Packaging Gummies: Can Standard Machines Handle It or Require Upgrading?

Packaging gummies using standard confectionery machines is possible but requires modifications to address their unique challenges like stickiness and moisture sensitivity. While these machines can be adapted, investing in specialized gummy packaging equipment is often more efficient. Specialized machines feature non-stick materials, precise environmental controls, and advanced detection systems that enhance product quality and consistency. They also comply with hygiene standards essential for food safety. This blog explores the considerations for using standard machinery versus specialized solutions in gummy production, emphasizing the importance of accuracy in packaging to maintain customer satisfaction and brand reputation.

How Can Gummy Packaging Differentiate Your Brand?

In the competitive gummy market, packaging plays a crucial role in brand differentiation. It enhances visual appeal, ensures product safety, and aligns with consumer demands for sustainability and transparency. Modern trends emphasize personalization through flexible formats like resealable bags and custom shapes. Transparent packaging builds trust by showcasing product quality while safety features such as tamper-proof designs enhance consumer confidence. Additionally, eco-friendly materials resonate with environmentally conscious consumers. By integrating these innovative packaging strategies, brands can effectively meet diverse consumer expectations and strengthen their market presence.

How To Keep Gummy Vitamins From Sticking Together (5 More Tips to Know)

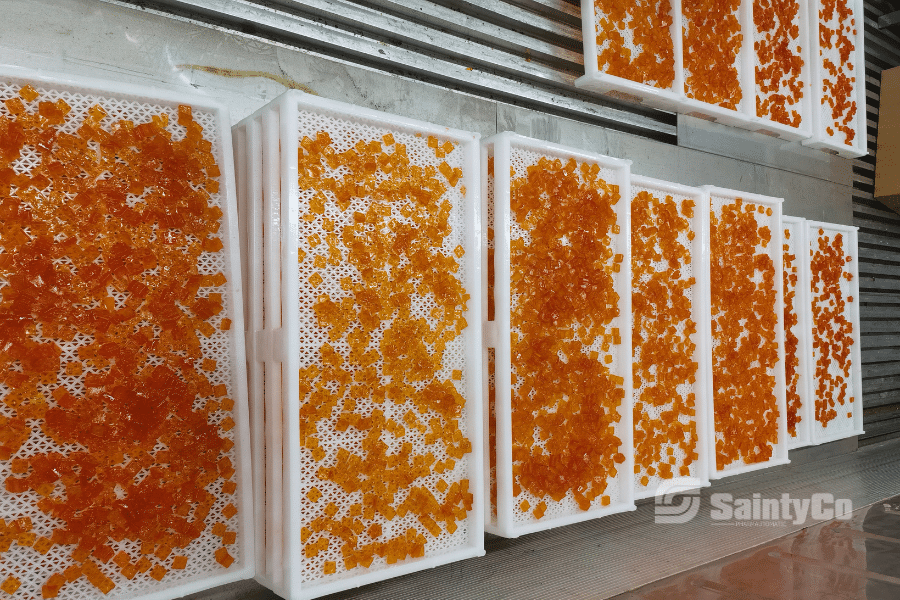

In the growing gummy market, especially for CBD, THC, hemp, and essential vitamin-infused gummies, it’s important to maintain quality during production. One problem many manufacturers face is gummies sticking together. This affects how they look, but it also affects how people feel about them and how they use them. In this article, I’ll show you […]