Flood & Scrape vs. Gummy-Making Machines: Which Is Best for Your Production?

Gummy-making machines offer significant advantages over the traditional Flood & Scrape method in gummy production. These machines provide enhanced efficiency, consistency, and scalability, making them ideal for expanding businesses. By minimizing waste through precision dosing and automated cleaning systems, they ensure higher quality and more reliable output. Automation also allows for better control of ingredient handling and environmental factors, reducing human error and improving product uniformity. As demand for gummies grows, investing in modern machinery not only supports sustainability but also aligns with regulatory compliance needs in industries like nutraceuticals and CBD. Ultimately, while initial costs may be higher, the long-term benefits of reduced labor expenses and increased production capacity make gummy machines a cost-effective choice for manufacturers aiming to scale their operations effectively.

Pharma Grade vs. Confectionery Gummy Machines: What’s the Difference?

This article compares pharma-grade and confectionery-grade gummy production machines, highlighting differences in regulatory compliance, material integrity, cleaning protocols, precision, and cost to guide informed purchasing decisions.

Should You Invest in Gummy Manufacturing Equipment Now?

The gummy market is booming, especially in health and wellness sectors. With such growth, it’s essential to consider if now is the right time to invest in gummy manufacturing equipment. This article dives deep into market trends, automation benefits, compliance considerations, and technological advancements that can impact your decision to invest.

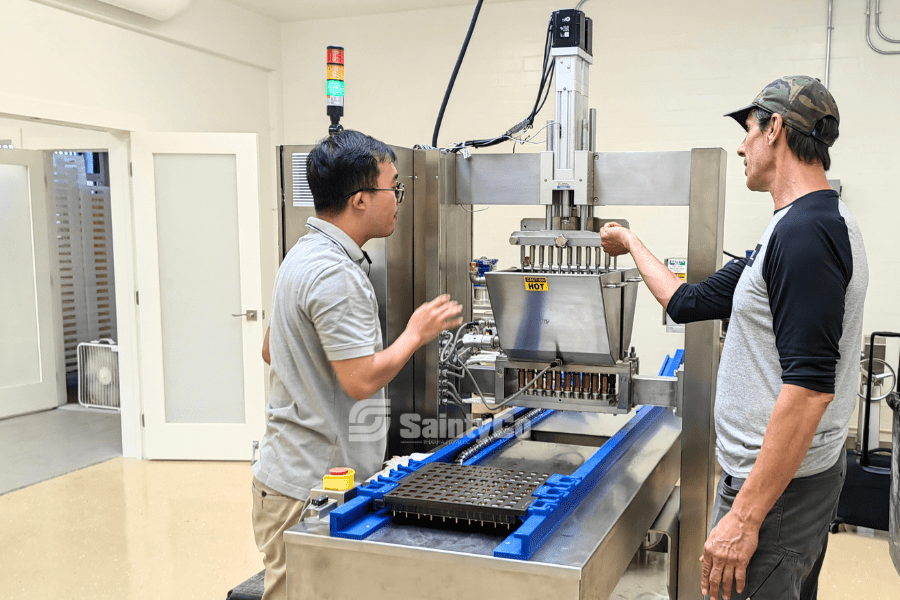

Semi-Automatic vs. Fully-Automatic Gummy Machines: What Are the Key Differences?

This blog post explores the key differences between semi-automatic and fully-automatic gummy machines, focusing on automation levels, operational efficiency, cost implications, production speed, and maintenance needs to guide your investment decision.

How to Choose Small Gummy-Making Machines for Your Restaurant?

This ultimate guide helps restaurants choose the right small gummy-making machines by considering production volume, space, customization options, ease of use, budget, and after-sales support for optimal operations.

How Are Jelly Candies Produced?

Discover the fascinating process behind jelly candy production. From ingredient selection to specialized machinery, learn how sugar, gelatin, and flavorings combine to create these beloved treats. This article explores key ingredients like gelling agents, the role of equipment in manufacturing, and the importance of packaging and quality control in maintaining freshness and consumer satisfaction. Whether targeting traditional or vegan markets, understanding these processes can enhance product offerings while meeting diverse consumer preferences.

What Production Equipment is Essential for Making Energy Gummies for Running?

To successfully produce energy gummies for runners, manufacturers need essential equipment such as precision dosing systems for accurate ingredient incorporation, multi-hopper integration for complex formulations, and high-shear mixing to maintain consistent potency. These technologies enhance production efficiency while ensuring that each gummy is packed with performance-enhancing ingredients. Precision dosing minimizes waste and ensures compliance with regulatory standards by maintaining accurate ingredient levels. Multi-hopper systems allow simultaneous addition of various active ingredients, supporting complex formulations tailored to athletes’ needs. High-shear mixing guarantees uniform texture and flavor distribution across batches. Understanding these key components can help manufacturers create high-quality energy gummies that meet the demands of health-conscious consumers.

Starting a Gummy Manufacturing Business in Peru: What Are the Key Regulatory Compliance and Machine Selection Considerations?

Establishing a gummy manufacturing business in Peru involves navigating regulatory compliance set by DIGESA, ensuring machinery meets food-grade standards, and selecting equipment based on production scale. Key considerations include local health regulations, international certifications like FDA and ISO 9001:2015, and environmental guidelines. Understanding the specific needs for small to large-scale production helps optimize efficiency. For artisanal setups, semi-automatic machines are ideal; medium operations benefit from fully automated lines; while large facilities require high-capacity machines. Additionally, facility layout plays a crucial role in enhancing workflow and minimizing bottlenecks. By addressing these factors, manufacturers can ensure quality production while preparing for future growth.

How Are Creatine Gummies Made and Which Machines Ensure the Best Production?

Creatine gummies are transforming the supplement market by offering a convenient, tasty alternative to traditional powders. Made through a meticulous process involving specialized machines like gummy depositors and cooling tunnels, these gummies ensure precise dosing and maintain ingredient efficacy. Their appeal lies in their chewable format, pleasant flavors, and ease of use for athletes and everyday consumers alike. As consumer preferences shift towards more accessible supplement forms, creatine gummies stand out for their ability to deliver essential nutrients without the hassle of mixing or measuring. The production process faces challenges such as managing creatine’s hygroscopic nature and ensuring even distribution of ingredients; however, innovative machinery addresses these issues effectively. Customization options in flavor profiles and dosages further enhance their marketability, making them a popular choice among health-conscious individuals.

Fortified Gummies: Why They Outperform Traditional Vitamins & How Are They Made?

Fortified gummies are increasingly popular due to their taste, convenience, and nutritional benefits. They are easier to consume than traditional pills, making them ideal for children and seniors alike. With flavors that appeal across age groups, these chewable vitamins often contain essential nutrients but may have added sugars. Their manufacturing process ensures quality and efficacy, with advanced techniques for ingredient mixing and hygiene standards. While they offer comparable absorption rates to pills, consumers should be mindful of sugar content and nutrient levels when selecting gummies. Overall, fortified gummies combine practicality with pleasure for a delightful health supplement experience.