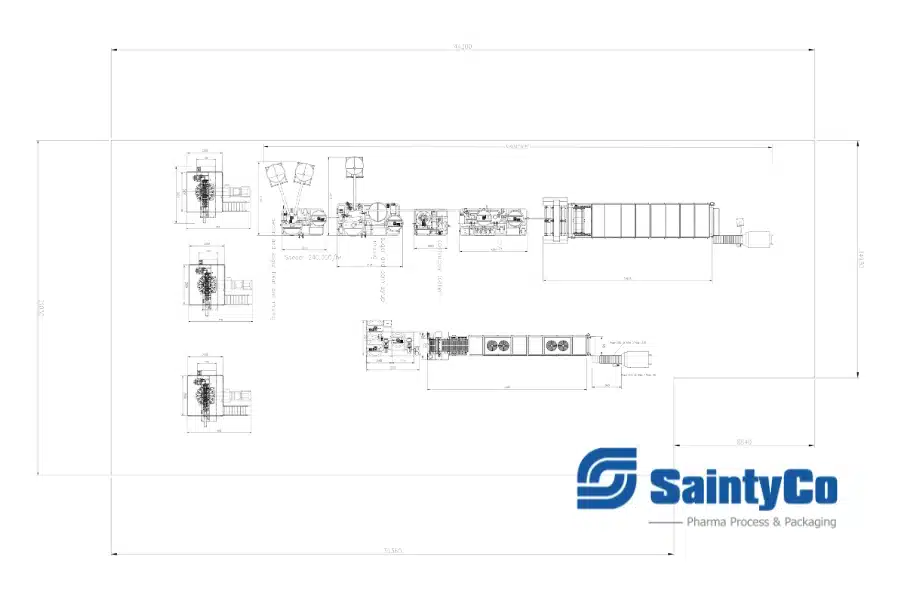

Gummy Production Line Layout: How to Optimize Machine Placement and Integration?

This blog explores how to optimize gummy production layouts and machine integration for enhanced efficiency. Key strategies include selecting compatible equipment, optimizing workflows, ensuring safety compliance, and maximizing space utilization.

Making Sugar-Free Gummies: Challenges and Solutions for Manufacturers at Different Scales

Sugar-free gummies are increasingly popular among health-conscious consumers, but their production involves unique challenges. Key issues include maintaining texture and flavor balance without sugar, as well as navigating regulatory compliance. Manufacturers must choose appropriate sweeteners like Maltitol or Stevia while utilizing specialized machinery to optimize production at different scales. Small-scale producers can benefit from compact depositors for experimentation, while medium to large-scale operations require advanced lines that ensure consistency and quality. Understanding the impact of sweeteners on taste and texture is crucial for creating appealing products that meet consumer expectations. This guide explores effective strategies for overcoming manufacturing obstacles and achieving success in the sugar-free gummy market.

What Are the Key Steps to Set Up an OTC Gummies and Supplements Factory in the UK?

Setting up a supplements and OTC gummies factory in the UK requires regulatory compliance, equipment selection, ingredient sourcing, quality control, and financial planning to ensure successful operations and product safety.

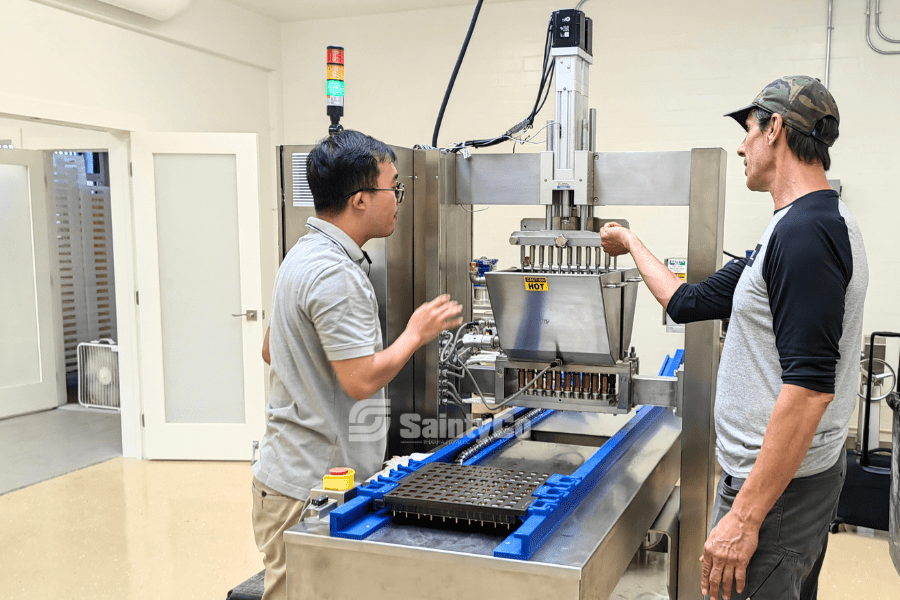

Semi-Automatic vs. Fully-Automatic Gummy Machines: What Are the Key Differences?

This blog post explores the key differences between semi-automatic and fully-automatic gummy machines, focusing on automation levels, operational efficiency, cost implications, production speed, and maintenance needs to guide your investment decision.