Fibre Gummies Production: How to Perfect Texture and Quality?

Fibre gummies are a growing segment in the health supplement market. To manufacture them successfully, focus on key aspects such as ingredient selection (like inulin and pectin), precise temperature control, effective moulding techniques, and appropriate packaging solutions. Each stage of production presents unique challenges that can be optimized for efficiency and quality. Proper management of moisture levels during drying and cooling is crucial for achieving the desired texture. Additionally, adhering to regulatory standards ensures product safety and builds consumer trust. By understanding these factors, manufacturers can create fibre gummies that are not only tasty but also beneficial for health.

Flood & Scrape vs. Gummy-Making Machines: Which Is Best for Your Production?

Gummy-making machines offer significant advantages over the traditional Flood & Scrape method in gummy production. These machines provide enhanced efficiency, consistency, and scalability, making them ideal for expanding businesses. By minimizing waste through precision dosing and automated cleaning systems, they ensure higher quality and more reliable output. Automation also allows for better control of ingredient handling and environmental factors, reducing human error and improving product uniformity. As demand for gummies grows, investing in modern machinery not only supports sustainability but also aligns with regulatory compliance needs in industries like nutraceuticals and CBD. Ultimately, while initial costs may be higher, the long-term benefits of reduced labor expenses and increased production capacity make gummy machines a cost-effective choice for manufacturers aiming to scale their operations effectively.

Pharma Grade vs. Confectionery Gummy Machines: What’s the Difference?

This article compares pharma-grade and confectionery-grade gummy production machines, highlighting differences in regulatory compliance, material integrity, cleaning protocols, precision, and cost to guide informed purchasing decisions.

What Are the Expert Tips for Making CBD Gummies?

Learn expert tips for making high-quality CBD gummies at home. Discover the importance of choosing the right CBD extract, ingredient selection, dosage precision, and essential equipment for successful production.

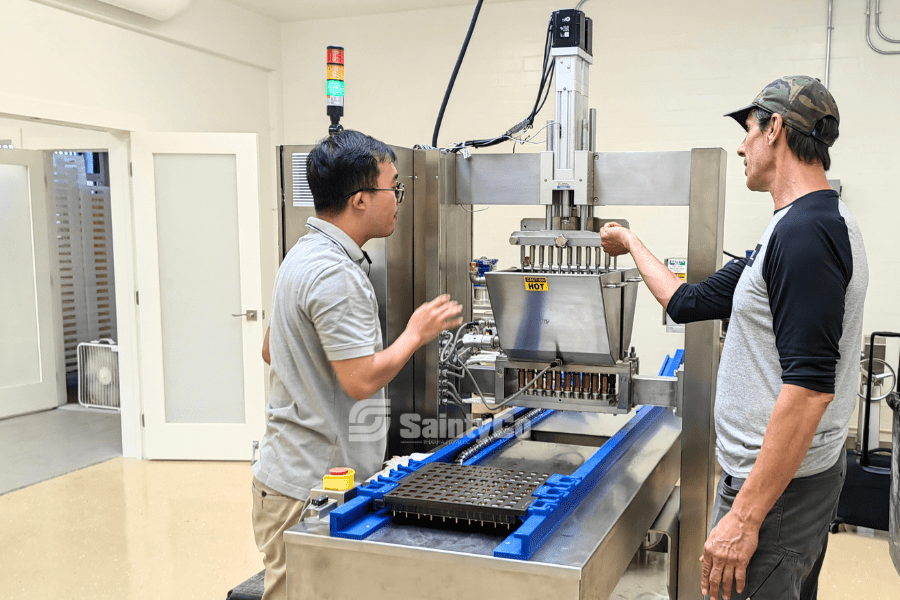

Should You Invest in Gummy Manufacturing Equipment Now?

The gummy market is booming, especially in health and wellness sectors. With such growth, it’s essential to consider if now is the right time to invest in gummy manufacturing equipment. This article dives deep into market trends, automation benefits, compliance considerations, and technological advancements that can impact your decision to invest.

Gummy Production Line Maintenance: Daily & Deep Cleaning Tips

Maintaining hygiene in gummy production is crucial. This guide outlines effective daily and weekly cleaning methods, safety protocols, and best practices to ensure optimal machine performance and product quality.

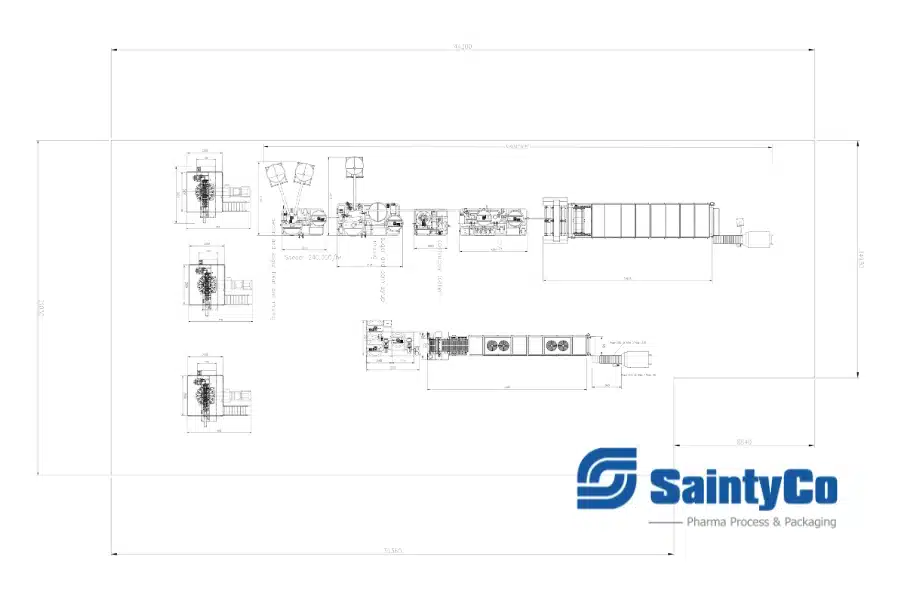

Gummy Production Line Layout: How to Optimize Machine Placement and Integration?

This blog explores how to optimize gummy production layouts and machine integration for enhanced efficiency. Key strategies include selecting compatible equipment, optimizing workflows, ensuring safety compliance, and maximizing space utilization.

Semi-Automatic vs. Fully-Automatic Gummy Machines: What Are the Key Differences?

This blog post explores the key differences between semi-automatic and fully-automatic gummy machines, focusing on automation levels, operational efficiency, cost implications, production speed, and maintenance needs to guide your investment decision.

What is the Process Behind Gummy Vitamin Manufacturing?

This blog post explores the intricate process of gummy vitamin manufacturing, detailing essential ingredients, production techniques, quality control measures, and emerging trends shaping the industry. Learn how to create effective and appealing gummy vitamins.

How Are Sour Gummy Worms Made: Which Production Method Is Best, Starch Mogul or Starchless Depositing?

This blog post explores the production methods for sour gummy worms, comparing Mogul lines and starchless depositing. It highlights their advantages, challenges, and key considerations for manufacturers to make informed decisions.