In gummy production, moisture control is crucial to getting the right texture. Too much moisture leads to sticky, misshapen gummies that nobody wants to eat. Proper moisture control also extends shelf life and keeps your customers happy. In this article, I’ll show you how to dehydrate gummy bears the right way so you can make sure your products are the best they can be.

To effectively remove moisture from gummy bears, the ideal temperature for drying should not exceed 80°F. You also need to control the humidity in the room where you’re drying them. You can do this by using a dehumidifier. Use hygrometers to measure humidity levels accurately and adjust your dehumidifiers accordingly. By carefully monitoring these conditions, you can consistently produce high-quality gummies.

.

.

Let's delve deeper into the details of each step.

Identify Sources of Moisture

When it comes to dehydrating gummy bears, identifying sources of moisture is paramount. Here are some key considerations:

- How much infiltration? Assess how often doors to outside rooms are opening and closing.

- What type of door is it? The type and quality of the door can significantly impact moisture levels.

- How well does the door seal? Check for any gaps that might let moisture in.

- Gaps in walls or ceiling: Ensure there are no breaches that could allow moisture to enter.

- HVAC system: Evaluate the system in place and how it might affect humidity. Consider using HVAC systems specifically designed for humidity control in food production environments.

- Room occupancy: Consider how many people are working in the room during a 24-hour cycle, as this can introduce additional moisture.

In smaller nutraceutical facilities, scaling up production without separate rooms for production and drying can lead to significant humidity issues, potentially ruining your products.

.

.

How to Remove Moisture from Gummies?

The most common method to remove moisture from gummies is open-air drying. This involves leaving the gummies in a dry place to air out for a few days. Gummies made from gelatin benefit from this method as it allows easy control and requires minimal equipment. Following industry guidelines, such as those from the FDA, can enhance the effectiveness of this method.

.

.

What Temperature to Dehydrate Gummy Bears?

Maintaining the correct temperature is crucial. The ideal temperature for drying gummy bears should not exceed 80°F. Monitoring the drying conditions with a temperature gauge ensures that the gummies dry evenly without becoming too hard or losing their shape. Utilizing automated temperature control systems can help maintain consistency in large-scale production.

.

How Long Do Gummies Need to Air Dry?

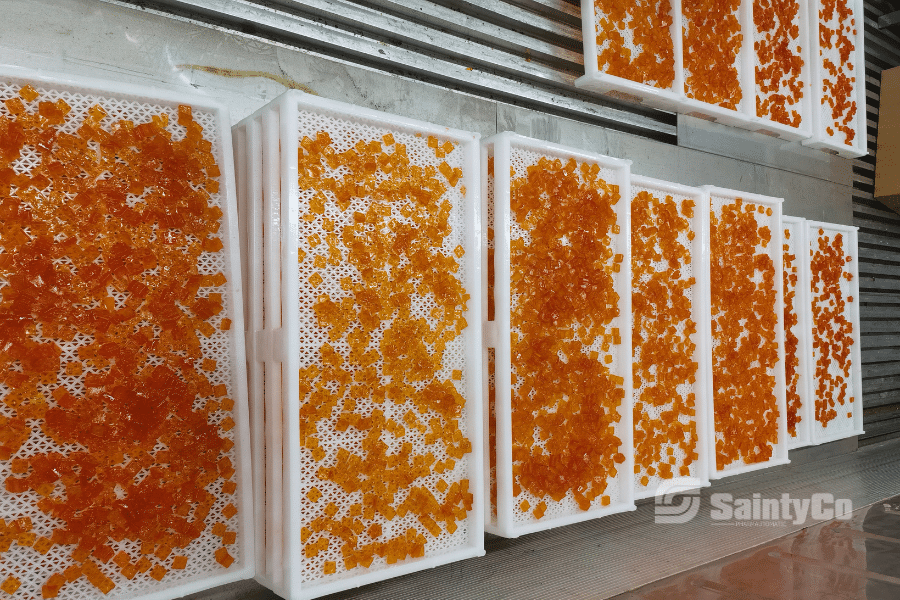

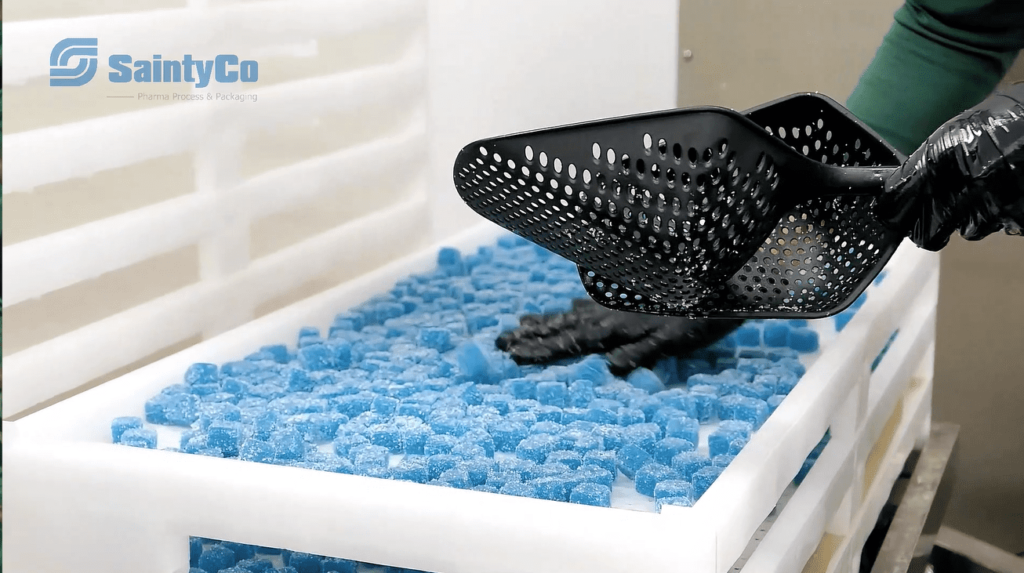

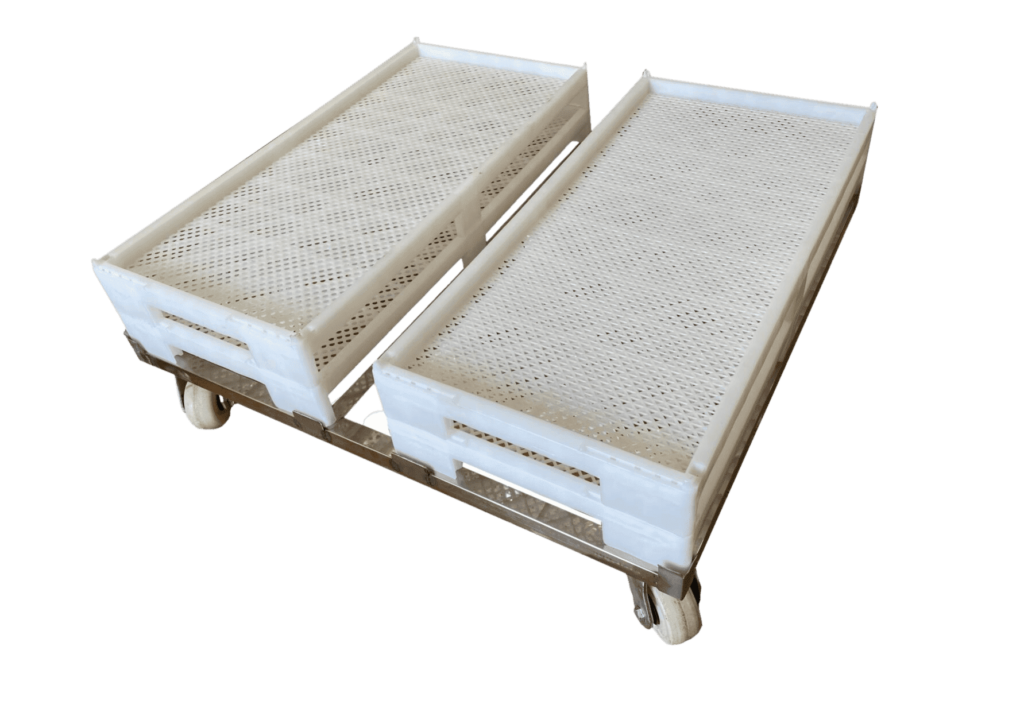

To begin, remove the gummies from the moulds and place them on drying trays. Allow them to air dry at room temperature for 2-48 hours, depending on your preference for texture and consistency. The 360° airflow provided by the slotted vent design of gummy drying trays does most of the work - reducing drying times by 25% or more. To further expedite the process, you can use industrial fans or dehumidifiers. Factors such as gummy thickness and room airflow can influence drying time.

.

.

How to Dehydrate Gummies?

In addition to air drying, using a dehumidifier can greatly improve the drying process by controlling the humidity levels in the drying room. This method ensures that the gummies dry uniformly and reduces the risk of mold or spoilage. Based on your specific needs, consider different types of dehumidifiers, such as desiccant or refrigerant models.

.

.

Why Are My Gummies Wet?

Gummies can become wet and sticky due to the use of citric acid. Citric acid is highly water-soluble and can pull moisture out of the gelatin, causing the candy to become wet and sticky. Applying the citric acid, sugar mix too soon after removing the gummies from the mold can exacerbate this issue. Preventive measures during the gummy-making process, such as allowing gummies to set properly before coating, can help.

.

How to Fix Sticky Gummies?

Sticky gummies can be a nuisance. To fix this, use a mixture of neutral-flavored oil and carnauba wax. A 90% oil and 10% carnauba wax mixture will coat the gummies, keeping them separate and preventing weeping. Ensure uniform coating and proper storage in airtight containers.

.

.

How to Stop Gummies from Sweating?

To keep your gummies from sweating, control the humidity in your production space. Dehumidifiers are your best friends here, and making sure your drying room is sealed tight will go a long way. Regular maintenance on your dehumidifiers is crucial for keeping things running smoothly.

.

What is the Best Humidity for Drying Gummies?

Ideally, you'll want to keep your relative humidity at 35 to 40% during drying. Go too high, and gummies stay sticky in the package. Go too low, and you create “case hardening,” where the outside dries too fast and the inside stays liquid. Tips on achieving and maintaining the ideal humidity levels include using hygrometers to monitor conditions and adjusting your HVAC and dehumidification systems as needed.

.

Summary

By understanding and controlling the various sources of moisture, you can significantly improve the quality of your gummies. Implementing these strategies will help you produce gummies that meet your quality standards and delight your customers.

Why GummyGenix by SaintyCo Can Help

At Gummygenix, powered by SaintyCo, we specialize in providing a wide range of gummy manufacturing equipment, including semi-automatic and fully automatic gummy machines, production and packaging lines, and auxiliary machines.

Our gummy production line equipment can be customized to meet your specific requirements. From entry-level solutions to grand-scale production lines, molding, and gummy coating, we have it all. We understand the complexities of gummy production and offer innovative, hygienic designs that meet the highest quality standards, including cGMP/GMP regulations, ISO 9001:2015, CE Electrical Certification, and FDA Quality Standards. With our global sales support and competitive pricing, we are committed to helping you achieve your production goals and maintain the quality your customers expect.

.

.

As a bonus, our extensive experience with real production environments and on-site visits means we can offer practical, hands-on advice for optimizing your drying rooms. Our team can conduct initial assessments to recommend the best equipment and practices, ensuring you achieve efficient and consistent gummy production and drying processes.

Explore our selection of high-quality commercial gummy machines and discover the best fit to enhance your production needs.

If you need more ideas about drying room design or to schedule a consultation on gummy machinery, don't hesitate to contact us at [email protected].