking.

- Optimizes production time with precise heat control.

.

Looking to improve consistency in your gummy production? Contact GummyGenix for automated mixing and cooking solutions that ensure precise temperature control and flawless results!

.

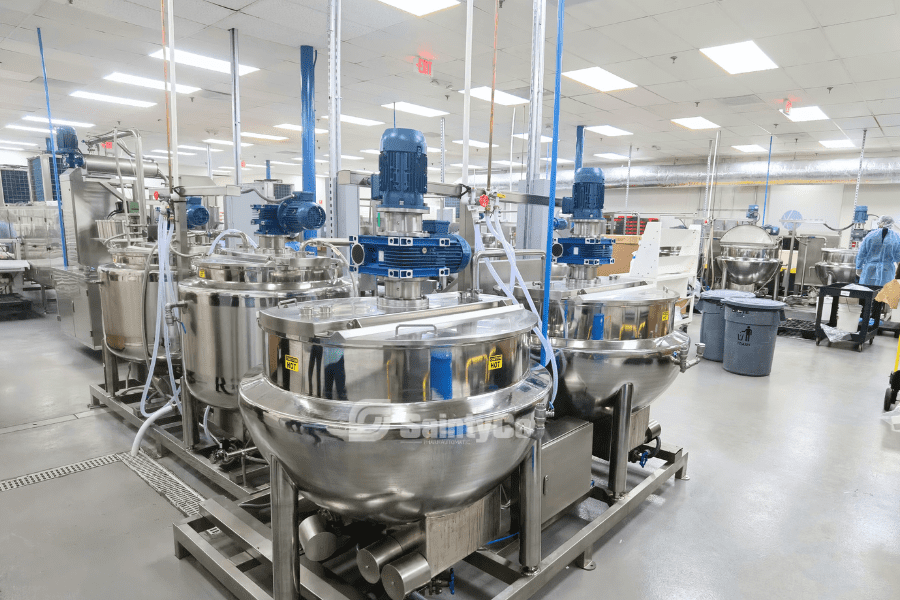

2. Storage Tanks & Mixing Tanks

Purpose:

Efficient storage and mixing tanks are essential for holding and blending large volumes of gummy syrup before it is deposited into molds. This ensures the syrup is evenly distributed and maintains the correct temperature and consistency.

Small-Scale Production:

- For small-scale or artisan production, the GummyGenix 100L Dissolving Tank is an excellent choice for mixing and storing gummy syrup.

- Specifications:

- Capacity: 100L

- Temperature control: 0-200°C, with electrical heating using 300°C heat conduction oil.

- Material: Made from SUS304 stainless steel for durability and hygiene.

- Mobility: Equipped with wheels, making it easy to move within the production area.

- Power: Stirrer motor power of 1.1 kW ensures consistent mixing of thick syrups.

- This tank is perfect for small-batch production, maintaining the right syrup consistency and temperature throughout the process.

- Specifications:

.

Large-Scale Production:

- For larger operations, the G150 Automatic Gummy Production Line by GummyGenix comes equipped with high-capacity storage and mixing tanks.

- Specifications:

- Output: 60,000 gummies per hour

- Jacketed storage tanks: Ideal for maintaining syrup at the correct temperature, ensuring uniform consistency before the syrup enters the depositor.

- Automated control panel: Minimizes manual intervention by controlling temperature and mixing precisely

- Specifications:

- The G150 system is designed for high-volume production, handling multiple gummy formulations with consistent syrup quality.

.

Why Proper Syrup Handling Matters:

- Prevents ingredient separation with continuous stirring.

- Ensures consistent quality by preventing crystallization.

- Boosts production efficiency by reducing downtime.

.

3. Gummy Depositing and Molding Equipment

Purpose:

Depositing and molding are essential for shaping gummies accurately and ensuring precise dosing of active ingredients such as CBD or vitamins. High-quality depositing ensures consistency in size, weight, and ingredient distribution, which is particularly important for functional gummies.

Small-Scale Production:

- MINI DP-10S Table Top Depositor

- Ideal for entry-level operations and small-batch production.

- Specifications:

- Capacity: 3,000 to 5,000 gummies per hour.

- Dosage: Up to 3ml per shot.

- Hopper: 20L with heated panels to maintain syrup flow.

- Features: Servo-driven, adjustable nozzles for various mold layouts, compatible with silicone and polycarbonate molds.

- This compact depositor offers flexibility and precision for artisanal production, ensuring accurate temperature and volume control.

.

.

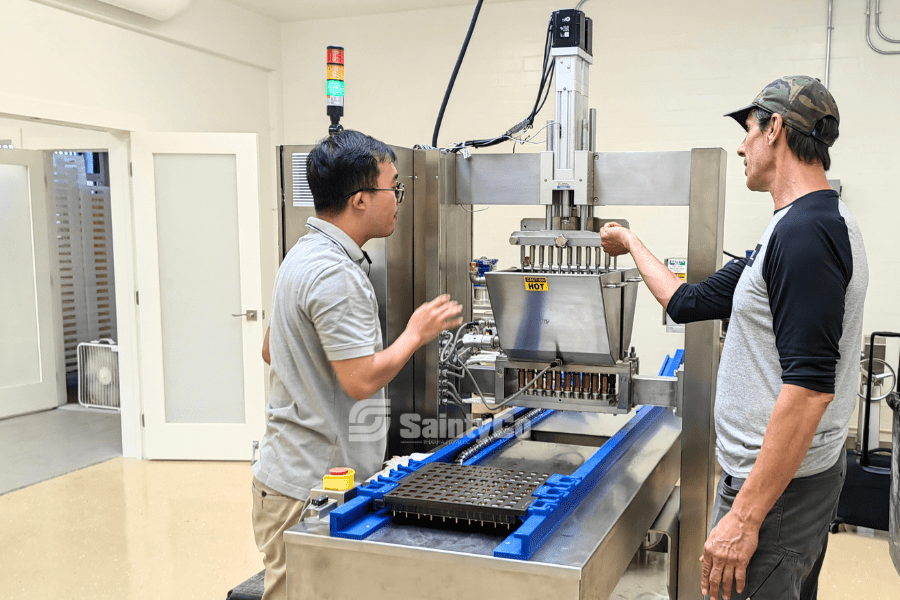

- DM-20S Small Batch Depositor

- Suitable for R&D or entry-level production with higher output requirements.

- Specifications:

- Output: 6,000 to 10,000 gummies per hour.

- Dosators: 20 servo-driven dosators for a batch of 12kg, adjustable based on gummy weight.

- Hopper: 25L with thermostatically controlled heating.

- Control: Touchscreen PLC for deposit speed, volume, and temperature control

- Ideal for small-scale production of functional gummies (CBD, vitamins), ensuring consistent product quality.

.

.

Mid-Large Scale Production:

- DM-50X Small Batch Depositor

- Best suited for semi-automatic production lines handling a variety of gummies, hard candies, and toffees.

- Specifications:

- Output: Up to 18,000 gummies per hour.

- Dosage: Handles 2g to 16g per piece.

- Hopper: 30L, with an optional second hopper for two-color or center-filled products.

- Depositing speed: Up to 35 strokes per minute.

- DM-50X is designed for semi-automatic production lines, delivering high-speed depositing with consistent size and weight.

.

.

- G150 Automatic Gummy Production Line

- Designed for large-scale commercial production with high-speed capabilities.

- Specifications:

- Output: 60,000 gummies per hour.

- Depositing system: Servo-driven dosators with adjustable doses from 1 to 15 grams per gummy.

- Dual-color capability: Integrated dual-color depositor for multi-layer gummies.

- The G150 offers precision and consistency, ideal for high-volume production of CBD, vitamin, and other functional gummies.

.

![[Gummy Machine] G150 Gummy Production Line - SaintyCo](https://gummygenix.com/wp-content/cache/flying-press/TXs20euXnkY-hqdefault.jpg)

.

Why Depositing Matters:

- Ensures uniformity in shape and size, important for branding and compliance.

- Guarantees accurate dosing for functional gummies like CBD.

- Improves efficiency with high-speed, automated depositors.

Request a Free Quote

.

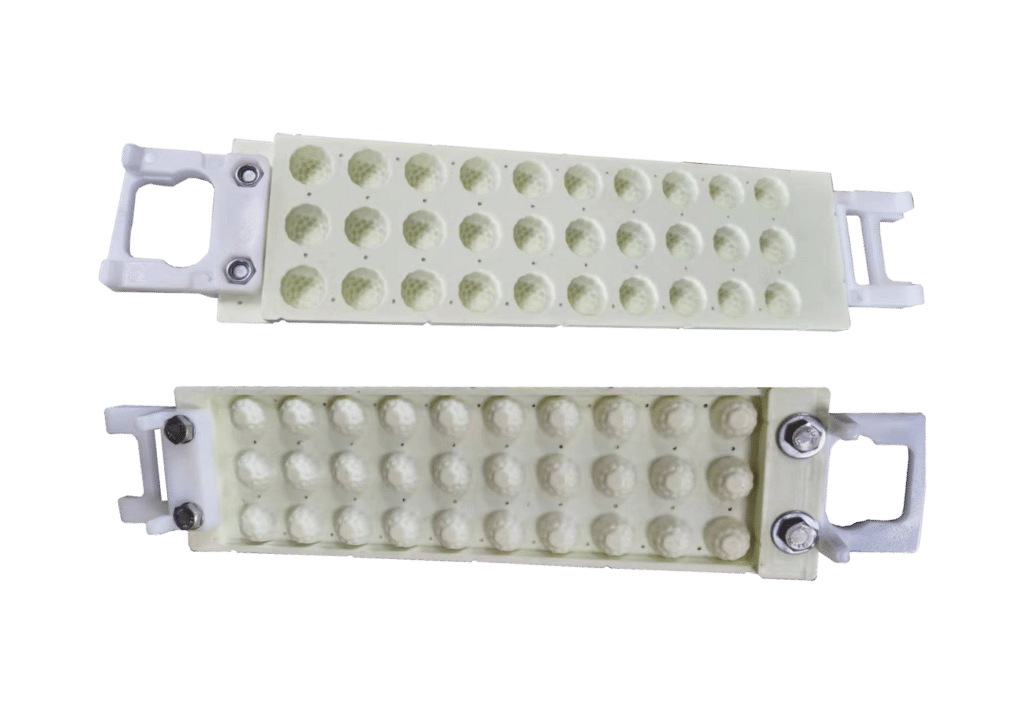

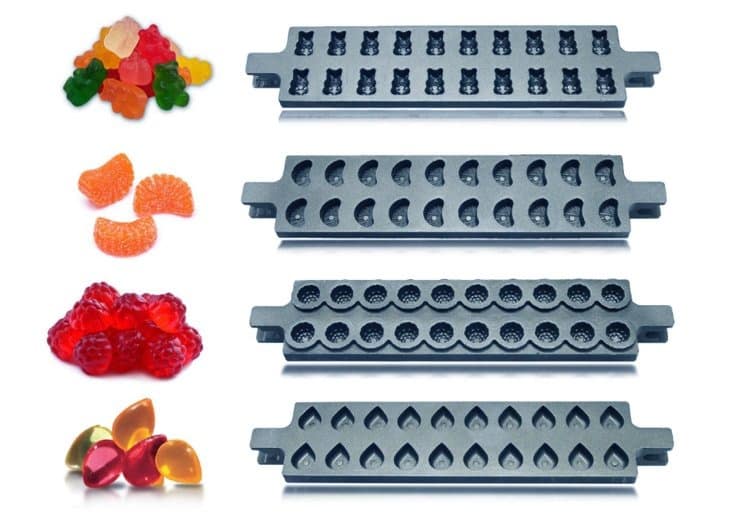

4. Gummy Molds

Purpose:

Gummy molds determine the final shape, size, and weight of each gummy. Whether producing classic gummy bears or custom shapes, high-quality molds are critical to achieving precise, consistent results. They also play a significant role in ensuring dosing accuracy for functional gummies like CBD or vitamin-enriched products.

Small-Scale Production:

- For small-scale or boutique production, flexible silicone molds are ideal:

- Customization: Allows for unique shapes to cater to niche markets

- Ease of Use: Non-stick, easy to clean, suitable for small-batch production

- Standard Molds Available: Bears (1.55-3g per gummy), cubes (1-6g), and round molds

- Challenge: Slower for large volumes due to manual handling.

.

.

Large-Scale Production:

- For high-volume operations, metal molds with quick-release tooling are more appropriate:

- Durability: Designed for continuous production without wear

- Precision: Quick-release molds ensure consistent shape and size

- Mold Sizes: Example: Bear molds with 20 cavities, each weighing 2.5-3.5g

The quick-release system supports high-speed production lines like the G150.

.

Why Mold Quality Matters:

- Consistency: Uniform molds ensure each gummy is identical.

- Production Efficiency: Quick-release molds reduce downtime during demolding.

- Accurate Dosing: Essential for functional gummies to maintain proper dosage.

.

GummyGenix Advantage:

GummyGenix offers a range of customizable silicone molds for small-scale production, as well as quick-release metal molds for larger operations. With a wide selection of standard mold sizes, including cubes, bears, cylinders, and custom designs, we provide solutions tailored to your production needs. The G150 production line features a quick-release mold system that supports rapid demolding, ensuring precision and efficiency at high output levels.

.

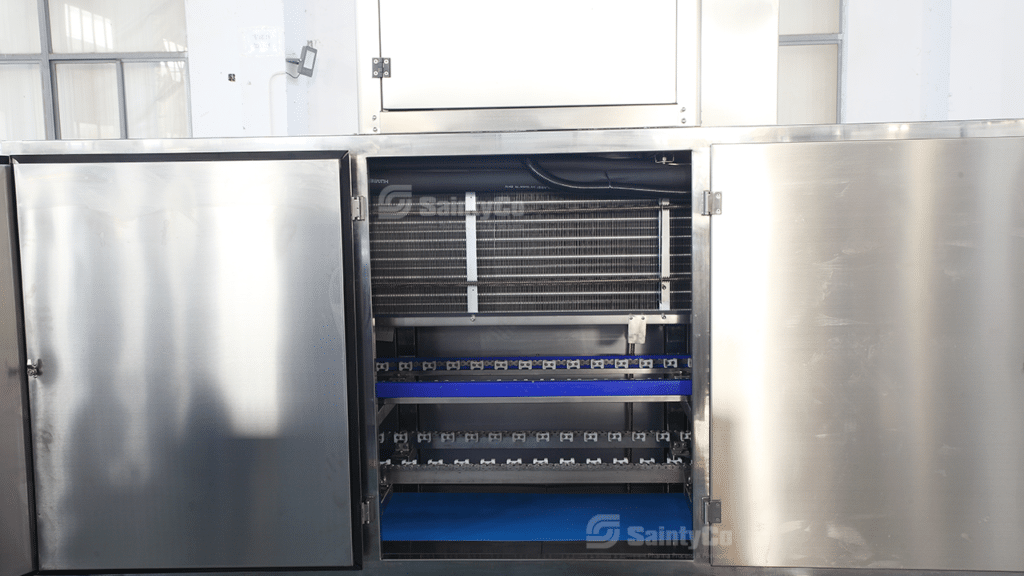

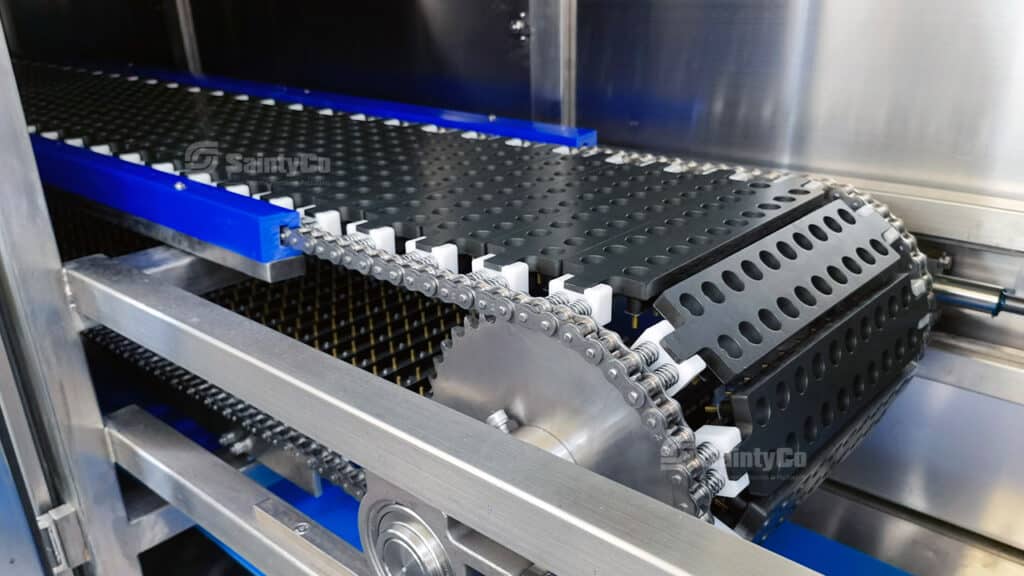

5. Gummy Candy Cooling Tunnel And Drying

Purpose:

Proper cooling and drying maintain the texture, shape, and shelf life of gummies, especially for sensitive formulations like sugar-free or CBD gummies.

Small-Scale Production: Manual cooling and drying rooms

- Flexibility: These systems offer flexibility in the process, allowing for adjustment based on production size.

- Challenges: In manual cooling environments, there can be inconsistent cooling across batches, leading to variations in texture and firmness. For sensitive products like CBD gummies, this can result in uneven distribution of active ingredients or potency loss, as these gummies require precise temperature contro

- Cooling Time: Manual cooling typically takes 1-2 hours depending on room conditions and the batch size, which can slow down overall production.

.

.

Large-Scale Production:

- Automated cooling tunnels like those integrated in the G150 Automatic Gummy Production Line provide more consistent and rapid cooling, which is essential for large-scale operations:

- Specifications:

- Cooling Capacity: The G150 system supports high-speed production, cooling up to 60,000 gummies per hour.

- Temperature Control: Automated cooling tunnels maintain precise temperatures between 0°C to 10°C for rapid setting without compromising texture.

- Cooling Duration: Gummies can pass through the cooling tunnel in as little as 10-15 minutes, drastically improving production efficiency.

- Specifications:

.

.

Why Efficient Cooling Matters:

- Maintains correct texture by preventing over-firming.

- Preserves potency of active ingredients in functional gummies.

- Improves shelf stability by reducing moisture buildup.

.

GummyGenix Advantage:

GummyGenix offers advanced cooling and drying solutions tailored for both small-scale and large-scale gummy production. GummyGenix by SaintyCo offers G-series fully automated Gummy Production Lines includes automated cooling tunnels that ensure precise temperature control and efficient processing. These systems are designed to handle high-output production while maintaining the texture, potency, and shelf stability of your gummies.

.

6. Gummy Demolers

Purpose:

Demolding is crucial for maintaining gummy shape, texture, and dosing accuracy.

Small-Scale Production: Pneumatic demolders

- Air-Puff Release: Uses compressed air to gently release gummies

- Efficiency: Reduces manual intervention, ideal for smaller batches

- Challenge: Sticky formulations (e.g., pectin-based gummies) may slow release.

.

.

Large-Scale Production:

- For large-scale operations, fully automated demolding systems like the one in the G150 Automatic Gummy Production Line are essential:

- Quick-Release Molds: Ensures high-speed demolding without damaging gummies

- Non-stick Molds: Ideal for sticky formulations like sugar-free or CBD gummies

- Air-Puff Technology: Ensures quick and clean release, even for high-output operations

.

.

Why Clean Demolding Matters:

- Preserves Shape and Texture: Prevents gummies from losing form.

- Ensures Dosing Accuracy: Especially for functional gummies like CBD or vitamins.

- Optimizes Production Speed: Reduces downtime and manual labor.

.

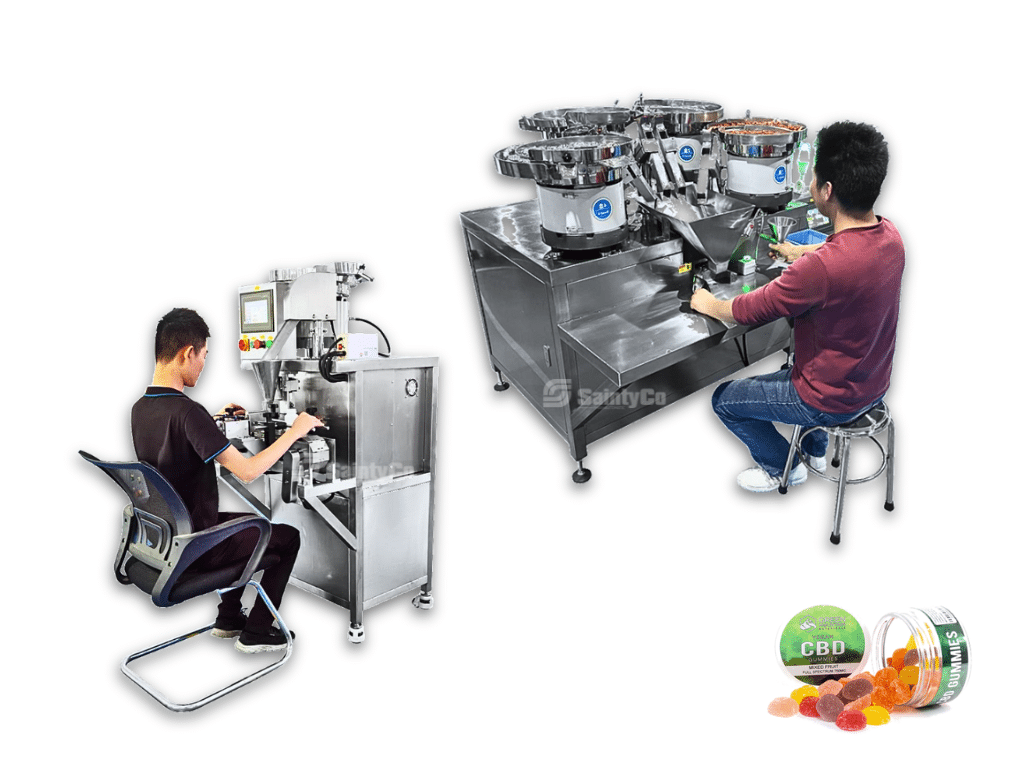

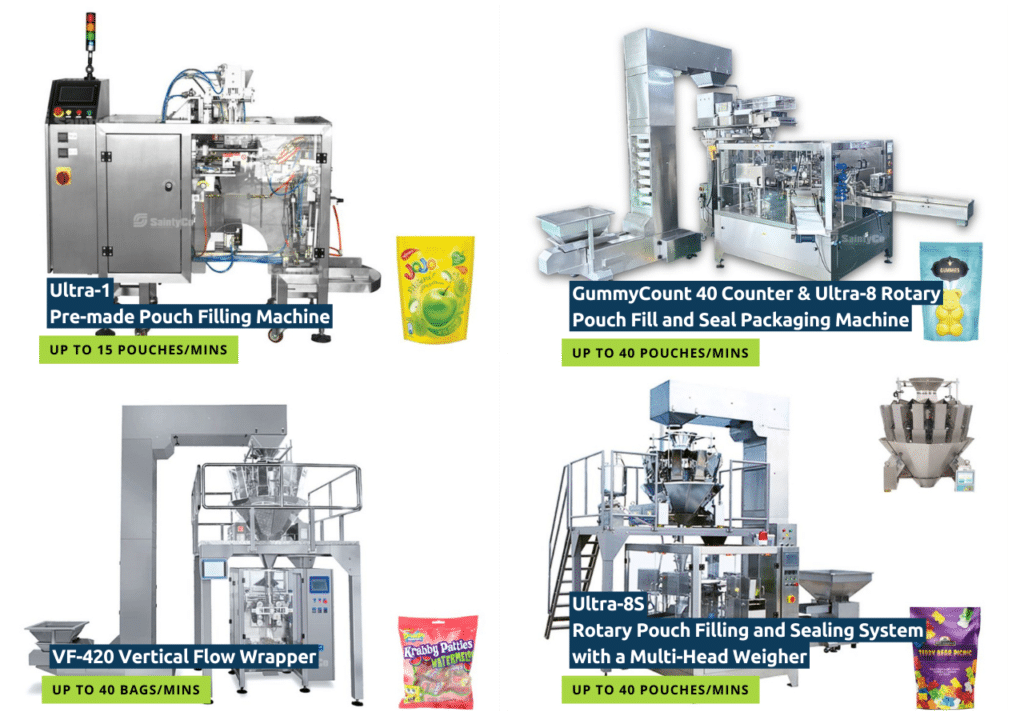

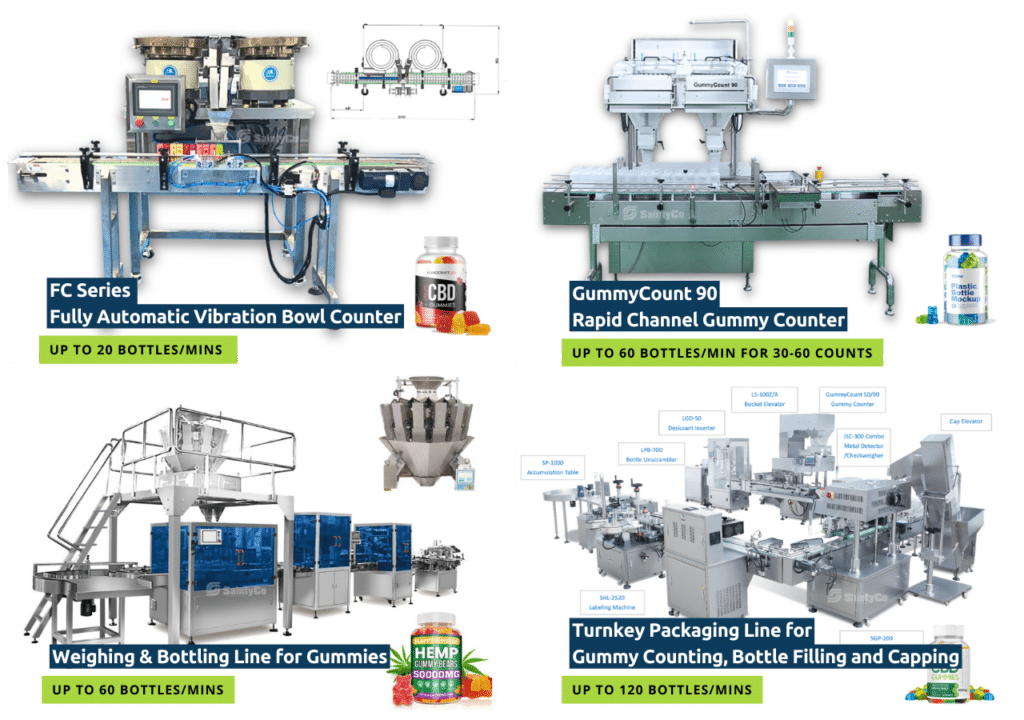

7. Gummy Packaging Machines

Purpose:

Packaging is the final step in gummy production. It’s crucial to preserve freshness, potency, and shelf life, especially for sensitive ingredients like CBD or sugar-free formulations.

.

Small-Scale Production:

- Semi-automatic packaging systems provide flexibility for boutique products but may struggle with airtight sealing, which is crucial for products like CBD gummies.

Large-Scale Production:

- Automated packaging lines are essential for large-scale production, ensuring that each gummy is packed in airtight, tamper-proof containers.

- This is vital for gummies like CBD or probiotic-enriched varieties, where exposure to air or moisture can degrade active ingredients.

.

.

Step-by-Step Guide to the Gummy Manufacturing Process in Commercial Production

Step 1: Make Your Gummy Recipe

Formulate a recipe with the right ratios of gelatin, sweeteners, water, flavorings, and colorants.

Step 2: Prepare Ingredients

Weigh and measure all ingredients precisely. These include gelling agents, sweeteners, water, flavorings, colors, and vitamins.

Step 3: Cook and Blend

Heat the water and sweeteners in the industrial cooker. Add the gelling agent and blend until smooth and homogenous.

Step 4: Deposit Into Molds

Transfer the gummy syrup to the storage tank. Use the depositing machine to fill the molds with precise amounts, ensuring uniformity.

Step 5: Cool, Solidify, and Set

Move the filled molds to the cooling tunnel. Let the gummies solidify and set. Time and temperature depend on the recipe and mold type.

Step 6: Demold the Gummies

Once cooled, use the demolder to remove the gummies automatically. Inspect them for quality and texture.

Step 7: Package for Distribution

Package the gummies for shipping. Use GummyGenix packaging solutions to ensure freshness and avoid contamination.

.

.

Automating these steps with high-efficiency machines allows you to meet large-scale demand while maintaining product quality. For reliable machinery, molds, and packaging solutions, choose GummyGenix. Ensure a smooth production process from start to finish.

Get an instant quote on GummyGenix commercial gummy machines and optimize your production line!

.

Where To Source High-Quality Gummy Production Equipment?

Scaling up gummy production requires reliable, efficient machines to keep operations running smoothly. GummyGenix is a trusted global supplier with years of experience in the confectionery machinery industry. We offer equipment for every stage of gummy production.

Whether you need machines for specific tasks or a complete production line, GummyGenix provides solutions tailored to your needs.

Benefits of GummyGenix Equipment:

- Seamless Integration: All machines work together smoothly, minimizing downtime and manual work.

- Customization: We tailor machinery to meet your production needs, whether for standard or specialized gummies like CBD.

- Reliability & Durability: Built with high-quality materials, our equipment is designed for long life and low maintenance.

- Global Support: Our worldwide technical support ensures your production line runs smoothly.

.

.

Case Study: How GummyGenix Helped a CBD Startup Boost Production Efficiency

A CBD gummy startup approached GummyGenix to scale up their production while maintaining product quality. By implementing GummyGenix's economical gummy machinery, the company was able to:

- Increase gummy output by 35% within the first month of using the automated depositor.

- Achieve a 20% reduction in production downtime, thanks to the efficiency and reliability of GummyGenix’s automated gummy manufacturing equipment.

- Enhance the consistency of their product, ensuring that every batch met strict quality standards, which helped boost customer satisfaction and loyalty.

.

This case study is a testament to the value of GummyGenix’s machinery in helping small- to medium-sized gummy manufacturers optimize their processes, reduce costs, and scale production.

Read the full case study here.

Ready to scale up your gummy production? Request a free consultation with GummyGenix today and discover how our machinery can boost your output!

.

Conclusion

Making gummies, whether at home or commercially, requires careful attention to ingredients and processes. Homemade gummies offer flexibility in flavors, shapes, and ingredients. Commercial production, however, needs specialized equipment and precise techniques for consistency and efficiency.

GummyGenix is your trusted partner for gummy production equipment. From cookers and depositors to molds and cooling tunnels, we ensure seamless integration for your production line.

Contact our sales team today to enhance your gummy-making capabilities and place your orders!

.

FAQs for Homemade and Small-Scale Gummy Makers

What can I use as a substitute for gelatin in homemade gummies?

For vegan or vegetarian options, use agar-agar or pectin.

- Agar-agar creates firmer gummies and sets at room temperature. Pour quickly into molds.

- Pectin works well with fruit-based recipes but needs a higher temperature to activate. It results in a softer, jelly-like texture.

.

Why are my homemade gummies too soft or too hard?

- Soft gummies: Not enough gelatin. Add more in your next batch.

- Hard gummies: Too much gelatin or overcooking. Reduce gelatin or add more liquid to soften.

.

How can I fix flavor issues in my homemade gummies?

- Overpowering flavor: Use less concentrated flavoring or diluted fruit juice.

- Weak flavor: Increase the flavoring or add citric acid for a sour kick.

- Natural flavors: Use fruit juices, extracts, or purees for a healthier taste.

.

Why are my gummies sticking together?

Moisture in the air or insufficient drying causes sticking.

Solution: Dust gummies with cornstarch or powdered sugar. Store in an airtight container or refrigerate to reduce humidity exposure.

.

Can I make sugar-free gummies at home?

Yes. Use sweeteners like stevia, erythritol, or monk fruit. Adjust the recipe for different sweetening strengths.

.

How should I store my homemade gummies?

Store gummies in an airtight container at room temperature. In humid environments, refrigerate them to maintain texture.

.

FAQs for Industrial Gummy Production

How can I start my own gummy candy business?

- Identify your target audience and study competitors.

- Create a business plan outlining goals, marketing, financials, and production capabilities.

- Develop unique recipes considering dietary preferences.

- Source high-quality equipment and ingredients (GummyGenix offers tailored solutions).

- Obtain necessary permits and follow food safety regulations.

- Build a strong brand and market it effectively.

- Establish sales channels online and offline.

.

What are gummies usually made of?

Gummies are made from gelatin, sweeteners (like glucose or corn syrup), flavorings (natural or artificial), colorings, and acids (citric or malic) for balance. Optional vitamins can also be added.

.

What are the common issues in the gummy candy manufacturing process and their solutions?

- Inconsistent texture: Caused by incorrect gelatin ratios or improper cooling. Use precise gelling agents, adjust cooking temperature, and monitor cooling.

- Flavor imbalance: Overpowering or weak flavors occur from incorrect measurements. Standardize flavoring amounts and ensure thorough blending.

- Gummies sticking together: Results from insufficient drying. Use quality molds, drying rooms, or dust with cornstarch to prevent sticking.

- Quality control: Consistency can be tricky. Use automated equipment like depositors and cooling tunnels for precision. GummyGenix machines integrate easily into your production process.

.

How do commercial gummy manufacturers achieve consistent quality and flavor?

- Exact ingredient ratios and temperature settings prevent variations in texture and flavor.

- Automated systems ensure even flavor distribution and standardized recipes.

- Real-time monitoring detects inconsistencies and allows immediate corrections.

.

Looking to optimize your gummy production?

Contact GummyGenix for customized equipment solutions!