Are you struggling with stickiness or a less-than-perfect finish for your gummies? Mastering the art of sugar-coating gummies is the secret. It elevates these chewy treats with a delightful texture and burst of sweetness. So, are you ready to learn how to sugar coat gummies? Dive in and learn everything from basic tips to advanced equipment for a perfect sugar-coated finish.

Why Sugar Coating Gummies Is Crucial for Flavor, Texture, Appearance, and Preservation

Sugar coating is the process of dusting the outer surface of gummies with sugar or a sugar-based mixture. This step plays a vital role in enhancing the texture, flavor, and appearance of gummies, while also helping to preserve their freshness. From adding the perfect balance of sweetness and reducing stickiness to extending shelf life, sugar coating is essential for gummy manufacturers striving to create high-quality, consumer-friendly products. Here’s how it helps:

1. Improve Gummy Flavor and Texture

- The sugar coating provides an additional layer of sweetness, enhancing the gummy's overall flavor profile.

- It also adds a slight crunch, offering a delightful contrast to the soft, chewy center.

2. Reduce Gummy Stickiness

- Without a sugar coating, gummies can become sticky, especially in humid conditions.

- The coating acts as a barrier, reducing tackiness and making the gummies easier to handle, package, and consume

3. Control Moisture in Gummies

- Sugar coating helps absorb excess moisture, maintaining the gummy’s firmness.

- Crucial for ensuring the gummies retain their shape and chewiness over time.

4. Enhance Gummy’s Visual Appeal and Consumer Experience

A sugar coating doesn’t just improve the gummy’s appearance — it enhances the entire sensory experience, directly impacting consumer satisfaction and purchasing decisions. By focusing on appearance, texture, and taste, you can set your gummies apart in a competitive market.

- Taste: A thin layer of sugar adds a touch of extra sweetness, elevating the gummy’s natural flavor profile. For sour gummies, the combination of sugar and citric acid creates the perfect tangy-sweet balance that many consumers crave.

- Texture: The sugar coating provides a subtle crunch that contrasts beautifully with the soft, chewy gummy inside. This dual texture creates a more dynamic and enjoyable eating experience, keeping consumers coming back for more.

- Appearance: Sugar crystals give the gummies a shiny, professional finish, significantly increasing shelf appeal. Products that look more enticing are more likely to attract customers.

.

.

Emerging Trends: Visual Appeal and Consumer Preferences

In today’s market, visual appeal isn’t just about being attractive—it also plays a key role in how consumers perceive quality and health benefits. With the rise of health-conscious, organic, and specialty gummies, brands are leveraging sugar coatings to differentiate their products:

- Organic and Natural Gummies: Brands in the organic or clean-label gummy market often use natural sugars, like cane sugar, to emphasize their product’s healthiness while still maintaining texture and appearance. Visually appealing coatings using minimally processed ingredients can help reinforce the perception of natural, high-quality products.

- Sugar-Free or Reduced-Sugar Options: As more consumers shift toward low-sugar or sugar-free diets, some brands have found success by incorporating alternative sweeteners into their coatings. This allows them to deliver on taste and appearance without excess sugar, attracting health-conscious buyers.

5. Extend Gummy Shelf Life

- The sugar coating helps preserve freshness by regulating moisture.

- It protects the gummies, ensuring they stay delicious and safe to eat for longer periods.

.

Managing Environmental Factors in Sugar Coating

The success of sugar coating is highly dependent on controlling environmental factors such as temperature and humidity. These factors directly affect the texture, stability, and adhesion of the sugar coating, and managing them properly is critical to avoid common issues like stickiness or clumping.

Note: While the recommended temperature and humidity ranges provided below work well for most gummy types, individual results may vary depending on the specific gummy formulation—especially with products like sour gummies, which are more sensitive to moisture due to their acidic ingredients.

.

1. Temperature Management

Why it matters:

Excessively warm conditions can cause the sugar coating to melt or dissolve too quickly, resulting in a sticky surface and uneven coverage.

Precise Guidelines:

For best results in large-scale production, maintain a controlled environment with temperatures below 70°F (21°C) to prevent premature sugar dissolution and ensure consistent coating across batches.

Solution for Industrial Production:

- Climate-Controlled Rooms: Utilize climate-controlled rooms or industrial cooling systems to maintain ideal temperature levels for gummy processing.

- Automated Systems: Automated cooling systems help manage large volumes of gummies efficiently, ensuring the sugar coating adheres without melting.

Solution for Small-Scale Production:

- Use a portable air conditioner or fan to lower the room temperature.

- Ensure gummies are fully cooled before applying the sugar, which helps the coating adhere without melting.

.

2. Humidity Control

Why it matters:

Since gummies require moisture to retain their texture and consistency—unlike ordinary powder pills—humidity plays a crucial role in the production process. Some gummies are coated with sugar using humidity as well. The application of moisture and humidity, as well as when to do so, are carefully considered by manufacturers. Gummies can end overly soft or too firm, or they might take a long time to harden if done incorrectly.

Precise Guidelines:

Maintain humidity levels below 50% for optimal results. If humidity exceeds 60%, sugar may not properly adhere to the gummies, leading to coating failure.

Solution for Industrial Production:

- Dehumidifiers or HVAC Systems: Install industrial-grade dehumidifiers or humidity control systems to maintain low moisture levels during the coating process.

- Desiccant Systems: Consider using desiccant systems or regulating air with an HVAC setup to prevent sugar from absorbing excess moisture, particularly in humid environments.

Solution for Small-Scale Production:

- Use silica gel packets or an at-home dehumidifier to lower moisture levels in your workspace.

- Pre-dry gummies in a low-temperature oven to reduce their moisture content, which helps the sugar coating stay dry.

.

3. Cooling Gummies for Proper Sugar Adhesion: Tips for Small-Scale and Industrial Production

Why it matters:

Before sugar coating, it is essential to ensure your gummies are completely cooled. This prevents the sugar from melting or dissolving prematurely, ensuring an even, crisp coating.

Precise Guidelines: For optimal sugar adhesion, gummies should be cooled to room temperature (65-70°F or 18-21°C). Proper cooling techniques vary depending on the production scale.

Solution for Industrial Production:

- Climate-Controlled Rooms: Ensure the production area maintains a consistent temperature below 70°F (21°C) with humidity levels no higher than 50%. Using industrial cooling systems or refrigerated cooling tunnels ensures rapid and uniform cooling across large batches.

- Batch Cooling Systems: Utilize automated batch cooling systems to cool gummies uniformly before they enter the coating stage. These systems prevent moisture buildup and optimize sugar adhesion.

Solution for Small-Scale Production:

- Room Temperature Cooling: Place gummies in a well-ventilated area at room temperature for 1-2 hours. Spread gummies out on trays to avoid sticking, and use a fan or air conditioner if the environment is warm or humid.

- Refrigeration Option: For smaller batches, speed up the process by refrigerating the gummies for 15-20 minutes. However, avoid over-chilling as condensation can form, causing sugar to dissolve when applied.

- Tip for Efficiency: To streamline the process, cool the gummies immediately after depositing them in molds and before moving them to the coating section. Automated temperature and humidity control systems ensure that the production cycle remains efficient without compromising coating quality.

.

What Are The Best Sugar Types for Gummy Sugar Coating?

Selecting the right type of sugar is essential for achieving the desired texture, sweetness, and appearance of your gummies. Each sugar type offers distinct characteristics that influence the sensory experience, and for manufacturers, it's also important to consider the cost-effectiveness and scalability of these sugars when producing at a large scale.

Breakdown of Sugar Types

| Sugar Type | Powdered Sugar | Sour Sugar | Sanding Sugar | Granulated Sugar | Nonpareils |

| Appearance | Smooth, powdery | Sparkling, sour | Sparkling, colorful | Sparkling, colorful | Colorful, textured |

| Texture | Soft | Crunchy | Sparkly | Crunchy | Crunchy |

| Common Uses | Coating or glazing of gummies | Providing an additional sour flavor | Decorating gummies with a delightful crunch | Dusting for a sweet and crunchy texture | Toppings for decorating gummies |

| Impact on Product | Adds a delicate, smooth coating with mild sweetness, perfect for gummies with subtle flavors. Creates a refined look. | Enhances tangy flavor profiles, ideal for sour gummies. The crunchy sugar balances the gummy's soft texture, giving it a bolder contrast. | Adds a bright sparkle and crunch, making gummies visually more appealing. Popular for eye-catching decorations. | Creates a more pronounced crunch with a noticeable sugar granule texture. Suitable for gummies where texture contrast is a key selling point. | Adds bold, colorful accents, making the gummy highly appealing visually. Great for enhancing the playful look of novelty gummies. |

Choosing the Right Sugar for Large-Scale Production

Sugar and Texture: Finding the Right Balance

When it comes to coating gummies, the choice of sugar significantly affects the texture:

- Powdered sugar creates a soft, smooth coating that complements delicate, subtle flavors. It gives the gummy a mild sweetness and a refined finish, but the coating may be less resistant to humidity.

- Sour sugar, often a mixture of sugar and citric acid, provides a crunchy texture and a tangy kick. This is ideal for sour gummies where the contrast between the sour coating and chewy interior creates a satisfying bite.

- Sanding and granulated sugar are preferred for gummies that need a crunchier, more dynamic texture. The granules create a more intense bite while also enhancing the visual sparkle of the product. This works well for decorative or premium products where both texture and appearance are vital.

.

Sugar and Appearance: Enhancing Visual Appeal

Visual appeal is key to a gummy’s success, and the right sugar coating can significantly improve shelf appeal:

- Sanding sugar and granulated sugar provide a sparkly finish, catching the light and making gummies more visually appealing. These sugars are often used in premium or holiday-themed products to create a sense of special occasion.

- Nonpareils, with their colorful, textured coating, are excellent for adding a playful, fun look to gummies. These are often used for children’s gummies or novelty candies, where color and excitement play a big role in purchasing decisions.

.

Sugar and Flavor: Amplifying or Balancing Taste

The sugar type you choose will also impact the flavor balance of your gummies:

- Powdered sugar offers a more subtle sweetness, which won’t overpower delicate gummy flavors like fruit-based or herbal gummies.

- Sour sugar adds an extra burst of flavor, creating the perfect balance between sweet and sour. This sugar type works best for gummies that require a tangy punch to satisfy consumer cravings for sour candies.

.

When producing at scale, it's important to balance aesthetics, texture, and cost. Granulated and sanding sugar are among the most cost-effective and scalable options for large operations, offering a combination of visual appeal and economical production. For sour gummies, investing in the right sour sugar blend is key to maintaining the desired flavor profile without increasing costs significantly.

.

How to Find the Best Sugar-to-Gummy Ratio for Gummy Candy with Sugar Coating

Finding the right sugar-to-gummy ratio is critical for achieving your desired level of sweetness and texture. A typical ratio is 1 part sugar to 1 part gummies by weight for regular sugar or 2 parts sour sugar to 1 part gummies for sour products.

- Lightly dusted gummies may require only a small amount of powdered sugar, while sour gummies may need a thicker layer of sour sugar to balance the bold flavors.

- Adjust your ratios based on consumer preferences and the desired effect. For example, children’s gummies may benefit from a heavier decorative sugar coating (like nonpareils or sanding sugar) for visual impact, while adult-focused or premium gummies may prefer the subtlety of a finely powdered or lightly granulated coating.

.

What Are the Different Coating Methods for Gummies?

When it comes to coating gummies, sugar is not the only option. Depending on the type of gummies you’re making and the desired outcome, you can choose between sugar, oil, and wax coatings. Each method offers different benefits and is suited to specific types of gummies. Below is a comparison to help you decide the best method for your production needs.

Comparison of Gummy Coating Methods: Sugar, Oil, and Wax

| Coating Method | Best Suited For | Key Benefits | Challenges | Common Uses |

| Sugar Coating | - Sweet gummies- Sour gummies (using sour sugar) - Fruity flavors | - Adds sweetness and texture - Enhances visual appeal with a sparkling finish - Reduces stickiness in humid environments | - Can dissolve if the gummy is too moist - May make gummies overly sweet if not balanced | - Common for classic gummy bears, fruit-flavored gummies, and sour candies |

| Oil Coating | - CBD-infused gummies - Gummies with natural oils- Gummies requiring smooth texture | - Prevents stickiness- Improves smoothness and mouthfeel - Prepares the surface for additional coatings (like sugar) | - Does not enhance visual appeal - Requires precise application to avoid a greasy texture | - Typically used for CBD or health gummies to provide a protective base layer before adding sugar |

| Wax Coating | - Gummies with extended shelf life - Gummies meant for premium or luxury packaging | - Provides a glossy, professional appearance - Adds a protective layer, extending shelf life - Helps gummies resist humidity | - Can make the gummy surface too hard - Does not enhance flavor | - Often used for gourmet gummies, or gummies sold in premium packaging for an upscale look |

Best Coating Method for Different Gummy Types

- Sweet Gummies:

Best Method: Sugar Coating

Sugar coating enhances sweetness and adds an eye-catching sparkle, making it ideal for classic fruit-flavored or sweet gummies. The crunch of sugar pairs perfectly with the chewy interior, creating a delightful contrast in texture. - Sour Gummies:

Best Method: Sour Sugar Coating

Sour gummies are best coated in a blend of sugar and citric acid (sour sugar). This coating provides a tangy kick that complements the gummy’s flavor profile. However, moisture control is key to preventing the sugar from dissolving too quickly. - CBD Gummies:

Best Method: Oil Coating

CBD-infused gummies benefit from an oil coating, as it creates a smooth barrier that prevents the gummies from sticking together. This coating also acts as a foundation for an optional sugar layer to be added later, without compromising the efficacy of the CBD. - Luxury Gummies:

Best Method: Wax Coating

High-end gummies, often sold as gourmet or premium products, are best coated with wax. This provides a glossy finish that looks professional and appealing, while also extending the shelf life by protecting the gummies from moisture and humidity.

.

.

By understanding the strengths and weaknesses of each coating method, manufacturers can better align their production processes with both market demands and consumer expectations.

.

For Small-Scale Producers: Simple Sugar Coating Techniques for Homemade Gummies

If you're making gummies at home, you'll need minimal yet precise equipment to ensure successful sugar coating.

Essential Equipment for Home-Based Gummy Production

Here’s the basic equipment you'll need for home-based gummy production:

- Bowl: To hold the sugar for coating.

- Tongs/Spoon: For manual coating by dusting or sprinkling sugar onto the gummies.

- Sieve/Shaker: Helps evenly coat gummies by gently tossing them with sugar.

- Baking Sheet and Parchment Paper: Provides a clean surface for the gummies to dry and set after coating.

.

Source: Kitchen Alchemy

.

Step-by-Step Sugar Coating Process for Home-Based Producers

Here’s the step-by-step process for sugar-coating gummies in a home-based setting:

- Cool Your Gummies Completely: Ensure the gummies have cooled down fully before applying any coating. Warm gummies may cause the sugar to melt or dissolve, leading to an uneven coat.

- Prepare the Sugar Mixture: Create a mixture of sugar and cornstarch, or a blend of sugar and citric acid for a sour finish. Stir until well-combined.

- Toss the Gummies in the Mixture: Using a sieve or shaker, gently toss the cooled gummies in the sugar mixture until they are fully coated.

- Let Them Air Dry: Place the coated gummies on a baking sheet lined with parchment paper. Allow them to air-dry for a few hours until the sugar has set firmly.

- Store Properly: Once dry, store your gummies in an airtight container to maintain freshness and prevent them from absorbing moisture.

.

.

For Industrial-Scale Producers: Advanced Sugar Coating Solutions for High-Volume Gummy Production

The equipment used to coat gummies varies based on the type of coating you’re applying, whether it's sugar, oil, or wax. Choosing the right tools is essential to achieving consistent, high-quality results. Below, we’ll first compare the different coating methods, so you can choose the best one for your gummy type. Then, we’ll cover the essential equipment for both home-based and commercial production.

Essential Equipment for Commercial-Scale Gummy Production

1. CP-1000 Sugar Polishing Pan

Engineered from stainless steel, the CP-1000 Sugar Polishing Pan is the go-to machine for coating confectionery products like gummies, nuts, and chocolates. Its adjustable pan angle ensures better control over coating precision, while optional hot or cold air blowers and spray systems enhance the coating process. With a batch capacity of 50-70 kg and rotation speeds of 30-32 rpm, this machine is ideal for small to medium-scale production. Easy to operate and maintain, the CP-1000 guarantees smooth and consistent coating results every time.

- Capacity: 50-70 kg per batch

- Power: 1.5 kW motor, 3.5 kW heating

- Adjustable Pan Angle: For optimal coating control

- Optional Features: Hot/cold air blowers and spray systems for versatile production

.

2. VP Series Tilt To Pour Coating Pan

The VP Series Tilt To Pour Coating Pan offers an efficient and damage-free solution for applying sugar, oil, or wax coatings to products like gummies and chocolates. Its innovative tilt-to-pour design allows for smooth material handling, reducing product loss during the coating process. Built with durable stainless steel, this machine has a capacity range of 5-50 kg and delivers stable, low-noise performance, making it perfect for small-scale production environments.

- Capacity: 5-50 kg per batch

- Power: 2.2 kW

- Tilt-to-Pour Design: Minimizes product damage for a consistent coating

- Material: High-grade stainless steel for durability and easy cleaning

.

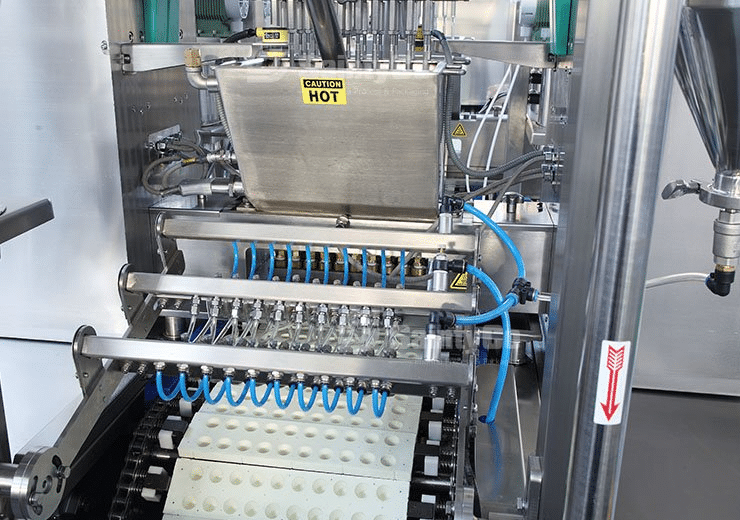

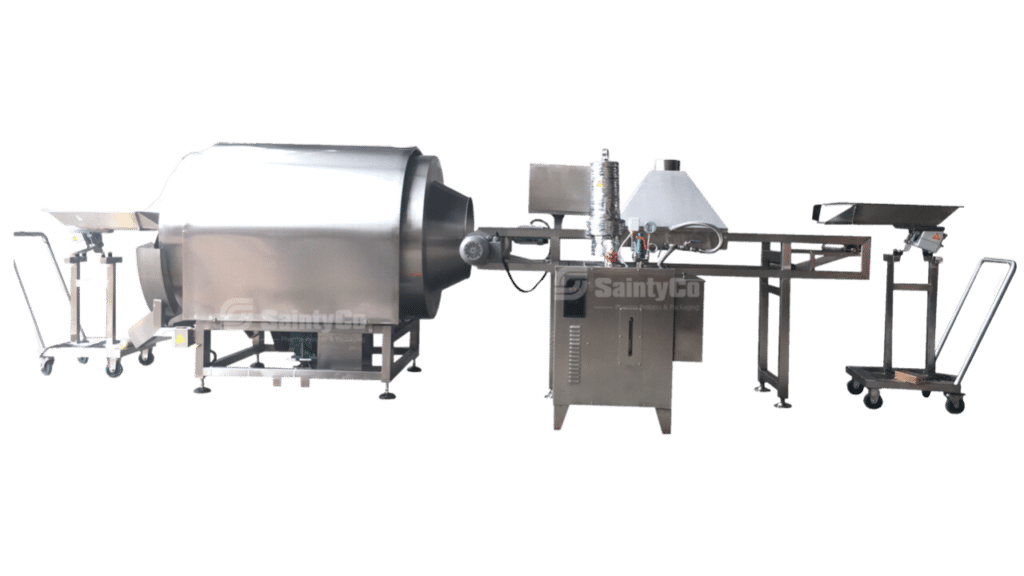

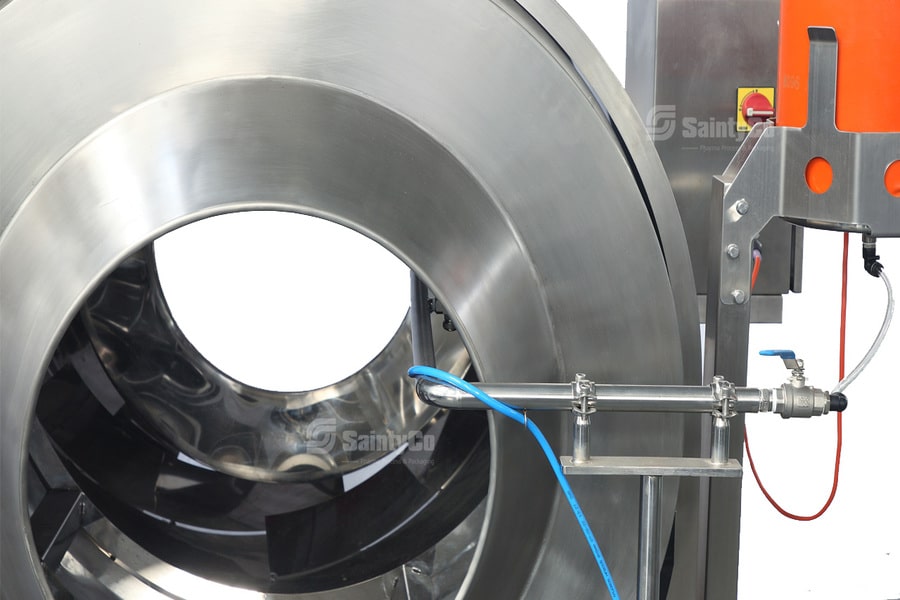

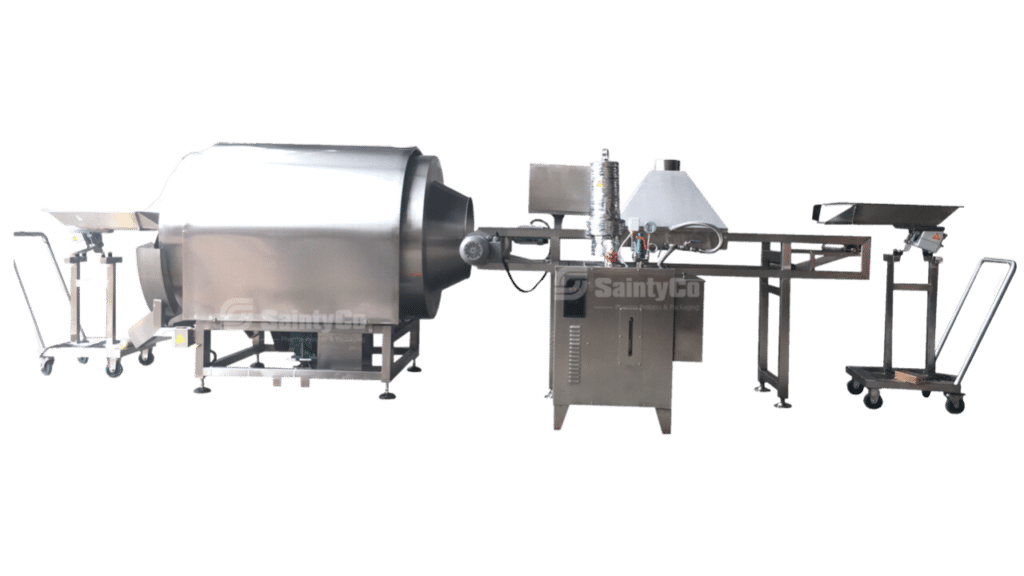

3. SW-600 Sugar Sanding Drum

The SW-600 Sugar Sanding Drum is an automatic, high-efficiency system for sugar-coating gummies, jelly candies, and other starch-molded confections. With a production capacity of 500-600 kg per hour, this machine delivers consistent coating while maintaining product texture and shape. The stainless steel perforated inner drum recycles excess sugar for improved efficiency, and its variable speed drive allows for flexible production adjustments. Designed for large-scale operations, the SW-600 reduces labor while maintaining high-quality results.

- .Capacity: 500-600 kg per hour

- Material: Stainless steel 304

- Power: 2.05 kW

- Features:

- Automated sugar feeding with vibration and auger control

- Perforated drum for recycling excess sugar

- Variable speed control for flexible production

.

.

4. SW-600A Turbo Sugar Coater

For large-scale production requiring speed and precision, the SW-600A Turbo Sugar Coater delivers flawless sugar coating for gummies and other starch-molded confections. This machine incorporates an integrated steaming conveyor, a turbo-powered coating drum, and a heated air blower for optimal sugar adhesion. With a capacity of up to 600 kg per hour, it combines efficient pre-coating preparation with advanced sugar circulation systems. Adjustable steam jets and a reversible drum drive make cleaning easy, while the precise coating process ensures minimal sugar waste.

- Capacity: 500-600 kg per hour

- Power: 2.05 kW

- Material: Stainless steel for durability and hygiene

- Features:

- Steaming conveyor for effective pre-coating preparation

- Adjustable sugar hopper with vibratory feed

- Heated air blower for maintaining optimal sugar consistency

- Variable drum rotation and steam regulation for precision coating

.

.

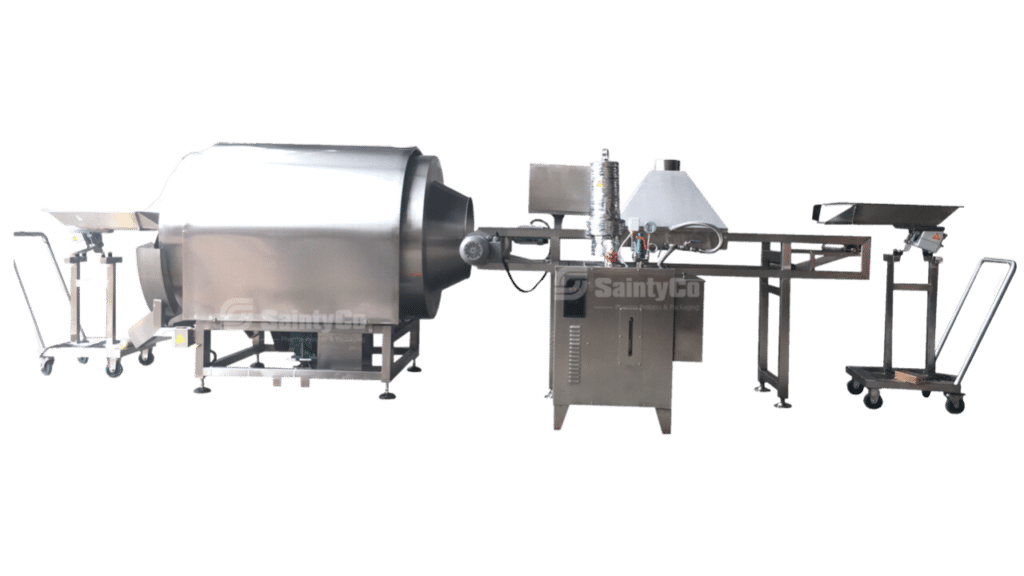

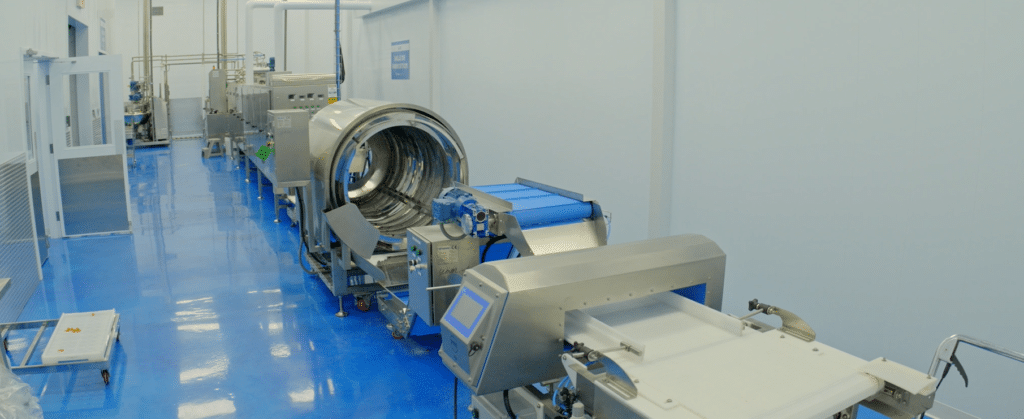

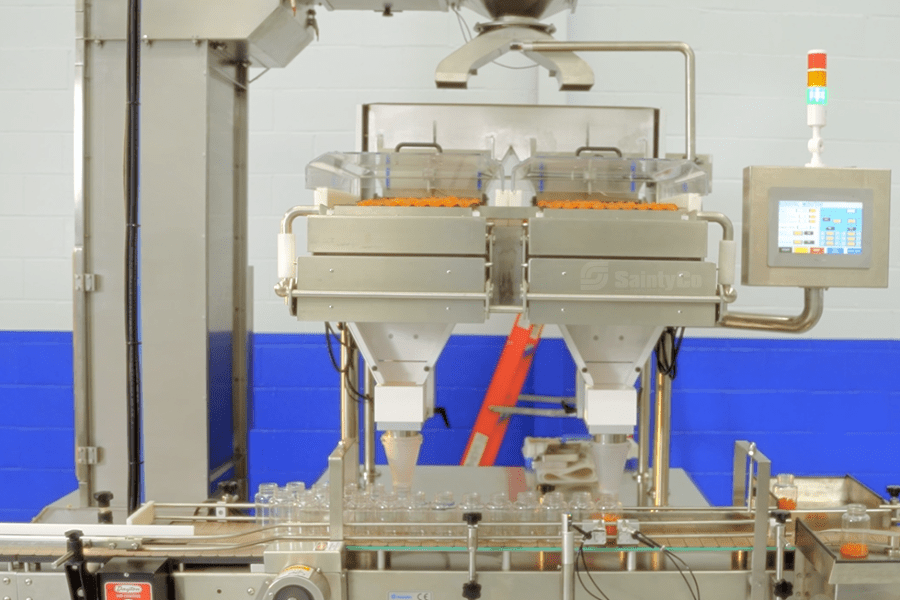

5. The Complete Gummy Production Line

For a seamless transition from production to coating, GummyGenix by SaintyCo offers Semi-automatic gummy depositors as well as G-series fully automatic gummy production lines. This integrates perfectly with the sugar coating machines, making mass production easy and smooth. GummyGenix makes quality and durable equipment with customization options to meet specific gummy manufacturing needs. This ensures that every gummy is consistently coated with the highest quality standards.

.

Each of these machines is designed to streamline your gummy production, enhancing efficiency and ensuring consistent, high-quality results. Contact us today to learn more about how our equipment can elevate your confectionery business.

![[Gummy Machine] G150 Gummy Production Line - SaintyCo](https://gummygenix.com/wp-content/cache/flying-press/TXs20euXnkY-hqdefault.jpg)

Step-by-Step Sugar Coating Process for Industrial Producers

The process of coating your gummies with sugar is simple, whether you are doing it at home or in a factory setting. Here are the steps to finding the perfect balance of sweetness and consistency:

Step 1: Prepare the gummy ingredients

Before you begin the sugar-coating process, gather all the necessary ingredients. You’ll need pre-made gummies, cornstarch, citric acid, sugar, and a small amount of flavorless oil, such as vegetable or coconut oil. The cornstarch helps absorb excess moisture. The oil enables the sugar to stick to the gummies, while the citric acid creates a tangy taste.

Step 2: Start Coating Gummies with Sugar

After gathering your coating ingredients, it’s essential to manage temperature and humidity during the sugar-coating stage. As mentioned earlier, gummies should be fully cooled before starting the coating process to ensure the sugar adheres properly. In humid environments, it’s best to work in a controlled space with humidity levels below 50% to prevent the sugar from dissolving or clumping.

Begin by dissolving sugar and citric acid in warm water, stirring until the sugar has completely dissolved. Monitor the temperature carefully — if the mixture is too hot, the sugar might not form a proper layer and will instead dissolve into the gummy surface. Maintaining an optimal temperature of 70-75°F (21-24°C) is ideal for ensuring a smooth and even coating.

For industrial production, automated systems like the SW-600 Sugar Sanding Drum help regulate both temperature and humidity, ensuring consistent coating in every batch.

.

.

If you are producing gummies on a small scale, you can manually control this by using a thermometer and an air conditioner or dehumidifier to maintain optimal conditions.

Step 3: Let the gummies cure and dry

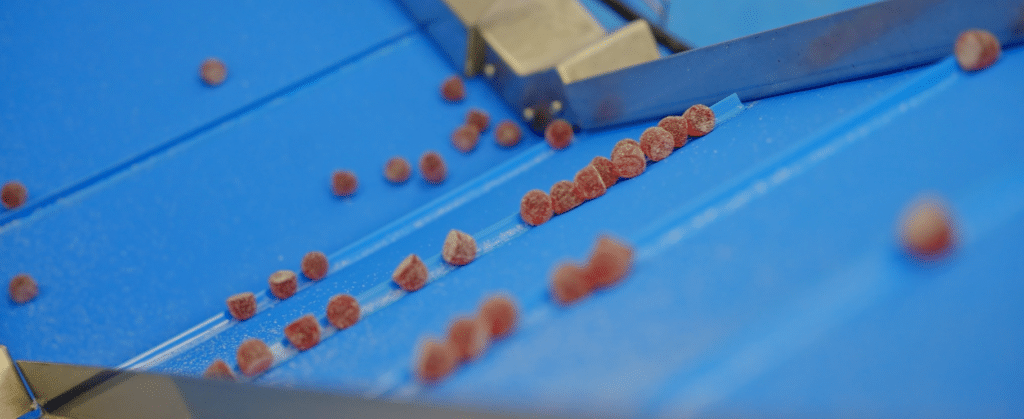

Place the coated gummies on drying trays, ensuring they aren’t touching. Let them air dry in a drying room until the sugar coating sets properly and becomes firm.

.

.

Step 4: Clean up excess sugar coating

Once dried, gently roll the gummies in cornstarch to remove any excess sugar and prevent them from becoming sticky or too sweet. Take your time in this step to ensure the final gummies don’t become crunch bombs. Afterward, use a soft brush to eliminate any remaining cornstarch for a smooth and balanced finish.

Step 5: Package gummies for sale

After the sugar-coated gummies are fully dried, they are ready to be packaged for distribution. GummyGenix offers proper packaging solutions to enhance presentation and shelf life.

.

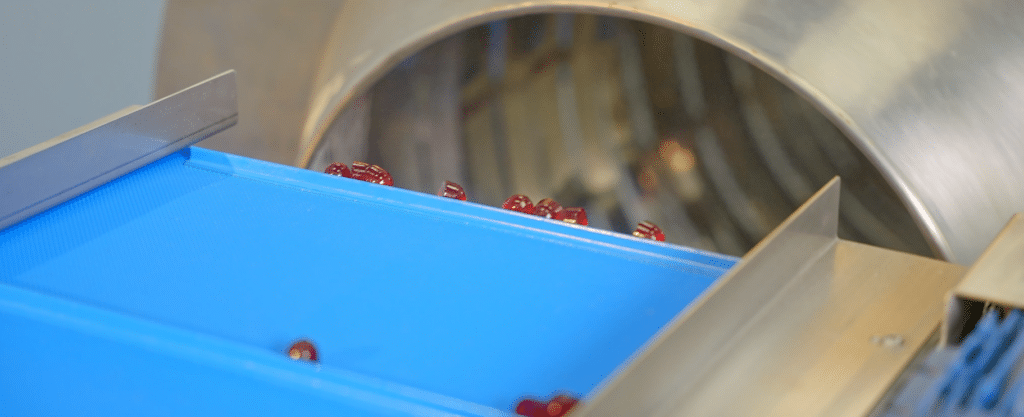

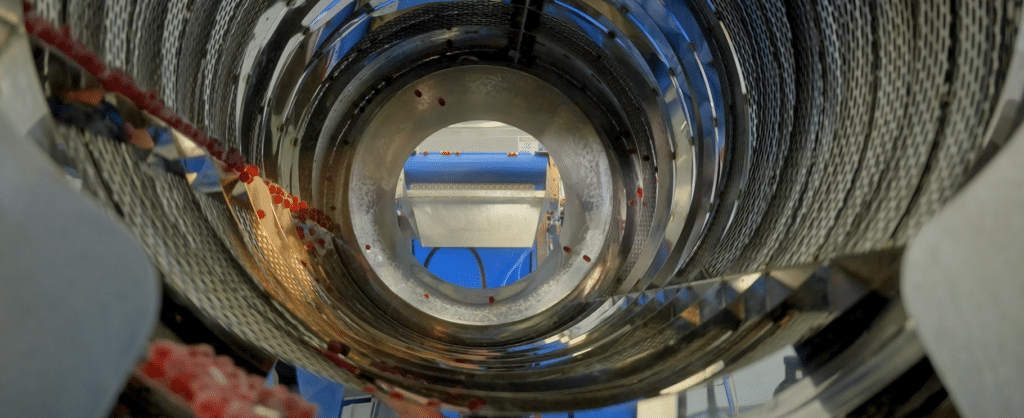

These images were taken at a SaintyCo client's production facility in Canada. They serve as reference material, highlighting the gummy sugar coating and packaging processes, along with the SaintyCo machinery used in these operations.

.

Common Challenges and Solutions for Coating Gummies with Sugar

Coating gummies with sugar presents several challenges, particularly in large-scale production environments. Below are common issues and their solutions, tailored to small, medium, and large-scale production setups.

1. Dealing with Wet and Sticky Gummies Due to High Humidity

The Challenge: Humidity causes sugar to absorb moisture, leading to stickiness, clumping, or the dissolving of the sugar coating. Sour gummies are especially sensitive to humidity due to their acidity.

Solution: Managing humidity levels is critical for achieving optimal sugar adhesion, ideally keeping levels below 50%.

- Small-Scale Production: Use at-home dehumidifiers or silica gel packs to control moisture.

- Medium-Scale Production: The CP-1000 Sugar Polishing Pan helps regulate humidity with its optional hot/cold air blowers, ensuring even sugar adhesion.

- Large-Scale Production: Industrial-grade humidity control systems, like those used with the SW-600 Sugar Sanding Drum, maintain low humidity to ensure smooth sugar coating.

.

2. Sugar Crystallization or Dissolving

The Challenge: Warm or moist gummies can cause sugar to crystallize or dissolve, leading to a sticky or gritty texture.

Solution: Cooling the gummies properly and keeping the production area at low humidity is essential.

- Small-Scale Production: Ensure gummies are fully cooled to room temperature (65-70°F) before applying sugar, and use a dehumidifier to keep moisture under control.

- Medium-Scale Production:

The CP-1000 Sugar Polishing Pan is equipped with air blowers to control both temperature and humidity during the coating process, preventing crystallization or dissolution.

- Large-Scale Production:

The SW-600A Turbo Sugar Coater ensures optimal cooling and sugar adhesion with its heated-air blower and variable steam regulation.

.

3. Preventing Uneven or Patchy Sugar Coating

The Challenge: Inconsistent or insufficient sugar application can lead to uneven coverage, affecting both appearance and texture.

Solution: Maintain consistent sugar application throughout the process.

- Small-Scale Production: Make sure you have enough sugar mixture and toss the gummies gently to ensure even coverage.

- Medium-Scale Production: The CP-1000 Sugar Polishing Pan offers precise control with its adjustable pan angle, ensuring consistent coverage across all gummies.

- Large-Scale Production: The SW-600A Turbo Sugar Coater uses contra-flow sugar circulation and variable drum rotation for consistent coating, making it ideal for large-scale operations.

.

4. Incomplete Coating on Gummies

The Challenge: Incomplete or thin coatings are often caused by excess moisture or insufficient sugar.

Solution: Thoroughly dry the gummies before applying the sugar coating.

- Small-Scale Production: Dry gummies thoroughly and prepare extra sugar coating to ensure full coverage.

- Medium-Scale Production: The CP-1000 Sugar Polishing Pan allows for multiple layers of sugar to be applied for a perfect finish.

- Large-Scale Production: The SW-600 Sugar Sanding Drum delivers multiple layers of sugar with its cleated conveyor system, ensuring full and consistent coverage.

.

5. Sugar-Coating Mixture Hardening Too Quickly

The Challenge: If the sugar mixture hardens too quickly, it can lead to clumps and uneven application.

Solution: Keep the sugar mixture at the right temperature to ensure pliability throughout the coating process.

- Small-Scale Production: Keep the sugar mixture warm and stir frequently to prevent hardening. Add glucose syrup or corn syrup to stabilize the mixture.

- Medium-Scale Production: The CP-1000 Sugar Polishing Pan features a heated-air blower to prevent the sugar from hardening too quickly.

- Large-Scale Production:

.

The SW-600A Turbo Sugar Coater ensures optimal cooling and sugar adhesion with its heated-air blower and variable steam regulation.

.

Cost and Scalability Analysis in Gummy Sugar Coating

Transitioning from small-scale to industrial-level production requires careful consideration of both equipment and sugar types. Cost and scalability are key factors in maintaining efficiency and product consistency at scale.

1. Equipment Scalability:

- Small-Scale: Manual or semi-automatic machines like the CP-1000 Sugar Polishing Pan work well for smaller batches.

- Industrial-Level: The SW-600 Sugar Sanding Drum and SW-600A Turbo Sugar Coater handle large batches, offering automated control for consistent sugar application.

.

.

2. Sugar Type Scalability:

- Granulated Sugar: Economical and suitable for large-scale production, but quality control is essential for consistency.

- Sanding Sugar: Offers premium appearance for high-end markets, but scaling increases costs.

- Powdered Sugar: Challenging to scale due to clumping issues in humid environments.

- Sour Sugar: Costlier due to citric acid, but necessary for sour gummy products with a tangy flavor.

.

3. Labor and Operational Costs

Automation reduces the need for manual labor, while improving production consistency.

- Small-Scale Production: Manual labor plays a significant role but may lead to inconsistent results.

- Industrial-Scale Production: Automated machines like the SW-600 Sugar Sanding Drum allow for consistent output with minimal oversight, although maintenance and energy costs increase.

.

Key Takeaways for Manufacturers Planning to Scale

- Invest in Scalable Equipment: Machines like the SW-600A Turbo Sugar Coater are designed for high-capacity production with consistent results.

- Cost-Effective Sugars: Granulated sugar offers the best balance of cost and scalability, while more premium sugars should be reserved for higher-end markets.

- Balancing Cost and Consumer Expectations: For premium gummy markets, higher-cost sugar types and specialized equipment can justify premium price points.

.

The Best Equipment for Gummy Bear Coating and Sugar-Coated Gummies

To achieve the perfect sugar coating on your gummy bears, sour gummies, or other sugar-coated candies, using the right equipment is crucial. Specialized machines like the SW-600 Sugar Sanding Drum, SW-600A Turbo Sugar Coater, and CP-1000 Sugar Polishing Pan are designed to tackle common challenges like uneven coating, moisture control, and temperature regulation. These machines ensure that your gummies are coated evenly while maintaining consistent quality across production runs.

Whether you're producing gummy bears or other types of gummy candy with sugar coating, these solutions streamline the process, helping you scale production efficiently without compromising on quality.

.

Conclusion: Master the Art of Gummy Sugar Coating

Sugar coating your gummies doesn’t have to be a challenge. With the right techniques and equipment, you can easily produce flawless, mouthwatering treats. Whether you’re a small-scale producer or an industrial manufacturer, Contact GummyGenix to learn more about the tools and expertise to help you scale your production while ensuring top-notch quality. Ready to take your gummy game to the next level? Check out our full range of sugar coating equipment.

.

FAQs

What are the benefits of using the gummy sugar-coating machine?

Using the gummy sugar coater or from GummyGenix offers many advantages, including:

- Increases speed of production: A gummy coater automates the sugar coating process, allowing for faster and more efficient production compared to manual methods.

- Increases accuracy: The sugar coating equipment ensures consistent and even coating on each gummy, leading to a more uniform product.

- High durability levels: Since the sugar coating machines are built and designed to withstand the demands of continuous production, they minimize downtime and maintenance costs.

- Easy to operate: GummyGenix sugar coaters are designed with user-friendly interfaces and controls, making them easy to learn and use. They can be operated by one or two persons.

- Easy to clean and maintain: The sugar coaters by GummyGenix are designed for easy cleaning and maintenance, promoting hygiene and extending the machine's lifespan.

.

What to consider when choosing the right sugar coating equipment?

Finding the perfect sugar-coating equipment involves careful consideration of the following factors:

- Level of automation: Based on your gummy production needs and budget, you must determine the desired automation level. From semi-automatic to fully automatic machines.

- Type of materials: You should look for equipment that is compatible with the specific sugar-coating materials you plan to use.

- Compatibility with existing units: Check the equipment’s specifications to ensure it integrates and fits well with other machines in your production line.

- Dimensions of the machine: Ensure the sugar coating machine fits your available workspace and production line layout.

- Speed of production: This is a significant factor. You must think about the machine's production capacity to ensure it meets your output requirements.