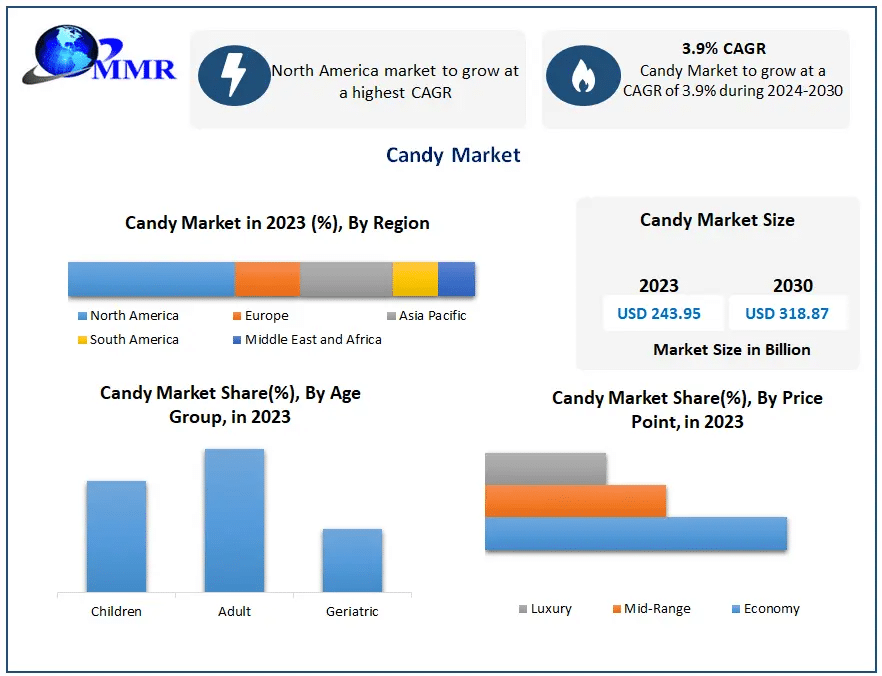

Global Candy Market size was valued at USD 243.95 Bn. in 2023 and the total Candy revenue is expected to grow by 3.9 % from 2024 to 2030, reaching nearly USD 318.87 Bn.

Candies known as confectioneries, contain sugar, honey and other natural or synthetic sweeteners in combination with chocolate, milk, fruits, nuts, or other ingredients that are made in the form of bars, drops, and pieces. Certain types of candies can add valuable protein, minerals, and vitamins that support bodybuilding and encourage general well-being.

.

Entrepreneurs are not only eyeing the traditional candy market but also finding lucrative opportunities in niche segments like vitamin-infused candies and CBD-infused candies.

In this guide, we’ll cover everything from setting up your candy business to specific candy production methods, licensing, equipment usage, and packaging solutions. Whether you want to craft classic treats or explore functional candies, this guide will show you how to carve out your sweet spot in the booming candy-making business.

.

Essentials to Open a Candy Business

1. Business Plan

A well-crafted business plan is your roadmap, outlining your vision, strategies, and financial projections. You need a thorough market analysis to identify your target customers and their preferences so that you can tailor your products to their tastes. Besides, you should assess your competition to differentiate your candy offering and carve out a unique niche in the market.

2. Legal and Financial Considerations

Before whipping up batches of your signature candy, you should obtain the necessary permits and licenses and understand food safety regulations. Simultaneously, you should adequately manage costs, set prices for your candies, and secure any necessary funding.

.

3. Licenses and Regulations Specific to the Candy Business

When starting a candy business, it’s essential to comply with all necessary licenses and regulations to ensure your operation is legal and safe. Below are the key steps for meeting candy-specific legal requirements:

FDA Food Facility Registration

- Any candy business that processes, manufactures, or packages candy products in the U.S. must register with the FDA. This is a key requirement to ensure food safety and compliance with Good Manufacturing Practices (GMP).

- Complete the FDA food facility registration online.

- Prepare for FDA inspections to ensure compliance with sanitation and safety guidelines.

- Pro Tip: For CBD-infused candies, be aware of THC content limits (typically below 0.3%) to avoid legal issues. Always verify your CBD supplier’s certification to meet FDA guidelines for food safety.

.

Local Business Licenses

- Your local health department or government may require specific permits, including:

- Food Production Permits from your local health department.

- Zoning Permits to confirm your location is approved for food production.

- Sales Tax Permits if you’re selling directly to consumers.

- Pro Tip: For CBD-infused candies, check local cannabis laws and obtain any additional permits related to the sale of hemp-derived products.

.

Food Safety Regulations for Specific Ingredients

- If you’re making vitamin-infused or CBD-infused candies, you’ll need to meet strict labeling and food safety standards:

- For vitamin candies, ensure proper nutritional labeling that complies with FDA guidelines.

- For CBD gummies, perform regular THC testing to comply with federal and state laws.

- Pro Tip: Partner with a third-party testing lab to verify the safety and content of your products. This is especially important when working with CBD to ensure transparency and legal compliance.

.

4. Ingredients, Equipment, and Recipe

You must find high-quality ingredients to create treats that drive repeat purchases. Equally important, the right equipment will streamline production and ensure consistency, while unique and irresistible flavors will set you apart from the competition and create a loyal customer base.

.

5. Candy Packaging

How you package your candy treats matters a lot since it protects your candy products and determines their freshness. You need the right material, package size, color scheme, and design elements that comply with your local candy packaging regulations.

.

6. Branding

Your brand identity differentiates you from competitors, so you should craft a unique brand story, visual identity, and tagline. Moreover, find a product line that tantalizes taste buds and captures attention while your packaging should reflect your brand’s personality.

Starting a candy business requires more than just a love for sugar. The above essentials are necessary for success, and among them, your candy production equipment can make or break your candy business. In the next section, we’ll explore how to choose your equipment.

.

Quick Start Checklist for Opening a Candy Business

- Conduct a thorough market analysis.

- Draft a business plan with financial projections.

- Register your business and obtain FDA and local permits.

- Source high-quality ingredients and reliable equipment.

- Plan your branding and packaging strategy.

- Set up an online presence or local retail channels.

.

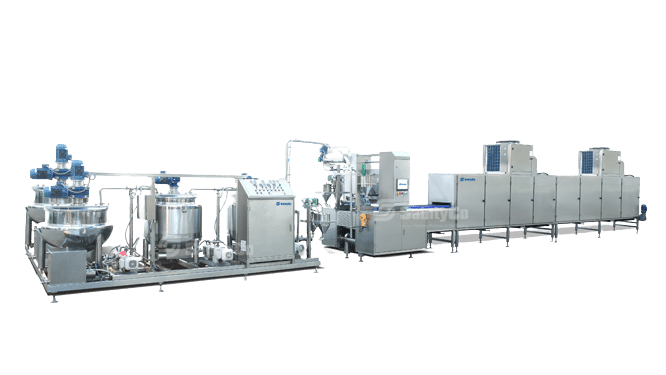

How to Produce High-Quality Gummies: A Step-by-Step Guide

1. Recipe Development and Ingredient Sourcing

Develop a precise recipe with balanced ingredients—sugar, gelatin, flavorings, and colorings. If producing vitamin or CBD-infused gummies, ensure you source ingredients from reputable suppliers who can provide nutrient-rich or third-party tested ingredients.

- Pro Tip: Test your recipes in small batches first to ensure consistency and stability, especially if working with heat-sensitive ingredients like CBD or vitamins.

.

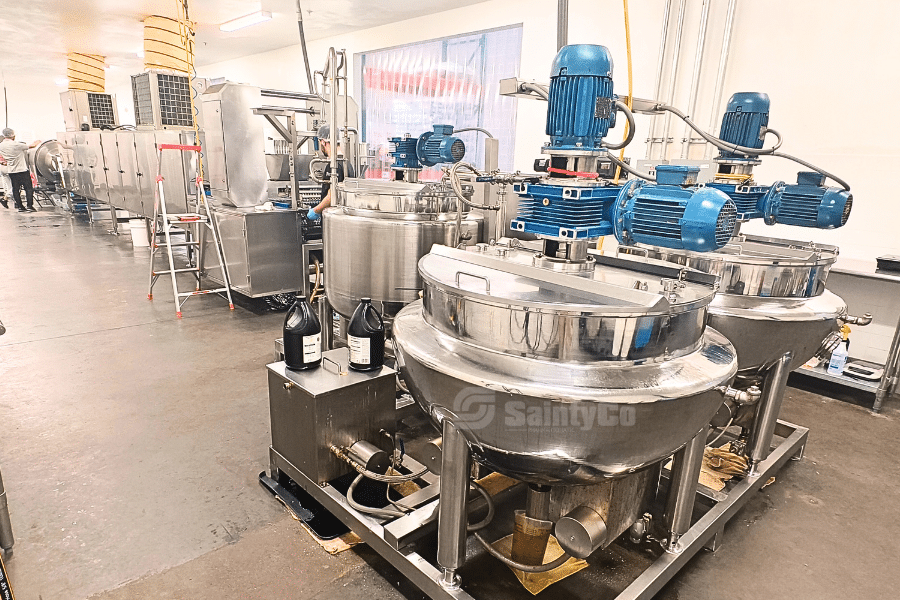

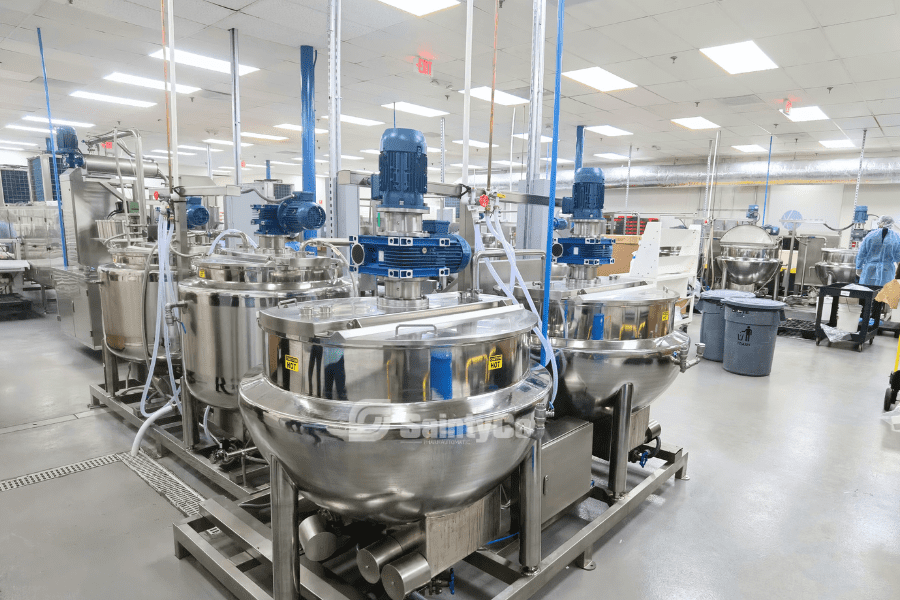

2. Batch Preparation: Mixing and Heating

Use an industrial candy cooker or kettle to mix ingredients at the correct temperature. For gelatin-based gummies, heat between 212°F to 230°F. For CBD gummies, avoid temperatures above 320°F to prevent CBD degradation.

- Pro Tip: Use a vacuum cooker to eliminate air bubbles and reduce oxidation, crucial for preserving vitamins and CBD.

.

.

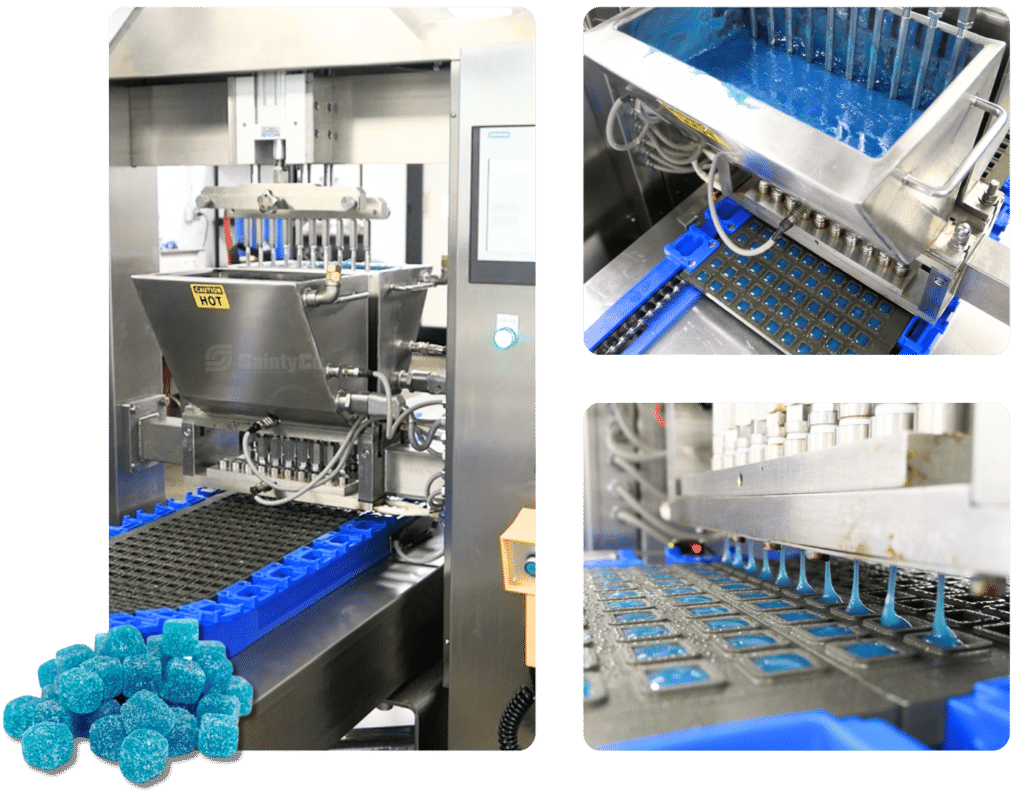

3. Molding and Depositing

Transfer the mixture to gummy molds using an automated depositor for consistent size and shape. Low-pressure depositors are recommended for gummies with sensitive active ingredients.

- Pro Tip: Maintain structural integrity for CBD or vitamin gummies by using depositors that carefully handle the mixture.

.

.

4. Cooling and Setting

Move the gummies into a cooling tunnel or tray cooler for proper setting. The cooling process can take anywhere from 30 minutes to 2 hours, depending on ingredients.

- Pro Tip: Avoid high humidity during cooling to prevent gummies from becoming sticky.

.

5. Demolding and Sugar Coating

Use a gummy demolder or manual methods for smaller batches. For sugar-coated gummies, place them in a sugar sanding drum after demolding.

- Pro Tip: For CBD or vitamin gummies, use coatings that won't degrade the active compounds.

.

.

6. Packaging and Shelf-Life Considerations

Gummies must be packed in air-tight, tamper-proof packaging to extend their shelf life. For CBD gummies, use child-resistant packaging and include detailed dosing and legal disclaimers.

- Pro Tip: For sensitive products, consider UV-blocking bottles or nitrogen-flushed packaging to maintain ingredient integrity.

.

Current Candy Industry Trends and Market Demand in 2024

The candy industry is evolving rapidly, with new trends and consumer preferences shaping the market. To succeed in this space, it’s crucial to understand the latest developments and how they can impact your candy business. Here are some key trends and market insights to guide your strategy:

1. Growing Demand for Low-Sugar and Health-Conscious Candies

Consumer preferences are shifting towards health-conscious and functional candies. According to a 2023 report by Euromonitor International, the global sugar reduction trend is driving demand for candies that are lower in sugar or offer additional health benefits, such as added vitamins or supplements.

- Data Insight: In a survey by Mintel, 67% of U.S. consumers reported they were concerned about their sugar intake. This has led to increased sales of low-sugar or sugar-free candies, as well as functional candies that promote health, such as vitamin-infused gummies.

- Actionable Tip: Consider developing a product line of low-sugar gummies or functional candies (e.g., gummies enriched with vitamin C, zinc, or other immunity-boosting ingredients) to meet this growing demand. This also aligns with the increasing focus on sustainable ingredients and clean labels, appealing to health-conscious consumers.

.

.

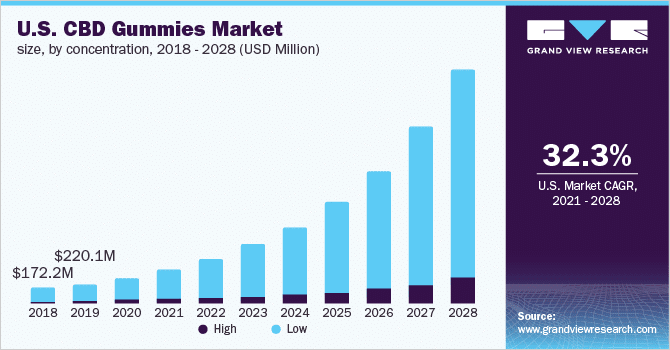

2. CBD and Nutraceutical Candies on the Rise

The CBD-infused candy market is experiencing rapid growth due to the increasing legalization of cannabis-related products. The global CBD gummies market size was valued at USD 1.6 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 30.7% from 2021 to 2028, according to Grand View Research. CBD gummies have become one of the most popular forms of ingestible CBD, known for their ease of consumption and perceived health benefits, including anxiety relief and pain management.

- Actionable Tip: If you are considering entering the CBD candy niche, focus on compliance with legal regulations in your region, particularly concerning THC levels and labeling requirements. GummyGenix provides the equipment and expertise needed to ensure precise dosing and product consistency in the highly regulated CBD candy market.

.

.

3. Sustainability and Eco-Friendly Packaging

The rise in sustainable consumer behavior is also impacting the candy industry. Many consumers are looking for products packaged in eco-friendly materials such as biodegradable plastics and recyclable paper. Brands that adopt sustainable packaging solutions are seeing increased customer loyalty and preference, particularly from younger demographics who prioritize environmental responsibility.

- Data Insight: According to a 2024 McKinsey & Company survey, 58% of consumers reported being more likely to buy from companies that offer sustainable packaging options. This trend is particularly prevalent among Millennials and Gen Z consumers.

- Actionable Tip: Incorporating eco-friendly packaging options into your candy business can differentiate your brand in a crowded market. Consider using recyclable or biodegradable materials, which appeal to environmentally conscious consumers. At GummyGenix, we offer automated packaging solutions that can handle these sustainable materials efficiently.

.

.

Case Study Example: A Success Story from the CBD Candy Market

Company: Verma Farms

Verma Farms, a U.S.-based CBD company, successfully entered the CBD gummy market in 2020. By focusing on high-quality, organically sourced CBD and offering gummies in a variety of flavors and doses, Verma Farms quickly became a market leader in the CBD candy sector. Their commitment to third-party lab testing and transparent labeling helped build consumer trust and positioned the brand as an authority in the CBD space.

- Key Insight: Verma Farms leveraged the growing demand for functional gummies by offering products that promote wellness, such as sleep aids and stress relief gummies. By investing in branding and product quality, they captured a loyal consumer base in a highly competitive market.

- Actionable Tip: This success story highlights the importance of quality control and transparent marketing when entering niche markets like CBD. If you’re considering a similar strategy, ensure your production processes meet the highest standards and that your labeling complies with legal guidelines to build consumer trust.

.

4. Consumer Behavior Shifts and How They Affect the Candy Market

Understanding consumer behavior is key to aligning your product offerings with what customers want. Recent shifts suggest that consumers are looking for more than just sugary treats—they want functional benefits, natural ingredients, and transparency from brands.

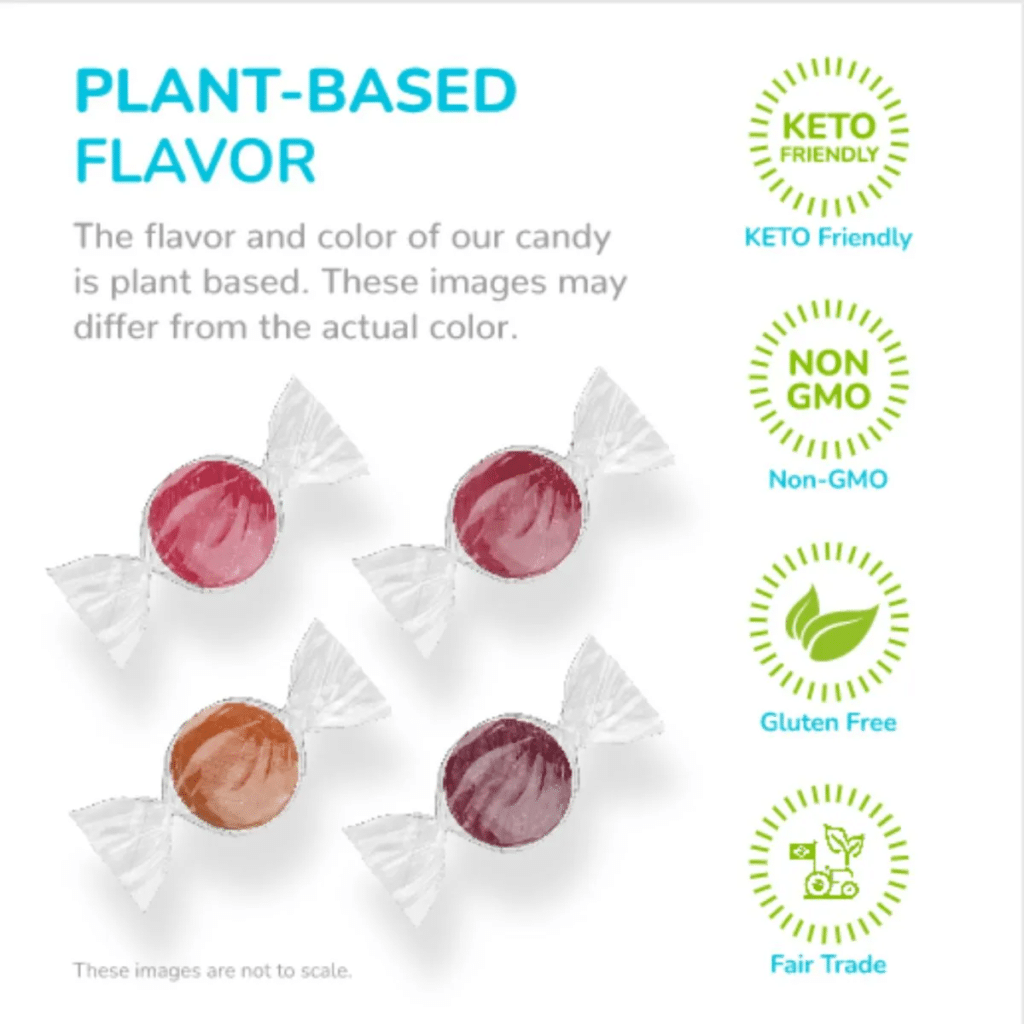

1) Natural and Organic Ingredients

In 2024, consumers are increasingly drawn to candies made with natural, organic, and non-GMO ingredients. A report by Nielsen indicates that 45% of consumers globally are looking for candy products that contain no artificial ingredients. This trend is even stronger among health-conscious demographics.

- Data Insight: Organic candy sales grew by 15% in 2023, showing the strong consumer preference for clean-label products that contain fewer artificial preservatives, colors, or flavors.

- Actionable Tip: Consider developing a line of natural gummies that use plant-based coloring and flavoring, which aligns with this growing market demand. Additionally, focusing on organic certification can set your brand apart.

.

.

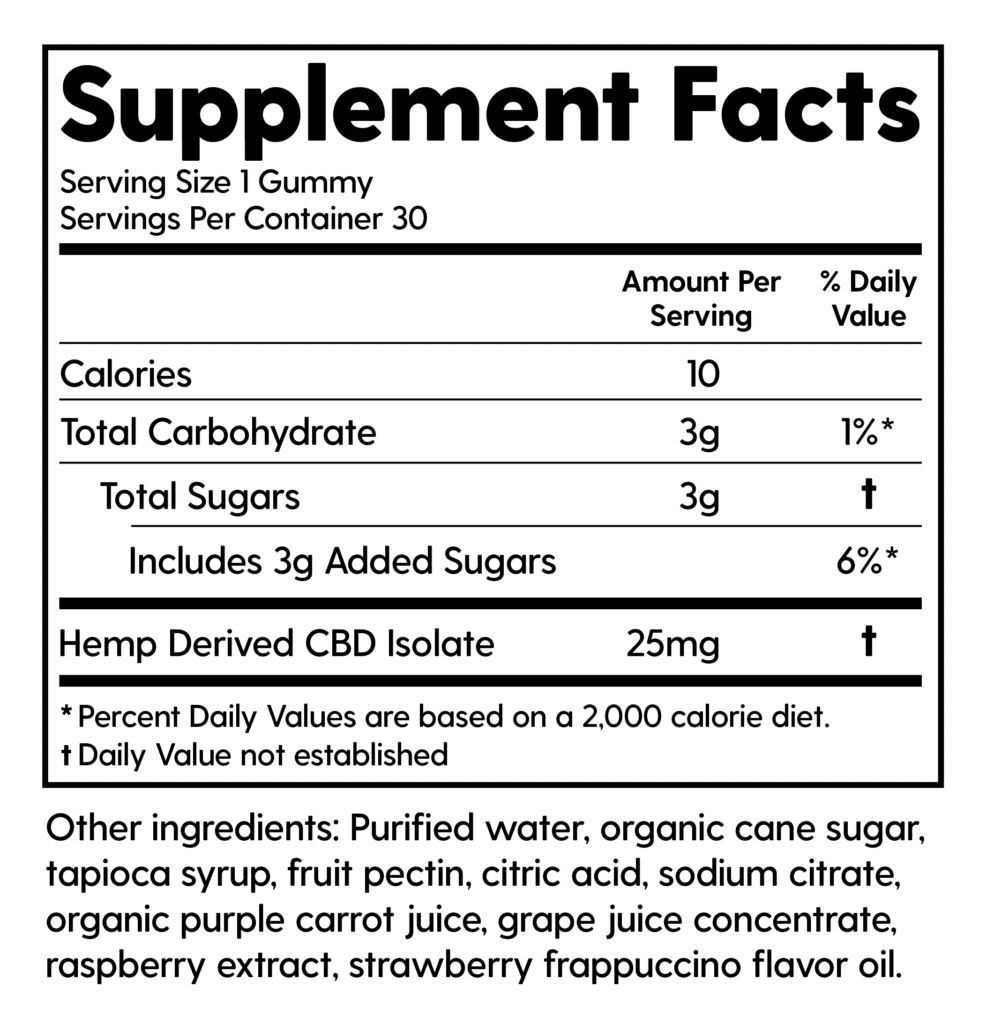

2) Transparency and Clean Labels

Today’s consumers are more informed than ever and demand transparency from the brands they purchase. This is especially true for products like CBD gummies and functional candies. Clear labeling of ingredients, health benefits, and potential side effects is crucial to gaining consumer trust.

- Data Insight: A 2023 study by Label Insight revealed that 73% of consumers are willing to pay more for products that offer complete transparency in labeling. Label Insight study reveals what product transparency means to consumers and how it affects shopper behavior, trust and loyalty.

- Actionable Tip: Ensure that your product packaging includes clear, accurate labeling that highlights not just ingredients but also the benefits of your candies. For example, if your candies contain vitamins or CBD, clearly state the health benefits and dosage recommendations.

.

.

5. Entering Niche Candy Markets: Vitamin Candies and CBD-Infused Candies

The candy industry offers plenty of room for niche markets, where you can create health-focused candies like vitamin supplements or capitalize on the fast-growing CBD-infused candy sector. Let's explore the opportunities and specific challenges in these specialized candy businesses.

Starting a Vitamin Candy Business

Why Choose Vitamin Candies?

Consumers today are looking for more than just sugary treats. Health-conscious individuals, parents, and fitness enthusiasts are turning to functional foods to supplement their diet. Vitamin candies combine the enjoyment of sweets with the health benefits of essential nutrients like Vitamin C, D, or B12. This growing trend has resulted in a sharp demand for candies that support wellness and immune health, offering a sweet spot for new businesses.

.

.

Key Considerations for Vitamin Candy Production:

- Ingredient Sourcing: Your success will depend on sourcing high-quality, bioavailable vitamins and minerals that maintain their potency during the candy-making process. It's essential to partner with reliable suppliers who can provide food-grade vitamins compliant with local and international regulations.

- Production Challenges: Vitamin candies require careful handling to ensure that nutrients are evenly distributed and do not degrade due to heat or processing. You may need specialized equipment like low-temperature depositors to preserve nutrient integrity.

- Regulations and Labeling: The vitamin candy market is subject to stricter labeling laws than regular candies, particularly regarding health claims. You’ll need to ensure your product complies with FDA (USA) or EFSA (EU) regulations, especially if you plan to market the candies as dietary supplements.

.

GummyGenix Solutions for Vitamin Candy Production:

At GummyGenix by SaintyCo, we offer equipment designed to meet the unique needs of vitamin candy production. Our machines ensure precise dosing and gentle processing, preserving the efficacy of active ingredients. From depositors to packaging machines, our equipment can help you scale your vitamin candy production efficiently.

.

Starting a CBD-Infused Candy Business

Why Choose CBD Candies?

The CBD market is experiencing exponential growth, with gummies being one of the most popular delivery forms for cannabidiol. CBD-infused candies offer users a convenient, tasty way to enjoy the therapeutic benefits of CBD, which is known for reducing anxiety, improving sleep, and managing pain. This makes CBD candy a highly lucrative niche, especially as more states and countries legalize cannabis-related products.

.

.

Key Considerations for CBD Candy Production:

- CBD Sourcing and Compliance: One of the biggest challenges in the CBD candy market is ensuring your CBD is sourced from reputable, third-party tested suppliers. You’ll need to meet local legal requirements for THC content, which should remain below the legal threshold (e.g., 0.3% in the U.S.).

- Infusion Process: Producing CBD candies requires specialized equipment to infuse the compound uniformly across batches. The potency of each candy must remain consistent, which is crucial for consumer trust and regulatory compliance.

- Packaging and Labeling Requirements: CBD candies often require child-resistant, tamper-proof packaging due to their therapeutic effects. Ensure that your packaging meets local regulations for cannabis products and communicates accurate dosage information to consumers.

.

GummyGenix Solutions for CBD Candy Production:

We provide a range of machinery designed specifically for CBD-infused candy production, ensuring accurate dosing and efficient manufacturing. Our equipment can be tailored for CBD gummies, hard candies, or even center-filled CBD candies, offering flexibility as your business grows. Additionally, we supply child-resistant packaging solutions to meet industry standards and keep your products compliant.

.

How to Choose the Right Candy Production Equipment for Traditional and Niche Candies?

When selecting candy production equipment, it's essential to consider several factors to ensure you meet your business needs. Below is a comprehensive checklist broken down into clear sections.

1. Your Candy Type and Design

The type of candy you produce will determine the specific equipment you need. GummyGenix specializes in various candy production solutions for different types and designs, from mono to double-layered, center-filled, and side-by-side. They have equipment for gummy products, CBD & cannabis edibles, confectionery, pharmaceuticals, and nutraceuticals & supplements. You can request a free consultation to guide your equipment selection based on your candy type.

.

.

2. Equipment for Specific Candy Types

- Specialized Machines: Identify machines designed for the specific candy types you plan to produce (e.g., gummy vs. hard candies).

- Versatility: Look for equipment that can handle multiple types of candies to diversify your product line without needing extensive new investments.

- Hygienic Design: Ensure that the equipment meets safety standards, particularly for food production.

.

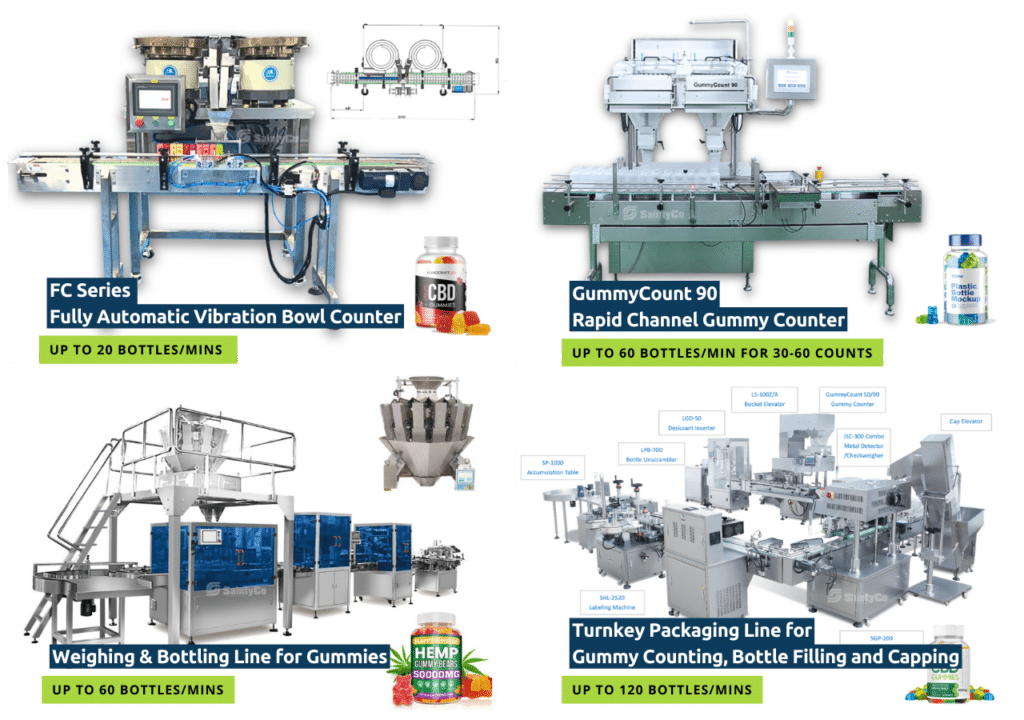

3. Production Volume Considerations

- Assess Your Production Needs: Determine the daily, weekly, or monthly volume you aim to achieve.

- Scalability: Choose equipment that can grow with your business. Look for machines that can handle increased production without compromising quality.

- Efficiency Rates: Evaluate the efficiency of the equipment in terms of output per hour. Higher efficiency can lead to cost savings in the long run.

.

The scale of your candy business will significantly influence your candy equipment needs. For lab-scale entry levels, manual or semi-automatic equipment might suffice. For example, a small candy shop might use a simple double boiler and a candy thermometer. However, larger-scale production lines dealing with thousands of candies daily require industrial-grade equipment like enrobers, molders, and cutters.

.

4. Budget-Friendly Equipment Options

- Initial Investment vs. Long-term Costs: Consider both the purchase price and ongoing operational costs.

- Leasing vs. Buying: Explore leasing options for expensive equipment to reduce upfront costs while maintaining flexibility.

- Cost-effective Brands: Research brands known for providing high-quality equipment at competitive prices.

.

While purchasing candy production equipment can be costly, you shouldn’t exceed your budget requirements. GummyGenix offers a variety of candy production machines, including laboratory gummy depositing, medium to large-batch gummy production lines, and ancillary equipment for different prices. Moreover, you can contact the GummyGenix sales team for a custom solution at a quote that fits your budget.

.

If you're entering niche markets like vitamin candies or CBD-infused candies, you’ll need equipment capable of low-temperature processing to preserve active ingredients, such as vitamins or CBD, during production. Specialized depositors ensure even distribution of nutrients or CBD extracts in every batch. GummyGenix offers tailored solutions that cater to the specific requirements of these niches, ensuring compliance with local and international regulations.

.

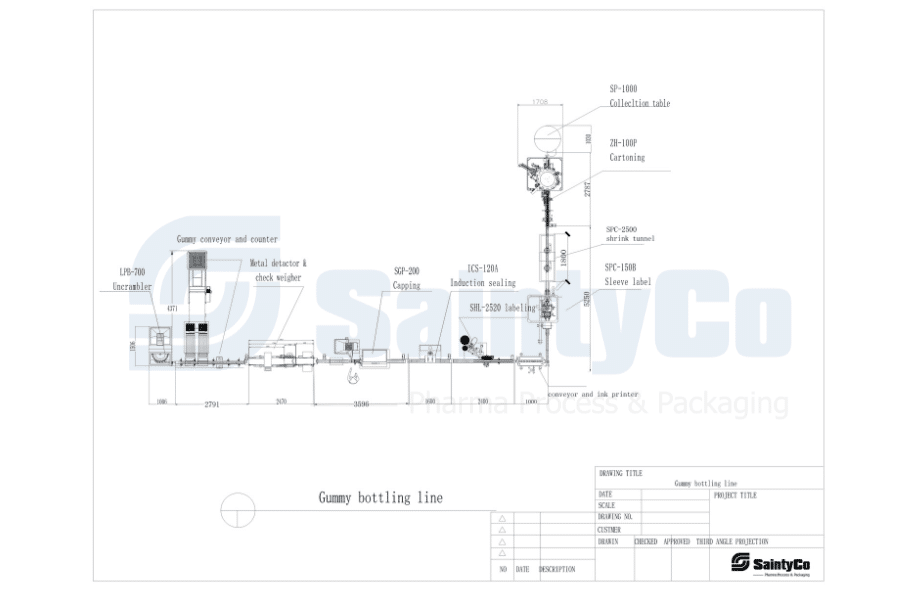

5. Space Availability and Limitations

Another critical aspect when choosing candy-making equipment is the size and layout of your production space. You must factor in the machine's dimensions and the required clearance to ensure it fits perfectly.

.

.

What Candy Business Equipment is Ideal for a Start-Up?

As a candy business startup, invest in cost-effective equipment that meets your production needs. For those entering niche markets like CBD gummies or vitamin-infused candies, consider equipment that offers precise dosing, temperature control, and compliance with food safety standards.

For smaller operations:

- Start with semi-automatic machines such as basic depositors, molding equipment, and tilt kettles.

- Gradually invest in advanced low-pressure depositors or temperature-controlled cookers for sensitive ingredients like vitamins and CBD.

- Pro Tip: GummyGenix offers a range of customizable machines designed to meet the specific needs of CBD and vitamin gummy production.

.

.

.

As you scale:

- Upgrade to automated lines for tasks like molding, cooling, and packaging.

- Use equipment that maintains the integrity of active ingredients, such as low-heat vacuum cookers or specialized packaging lines for child-proof and tamper-proof solutions.

.

.

| Equipment Type | Recommended For | Key Features | Cost Range |

| Basic Depositors | Small-batch production | Semi-automatic, flexible volume, ensures precise dosing | $5,000 - $20,000 |

| Automated Production Line | Scaling up to large production | Fully automated, includes cooling | $20,000+ |

Thankfully, at GummyGenix, we understand the cost ownership. We are committed to supplying high-performance, precision, and reliable equipment. Our candy production machines are easy to use and affordable. You should add them to your candy production line to produce faster and more profitably.

GummyGenix by SaintyCo have a variety of small-scale candy production machines for soft gummies and hard candies and can supply equipment designed for marshmallows and lollipops. These include small-batch depositors, tilt sugar dissolving kettles, sugar sanding drums, sugar/wax polishing pans, oil coating drums, trays, and tray washers. Additionally, we create dolly molds, silicone gummy molds, 3D metal gummy molds, and gummy demolders.

You can order customized solutions tailored to client-specific gummy production needs. For consultation or order placement, email us at [email protected] or call or WhatsApp at 008618518203862 for a quicker response.

.

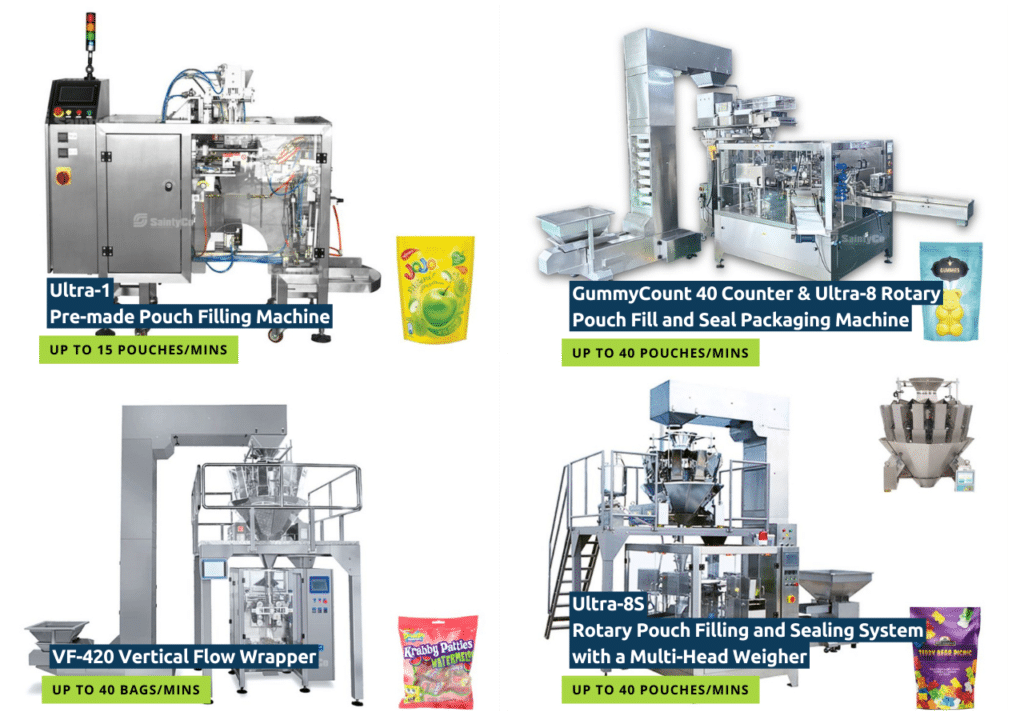

What is the Most Suitable Candy Business Packaging Solution?

There are many candy packaging trends to consider when starting a candy workshop. Some popular choices include

- Eco-friendly materials: As more consumers become increasingly conscious of environmental impact, you should opt for eco-friendly materials like recyclable paper, compostable films, or biodegradable plastics.

- Child-resistant packaging: This candy packaging method is ideal for candies like CBD-infused gummies, which young kids should not consume. An example of child-proof packaging includes using cans or bottles.

- Tamper-proof packaging: If you aim to attract loyal customers, you can opt for a package that deters unwanted tampering, especially when your candies are on store shelves. You can opt for heat-sealed bags or tamper-proof bottle caps.

- Shelf-Life Packaging: For CBD or vitamin gummies, use UV-blocking bottles or vacuum-sealed packaging to preserve active ingredients and extend shelf life.

- Transparent packaging: This is a powerful candy packaging method. It showcases your candy treats to entice customers before they buy. You should opt for this method if your candies have unique shapes, colors, and textures.

.

Pro Tip: Always label CBD products with detailed dosing instructions and include legal disclaimers where necessary.

.

At GummyGenix, we have different candy packaging equipment to streamline various steps and processes. Our automated packaging machines can handle different packaging containers, including bottles and pouches. They are capable of counting, weighing, bagging, individual gummy wrapping, flow wrapping, unscrambling, cartoning, capping, filling, and labeling.

.

Actionable Tips for Scaling Up Your Candy Business

Scaling a candy business requires strategic planning, investment in equipment, and effective management of increased production volumes. Below are detailed, actionable tips to help you scale your business and transition smoothly from small-batch production to large-scale manufacturing.

1. Identify Production Bottlenecks and Address Them with Automation

As your business grows, you may encounter bottlenecks in areas such as mixing, molding, or packaging. To scale efficiently, it’s important to identify these bottlenecks and implement solutions that allow for greater production output. The use of automation can significantly streamline these processes, reduce labor costs, and improve consistency.

Steps to Transition from Small-Batch to Automated Production:

- Start with Semi-Automation: If you're producing small batches manually, begin by investing in semi-automatic equipment. This will allow you to automate repetitive tasks like mixing, depositing, or molding without the significant upfront costs of fully automated machinery.

- Example: A small candy shop might start using a semi-automatic depositor to ensure uniform candy shapes and sizes, freeing up time for workers to focus on other tasks like packaging and quality control.

- Upgrade to Fully Automated Production Lines: As demand grows and production scales, consider upgrading to fully automated equipment that can handle larger production volumes. This might include automated machinery for molding, enrobing, cooling, and packaging.

- Pro Tip: Choose equipment that can grow with your business, such as modular production lines that allow you to add new machines as needed.

.

2. Leverage Co-Manufacturing or Outsourcing

If the upfront investment in automated equipment seems too costly, consider partnering with a co-manufacturer. These companies specialize in producing goods for other businesses, allowing you to outsource production without the overhead of buying new equipment.

Steps for Co-Manufacturing:

- Find a Reliable Partner: Research and vet co-manufacturers that have expertise in producing your specific type of candy, whether it’s gummies, hard candies, or CBD-infused products.

- Pro Tip: Ensure that the co-manufacturer complies with your required food safety standards, such as FDA or GMP certifications, especially if you’re working with regulated products like CBD-infused candies.

.

- Negotiate Flexible Terms: Structure your contract so that it allows for flexibility in terms of production volume. This will give you the ability to scale up without the need for significant upfront investment in machinery.

- Example: SmartSweets, a low-sugar candy brand, initially partnered with a co-manufacturer to scale their production quickly. This allowed them to focus on branding and marketing while the production was handled by an expert manufacturer. Once they reached a critical scale, they reinvested profits into their own manufacturing setup.

.

3. Secure Funding for Growth

Scaling a candy business often requires significant capital investment in equipment, raw materials, and labor. Securing funding is crucial to successfully scaling up.

Steps to Secure Funding for Your Candy Business:

- Explore Traditional Loans and Lines of Credit: Reach out to banks and credit unions that offer small business loans or lines of credit tailored to manufacturing businesses. Having a well-detailed business plan will increase your chances of securing favorable terms.

- Pro Tip: Highlight your company’s scalability, citing growing demand for specific candy products such as CBD-infused gummies or low-sugar candies. Use market research to back up your growth projections.

- If you're a small business looking to scale, platforms like Kiva or Fundera offer loan options specifically tailored for food and beverage startups. This can help you secure the necessary capital to invest in quality equipment.

.

- Seek Investment from Angel Investors or Venture Capitalists: Investors looking to enter the fast-growing health food or cannabis edibles sectors might be interested in investing in innovative candy businesses. Pitch your business’s unique selling points, such as sustainable packaging, organic ingredients, or CBD offerings.

- Example: Sugarfina, a luxury candy brand, raised funds through angel investors and venture capital firms. By positioning themselves as a luxury, adult-focused candy company, they were able to secure enough capital to open multiple retail locations and scale their online business.

.

- Consider Crowdfunding: Platforms like Kickstarter or Indiegogo can provide the funds needed for scaling while also building a loyal customer base. Many specialty candy businesses have successfully raised capital through crowdfunding by offering exclusive flavors, discounts, or early access to new products as rewards.

- Case Study: Crowdfunding Success

Project 7 , rebranded as JOYRIDE, a specialty gum and candy company, used crowdfunding to raise money for product development and scale their production of sugar-free, functional gum. Their campaign not only generated significant capital but also created a buzz around the product before it hit the shelves.

- Case Study: Crowdfunding Success

.

4. Optimize Production Space and Layout for Scaling

When scaling, it’s not just about upgrading your equipment—optimizing your production space is crucial to ensuring smooth operations. Efficient use of space can reduce production times, minimize bottlenecks, and ensure proper workflow.

Steps for Optimizing Production Space:

- Plan for Larger Equipment: As your production scales, ensure your facility can accommodate larger equipment. You may need to redesign the layout of your production floor to allow for clear pathways, easy access to materials, and efficient flow between production stages.

- Pro Tip: Use CAD (Computer-Aided Design) software to simulate different equipment layouts and choose the most efficient setup before making any major purchases or changes.

.

.

- Implement Lean Manufacturing Principles: Consider adopting lean manufacturing principles, such as just-in-time inventory and 5S (Sort, Set in order, Shine, Standardize, Sustain). These principles help streamline production processes, reduce waste, and improve efficiency.

- Example: Many successful candy companies, like Tootsie Roll Industries, have implemented lean manufacturing practices to ensure high production efficiency while maintaining product quality.

.

5. Expand Distribution Channels to Increase Reach

As you scale your production, expanding your distribution network will help you reach new markets and boost sales.

Steps to Expand Distribution Channels:

- Partner with Large Retailers: Work on getting your products into larger grocery chains or big-box stores like Walmart, Target, or Whole Foods. The credibility and shelf space in these stores can significantly increase your brand visibility.

- Pro Tip: Ensure that your production capacity can handle the increased demand that comes with large retail partnerships. Have automated production and packaging lines in place to fulfill large orders on tight deadlines.

.

- Go Global: Consider expanding into international markets where there is demand for innovative candies, such as functional gummies or low-sugar treats. For international growth, make sure your production processes and packaging meet the regulations of the countries you plan to enter.

- Case Study: Global Expansion

Haribo, the famous gummy candy brand, started in Germany and now operates in over 100 countries worldwide. By scaling their production capacity and adapting their products to suit the preferences and regulations of various international markets, Haribo became a global leader in the gummy candy industry.

- Case Study: Global Expansion

.

How to Choose the Right Candy Machinery Supplier

Choosing the right machinery supplier is crucial for ensuring that your candy business operates efficiently and scales successfully. Here are the key factors to consider when evaluating suppliers for candy production equipment.

1. Advanced Technology and Equipment Capabilities

The technology behind your candy production equipment directly affects your product quality, production efficiency, and ability to scale. Look for a single source candy equipment supplier that offers state-of-the-art features like automated depositing, temperature control, and low-pressure systems to ensure consistency and product integrity.

- Case Study: Scaling Gummy Production with Advanced Equipment

One company leveraged GummyGenix's state-of-the-art equipment to scale their gummy production from small batches to over 100,000 gummies per day. By upgrading to automated depositors and cooling tunnels, they increased their output without sacrificing quality. Their production line was modular, allowing them to expand seamlessly as their business grew.

Read the full case study.

.

2. Customization Options to Fit Your Business

Customization is key for candy businesses looking to produce niche products like CBD gummies, vitamin supplements, or multi-layered candies. A supplier that offers flexible, tailored machinery can help you meet specific production requirements while ensuring regulatory compliance.

- Case Study: Economical Gummy Machinery for a CBD and THC Startup

A CBD and THC startup turned to GummyGenix for a cost-effective machinery solution tailored to their unique needs. The equipment allowed them to produce high-quality, precise gummies in compliance with regulatory standards while staying within budget. The machinery’s flexibility also helped the startup scale their production as their business grew.

Read the full case study.

.

3. Competitive Pricing and Financing Options

The cost of equipment is a major factor when choosing a supplier, but it’s important to balance price with value. High-quality, long-lasting machines that can scale with your business are often more cost-effective in the long run.

- Affordable yet Scalable Solutions: Many businesses, especially startups, have benefitted from GummyGenix’s competitive pricing. Offering both cost-effective equipment and flexible financing options, GummyGenix ensures that you can scale your production efficiently while keeping capital costs manageable.

.

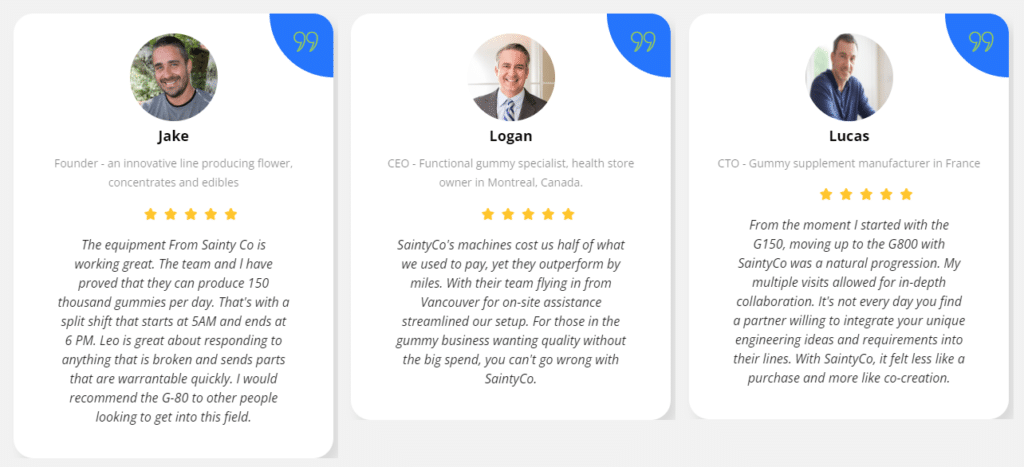

4. Customer Support and After-Sales Service

After-sales support is just as important as the initial purchase when selecting a supplier. Look for suppliers that offer ongoing technical support, maintenance packages, and accessible customer service.

- Reliable Customer Service: Both case studies mentioned above show that GummyGenix supports clients with comprehensive after-sales service, ensuring that equipment runs smoothly and can be easily upgraded as the business grows.

.

Client Testimonial:

.

5. Reputation and Client Success Stories

When choosing a supplier, research their track record. Case studies and client testimonials provide valuable insight into how a supplier’s equipment performs in real-world situations.

- Client Success Stories: The success stories from GummyGenix provide real-world examples of how businesses in both traditional and niche candy markets have used their equipment to increase production, improve efficiency, and scale successfully.

.

6. Compliance with Industry Regulations

If you're working with regulated products like CBD gummies or nutraceutical candies, your machinery must meet specific legal and safety standards. Choose a supplier that can ensure compliance with FDA, GMP, or local cannabis regulations.

- Regulatory Compliance: The case study on CBD and THC gummy production demonstrates how GummyGenix’s custom equipment helped a startup meet THC compliance regulations while producing accurate, consistent product dosages.

.

Here’s a breakdown of essential features to look for in a confectionery machinery supplier:

| Feature | Why It’s Important | GummyGenix | Supplier 1 | Supplier 2 | … |

| Advanced Technology | Ensures product consistency and efficient, scalable production. | State-of-the-art | |||

| Customization Options | Tailors equipment to your specific candy type and production needs. | Yes (Fully tailored) | |||

| Competitive Pricing | Provides value without compromising on quality or durability. | Competitive pricing | |||

| Comprehensive Support | Minimizes downtime with reliable customer service and maintenance. | 24/7 availability | |||

| Reputation and Reviews | Demonstrates proven results and satisfied clients in the industry. | Good reputation in the US, Canada, France and globally | |||

| Regulatory Compliance | Ensures machines meet FDA and other relevant food production standards. | Yes |

When selecting a machinery supplier for your candy or confectionery business, it’s essential to consider factors like technology, customization, pricing, and customer support. The right supplier will not only provide you with reliable equipment but will also support your business as it grows, helping you scale efficiently and meet consumer demand.

By carefully evaluating your options and considering the factors above, you can choose a supplier that aligns with your business goals and ensures the long-term success of your candy production.

.

Conclusion

Generally, starting a candy business can be a sweet venture, but it requires careful planning, strategic execution, and a passion for confectionery. You should follow the guidelines outlined in the post above to navigate the challenges and seize the opportunities. Consider GummyGenix candy production and packaging solutions to streamline your processes as you embark on this delicious entrepreneurial journey.

.

Contact us today for a free consultation and receive a customized equipment recommendation based on your candy production needs.