Ever wondered how gummy vitamins are made?

The process behind gummy vitamin manufacturing involves a series of steps including ingredient preparation, cooking, depositing, cooling, demolding, coating (optional) and packaging. Understanding this intricate procedure is essential for anyone looking to create or sell gummy vitamins, as it highlights both the technical and creative aspects of production.

This blog post will guide you through the complete manufacturing journey of gummy vitamins, offering insights that could prove invaluable whether you're entering the market or simply expanding your knowledge.

Gummy vitamins require cooking during manufacturing.True

The manufacturing process of gummy vitamins includes a cooking step to blend ingredients effectively.

Gummy vitamin production is solely a technical process.False

While technical, gummy vitamin production also involves creative aspects in formulation and design.

What Ingredients Are Essential for Gummy Vitamin Production?

Discover the fundamental ingredients needed to produce gummy vitamins that are both tasty and effective.

Essential ingredients for gummy vitamin production include gelling agents (gelatin or pectin), sweeteners (sugar or sugar substitutes), flavoring agents, coloring agents, vitamins, and preservatives. Each plays a critical role in texture, taste, and nutrition.

Key Ingredients for Gummy Vitamins

Gummy vitamins are typically formulated with a few common ingredients that help achieve the desired texture, taste, and nutritional benefits. Here’s a closer look:

-

Gelling Agents

The primary component of gummy vitamins is the gelling agent. The most commonly used agents include:- Gelatin: Derived from animal collagen, it gives gummies their chewy texture.

- Pectin: A plant-based alternative suitable for vegan formulations.

- Agar-Agar: Another vegetarian option, derived from seaweed, providing a firmer texture.

-

Sweeteners

Sweetness is crucial for making gummies palatable. Common sweeteners include:- Sugar: The traditional choice, although high in calories.

- Sugar Substitutes: Such as stevia or xylitol for sugar-free options.

-

Flavoring Agents

Flavoring is essential to create a delightful taste. Options may include:- Natural Flavors: Extracts from fruits or herbs.

- Artificial Flavors: Used for consistency and cost-effectiveness.

-

Coloring Agents

Colors enhance visual appeal. Types include:- Natural Colors: Derived from plants or vegetables (e.g., beet juice for red).

- Artificial Colors: Synthetic options that provide vibrant hues.

-

Vitamins and Nutrients

The core purpose of these gummies is to deliver vitamins and minerals such as:

| Vitamin | Purpose |

|---|---|

| Vitamin C | Immune support |

| Vitamin D | Bone health |

| B Vitamins | Energy metabolism |

| Omega-3 Fatty Acids | Heart health |

- Preservatives

To ensure shelf stability, preservatives may be added. Common choices include:- Citric Acid: Also adds tartness to the flavor profile.

- Potassium Sorbate: Prevents mold growth.

Production Process Insights

The combination of these ingredients must be carefully balanced. The production process involves mixing, cooking, and cooling the gummy mixture. Each ingredient plays a role in the final product's texture and taste. Here’s a brief overview:

- Mixing & Cooking: All ingredients are blended at controlled temperatures to achieve the desired consistency.

- Depositing: The mixture is poured into molds, where it takes shape.

- Curing: Gummies are cooled to set, ensuring they maintain their form.

For more insights on the gummy vitamin production process1, explore our detailed guide!

Considerations for Customization

When formulating gummy vitamins, customization can cater to specific market demands:

- Allergen-Free Options: Ensure products are free from common allergens like gluten or nuts.

- Vegan Formulations: Use pectin or agar instead of gelatin to appeal to vegan customers.

By understanding these essential ingredients and their roles, manufacturers can create gummy vitamins that not only meet consumer preferences but also stand out in a competitive market. For further exploration of ingredient sourcing, we can provide resource on [sourcing quality ingredients] globally.

Gelatin is a common gelling agent in gummy vitamins.True

Gelatin, derived from animal collagen, is widely used for its chewy texture in gummy vitamins.

Gummy vitamins can be made without any sweeteners.False

Sweeteners are essential for palatability, making gummies enjoyable to eat, so they cannot be made without them.

How Do Different Gummy Machines Affect Gummy Vitamin Quality?

Understanding how different gummy makimg machines affect gummy vitamin quality is essential for manufacturers aiming for excellence in their products.

The type of gummy machinery used in gummy vitamin production significantly influences quality. Semi-automatic gummy machines offer flexibility but may introduce variability, while fully automatic systems enhance consistency and efficiency.

The Role of Machines in Gummy Vitamin Production

Gummy vitamins are increasingly popular, but the manufacturing process is crucial for ensuring quality. Different machines can significantly impact the final product's consistency, potency, and overall appeal.

Semi-Automatic vs. Fully Automatic Machines for Gummy Vitamins Manufacturing

Semi-automatic gummy making machines are ideal for small operations. They require manual intervention, which can lead to variability in product quality. For example, manually transfer the slurry to a gummy depositor and demolding can introduce inconsistencies in texture and shape.

| Machine Type | Key Features | Impact on Quality |

|---|---|---|

| Semi-Automatic | Manual mold placement, basic cooling | Variable quality due to manual processes |

| Fully Automatic | Streamlined process, automatic controls | Consistent quality, high output |

Fully automatic gummy making machines, on the other hand, enhance quality control through automation. They ensure uniform ingredient mixing, precise syrup dispensing, and automated cooling, which minimizes human error.

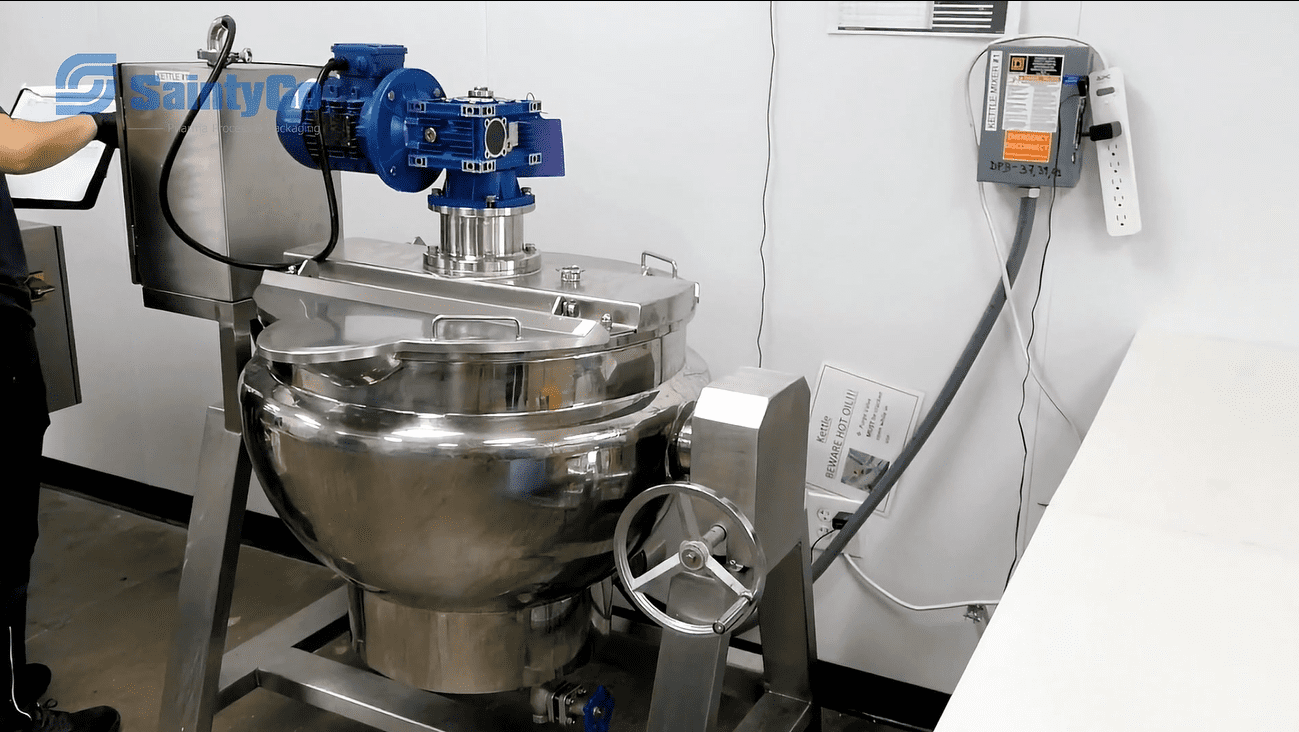

Cooking Equipment for Gummies Production: Ingredient Mixing and Cooking

The initial stages of gummy production—mixing and cooking—are critical. Cooking Machines for gummy vitamins that provide precise temperature control contribute to the consistency of the gummy base.

Cooking at exact temperatures is essential for activating gelling agents like gelatin or pectin,the latter is more sentitve to temperature. The cooking part equipped with advanced monitoring systems can maintain these temperatures accurately, which results in better consistency and texture in the final product.

|

|

|---|

Jacket Cooker with High-Shear Mixer blending vibrant gummy candy mixture in a modern facility | Machine Brand: SaintyCo | Click to know more

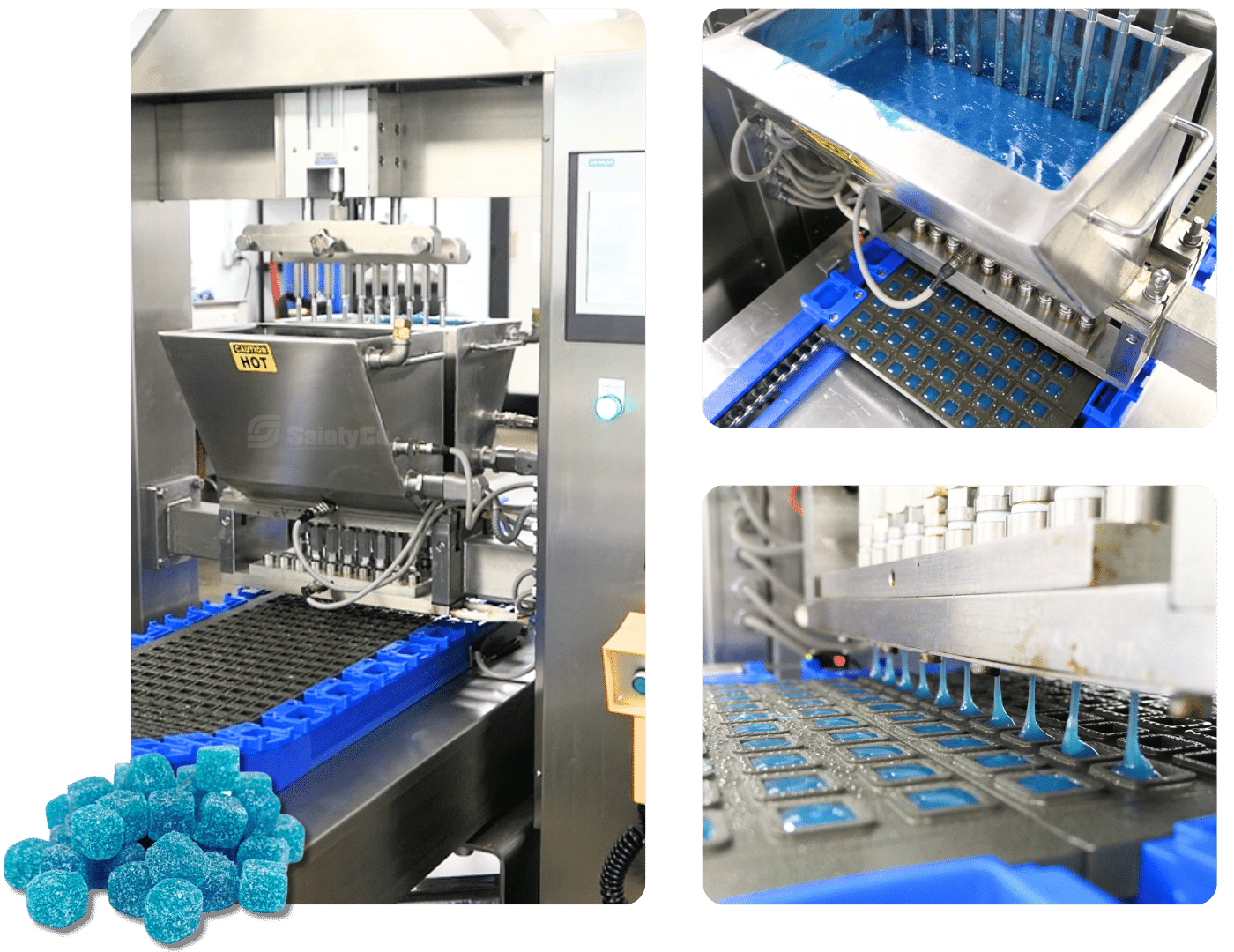

Gummy Depositing and Molding Equipment: Precise Dosing and Consistency

Depositing and molding are essential for shaping gummies accurately and ensuring precise dosing of active ingredients such as vitamins. High-quality depositing ensures consistency in size, weight, and ingredient distribution, which is particularly important for functional gummies.

Quality control is paramount in gummy vitamin production. Machines with integrated quality control features can monitor important parameters like water activity levels and vitamin potency in real-time. This ensures that each batch meets regulatory standards and consumer expectations.

| Quality Control Feature | Benefits |

|---|---|

| Water Activity Meters | Prevents spoilage and maintains freshness |

| Automated Quality Checks | Ensures batch consistency and compliance |

Implementing these features not only enhances product quality but also builds trust with consumers who are increasingly conscious about supplement efficacy.

Gummy Polishing Machine: Coating and Aesthetic Appeal

The gummy coating process is another area where machines play a significant role. Different types of coatings (e.g., sugar coating, oil coating) can enhance the visual appeal and taste of gummy vitamins.

Polishing/sanding Machines designed for coating vitamin gummies can apply these layers evenly, which prevents clumping and improves presentation. This can be a deciding factor for consumers when choosing between products on the shelf.

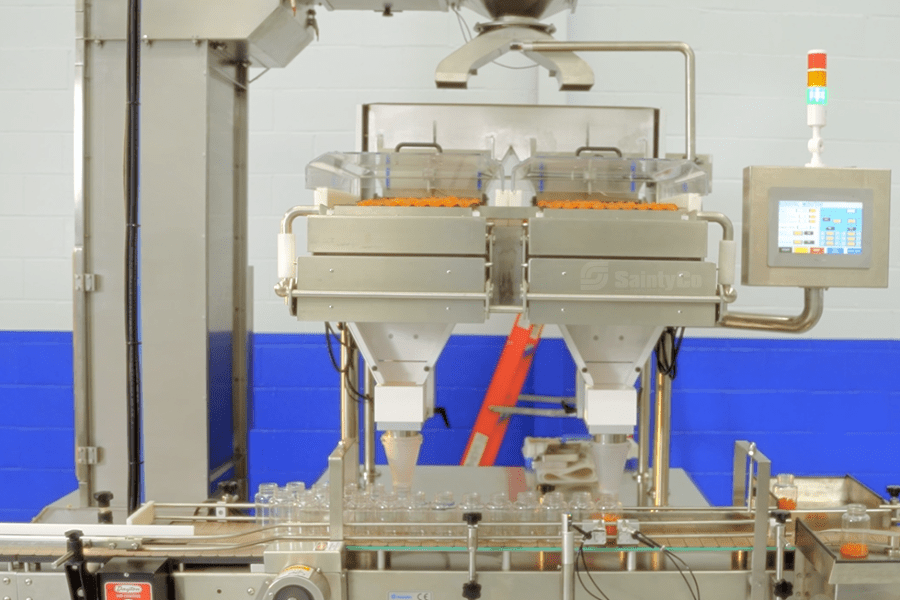

Gummy Packaging Machines:Packaging Impacts Quality

Finally, the packaging stage cannot be overlooked. The type of machinery used for packaging gummy vitamins affects how well the products are preserved. Automated packaging machines ensure accurate filling, sealing, and labeling. Proper packaging maintains freshness and protects against contamination.

| Packaging Variant | Advantages |

|---|---|

| Bottles | Excellent for visibility and protection |

| Pouches | Lightweight and space-efficient |

| Eco-friendly Options | Appeals to sustainability-conscious buyers |

Investing in quality machinery at every stage of gummy vitamin production can lead to superior products that not only meet but exceed consumer expectations.

|

|

|---|

GummyCount 90 ensures flawless accuracy and speed, bottling up to 60 containers per minute for gummy vitamins, combining precision, hygiene, and unmatched efficiency | Machine Brand: SaintyCo | Click to know more

Semi-automatic machines ensure consistent gummy vitamin quality.False

Semi-automatic machines introduce variability due to manual processes, affecting consistency in gummy vitamins.

Fully automatic machines enhance quality control in production.True

Fully automatic machines provide precise controls, ensuring uniform mixing and minimizing human error, thus improving product quality.

What Are the Key Steps in Quality Control During Gummy Production?

Understanding the key steps in quality control during gummy production is vital for ensuring product excellence. This section outlines essential practices that manufacturers should adopt.

Key steps in quality control during gummy production include establishing quality standards, implementing a control plan, training staff, conducting audits, utilizing technology, and practicing continuous improvement.

1. Establishing Quality Standards

Before production begins, it's crucial to set clear quality standards for your gummy vitamins. These should align with industry regulations and consumer expectations. Common standards include:

| Standard Type | Examples |

|---|---|

| Nutritional Content | Vitamin potency, calorie count |

| Safety Regulations | Allergen labeling, ingredient sourcing |

| Manufacturing Practices | ISO certifications, HACCP protocols |

Setting these standards will serve as a benchmark during the quality control process.

2. Implementing a Quality Control Plan

A well-defined quality control plan is essential. This plan outlines the procedures and methodologies to ensure that each batch meets the established standards. Key components include:

- Inspection Protocols: Regular checks on raw materials and finished products.

- Testing Procedures: Methods for assessing texture, moisture content, and vitamin potency.

Consider integrating automated systems for real-time monitoring, which can enhance accuracy and efficiency in quality control2.

3. Training Staff on Quality Practices

Your team plays a critical role in maintaining quality. Regular training ensures that staff understand:

- The importance of quality control.

- Specific procedures for monitoring and testing.

Additionally, fostering a culture of quality can motivate employees to take ownership of their roles in the production process. Implementing a training program3 can lead to significant improvements.

4. Conducting Regular Audits

Scheduled audits are vital for assessing compliance with quality standards. These audits should cover:

- Equipment functionality

- Process adherence

- Employee performance

Conducting these audits can reveal potential issues before they escalate, ensuring product reliability and compliance with regulatory standards4.

5. Utilizing Technology for Quality Control

Incorporating technology into your quality control processes can greatly enhance efficiency. Tools such as:

- Automated Inspection Systems: Can detect defects in real-time.

- Data Analytics Software: Helps identify trends and areas for improvement.

By leveraging technology, you can streamline operations and improve accuracy in quality assessments5.

6. Continuous Improvement Practices

Quality control is not a one-time effort; it requires continuous improvement. Implement strategies like:

- Feedback Loops: Gather insights from customers and staff to improve processes.

- Kaizen Events: Regularly assess processes for efficiency gains.

Adopting a mindset of continuous improvement can foster innovation and help maintain high-quality standards in production.

Quality standards must align with industry regulations.True

Establishing quality standards ensures compliance with industry regulations and meets consumer expectations, which is crucial for product safety and reliability.

Regular audits are unnecessary for quality control.False

Conducting regular audits is essential to assess compliance with standards and identify potential issues, making them vital for effective quality control.

How Do Flavor and Shape Influence Consumer Preference?

The interplay between flavor and shape is essential in shaping consumer preferences for gummy vitamins. Let's explore how these two elements impact buying decisions.

Flavor and shape significantly influence consumer preference in gummy vitamins by enhancing taste perceptions and visual appeal. Unique flavors create differentiation, while engaging shapes foster brand recognition and loyalty.

Understanding Flavor's Role in Consumer Preference

Flavor plays a critical role in attracting consumers to gummy vitamins.

Studies show that flavor is often the first sensory attribute consumers notice.

A pleasant taste can lead to repeat purchases and brand loyalty.

Companies should consider offering unique flavors like exotic fruit blends6 that can create differentiation in a crowded market.

When developing flavors, think about seasonal trends as well. For example, pumpkin spice flavors can attract consumers during fall.

Innovative flavor combinations can also cater to niche markets, such as wellness-focused consumers looking for herbal infusions7.

The Impact of Shape on Consumer Attraction

Shape significantly influences consumer perception and preference.

Gummy vitamins can be molded into various shapes, including bears, fruits, or even custom logos.

These shapes can enhance visual appeal and brand recognition, making products more memorable. For instance, using unique molds can lead to a better customer experience and foster emotional connections.

Consider creating a fun, engaging design that resonates with your target audience, such as educational shapes8 that teach children about vitamins.

Color Psychology and Its Influence on Taste Perception

Color is another crucial aspect that can affect consumer choices.

Research indicates that people often associate colors with specific flavors. For example, a red gummy might be perceived as strawberry-flavored, while a green one could suggest apple.

Understanding this connection can help manufacturers design their products more effectively.

Utilizing bright, attractive colors in your packaging can grab attention on store shelves.

Moreover, consistent color usage across product lines can strengthen brand identity.

The Synergy of Flavor and Shape in Marketing Strategies

Combining appealing flavors with engaging shapes can significantly enhance marketing efforts. For example, limited edition flavors or seasonal shapes can entice consumers to try new products.

Develop marketing campaigns that emphasize both aspects, showcasing the fun side of gummy vitamins through vibrant imagery and taste descriptions.

Use social media platforms to gather feedback and create buzz around new flavors and shapes before launch. This interactive approach can drive consumer engagement and excitement, leading to increased sales and brand loyalty.

Flavor is the first sensory attribute consumers notice in gummies.True

Research shows that flavor is often the initial characteristic that attracts consumers to gummy vitamins, influencing their purchasing decisions.

Unique shapes improve brand recognition of gummy vitamins.True

Custom shapes enhance visual appeal and create memorable experiences, leading to better brand recall among consumers.

What Trends Are Emerging in Gummy Vitamin Manufacturing?

Gummy vitamin manufacturing is rapidly evolving, influenced by consumer preferences for health, innovation, and sustainability. Let’s explore the key trends shaping this industry.

Emerging trends in gummy vitamin manufacturing include a shift towards health-conscious formulations, customization of shapes and flavors, technological advancements in production processes, and sustainable packaging solutions.

Emerging Trends in Gummy Vitamin Manufacturing

The gummy vitamin industry is experiencing notable trends that reflect shifting consumer preferences and advancements in manufacturing technologies. With a projected market size of $52.24 billion by 2030, staying updated on these trends is crucial for manufacturers looking to maintain competitive advantages.

1. Health-Conscious Formulations

Consumers are increasingly seeking healthier options. This includes:

- Vegan and Plant-Based Options: The shift towards plant-based diets has led to the incorporation of pectin, moving away from gelatin derived from animals. This aligns with growing health awareness and caters to vegan consumers.

- Allergen-Free and Sugar-Free Choices: Manufacturers are responding to dietary restrictions by creating gummies that are free from common allergens and sugar substitutes, appealing to a broader audience. For more information, check out this detailed guide9.

| Trend | Description | Example |

|---|---|---|

| Vegan Options | Use of pectin instead of gelatin | Gummy bears |

| Sugar-Free Alternatives | Substitutes like stevia or xylitol | Multivitamins |

| Allergen-Free Products | Free from gluten, nuts, soy | Immune gummies |

2. Customization and Unique Shapes

Brand differentiation through custom molds is another growing trend. The unique shapes not only enhance consumer experience but also aid in brand recognition.

- Custom Shapes: Brands are creating gummies in various fun shapes like animals, fruits, or logos. This strategy encourages consumer loyalty and enhances market appeal.

- Flavor Innovation: Experimenting with exotic flavors can set products apart. For instance, tropical blends or herbal infusions may target niche markets effectively. Read more about flavor customization here10.

3. Technological Advancements in Production

The emergence of advanced manufacturing technologies is reshaping gummy vitamin production:

- Automation: Fully automatic machines streamline production, reducing labor costs and increasing efficiency. High-output systems can produce up to 240,000 gummies per hour.

- Quality Control Systems: Automated checks for texture, moisture content, and vitamin potency ensure product consistency and regulatory compliance. Learn about the latest technologies in gummy manufacturing here11.

4. Sustainable Packaging Solutions

With a rise in eco-conscious consumers, manufacturers are focusing on sustainable packaging options:

- Eco-Friendly Materials: Packaging options that reduce environmental impact are becoming essential for brand loyalty among sustainability-minded consumers.

- Innovative Packaging Designs: Employing biodegradable or recyclable materials can set brands apart in a crowded market.

| Packaging Type | Features | Benefits |

|---|---|---|

| Eco-Friendly Pouches | Biodegradable materials | Reduces environmental impact |

| Bottles | Recyclable plastics | Widely accepted by consumers |

| Flexible Packaging | Lightweight and space-saving | Cost-effective shipping |

By embracing these emerging trends, gummy vitamin manufacturers can position themselves strategically in a competitive market. Staying informed about consumer preferences and technological advancements will ensure they meet evolving demands effectively.

All gummy vitamins are made with gelatin as a base ingredient.False

This claim is false; many gummy vitamins now use pectin for vegan options instead of gelatin.

How Can Small Businesses Compete in the Gummy Vitamin Market?

Discover how small businesses can thrive in the competitive gummy vitamin market with strategic insights and innovative approaches.

Small businesses can compete in the gummy vitamin market by differentiating their products through unique formulations, effective branding, efficient production methods, and targeted marketing strategies.

Understanding Market Dynamics

Small businesses can effectively compete in the gummy vitamin market by understanding key market dynamics. According to projections, the gummy vitamin market is expected to reach $52.24 billion by 2030. To capitalize on this growth, entrepreneurs should focus on factors driving consumer preferences such as health awareness and the demand for vegan options. Emphasizing these aspects in marketing strategies can attract a broader audience.

Leveraging Unique Product Offerings

Differentiation is crucial. Small businesses should explore unique product offerings like vegan and allergen-free gummies. By using ingredients like pectin instead of gelatin, companies can cater to the growing demand for plant-based supplements. Consider also offering sugar-free options that use natural sweeteners, appealing to health-conscious consumers.

| Product Type | Key Features | Target Audience |

|---|---|---|

| Vegan Gummies | Plant-based, gelatin-free | Vegans, vegetarians |

| Sugar-Free Gummies | Natural sweeteners, low-calorie | Health-conscious |

| Allergen-Free Gummies | Free from common allergens | Allergy sufferers |

Utilizing Customization and Branding

Custom shapes and flavors can significantly enhance brand recognition and customer loyalty. Small businesses can invest in custom molds to create unique gummy shapes that resonate with their target demographic. Additionally, experimenting with diverse flavors can set your product apart. For example, introducing tropical or herbal flavors can tap into niche markets.

Efficient Production Techniques

Investing in the right machinery is vital for scaling production without compromising quality. Small businesses can start with semi-automatic machines that allow for flexibility in batch sizes. As demand grows, transitioning to fully automatic systems can optimize efficiency. For instance, SaintyCo's G800 machine12 handles up to 240,000 gummies/hour, making it suitable for high-volume production.

Marketing Strategies for Visibility

Effective marketing strategies can help small businesses gain visibility in a crowded market. Utilizing social media platforms and influencer partnerships can amplify brand awareness. Creating informative content around the benefits of gummy vitamins and engaging storytelling can captivate potential customers. Explore opportunities for SEO optimization by incorporating relevant keywords into website content and product descriptions.

Building Trust Through Certifications

Obtaining certifications like FDA, Halal, and Kosher can enhance credibility and trust among consumers. These certifications signal adherence to high-quality standards and can significantly impact purchasing decisions, especially in competitive markets where consumers are discerning about product origins.

By focusing on these strategic areas, small businesses can carve out a niche in the gummy vitamin market, leveraging unique offerings, efficient production methods, and effective marketing techniques.

Custom molds can enhance brand recognition for gummy vitamins.True

Investing in custom molds for unique gummy shapes can significantly boost brand visibility and customer loyalty in a competitive market.

Conclusion

Explore the detailed process of gummy vitamin manufacturing, including key ingredients, production steps, quality control practices, and current market trends influencing this growing industry.

At GummyGenix by SaintyCo, we're here to support your journey with cutting-edge, GMP-compliant gummy manufacturing equipment designed for efficiency, precision, and adaptability. Our machines are fully compatible with regulatory standards, and we offer reliable after-sales support to keep your operations running smoothly.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality gummy products to life—together.

Gummy Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

This link provides a comprehensive overview of the production process, which can enhance your understanding of ingredient roles. ↩

-

This link provides valuable insights on effective quality control strategies that can enhance your production processes. ↩

-

Explore this resource to learn about the latest technology used in quality control and how it can optimize your operations. ↩

-

This article highlights the importance of continuous improvement in quality management and offers actionable strategies. ↩

-

Learn how to conduct effective audits in manufacturing to ensure compliance with industry standards through this informative guide. ↩

-

Clicking this link provides deeper insights into flavor trends in the gummy vitamin market, helping you stay competitive. ↩

-

Explore how custom shapes in gummy vitamins can boost brand recognition and consumer engagement. ↩

-

Learn more about color psychology in food marketing to enhance your product appeal. ↩

-

This link provides up-to-date insights on market growth and innovations within the gummy vitamin sector. ↩

-

Learn how automation is revolutionizing gummy production processes for efficiency and quality. ↩

-

Explore sustainable packaging solutions that can enhance your brand's appeal to eco-conscious consumers. ↩

-

Explore proven tactics that small businesses can adopt to successfully enter the gummy vitamin market and differentiate their products from larger competitors. ↩