Embarking on the journey to establish a supplements and OTC gummies factory in the UK?

Setting up a supplements and OTC gummies factory in the UK involves several key steps including regulatory compliance, choosing the right gummy manufacturing equipment, sourcing materials, and ensuring a smooth production process. Understanding these elements is crucial for a successful launch.

Dive deeper into this guide as we explore each essential step and provide valuable insights to help you navigate the complexities of setting up your manufacturing facility.

Regulatory compliance is essential for factory setup in the UK.True

Establishing a supplements factory requires adherence to UK regulations to ensure safety and legality.

Choosing the right equipment is optional for manufacturing success.False

Selecting appropriate machinery is crucial for efficient production and quality control in the factory.

What are the regulatory requirements for gummy manufacturing in the UK?

Navigating the regulatory landscape for gummy manufacturing in the UK is crucial for ensuring product safety and compliance. Understanding these requirements can pave the way for successful operations.

To manufacture gummies in the UK, register with the Food Standards Agency, adhere to health claims regulations, follow Good Manufacturing Practices (GMP), ensure labeling compliance, and conduct regular audits.

Regulatory Compliance and Registration

To start manufacturing gummies in the UK, it’s essential to register your factory with the Food Standards Agency (FSA). This registration must occur 28 days before production begins. Failing to comply can lead to operational delays or fines.

Additionally, if your gummies include any new ingredients, such as CBD, they may require novel foods approval. This regulatory framework ensures that all food products, including supplements, meet safety and health standards.

Health Claims and Labeling Regulations

When making health claims about your gummies, you must adhere to UK regulations. Claims must be supported by scientific evidence and comply with the Nutrition and Health Claims Regulation. Misleading or unsubstantiated claims can result in significant penalties.

Ensure that your product labels include:

- Allergen information

- Accurate nutritional values

- Child-resistant packaging for OTC products

For more details on labeling standards, check out labeling guidelines1.

Good Manufacturing Practices (GMP)

Following Good Manufacturing Practices (GMP) is crucial for ensuring product quality. You may consider obtaining ISO 9001 certification, which signals a commitment to quality management. This not only enhances credibility but also reassures customers about product safety.

Regular Audits and Ongoing Compliance

Conducting regular audits is vital for maintaining compliance with GMP and UK food safety regulations. Staying updated on any changes in legislation will help you adapt and ensure ongoing adherence to required standards. Scheduling these audits can prevent issues down the line. For tips on effective auditing practices, explore audit techniques2.

Summary of Key Regulatory Requirements

| Requirement | Details |

|---|---|

| Factory Registration | Register with the FSA 28 days before production starts |

| Health Claims | Ensure all claims are scientifically supported and comply with regulations |

| Labeling Compliance | Include allergen information, nutrition values, and child-resistant packaging |

| GMP Compliance | Follow GMP standards and consider ISO 9001 certification |

| Regular Audits | Conduct internal audits for ongoing compliance with food safety laws |

For those looking to delve deeper into specifics regarding novel foods or health claims, check out food safety regulations3.

Gummy manufacturers must register with the FSA 28 days prior.True

Registration with the Food Standards Agency is mandatory for gummy production, ensuring compliance with UK food safety regulations.

Health claims on gummies can be made without scientific evidence.False

All health claims must be supported by scientific evidence to comply with UK regulations and avoid penalties.

How can I ensure compliance with UK food safety standards?

Ensuring compliance with UK food safety standards is vital for any food business. Understanding regulations, maintaining quality control, and training staff can help meet these standards effectively.

To ensure compliance with UK food safety standards, register with the Food Standards Agency, adhere to Good Manufacturing Practices (GMP), and train staff on hygiene and labeling requirements.

Understanding UK Food Safety Standards

To ensure compliance with UK food safety standards, it's crucial to understand the regulations set forth by the Food Standards Agency (FSA). Compliance begins with registration and adherence to guidelines that govern food production, hygiene, and labeling.

-

Registration with Authorities: Your factory must be registered with the FSA at least 28 days before commencing operations. This registration confirms that your facility meets health and safety standards.

-

Health Claims Compliance: If your gummies make health claims, these must align with UK regulations. For instance, new ingredients like CBD may require novel foods approval. You can learn more about health claim regulations4 for a clearer understanding.

-

Good Manufacturing Practices (GMP): Adopting GMP is essential for maintaining quality and safety in production. Obtaining ISO 9001 certification can further enhance your credibility in the market.

Key Areas of Focus for Compliance

Several aspects are critical in maintaining compliance within your operations:

| Area | Description | Importance |

|---|---|---|

| Labeling Compliance | Ensure labels include allergen information and accurate health claims. | Prevents legal issues and consumer deception. |

| Packaging Standards | Child-resistant and tamper-evident packaging is a must for OTC products. | Ensures product safety for consumers. |

| Quality Control | Implement regular quality checks throughout the production process. | Maintains product consistency and safety. |

Training Staff on Compliance

Training staff is another crucial component of compliance:

- Conduct regular training sessions on food safety protocols.

- Ensure staff understands proper hygiene practices and equipment usage.

- Familiarize team members with the legal requirements relevant to their roles.

Consider providing resources or links to training programs available online, such as food safety training5.

Ongoing Compliance Measures

Maintaining compliance is an ongoing effort:

- Regular Audits: Schedule internal audits to verify adherence to food safety standards and GMP.

- Stay Informed: Keep abreast of any changes in legislation that may affect your operations.

- Documentation: Maintain thorough records of production processes, quality checks, and staff training for reference during inspections.

By focusing on these areas, you can create a comprehensive strategy to ensure compliance with UK food safety standards.

Registration with FSA is required before food production starts.True

Food businesses must register with the Food Standards Agency 28 days prior to commencing operations to comply with UK food safety standards.

GMP certification guarantees compliance with food safety laws.False

While GMP certification enhances credibility, it does not alone guarantee full compliance with all food safety regulations in the UK.

How do I choose the right equipment for my gummies factory?

Choosing the right equipment for your gummies factory is crucial for quality production. This guide breaks down essential equipment and considerations to help you make informed decisions.

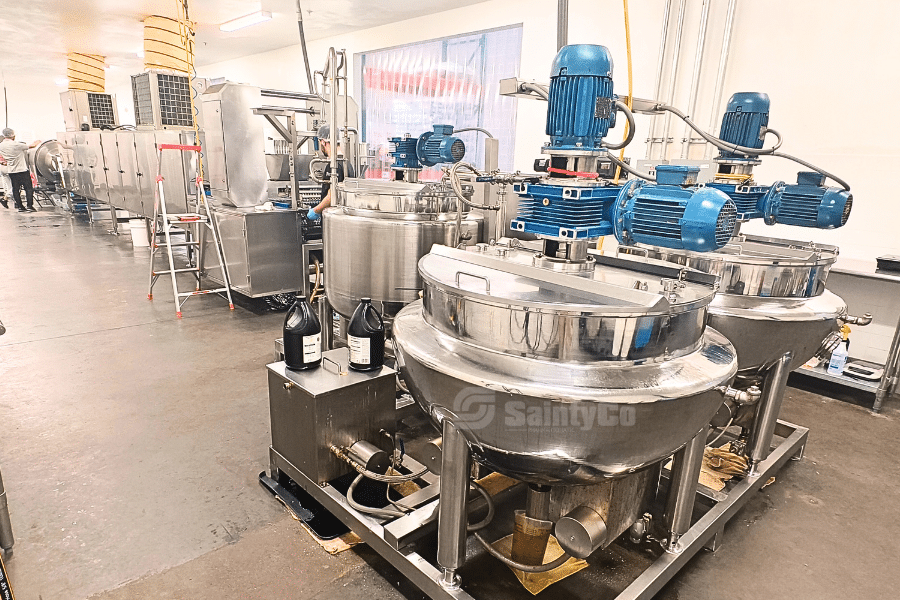

To choose the right equipment for your gummies factory, assess your production scale, required machinery types (cooking, depositing, cooling), automation level, regulatory compliance, and budget. These factors ensure effective operations and product quality.

Watch this client video showcasing gummy production with SaintyCo's DM-50X Gummy Depositor and add-on equipment in action!

Essential Equipment for Gummy Manufacturing

Choosing the right equipment is critical for your gummy manufacturing success. Here’s a breakdown of key machines:

| Equipment Type | Description | Key Considerations |

|---|---|---|

| Gummy Cooking Systems | Equipment like the 100L Dissolving Tank mixes ingredients. Precise temperature control is vital for the right texture. | Invest in high-quality models for consistency. Explore options6. |

| Depositing Machines | Essential for molding gummies, ranging from small-batch to large-scale production. | Match the machine to your production volume. Learn more here7. |

| Cooling Systems | Ensure gummies set properly with systems like Drying Trays. Consistent cooling leads to uniform quality. | Select efficient cooling solutions. See best practices8. |

| Coating Equipment | For coated gummies, choose a Sugar Polishing Pan or Oil Coating Drum. | Decide on your coating needs early. Find out how9. |

| Packaging Lines | Opt for automatic machines that can handle various formats, ensuring hygiene and efficiency. | Consider flexibility in design. Discover packaging solutions10. |

Automation Considerations

When selecting equipment, consider the level of automation that best suits your business model:

-

Semi-Automatic vs. Fully Automatic Gummy Machines:

- Semi-Automatic: Ideal for smaller volumes, offering flexibility.

- Fully Automatic: Best for larger operations, reducing labor costs and increasing efficiency.

-

All-in-One Systems:

Factors to Consider Before Purchase

- Production Scale: Determine whether you need small-scale or large-scale gummy machinery based on your target output.

- Regulatory Compliance: Ensure all gummy manufacturing equipment meets local health and safety regulations to avoid operational issues.

- Quality and Certification: Look for gummy machinery certified by relevant authorities (ISO 9001, FDA) to ensure quality and reliability.

- Support and Maintenance: Choose machinery suppliers that offer ongoing support and service agreements to keep your gummy production running smoothly.

- Budget: Factor in not just the purchase price but also installation, training, and long-term maintenance costs.

These considerations will help you select gummy manufacturing equipment that aligns with your operational goals and ensures a successful gummy manufacturing process.

High-quality gummy cooking systems ensure consistent texture.True

Investing in premium cooking systems is vital for achieving the right texture in gummies, impacting overall product quality.

Fully automatic equipment reduces labor costs significantly.True

Switching to fully automatic machinery can greatly lower labor expenses, especially in large-scale gummy production.

What are the best practices for sourcing high-quality ingredients?

Sourcing high-quality ingredients is essential for any successful food production operation. Discover the best practices that can elevate your sourcing strategy.

To source high-quality ingredients, prioritize regulatory compliance, build strong supplier relationships, focus on sustainability, balance local and global sourcing, and implement thorough quality control measures.

Understanding Ingredient Quality Standards

Sourcing high-quality ingredients begins with understanding the standards that define quality. Ingredients should meet relevant food safety regulations and certifications. For instance, raw materials like gelatin or pectin must adhere to UK food safety standards.

Choosing suppliers with certifications, such as ISO 900112, can provide assurance about their quality management practices. Consider creating a checklist of essential certifications that suppliers should possess to streamline your sourcing process.

Supplier Relationships

Building strong relationships with suppliers is vital for consistent quality. Engaging in long-term partnerships can lead to better pricing, priority during shortages, and access to premium ingredients. Regular communication helps ensure that suppliers understand your quality expectations.

| Supplier Criteria | Importance | Notes |

|---|---|---|

| Certifications | High | Verify food safety and quality standards |

| Communication | Medium | Maintain open channels for feedback |

| Reliability | High | Consistency in supply and quality |

Sustainable Sourcing Practices

As sustainability becomes a priority, consider sourcing ingredients from suppliers that prioritize eco-friendly practices. This not only enhances your brand’s image but may also improve ingredient quality. Look for suppliers that demonstrate responsible sourcing, such as those who use sustainable farming13 methods.

Local vs. Global Sourcing

Deciding between local and global suppliers can impact ingredient quality. Local sourcing often ensures fresher products and supports community businesses. On the other hand, global suppliers might offer unique ingredients that enhance your product offerings. Weigh the pros and cons based on your specific needs:

| Sourcing Option | Pros | Cons |

|---|---|---|

| Local | Fresher products, lower transport costs | Limited ingredient variety |

| Global | Wider variety, competitive pricing | Potential shipping delays and costs |

Quality Control Measures

Implement robust quality control measures to verify ingredient quality upon delivery. This includes visual inspections, lab testing for contaminants, and regular audits of suppliers. Establishing standard operating procedures (SOPs) for receiving and inspecting ingredients can minimize risks associated with poor-quality inputs.

Consider creating a template for supplier audits to ensure consistency in evaluation:

Supplier Audit Template

- Supplier Name:

- Date of Audit:

- Quality Standards Met: Yes/No

- Inspection Results:

- Visual Check:

- Lab Tests:

- Documentation Verification:

- Notes:

By following these best practices, you can ensure that your ingredient sourcing aligns with high-quality standards while fostering strong supplier relationships that can benefit your business in the long run.

High-quality ingredients must meet food safety regulations.True

Compliance with food safety regulations is crucial for ensuring ingredient quality and consumer safety.

Local sourcing guarantees the best ingredient quality.False

While local sourcing often provides fresher products, it may limit variety compared to global suppliers.

What are the common challenges faced when starting a gummies factory?

Launching a gummies factory comes with its unique set of challenges that entrepreneurs must navigate carefully.

Starting a gummies factory presents common challenges such as regulatory compliance, equipment selection, supply chain management, quality control, and financial planning. Addressing these issues proactively can facilitate a smoother startup process.

1. Regulatory Compliance Challenges

Starting a gummies factory requires strict adherence to regulatory standards. In the UK, registering with the Food Standards Agency (FSA) is mandatory at least 28 days before operations begin. This involves ensuring compliance with health claims and novel foods regulations, especially if new ingredients like CBD are included.

Additionally, manufacturers must follow Good Manufacturing Practices (GMP). Achieving ISO 9001 certification can further enhance credibility and product quality. Regulatory hurdles can delay production and add to startup costs, so it’s vital to stay informed about changing regulations.

For more details, check out regulatory guidelines14.

2. Equipment Selection and Investment

Choosing the right equipment is crucial for efficiency and product quality. The initial investment can be substantial, with essential machinery like gummy cooking systems and depositing machines being key expenses. For example, the DM-50X Small Batch Depositor is suitable for small operations, while the SaintyCo G40 Gummy Production Line caters to larger volumes.

Investing in efficient cooling systems and automatic packaging lines is also essential. The layout and functionality of the equipment can significantly impact production rates and labor costs. Assessing whether to use semi-automatic or fully automatic systems will depend on your expected production scale.

Learn more about gummy production equipment15.

3. Supply Chain Management

Sourcing high-quality ingredients is another major challenge. Manufacturers must establish relationships with certified suppliers to ensure compliance with food safety standards. Moreover, managing logistics for timely delivery of raw materials and finished products is essential for maintaining operational flow.

Additionally, considerations around packaging must not be overlooked. Finding child-resistant and eco-friendly materials compliant with UK regulations can be a complex process that requires careful planning and execution.

Explore insights on supply chain strategies16.

4. Quality Control and Operational Workflow

Developing a reliable operational workflow is fundamental to success. This includes everything from recipe formulation to cooking and packaging processes. Ensuring consistent quality through regular audits and automated quality control systems can prevent defects in the final product.

Adhering to stringent quality control measures can be resource-intensive but is vital for maintaining brand reputation and customer satisfaction. A well-structured workflow minimizes waste and maximizes efficiency.

For tips on quality control best practices17.

5. Financial Planning Challenges

Starting a gummy factory involves considerable financial investment. Budgeting for equipment, regulatory compliance, and facility setup must be meticulously planned. Operating costs, including raw material sourcing, labor, and packaging, should also be accounted for in your financial projections.

Exploring funding opportunities or government grants aimed at food manufacturing can ease financial burdens for startups focusing on sustainability and innovation.

Regulatory compliance is optional when starting a gummies factory.False

This claim is false; regulatory compliance is mandatory for food safety and legal operations.

Investing in quality equipment is vital for gummy production efficiency.True

This claim is true; the right equipment directly impacts production rates and product quality.

How do I develop an effective marketing strategy for my gummy products?

Creating an effective marketing strategy for gummy products involves understanding your audience, building a strong brand identity, leveraging digital marketing channels, and monitoring performance.

To develop an effective marketing strategy for gummy products, understand your target audience, establish a strong brand identity, utilize digital marketing strategies like social media and influencer partnerships, and analyze campaign performance.

Understand Your Target Audience

Knowing your audience is key. Who are your potential customers? Are they parents looking for healthier treats for their kids, or young adults seeking a fun snack? Create buyer personas to define these groups. Use surveys and market research to gather insights.

Once you understand your audience, tailor your marketing messages to resonate with them. Highlight benefits that matter most to them, such as taste, health benefits, or convenience.

For example, if your target market includes fitness enthusiasts, emphasize the nutritional aspects of your gummies. Explore consumer trends18 to refine your approach.

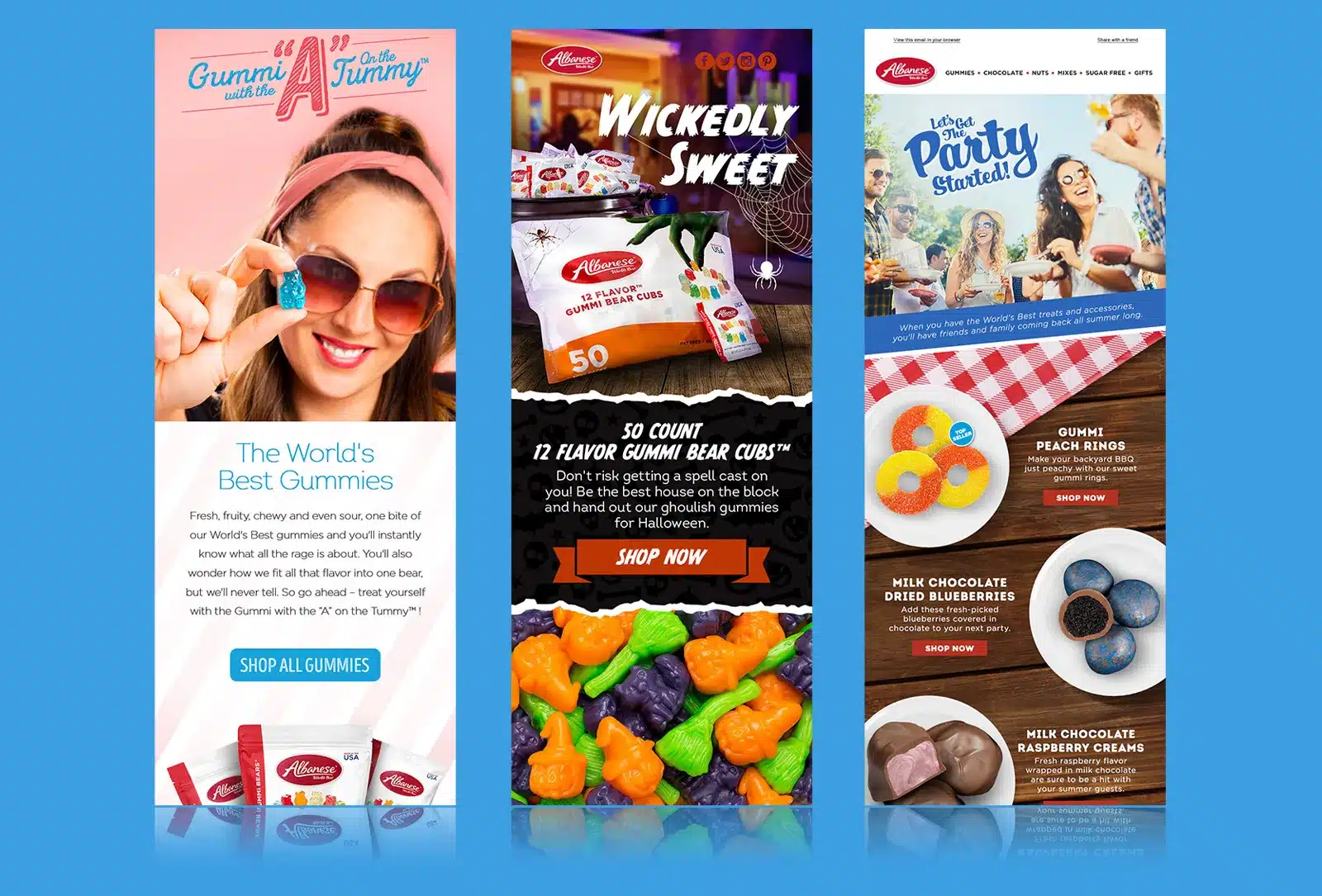

Build a Strong Brand Identity

A memorable brand identity can set you apart. Your brand should reflect the quality and uniqueness of your gummy products. Consider the following:

| Element | Description |

|---|---|

| Logo | Create a visually appealing logo that captures your brand essence. |

| Packaging | Invest in attractive packaging that stands out on shelves. Consider eco-friendly options to appeal to environmentally-conscious consumers. |

| Messaging | Develop a consistent tone of voice across all platforms. This includes your website, social media, and promotional materials. |

Utilize Digital Marketing Strategies

In today’s digital age, online presence is crucial. Here are effective strategies:

- Social Media Marketing: Platforms like Instagram and TikTok are ideal for showcasing visually appealing gummy products. Share engaging content, including recipes and user-generated posts.

- Influencer Partnerships: Collaborate with influencers who resonate with your target audience. This can enhance your brand’s visibility and credibility.

- Content Marketing: Create valuable content related to gummy products. This could include blog posts about the benefits of ingredients or fun ways to incorporate gummies into daily routines.

- For instance, write about how to use gummies in cooking or baking. Check out content ideas19.

Implement Email Marketing Campaigns

Email marketing remains a powerful tool. Use it to:

- Share product launches or promotions.

- Provide value through educational content, such as healthy recipes or ingredient benefits.

- Encourage repeat purchases by offering exclusive discounts to subscribers.

Monitor and Analyze Performance

Finally, track your marketing efforts. Use tools like Google Analytics and social media insights to measure the effectiveness of your campaigns. Analyze metrics such as engagement rates, conversion rates, and customer feedback.

- Regular analysis helps refine strategies and improve future campaigns.

By focusing on these areas, you can develop an effective marketing strategy tailored specifically for your gummy products.

Understanding your target audience is crucial for marketing success.True

Knowing your audience allows for tailored marketing messages that resonate, increasing engagement and sales.

Eco-friendly packaging has no impact on consumer purchasing decisions.False

Many consumers prefer brands that use eco-friendly packaging, influencing their buying choices positively.

Conclusion

Establishing a supplements and OTC gummies factory in the UK involves regulatory compliance, equipment choice, ingredient sourcing, quality control measures, and effective financial planning.

At GummyGenix by SaintyCo, we're here to support your journey with cutting-edge, GMP-compliant gummy manufacturing equipment designed for efficiency, precision, and adaptability. Our machines are fully compatible with regulatory standards, and we offer reliable after-sales support to keep your operations running smoothly.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality gummy products to life—together.

Gummy Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Discover essential guidelines and compliance measures for gummy manufacturing in the UK, ensuring your business adheres to all necessary regulations. ↩

-

Learn about GMP standards and certifications necessary for maintaining high-quality gummy production in the UK. ↩

-

Find out how to effectively label your gummy products according to UK regulations to avoid legal issues. ↩

-

Discover essential resources that will guide you through UK food safety compliance effectively. ↩

-

Learn about training programs that can help your staff meet food safety regulations. ↩

-

Clicking this link will provide you with essential details about various gummy manufacturing equipment options to make informed choices. ↩

-

This resource will detail the differences between semi-automatic and fully automatic gummy production lines, helping you understand which is best for your needs. ↩

-

This link covers efficient cooling solutions for gummies, ensuring proper setting and consistent product quality. ↩

-

Learn more about coating machines for gummies to enhance product appeal through sugar or oil coatings. ↩

-

Explore various packaging solutions to ensure your gummies are packaged efficiently and hygienically. ↩

-

Find comprehensive all-in-one gummy production systems that simplify operations while maximizing output. ↩

-

This link provides valuable insights into sustainable sourcing practices that can enhance ingredient quality and boost your brand's reputation. ↩

-

Explore how sustainable farming methods contribute to higher ingredient quality and help meet consumer demand for eco-friendly products. ↩

-

Discovering insights on common challenges will help you prepare effectively before launching your gummies factory. ↩

-

This link provides essential information about selecting the right equipment for your gummies production needs. ↩

-

Understanding supply chain strategies can help streamline your operations and avoid delays in production. ↩

-

Learning about quality control best practices will ensure that your products meet industry standards. ↩

-

Discover expert tips and actionable insights on creating a successful marketing strategy for gummy products. ↩

-

Learn how to effectively engage consumers through social media and digital marketing for gummy brands. ↩