Popping boba has become a staple in many beverages, offering a burst of flavor with every bite. But how do manufacturers ensure these delightful pearls are safe to consume?

Popping boba is sterilized through water bath pasteurization and water immersion retort methods. These processes eliminate harmful bacteria while preserving the product's quality, ensuring it remains safe and delicious for consumers.

While these methods sound simple, the intricacies involved in maintaining temperature control and ensuring uniform heat distribution are crucial for optimal results. Let's dive deeper into the techniques and equipment that make this possible.

Water immersion retort ensures uniform heat distribution.True

This method evenly distributes heat, sterilizing the boba effectively.

How Does Water Bath Pasteurization Ensure the Safety and Quality of Popping Boba Pearls?

Water bath pasteurization is a method used to kill harmful microorganisms in food products by immersing them in heated water. It ensures safety while preserving flavor and texture, making it ideal for delicate items like popping boba.

Water bath pasteurization involves submerging sealed popping boba packages in hot water at a controlled temperature, usually around 90°C, for a set duration. This gentle heating process effectively eliminates pathogens without damaging the bursting bubbles' quality.

|

|

|

|---|

Water bath pasteurization is versatile enough to be effective for popping boba pearls, regardless of the type of packaging—whether it be sealed bottles, bags, or metal cans.

Understanding the Water Bath Pasteurization Process

The technique of water bath pasteurization is highly valued for its ability to preserve delicate foods1. This process starts by sealing the food, such as popping boba, in airtight packages to prevent contamination.

Steps of Water Bath Pasteurization:

-

Preparation: Packages are submerged in a water bath preheated to a specific temperature, typically around 90°C.

-

Temperature Maintenance: Using a precision-controlled system, the water's temperature is kept constant. This ensures uniform heat distribution across all packages.

-

Timing: The immersion lasts from 40 to 60 minutes, carefully balancing pathogen elimination with preservation of the food's sensory qualities.

| Equipment Feature | Description |

|---|---|

| Thermostatic Heater | Maintains consistent temperature across all packages. |

| Circulation System | Ensures even heat distribution, preventing cold spots. |

| Temperature Sensors | Monitors and adjusts the water bath's conditions. |

Benefits and Applications

This method's popularity in industries like beverage and dessert production stems from its effectiveness in retaining product integrity and extending shelf life2. Water bath pasteurization is especially beneficial for items requiring precise temperature control, such as popping boba or certain beverages.

- Microbial Safety: The controlled environment effectively neutralizes pathogens, ensuring food safety without compromising quality.

- Preservation of Texture and Flavor: By avoiding direct heat contact and excessive temperatures, the food retains its original texture and flavor.

Comparing Water Bath with Other Techniques

While similar in concept, water immersion retort involves higher temperatures and pressure, suited for different types of products. Comparing both methods helps determine the most suitable process for specific applications:

| Method | Temperature | Pressure | Suitable for |

|---|---|---|---|

| Water Bath | ~90°C | Atmospheric | Delicate foods like boba |

| Water Immersion Retort | ~120°C | Pressurized | Sterilization of robust packages |

More about pasteurization techniques3. Understanding these processes aids manufacturers in selecting the best method to ensure product safety and quality.

Implementing water bath pasteurization in popping boba production lines not only enhances product quality but also meets safety standards crucial for market competitiveness.

Water bath pasteurization uses temperatures around 90°C.True

The process involves immersing food in water at approximately 90°C.

Water bath pasteurization lasts less than 30 minutes.False

The immersion typically lasts between 40 to 60 minutes.

How Does Water Immersion Retort Extend the Shelf Life of Popping Boba?

Water immersion retort is a cutting-edge sterilization process that significantly extends the shelf life of packaged foods. By using high temperatures under pressure, it effectively destroys harmful microorganisms, ensuring product safety and longevity.

Water immersion retort extends shelf life by using high-pressure, high-temperature water to evenly sterilize packaged bursting popping boba pearls. This method ensures comprehensive microbial destruction while preserving product quality and nutritional value.

The Science Behind Water Immersion Retort

Water immersion retort utilizes a pressurized environment to heat water to high temperatures, typically around 120°C. This high-temperature water envelops the packaged food, providing uniform heat distribution which is crucial for effective sterilization.

| Parameter | Details |

|---|---|

| Temperature | Up to 120°C |

| Pressure | Maintained high to prevent boiling |

| Time | 40-60 minutes |

This process ensures comprehensive microbial destruction without compromising the food's structural integrity or flavor. The uniform heat application avoids cold spots, a common issue in non-uniform heating methods.

Comparing with Other Methods

Unlike pasteurization4, which uses lower temperatures and longer times, water immersion retort achieves sterilization through a combination of high temperature and pressure. This ensures quicker processing and a more effective kill rate of microorganisms.

Equipment Features

- Preheating Tank: Rapidly heats the water, reducing cycle time.

- Control System: PLC-based intelligent controls for precise regulation.

- Safety Mechanisms: Automated shutoffs and alarms ensure secure operation.

The advanced control system allows for precise adjustments of temperature and pressure, ensuring each batch meets stringent safety standards.

Benefits for Food Production

The method is ideal for large-scale food production due to its ability to handle high volumes efficiently. It also aligns well with industry requirements for food safety, extending the shelf life of products like canned vegetables and soups by ensuring they remain safe for consumption5.

The application of water immersion retort in industries ensures not only microbial safety but also maintains the food's nutritional and sensory attributes, providing consumers with products that are both safe and flavorful.

Water immersion retort uses temperatures around 120°C.True

Water immersion retort heats water to approximately 120°C for sterilization.

Pasteurization is faster than water immersion retort.False

Pasteurization uses lower temperatures and longer times compared to retort.

Why is Temperature Control Critical in Popping Boba Sterilization?

Temperature control in popping boba sterilization ensures microbial safety without compromising quality. Maintaining precise heat levels is crucial for eliminating pathogens and preserving the boba's texture.

Temperature control in popping boba sterilization is crucial to eliminate harmful microorganisms while preserving the product's quality. Precise heat levels ensure microbial safety without damaging the boba's texture.

The Role of Temperature in Sterilization

Temperature plays a pivotal role in the sterilization of popping boba. By maintaining specific heat levels, manufacturers ensure that harmful microorganisms are eliminated without compromising the delicate texture of the boba.

Methods of Sterilization for Poppoing Boba Production

- Pasteurization: Involves heating at low temperatures (around 90°C) for an extended period. This method deactivates bacteria while preserving the boba's taste and texture.

- Water Immersion Retort: Utilizes high temperatures (around 120°C) under pressure to ensure comprehensive sterilization.

| Method | Temperature | Duration |

|---|---|---|

| Pasteurization | 90°C | 40 to 60 minutes |

| Water Immersion Retort | 120°C | 40 to 60 minutes |

Importance of Consistency

Consistent temperature control is vital. In a precision-controlled water bath6, any fluctuation can lead to uneven sterilization, risking contamination or quality degradation.

- Precision-Controlled Water Bath: Ensures even heat distribution.

- Temperature Sensors: Provide real-time monitoring to maintain desired conditions.

Impact on Product Quality of Popping Bursting Boba

Proper temperature management helps in retaining the popping boba's sensory attributes. High temperatures can lead to overcooking, altering the texture and flavor, thus affecting consumer satisfaction.

Manufacturers often employ calibration techniques7 to maintain equipment accuracy, crucial for preserving the boba's quality.

| Benefits | Description |

|---|---|

| Pathogen Neutralization | Eliminates harmful bacteria effectively. |

| Texture Preservation | Maintains structural integrity of the boba. |

| Nutrient Retention | Keeps essential nutrients and flavors intact. |

Maintaining optimal temperature levels is essential for balancing microbial safety with product integrity, ensuring a consistent quality that meets consumer expectations.

Pasteurization uses 90°C for sterilizing popping boba.True

Pasteurization involves heating boba at 90°C to deactivate bacteria.

High temperatures can improve the texture of popping boba.False

High temperatures risk overcooking, altering the boba's texture negatively.

What Are the Key Benefits of Proper Sterilization in Boba Production?

Ensuring safety and quality in boba production hinges on effective sterilization. This critical step eliminates harmful microbes, extends shelf life, and preserves flavor and texture, crucial for consumer satisfaction.

Proper sterilization in boba production ensures microbial safety, prolongs shelf life, and maintains product quality. It involves techniques like pasteurization and water immersion retort to eliminate pathogens while preserving boba's taste and texture.

Microbial Safety

Proper sterilization is essential for eliminating pathogens that could compromise product safety8. Techniques such as pasteurization and water immersion retort are employed to neutralize harmful microorganisms without damaging the boba's delicate texture.

| Method | Temperature | Duration |

|---|---|---|

| Pasteurization | 90°C | 40-60 minutes |

| Water Immersion Retort | 120°C | 40-60 minutes |

By utilizing controlled heat and pressure, these methods ensure that all parts of the boba packaging are uniformly treated, thus preventing any risk of contamination.

Shelf Life Extension

Sterilization extends the shelf life of boba products by inhibiting microbial growth. This is particularly crucial for suppliers aiming to reach distant markets9 without compromising on quality. The extended shelf life allows businesses to manage inventory more effectively, reducing waste and maximizing profit margins.

Quality Maintenance

The preservation of flavor and texture is vital for consumer satisfaction. Sterilization processes like pasteurization maintain these qualities by using lower temperatures that protect the boba's structure. This ensures that consumers receive a consistent product experience, essential for brand reputation in competitive markets.

| Benefit | Impact |

|---|---|

| Microbial Safety | Reduces health risks |

| Shelf Life Extension | Improves inventory management |

| Quality Maintenance | Ensures customer satisfaction |

Understanding the importance of proper sterilization can significantly impact production efficiency and product quality in the boba industry. For those involved in boba manufacturing10, staying informed about the latest sterilization techniques is essential for maintaining a competitive edge.

Sterilization extends boba shelf life by inhibiting microbes.True

Sterilization prevents microbial growth, prolonging product shelf life.

Pasteurization damages the texture of boba during sterilization.False

Pasteurization uses controlled heat to preserve boba's texture.

Conclusion

Popping boba is sterilized using water bath pasteurization and water immersion retort methods, ensuring safety by eliminating harmful bacteria while preserving flavor and texture.

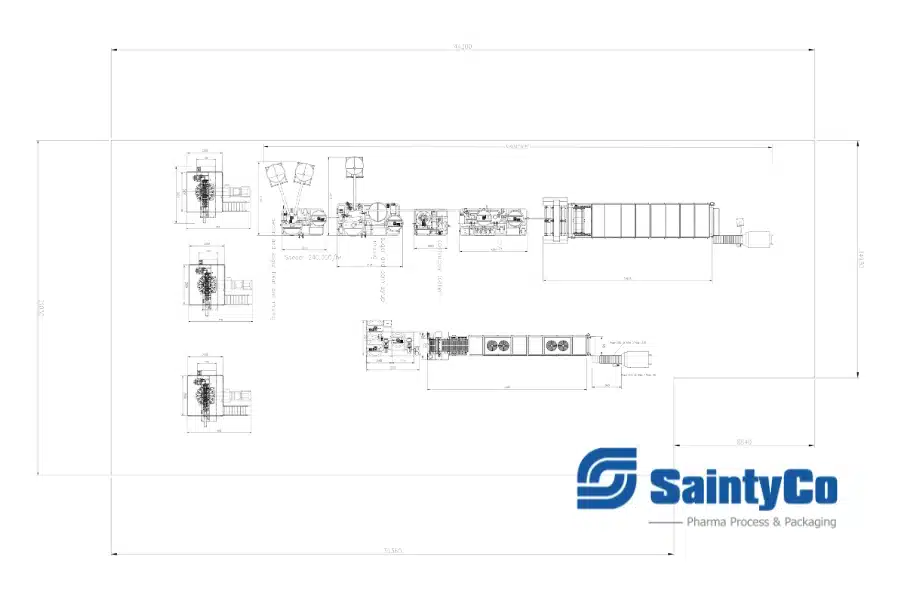

At GummyGenix by SaintyCo, we don’t just provide pharmaceutical and confectionary equipment—we empower your popping boba manufacturing business with solutions tailored to your success.

Why Choose SaintyCo for Your Popping Boba Business?

- Competitive Pricing: Get high-performance popping boba machines without breaking the bank. Our cost-effective solutions maximize your ROI.

- High-Quality Machinery: Food-grade, hygienic equipment engineered for precision, ensuring your production aligns with global standards.

- Flexible Financing Options: Partner with us to access flexible payment plans and financing support, reducing upfront costs while unlocking potential tax benefits.

- Quick Startup SOPs & Recipes: Begin production faster with starter recipes and workflows included. For advanced development, we connect you with top-tier consultants and suppliers worldwide.

- Comprehensive After-Sales Support: Enjoy peace of mind with our full-service assistance—from installation and training to troubleshooting and maintenance.

Popping Boba Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Explore how different foods can be safely preserved using this gentle pasteurization method. ↩

-

Learn about the scientific principles behind shelf life extension through controlled pasteurization. ↩

-

Compare various pasteurization methods to understand their unique benefits and applications. ↩

-

Learn about pasteurization, a method using lower temperatures for microbial reduction, to understand its benefits and limitations compared to water immersion retort. ↩

-

Explore the detailed mechanisms behind water immersion retort and its role in enhancing food safety by eliminating harmful microorganisms. ↩

-

Explore how precision-controlled water baths ensure even heat distribution during sterilization, essential for product safety. ↩

-

Discover how calibration ensures equipment accuracy, vital for maintaining consistent product quality during sterilization. ↩

-

Understanding pasteurization's role in ensuring food safety helps appreciate its importance in boba production. ↩

-

Exploring how extended shelf life benefits food producers highlights its importance for market reach. ↩

-

Staying updated on the latest sterilization techniques helps manufacturers maintain a competitive edge. ↩