Are you wondering why gummies have that delightful tang? It's all thanks to the acids used in the gummy production. But what's the science behind this, and why are gummies acidic? Well, acids play a significant role during gummy manufacturing. Understanding how different acids influence the overall gummy texture, taste, and shelf life is the secret to crafting irresistible gummy treats. So, whether you’re a small, medium, or large-scale gummy-making business, this guide is for you. Let's dive in.

How important are acids to gummy making?

Acids are crucial additions to your gummy recipes to ensure the final product is a delicious and appealing gummy treat. Here are the two primary reasons why gummy manufacturers use acids during production:

- Flavor enhancement

Acids like citric, malic, and tartaric provide a tangy and tart dimension or sour taste in gummies. They elevate the gummy fruity notes and complement their sweetness. This enhances the overall gummy taste experience. Therefore, your choice of acid can significantly impact the gummy taste, making it essential to select the right acid based on the desired flavor profile.

- Gelling process

Acids are essential for activating gelling agents and setting the gummy texture, especially in pectin-based recipes. They interact with the pectin molecules, forming a network that gives the gummies their structure and characteristic chewiness. The pH level of the gummy mixture is crucial for this process. If the pH is too high, the pectin may not gel properly, resulting in gummies that are too soft or runny. Conversely, if the pH is too low, the gummies may become overly hard and brittle.

Gummy manufacturers can find dealing with acids challenging due to their influence on pH and setting time. The addition of acids can lower the pH of the gummy mixture, which can affect the gelling process and the overall texture.

We recommend the following tips to ensure optimal gelling and texture in acidic gummies:

- Use a pH meter to measure the pH of the gummy mixture and adjust it as needed.

- Carefully control the amount of acid added to the mixture to avoid excessive pH changes.

- Combine different acids to help balance the pH and achieve the desired flavor profile.

- Be familiar with the properties of the pectin being used. Various types of pectin may have varying pH requirements.

.

.

Common acids used in the gummy manufacturing process

The following are some common acids used in the gummy manufacturing process and their properties:

1. Citric Acid

- Source: Found naturally in citrus fruits like lemon, orange, and lime.

- Flavor: Sharp, tart, and citrusy flavor.

- Role: Adds a tart, sour, fruity flavor to gummies, helps activate the pectin gelling agent for a firmer and chewier texture, and lowers the pH level, which is necessary for gelling.

- pH: 3.0 to 3.5.

- Pairing flavors: Apples, berries, pears, and tropical flavors.

- Uses: Common in citrus-flavored or sour-coated confections like lemon gummy bears.

.

2. Malic Acid

- Source: Naturally found in apples, pears, and other berried fruits.

- Flavor: Malic acid in candy has a tart and sour taste but is less tart than citric acid.

- Role: Adds a milder tart flavor to gummies, creates a smoother and more balanced taste, and aids in the gelling process.

- pH: 3.2.

- Pairing flavors: Green apple, cherry, and apricot flavors

- Uses: Common in stronger or more sour acidul gummies.

.

3. Tartaric Acid

- Source: Obtained from bananas, grapes, and byproducts of wine fermentation.

- Flavor: Sour and tangy flavor.

- Role: Adds a bitter, biting effect and assists with the gelling process, particularly in combination with other acids.

- pH: 3.1.

- Pairing flavors: Grapes, berries, and wine-inspired flavors.

- Uses: Often used in grape-flavored gummies and those with a wine-like taste.

.

4. Ascorbic Acid (Vitamin C)

- Source: Can be found naturally in citrus fruits or manufactured synthetically.

- Flavor: Very tart and acidic flavor.

- Role: Offers strong tartness, enhances certain fruit flavors, and can act as an antioxidant to extend the gummy’s shelf life.

- pH: 3.5 to 4.0.

- Pairing flavors: Citrus and berry flavors.

- Uses: Common in vitamin C acid gummy bears to enhance flavors or provide health benefits.

.

5. Fumaric Acid

- Source: Found naturally in some fruits, lichens, and fungi, also produced synthetically.

- Flavor: Very strong sour taste.

- Role: Provides a long-lasting sour flavor and helps stabilize gelling agents at high temperatures.

- pH: 3.2.

- Pairing flavors: Sour and tangy flavors.

- Uses: Commonly used in sour gummy candies and those with a prolonged sour taste.

.

6. Phosphoric Acid

- Source: A mineral acid manufactured synthetically.

- Flavor: Tart and acidic flavor.

- Role: Aids in adjusting the overall acidity and enhances certain flavors, particularly in cola gummies.

- pH: 3.5 to 4.6.

- Pairing flavors: Cola, citrus, and berry flavors.

- Uses: Common in specific gummy flavors, such as cola and certain citrus-flavored gummies.

.

The following table provides a quick summary of the most common acids used in gummy manufacturing, highlighting their key characteristics and applications.

Comparison Table: Common Acids Used in Gummy Manufacturing

| Acid | Source | Flavor Profile | Role in Gummy Making | pH Level | Pairing Flavors | Typical Uses |

| Citric Acid | Naturally found in citrus fruits like lemons, oranges, and limes. | Sharp, tart, citrusy | Adds a tart, sour flavor; helps activate pectin for firmer texture; lowers pH for gelling. | 3.0 to 3.5 | Apples, berries, pears, tropical flavors | Common in citrus-flavored gummies, sour-coated confections. |

| Malic Acid | Found in apples, pears, and other berries. | Tart, slightly less sharp than citric | Provides a milder tart flavor; creates a balanced taste; aids in the gelling process. | 3.2 | Green apple, cherry, apricot flavors | Used in sour gummies with milder tartness. |

| Tartaric Acid | Obtained from grapes, bananas, and wine fermentation byproducts. | Sour, tangy, slightly bitter | Adds a biting effect; stabilizes the gelling process, especially when combined with other acids. | 3.1 | Grapes, berries, wine-inspired flavors | Often used in grape-flavored gummies or wine-inspired flavors. |

| Ascorbic Acid | Found naturally in citrus fruits or manufactured synthetically. | Very tart, acidic | Provides strong tartness; enhances certain fruit flavors; acts as an antioxidant for longer shelf life. | 3.5 to 4.0 | Citrus, berry flavors | Common in vitamin gummies and health-focused gummies. |

| Fumaric Acid | Found in some fruits, lichens, fungi; also produced synthetically. | Very strong sour taste | Provides a prolonged sour flavor; stabilizes gelling agents at high temperatures. | 3.2 | Sour, tangy flavors | Used in sour gummies with long-lasting sour taste. |

| Phosphoric Acid | A mineral acid manufactured synthetically. | Tart, mildly acidic | Adjusts overall acidity; enhances flavors, especially in cola gummies. | 3.5 to 4.6 | Cola, citrus, berry flavors | Common in cola and specific citrus-flavored gummies. |

How are acidic gummies produced?

The production of acid gummies is a precise and intricate operation that you can achieve in the following key steps.

.

.

Step 1: Compounding

The first step in manufacturing acidulated candy is weighing, mixing, and cooking.

1. Weighing: You should use calibrated scales to carefully weigh all the raw materials for your gummy recipe, such as sugar, gelatin, corn syrup, acidulants, flavoring, and colorants.

2. Mixing: After you have the correct weight for each raw material, use a high-speed mixer to thoroughly combine the ingredients to form a homogeneous syrup. The mixing time and speed can be adjusted based on the specific acid gummy recipe and desired texture.

3. Cooking: Heat the syrup to a temperature of approximately 140-150°F (60-65°C), which is crucial for activating the gelatin and ensuring proper gelling. The cooking period can vary depending on the gummy-making recipe and the desired consistency.

Step 2: Forming gummy

Once you have the gummy syrup, it is time to mold your final gummy products.

1. Depositing: This step requires you to deposit the gummy syrup into gummy layouts and molds to shape the gummy treats into the desired forms. With a gummy depositing machine from GummyGenix, you can produce solid, stripped, or layered gummy treats.

2. Cooling: Now, pass the gummies deposited in your gummy molds through a cooling tunnel with a controlled temperature of around 50-60°F (10-15°C). This allows the gummies to solidify and set in their respective shapes without becoming too hard.

3. Demolding: After cooling, remove the acid gummies from the molds. Use a demolding machine from GummyGenix to gently remove the gummies without damaging them.

.

Step 3: Quality control

The last step is to ensure your acidic gummies meet the desired size and shape specifications with no visual defects such as cracks, air bubbles, or uneven surfaces. You must also measure the acid concentration in the gummies using a pH meter to check the tartness level. Substandard gummies are removed, and the final products are packaged.

If you want to establish a fully or semi-automatic gummy production line for your business, the following equipment from GummyGenix is essential!

.

What equipment do I need to make acidic gummy?

The right gummy production machines will streamline your processes and ensure consistency in your final gummy treats. These are the must-have auxiliary equipment:

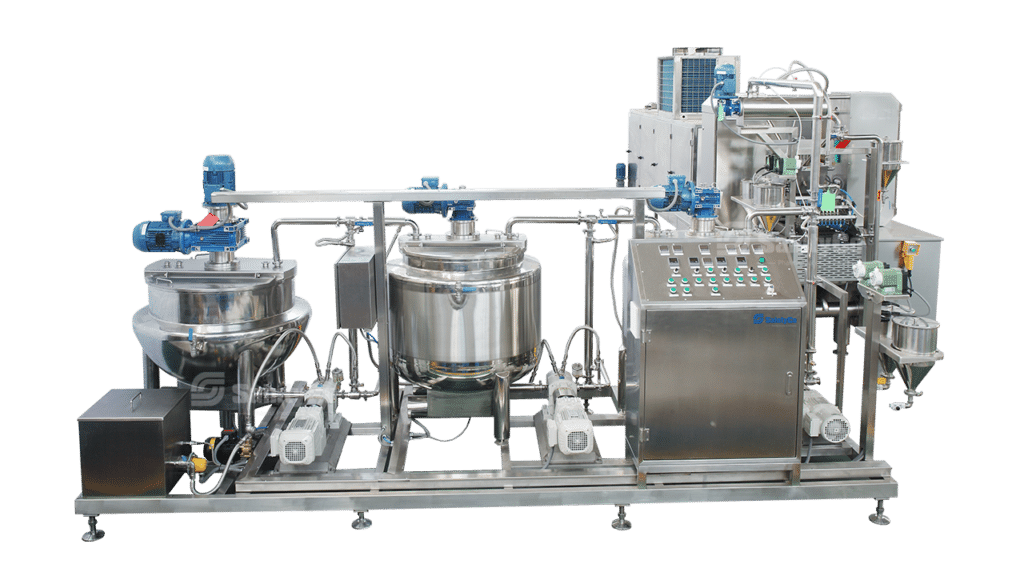

1. Cooking system

This fully automatic machine for dissolving and cooking syrup consists of a sugar dissolving tank and storage tank. It has a continuous vacuum cooker, PLC touch screen, and auto temperature control.

.

2. CFA dosing system

This helps accurately dispense ingredients, like acids, flavors, sugars, and colors, into the gummy mixture. It uses a continuous flow system with precision feeders and dosing mechanisms for consistent dosing, reduced waste, and improved product quality.

.

.

3. Mixing system

It is helpful for thoroughly combining all ingredients in the gummy mixture and includes the following:

- Inline mixer - This mixer uses rotating blades or impellers to mix the ingredients as they flow through it. It provides continuous mixing of ingredients directly in the production line but isn’t suitable for highly viscous or heterogeneous gummy mixtures.

- Static mixer - It uses a series of static elements to create turbulence and ensure thorough mixing. It is effective for mixing viscous materials. It is low maintenance and energy efficient, but it may require higher flow rates for effective mixing.

- Inline batch weighing systems - This accurately weighs ingredients directly into the production line, eliminating manual weighing and transfer. It improves efficiency and reduces waste, but it has a more complicated installation and maintenance.

.

You can get these gummy mixing systems from GummyGenix by SaintyCo. Our lines have advanced CFA units, which we can customize to your specifics. That’s why our production lines aren’t limited to confectionary gummies. They can make cannabis and nutraceutical gummies, too. Among the three mixing systems, the inline batch weighing system is the most efficient and accurate mixing method, which we have even realized in our G40 and G80 small-scale automated lines.

4. Depositing system

This is used to deposit the gummy mixture into molds, shaping the gummies into their desired forms. GummyGenix by SaintyCo offers a completely hygienic and low-cost oil spraying and servo depositing system.

.

.

5. Cooling system (cooling tunnel and conveyor)

This system cools the gummies after they are deposited into molds, allowing them to set and solidify. GummyGenix offers a cooling tunnel with a 10+HP chiller to guarantee the quality of your acidic gummy texture.

.

6. Demolding system

GummyGenix's dual brush removal system can help remove the gummies from the molds after cooling without damaging the gummy treats.

.

.

Whatever your gummy business, small, medium, or large, you can get a powerful whole-line production system from GummyGenix to satisfy your gummy manufacturing needs.

.

FAQs

1. Are there natural agents that I can use instead of acids for adding acidity during gummy manufacturing process?

Yes, there are natural agents that can be used to add acidity to gummies without relying on synthetic acids. These natural alternatives often come from fruits and vegetables and include ingredients like lemon juice, lime juice, orange juice, grapefruit juice, apple cider vinegar, and pomegranate juice. These natural agents not only provide acidity but also add natural flavors and antioxidants to your gummies. However, it's important to note that the acidity levels of these natural agents may vary, so careful testing and adjustment of your recipe may aid in achieving the desired gummy taste and texture.

.

2. What are the benefits of using natural versus synthetic acids in gummy production?

Natural acids, such as those derived from fruits (like citric acid from lemons or malic acid from apples), are often preferred for their clean-label appeal, offering a more natural taste and marketing advantage. However, synthetic acids can provide greater consistency in flavor, pH control, and cost-effectiveness. Choosing between natural and synthetic acids depends on your target market, product positioning, and regulatory requirements.

.

3. What factors should I consider when using different acids in gummy recipes?

When choosing different acids for your gummy recipes, consider the desired flavor profile, the gelling properties of the acid, and any potential interactions with other ingredients. Citric acid, for example, is a popular choice for its tangy flavor and ability to activate pectin, while malic acid offers a milder tartness and is often used in combination with other acids. Tartaric acid provides a strong sour taste and can help stabilize the gelling process. Additionally, consider the pH level of the acid, as it can affect the overall gummy taste and texture. Ultimately, the best acid choice will depend on your specific recipe goals and preferences.

.

4. Can I mix different acid types in my acidic gummies recipes?

Yes, you can mix different acid types in your acidic gummy recipes. This can help you achieve a more complex and nuanced flavor profile. For example, combining citric acid for its tartness with malic acid for its sweetness can create a balanced and enjoyable taste. However, it's important to experiment and find the right combination that suits your desired flavor profile and the overall balance of your gummy recipe.

.

5. What is sodium citrate doing in vitamin gummies?

Sodium citrate is a tart flavoring agent and an antioxidant in vitamin gummies. It is a strong but safe acid that candy manufacturers use to control the acidity of gelatin gummy products.

.

6. What is the difference between citric and malic acid?

In a malic acid vs citric acid candy comparison, they offer distinct flavor profiles and properties. Citric acid provides a sharp, tart, citrusy taste and creates a tangy flavor profile. On the other hand, malic acid has a slightly sweeter, fruity taste and is used to balance the tartness of citric acid for a more complex flavor profile. While both acids help achieve a sour taste, the choice between citric acid for candy making and malic acid depends on the desired flavor profile and overall balance of the gummy recipe.

.

7. How do acids affect gummy shelf life?

Acids like ascorbic acid (Vitamin C) can extend the shelf life of gummies by acting as preservatives, preventing oxidation, and maintaining freshness. However, the type and concentration of acid must be carefully controlled to avoid compromising the gummy texture and taste over time. The pH level also plays a crucial role in preventing microbial growth, which can further enhance shelf life.

.

8. Can the pH of gummies affect their color and flavor stability?

Yes, the pH of the gummy mixture can significantly affect both color and flavor stability. A lower pH (more acidic environment) can cause colorants and flavors to degrade or change over time, especially if natural colorants or delicate flavors are used. Maintaining an optimal pH balance helps preserve the intended color and flavor profile throughout the product's shelf life.

.

9. What are the most effective methods for incorporating acids into gummy recipes?

To ensure optimal texture and flavor, it is crucial to add acids at the right stage of gummy production. Acids should generally be added after cooking to prevent premature gelling and ensure even distribution throughout the mixture. Start with a small amount, and gradually adjust while monitoring the pH with a meter. Additionally, use a pre-dissolved acid solution to achieve a uniform taste and avoid localized over-acidification. Combining different acids can help balance the overall flavor profile and prevent unexpected texture changes.

.

Order the best gummy making machines from GummyGenix by SaintyCo

GummyGenix is a leading provider of innovative gummy manufacturing solutions designed to elevate your production process. With a focus on quality, efficiency, and customer satisfaction, we offer a broad range of equipment, from cookers, mixers, gummy depositing machines to cooling tunnels, demolding systems, and more. But why choose GummyGenix by SaintyCo as your equipment supplier?

.

.

Advanced product line: Our state-of-the-art machinery is engineered to deliver precision, reliability, and high production capacity. From gummy depositing machines to cooling tunnels and demolding systems, our equipment is designed to meet the demands of modern gummy manufacturing.

Reliable machinery: Our machines are built to last, using high-quality components and advanced manufacturing techniques. We prioritize durability and performance to ensure minimal downtime and maximum productivity.

Cost savings: By investing in GummyGenix equipment, you can reduce operational costs through increased efficiency, reduced waste, and optimized production processes. Our machines are designed to operate with minimal energy consumption and maximize output.

Time efficiencies: Our equipment is designed to streamline your production process, saving you valuable time and resources. From faster production cycles to reduced setup times, GummyGenix solutions can help you increase your output and meet market demands.

After-sales support: At GummyGenix by SaintyCo, we are committed to providing exceptional customer service and support. Our team of experts is available to assist you with equipment installation, maintenance, troubleshooting, and training. We aim to ensure that you have the know-how and resources needed to maximize the potential of your GummyGenix machinery.

Moreover, our engineers can work with you to develop customized gummy-making solutions that address your unique challenges and requirements.

.

Key Takeaways

As we have explored, understanding the role of acids in gummy production and selecting the right equipment is essential for creating high-quality gummy treats. To help you quickly recap, here are the key points from this guide:

1. Acids are Essential in Gummy Production

Acids like citric, malic, and tartaric acid play a crucial role in enhancing flavor, activating gelling agents, and influencing the texture of gummies.

.

2. Different Acids Offer Unique Benefits

Each acid used in gummy manufacturing contributes differently to taste and texture, such as citric acid for a sharp tang, malic acid for milder tartness, and ascorbic acid for added shelf life.

.

3. Proper pH Control is Critical

Managing the pH of the gummy mixture is vital for achieving the desired consistency and preventing gummies from becoming too hard or too soft. Techniques like using a pH meter and combining acids help maintain optimal pH.

.

4. Production Process Requires Precision

Gummy manufacturing involves specific steps—from compounding and forming to cooling and quality control—to ensure consistent quality and safety.

.

5. Advanced Equipment Enhances Efficiency

Using specialized equipment like GummyGenix's cooking systems, depositing machines, and cooling tunnels can optimize gummy production, improve product quality, and reduce costs.

.

6. Expert Guidance and Tailored Solutions Matter

Whether choosing between natural or synthetic acids or managing production variables, having access to customized solutions and expert support can significantly impact your gummy manufacturing success.

.

Transform Your Production Line Today! Contact Us Today

To learn more about GummyGenix by SaintyCo and our range of gummy manufacturing solutions or to place a customized order, please reach out to our sales team at:

Email: [email protected]