Ever wondered how those delightful jelly candies are made?

Jelly candies are produced by combining sugar, gelatin, flavorings, and colorings, which are then heated, mixed, and molded into their iconic shapes using specialized machinery. This process requires precision and quality control to ensure the perfect texture and taste.

While the basic steps might seem straightforward, the intricacies of jelly candy production involve much more than meets the eye. Let's delve into the detailed stages of this process, from ingredient selection to packaging, ensuring you get a comprehensive understanding of how these sweet treats make it from the factory to your mouth.

Jelly candies are made using gelatin.True

Gelatin is a key ingredient that gives jelly candies their texture.

Jelly candies are naturally colored.False

Artificial colorings are commonly used to achieve vibrant hues in jelly candies.

What Ingredients Are Used in Jelly Candy Production?

Ever wondered what's behind the sweet, chewy delight of jelly candies? Dive into the ingredients that make these treats irresistible, uncovering the secrets of their unique textures and flavors.

Jelly candies are primarily made using sugar, glucose syrup, and gelling agents like gelatin or pectin. Flavorings and colorings enhance the taste and appearance, while acids add tanginess. Preservatives ensure longevity.

Key Ingredients in Jelly Candy Production

1. Sugar and Glucose Syrup

Sugar is the backbone of jelly candies, providing sweetness and structure. Glucose syrup, a liquid sweetener1, enhances elasticity and prevents crystallization, ensuring a smooth texture.

2. Gelling Agents

- Gelatin: A protein derived from animal collagen, gelatin gives jelly candies their characteristic chewiness and firmness.

- Pectin: Extracted from fruits, pectin is used for a softer texture and is ideal for vegetarian-friendly options.

| Gelling Agent | Source | Texture |

|---|---|---|

| Gelatin | Animal Collagen | Firm |

| Pectin | Fruit | Soft |

3. Flavorings and Colorings

These are added to create the desired taste and visual appeal. Natural or artificial options exist, allowing customization to meet consumer preferences.

4. Acids

Citric acid or malic acid can be added to create a sour profile2, balancing the sweetness with a tangy kick.

5. Preservatives

These are crucial for extending shelf life by preventing microbial growth. Sorbic acid is a common choice in the candy industry.

Alternative Ingredients for Specific Markets

For those targeting the vegan market3, alternatives like agar-agar or carrageenan replace gelatin. This shift accommodates dietary preferences without compromising quality.

| Market | Gelling Agent Alternatives |

|---|---|

| Vegan | Agar-agar, Carrageenan |

| Vegetarian | Pectin |

Understanding these ingredients helps in crafting products that cater to diverse markets, whether you're aiming for traditional flavors or exploring innovative concoctions for niche audiences. The choice of ingredients can significantly influence not only taste and texture but also appeal to different dietary needs and cultural preferences.

Each ingredient plays a pivotal role in jelly candy production4, affecting factors from texture to shelf stability, making them vital components in creating these beloved confections.

Gelatin is used for a softer texture in jelly candies.False

Gelatin provides firmness and chewiness, not softness.

Pectin is ideal for vegetarian-friendly jelly candies.True

Pectin is fruit-derived, suitable for vegetarian diets.

How Does Gelatin Play a Role in Jelly Candy Texture?

Ever wondered why jelly candies have that perfect chewiness? The secret lies in gelatin. Dive into how this ingredient shapes the texture of your favorite sweets.

Gelatin is crucial in jelly candy texture, offering elasticity and chewiness. It forms a gel network that traps water, providing the candy's unique mouthfeel. This balance of firmness and flexibility distinguishes jelly candies from other sweets.

The Science Behind Gelatin's Role

Gelatin, derived from collagen, is a protein that transforms into a gel when dissolved in hot water and cooled. This transformation is key to creating the signature texture5 of jelly candies.

Gel Formation Process

When gelatin is heated, its triple helix structure unwinds into single strands. As it cools, these strands form a network, trapping water and other ingredients inside. This creates the elastic yet firm texture6 we associate with jelly candies.

| Property | Description |

|---|---|

| Elasticity | Provides chewiness |

| Firmness | Allows candies to hold shape |

| Mouthfeel | Offers a satisfying bite |

Comparing Gelatin to Other Gelling Agents

While gelatin is widely used, other gelling agents like agar-agar and pectin can also be used in candy-making. However, each has its own characteristics.

- Gelatin: Known for its smooth and flexible texture.

- Agar-Agar: A plant-based alternative, providing a firmer and more brittle texture.

- Pectin: Commonly used in fruit-based candies, offers a softer gel.

The Impact of Gelatin Concentration

Adjusting the amount of gelatin can significantly alter the candy's texture. Higher concentrations lead to firmer candies, while lower amounts offer softer products. Experimentation is key to finding the perfect balance for your gummy production7.

Practical Applications in Jelly Candy/Gummy Candy Manufacturing

Understanding gelatin's role allows manufacturers to fine-tune their products' texture. This knowledge is crucial for producing consistent quality in large-scale operations. By adjusting variables like gelatin concentration and cooling time, gummy producers can create a variety of textures8 to meet consumer preferences.

Gelatin's versatility makes it an indispensable ingredient in the confectionery industry, especially for those aiming to innovate in texture while maintaining quality.

Gelatin is derived from collagen.True

Gelatin is a protein obtained by processing collagen, usually from animal sources.

Agar-agar provides a more flexible texture than gelatin.False

Agar-agar results in a firmer and more brittle texture compared to gelatin.

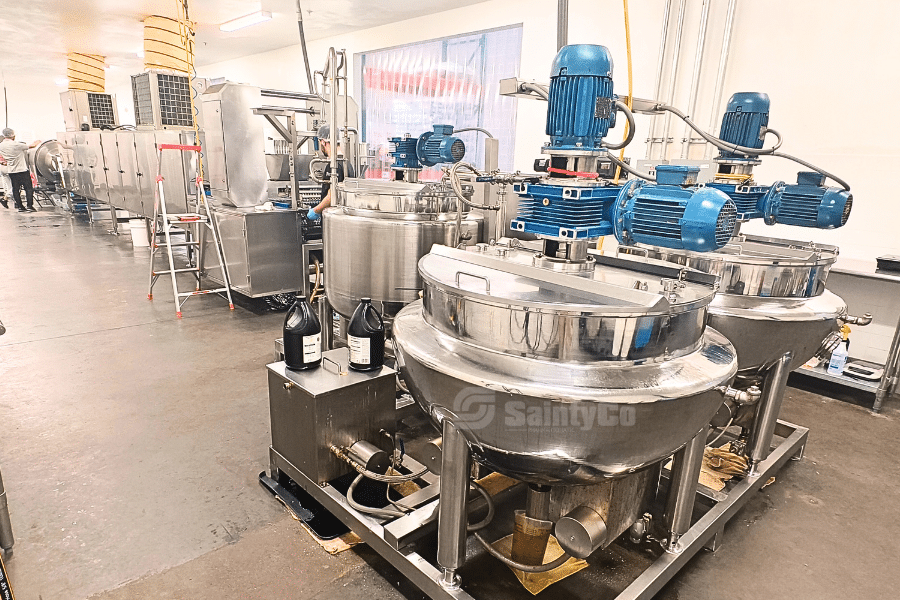

What Equipment is Essential for Making Jelly Candies?

Creating jelly candies requires more than just ingredients; it's about precision and the right tools. Discover the essential equipment needed to produce high-quality jelly candies effectively.

Key equipment for making jelly candies includes a cooking unit, a depositing machine, cooling tunnels, and packaging machinery. These tools ensure efficiency, consistency, and quality in candy production.

The Core Equipment List

To produce jelly candies, a robust setup is crucial. Here's a breakdown of the essential machinery:

| Equipment | Function |

|---|---|

| Cooking Unit | Heats ingredients to desired temperature |

| Depositing Machine | Accurately fills molds with jelly mixture |

| Cooling Tunnel | Ensures candies solidify at consistent rates |

| Packaging Machine | Wraps and seals finished candies |

Cooking Unit

The cooking unit is where it all begins. This equipment heats ingredients9 to the precise temperature required for optimal texture and flavor. A unit with precise temperature control can make all the difference.

Depositing Machine

Precision is key in candy production. The depositing machine ensures each mold10 receives the exact amount of jelly mix, maintaining consistency across batches.

Cooling Tunnel

Once molded, the jelly candies need to solidify properly. A cooling tunnel provides the controlled environment necessary to set candies uniformly11, preventing warping or melting.

Packaging Machine

Finally, packaging is more than just aesthetics. A reliable machine will wrap and seal your candies, protecting them from environmental factors and ensuring product longevity12.

Additional Considerations

Beyond core equipment, consider auxiliary tools like:

- Mixers: For blending ingredients smoothly.

- Mold Sets: Various shapes enhance market appeal.

- Quality Control Instruments: Ensure each batch meets your standards.

Investing in quality machinery is crucial for producing consistent jelly candies. Evaluate supplier credentials13 to avoid issues like certification fraud or shipping delays. Diversifying equipment sources can also mitigate supply chain disruptions. Consider global trends and innovations to stay competitive in the confectionery market.

A cooking unit is essential for jelly candy production.True

The cooking unit heats ingredients to the required temperature.

A packaging machine is optional for jelly candy making.False

Packaging machines are crucial to protect and seal candies.

How Do Packaging and Quality Control Affect Jelly Candies?

Packaging and quality control are vital in maintaining jelly candies' freshness and taste. They prevent spoilage and ensure consumer satisfaction by safeguarding against contamination.

Effective packaging shields jelly candies from moisture and contaminants, prolonging shelf life. Quality control ensures each candy meets safety and taste standards, enhancing consumer trust and brand reputation.

The Role of Packaging in Jelly Candy Preservation

Packaging serves as the primary defense against external factors that can degrade jelly candies. Moisture, air, and light are

common enemies that can spoil these delightful treats. By using materials such as

polypropylene or PET, manufacturers create a barrier that maintains freshness. These

materials are known for their durability and resistance to moisture.

Packaging Materials

| Material | Benefits |

|---|---|

| Polypropylene | High barrier to moisture, lightweight |

| PET | Strong, clear, excellent for product display |

Choosing the right packaging material14 is crucial for preserving flavor and texture. Considerations include cost, environmental impact,

and consumer appeal.

Quality Control: Ensuring Consistency and Safety

Quality control processes are critical in the jelly candy production line. From verifying raw ingredients to final product inspection,

every step must be monitored to meet safety regulations and maintain quality.

Automated systems help identify defects early, reducing waste and ensuring only the best

products reach consumers.

Key Quality Control Measures

- Ingredient Verification: Checking purity and concentration of flavors.

- Batch Testing: Ensuring consistency across production runs.

- Final Inspection: Detecting contaminants or packaging errors.

Integrating quality control measures15 builds consumer trust and prevents costly recalls.

Balancing Cost with Quality

Balancing packaging and quality control costs with product pricing is a challenge for manufacturers. Investing in superior packaging materials or advanced quality control may increase production costs, but it can also lead to higher consumer satisfaction and brand loyalty. Manufacturers must weigh these factors when developing their product strategy16.

Understanding the intricate balance between packaging, quality control, and cost management is crucial for any jelly candy manufacturer aiming for market success.

Polypropylene is moisture-resistant packaging for jelly candies.True

Polypropylene is known for its high barrier to moisture, preserving candy.

Quality control in jelly candy production prevents all defects.False

While it reduces defects, no system can prevent all possible issues.

Conclusion

Jelly candies are made by heating and mixing sugar, gelatin, flavorings, and colorings, then molding them into shapes. Precision in production ensures quality texture and taste.

As a candy manufacturer, choosing equipment requires looking beyond just jelly candies or gummy bears. A candy making machine should be versatile, allowing quick recipe changes and working seamlessly with both pectin and gelatin. This not only cuts costs but also keeps your production competitive and adaptable to market needs.

At GummyGenix by SaintyCo, we're here to support your journey with cutting-edge, GMP-compliant jelly candy/gummy bear manufacturing equipment designed for efficiency, precision, and adaptability. Jelly/gummy candy machines from GummyGenix by SaintyCo are manufactured to deliver on these priorities, offering efficient production, rapid changeovers, and support for diverse formulations. Our machines are fully compatible with regulatory standards, and we offer reliable after-sales support to keep your operations running smoothly.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality candy products to life—together.

Jelly Candy/Gummy Candy Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Discover how glucose syrup enhances texture and prevents crystallization in candies. ↩

-

Explore how acids balance sweetness with tanginess in jelly candies. ↩

-

Learn about plant-based gelling agents suitable for vegan candy production. ↩

-

Understand the key components that define jelly candies' texture and flavor. ↩

-

Learn how gelatin's properties influence candy texture for better understanding. ↩

-

Discover differences between gelatin and agar-agar in candy production. ↩

-

Explore how varying gelatin amounts affect candy firmness and chewiness. ↩

-

Uncover how gelatin enhances gummy texture in industrial production. ↩

-

Discover top-rated cooking units that offer precise temperature control and reliable performance. ↩

-

Learn about machines that offer precision deposition to maintain product consistency. ↩

-

Explore how cooling tunnels ensure uniform candy setting and prevent quality issues. ↩

-

Find out how advanced packaging solutions can extend your product's shelf life. ↩

-

Learn how to verify supplier certifications to avoid potential fraud risks. ↩

-

Learn about various packaging materials to choose the best one for preserving jelly candies. ↩

-

Explore effective quality control methods that ensure safe and consistent jelly candy production. ↩

-

Discover strategies to balance cost with quality in food production, ensuring profitability without sacrificing product standards. ↩