Spain is a promising market for supplements and OTC gummies, but establishing a factory there requires meticulous planning.

To set up a supplements and OTC gummies factory in Spain, you must adhere to EU regulations, design an efficient facility layout, choose appropriate production equipment, and develop compliant formulations. Partnering with experienced providers can streamline these processes.

While this overview provides the foundational steps, delving into each element can reveal insights that boost efficiency and ensure compliance. Read on to discover detailed strategies for a successful factory setup.

EU regulations are optional for Spain's factories.False

All factories in Spain must comply with EU regulations for operation.

Partnering with experienced providers aids factory setup.True

Experienced partners can streamline processes and ensure compliance.

How Do You Ensure Compliance with EU Food Supplement Regulations?

Ensuring regulatory compliance in Spain involves understanding EU directives and local laws. Businesses must align with food safety protocols, accurate labeling, and manufacturing practices to avoid legal pitfalls.

To ensure regulatory compliance in Spain, businesses must adhere to EU Food Supplements Directive 2002/46/EC, follow Hazard Analysis and Critical Control Points (HACCP), and implement Good Manufacturing Practices (GMP). Hiring local consultants for guidance can aid in compliance with Spanish laws.

Understanding Key EU Directives

The foundation of compliance lies in understanding the EU Food Supplements Directive[^hdyecwefsr-1] 2002/46/EC. This directive specifies which ingredients are permitted, such as vitamins and minerals, and sets out rules for labeling, including dosage instructions and health claims.

Compliance Checklist:

- Ingredients: Ensure all active ingredients meet EU standards.

- Labeling: Labels must be accurate, including all claims and dosage.

- Documentation: Maintain detailed records for each product batch.

Implementing HACCP and GMP

To minimize contamination risks, the implementation of HACCP[^hdyecwefsr-2] is mandatory. This management system focuses on controlling potential hazards throughout the production process.

Alongside HACCP, GMP ensures that the manufacturing processes meet the quality standards required by both EU and Spanish regulations.

Here's a concise table for easy reference:

| Regulation | Key Requirements |

|---|---|

| EU Food Supplements Directive | Permitted ingredients and accurate labeling |

| HACCP | Hazard control measures |

| GMP | Covers equipment, facilities, and processes to ensure product quality |

acility Design and Equipment Selection

Efficient facility design not only optimizes production but also helps meet regulatory requirements. Consider these aspects:

-

Zones and Workflow:

- Considerations should include distinct areas for raw materials, production, and packaging to prevent cross-contamination.

- Implement air filtration systems to control temperature and humidity.

-

Room Size and Equipment Placement:

- Plan for equipment like conveyors and cooling tunnels. Ensure there is ample space for operator movement.

For more detailed insights, see facility design best practices1.

When selecting equipment, opt for machines that offer precision in dosing active ingredients, such as vitamins or pharmaceuticals. For example, the DM-50X Small Batch Depositor is ideal for startups needing flexibility without compromising on compliance standards.

| Equipment | Benefits |

|---|---|

| Gummy Depositors | Ensure precise dosing of active ingredients. |

| Full Production Lines | Support high-volume operations with compliance in mind. |

| Auxiliary Equipment | Enhance production efficiency with optimal coating solutions. |

Steps for Compliance

-

Consulting Expertise:

- Hiring a regulatory consultant familiar with EU and Spanish laws can be crucial. They provide insights into navigating local regulations2 effectively, ensuring your business meets all legal requirements.

-

Validated Processes:

- Implement validated processes for ingredient dosing and mixing, especially important for supplements like CBD or vitamins. This ensures consistent product quality and safety.

-

Documentation:

Regulatory compliance is a multifaceted challenge requiring attention to detail across various business operations. From ingredient sourcing to facility layout, every aspect must align with legal standards to ensure success in the Spanish market.

HACCP systems are optional for businesses in Spain.False

HACCP systems are mandatory to control contamination risks in Spain.

Consulting with a local expert aids in Spanish compliance.True

Local consultants help navigate EU and Spanish regulations effectively.

What Are the Key Considerations for Facility Layout and Design?

Facility layout and design are critical for maximizing efficiency and safety in production environments. From optimal equipment placement to regulatory compliance, understanding these elements can streamline operations and enhance productivity.

Key considerations for facility layout and design include optimizing workflow, ensuring regulatory compliance, planning for future expansion, and integrating safety measures. Effective layouts improve efficiency, reduce costs, and increase production output.

Workflow Optimization

Effective facility layout4 begins with mapping out the workflow. Identify key processes, then arrange equipment and workstations to minimize movement and enhance efficiency. Clear pathways reduce bottlenecks and improve productivity.

Zoning and Space Utilization

Create dedicated zones for specific tasks, such as manufacturing, packaging, and storage. This reduces contamination risks and supports compliance with regulations5. Ensure enough space for equipment operation and maintenance, considering future growth.

| Area | Function | Considerations |

|---|---|---|

| Raw Material Storage | Safe keeping of raw materials | Temperature control and easy access |

| Production Area | Manufacturing processes | Equipment spacing and air filtration |

| Packaging Zone | Product packaging | Minimal contamination and efficient flow |

Regulatory Compliance

Adhering to local and international regulations is crucial. Implement systems like HACCP to manage food safety risks. Compliance with GMP standards6 ensures quality control across production stages.

Future Expansion

Plan for scalability by designing flexible layouts that accommodate additional equipment or processes without major disruption. Anticipate changes in product lines or production volume to keep your facility adaptable.

Safety Integration

Safety should be a core element of your design strategy. Install emergency exits, fire suppression systems, and safety signage. Regularly review safety protocols to adapt to any process changes or new equipment7.

Workflow mapping reduces facility bottlenecks.True

Mapping workflow helps identify and eliminate inefficiencies, enhancing flow.

Zoning increases contamination risks in facilities.False

Zoning minimizes contamination by separating tasks, ensuring cleaner operations.

What Are the Best Practices for Gummy Formulation and Recipe Development?

Unlocking the secrets to perfect gummy formulation requires understanding both the science and art behind ingredient selection and process management. Dive into the essential practices that ensure your gummies are a hit.

The best practices for gummy formulation include selecting stable ingredients, precise dosing, and using advanced equipment for consistent quality. Emphasize regulatory compliance and market trends for successful product development.

Ingredient Selection

Choosing the right ingredients is crucial. Focus on stability during cooking and depositing. Common bases include gelatin and pectin. Vegan options are in demand, using pectin-based recipes. Ensure all ingredients comply with regulatory standards8.

| Ingredient | Function | Considerations |

|---|---|---|

| Gelatin | Base | Not vegan-friendly |

| Pectin | Base | Vegan alternative |

| Vitamins | Active | Stability and dosage |

Dosing Precision

Accurate dosing is essential, particularly for supplements like CBD or vitamins. Use precise dosing systems to ensure consistent active ingredient delivery. This is critical for maintaining pharmaceutical-grade9 quality in gummies.

Equipment Utilization

Using advanced gummy production equipment optimizes efficiency and compliance. Consider equipment like gummy depositors for accurate dosing and full production lines for scalability. Scalable operations10 are achievable with machines offering features like dual-hopper systems.

Regulatory Compliance

Adhering to regulations is non-negotiable. Familiarize yourself with EU and local regulations, such as the EU Food Supplements Directive and GMP standards. Hiring a regulatory consultant may be beneficial for navigating these complex requirements11.

Market Trends and Innovation

Stay ahead by exploring market trends like vegan, sugar-free, or fortified gummies. Niche segments such as CBD gummies or those targeting joint health are gaining traction. Innovation in formulation can differentiate your products in competitive markets.

Developing Unique Recipes

Collaborate with food scientists to create unique recipes that meet market demands. Consider stability and taste during development. Use recipe management software for quick product switches and ensure your formulations comply with standards12.

Quality Assurance

Implement thorough quality assurance processes. Maintain documentation and conduct regular inspections to ensure safety and consistency in production. This includes everything from ingredient sourcing to final packaging.

By adhering to these best practices, you can develop gummies that not only meet consumer expectations but also comply with industry standards, thus ensuring your product's success in the market.

Gelatin is a vegan-friendly base for gummies.False

Gelatin is derived from animal collagen, making it non-vegan.

Pectin-based recipes are in demand for vegan gummies.True

Pectin is plant-based, suitable for vegan gummy formulations.

Which Equipment Is Essential for Gummy Production?

Starting a gummy production line requires specific machinery to ensure efficiency and quality. Discover the essential equipment needed to craft perfect gummies, from cooking to packaging.

Essential equipment for gummy production includes cooking vessels, gummy depositors, cooling tunnels, and packaging machines. These components ensure precise dosing, efficient production, and compliance with quality standards.

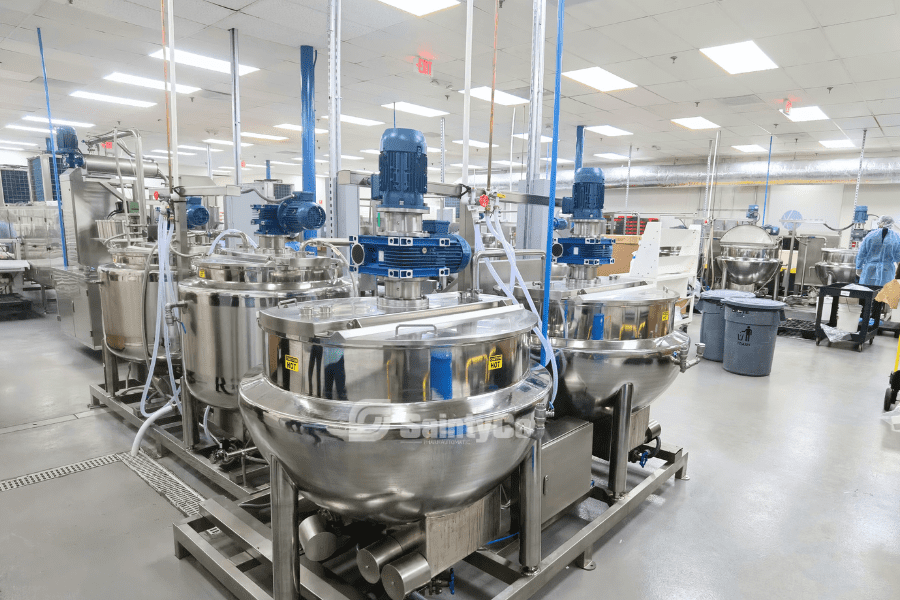

Gummy Production Machinery from GummyGenix by SaintyCo | Click to Know More

Key Equipment for Gummy Production

Cooking Vessels

Cooking vessels are pivotal for dissolving and mixing ingredients. They ensure consistent heat distribution and ingredient integration, crucial for product quality. High-capacity vessels can enhance production speed.

- Features: Jacketed for temperature control, agitators for mixing

- Considerations: Capacity, material (stainless steel)

Gummy Depositors

Depositors precisely fill molds with gummy mixture, crucial for consistency. Advanced models allow center-filled, multi-color or layered gummies.

- Features: Automated, adjustable dosing, multi-color capability

- Considerations: Speed, accuracy, flexibility

Cooling Tunnels

Cooling tunnels solidify gummies after depositing. They prevent melting and maintain shape during demolding.

- Features: Temperature control, adjustable speed

- Considerations: Length, cooling efficiency

Packaging Machines

Packaging ensures product safety and compliance. Options vary from individual wrapping to bulk containers.

| Type | Features |

|---|---|

| Individual Wrap | Secure, tamper-evident |

| Bulk Containers | Cost-effective for large volumes |

| Premade Pouches | Consumer convenience |

Auxiliary Equipment

Additional machinery supports production. This includes coating machines for sugar or oil finishes and drying trays.

- Coating Machines: Enhance aesthetic and texture

- Drying Trays: Optimize curing and storage

Explore coating solutions13 and drying technologies14 that enhance gummy quality.

Integrating Technology for Optimization

Utilize PLC touch-screen systems for real-time adjustments. Implement recipe management software to streamline product switches and minimize waste.

Discover software solutions15 that enhance efficiency through automation.

These components form the backbone of an efficient gummy production line. Each piece must be selected based on your specific production needs and scale. Understanding their roles helps ensure a smooth, high-quality production process.

Cooking vessels are used for mixing ingredients.True

Cooking vessels ensure ingredient integration and heat distribution.

Cooling tunnels are used for heating gummies.False

Cooling tunnels solidify gummies by preventing melting.

How Can You Optimize Gummy Production Processes for Efficiency?

Optimizing production processes is crucial for manufacturers aiming to enhance efficiency and reduce costs. It involves analyzing workflows, eliminating bottlenecks, and implementing strategic improvements.

To optimize production processes for efficiency, focus on streamlining workflows, integrating technology, and fostering a culture of continuous improvement. Utilize data analysis to identify bottlenecks and invest in employee training to maximize productivity.

Streamline Workflows

Streamlining workflows is essential to optimize production processes. Begin by mapping out each step of your current workflow to identify areas where delays occur. Use this workflow analysis16 to simplify tasks, eliminate redundancies, and enhance coordination between departments.

| Workflow Components | Potential Improvements |

|---|---|

| Material Handling | Automated systems |

| Task Sequencing | Real-time scheduling tools |

| Communication | Integrated platforms |

Integrate Technology

Investing in technology can revolutionize production efficiency. Consider implementing automation solutions17 such as robotic assembly lines or AI-driven quality control systems. These technologies not only speed up production but also reduce error rates.

- Robotic Assembly Lines: Increase speed and precision.

- AI Quality Control: Enhance defect detection and correction.

Foster Continuous Improvement Culture

Creating a culture of continuous improvement encourages employees to identify and suggest process enhancements. Establish regular feedback sessions where teams can discuss process inefficiencies and brainstorm solutions. Consider lean manufacturing principles18 to empower workers in decision-making.

Data-Driven Decisions

Leverage data analytics to gain insights into production performance. By analyzing metrics such as cycle times, machine utilization, and scrap rates, you can pinpoint bottlenecks. Implement data management systems that offer real-time monitoring and predictive maintenance alerts to keep operations running smoothly.

- Cycle Time Reduction: Analyze time per task.

- Machine Utilization: Optimize scheduling.

- Scrap Rate: Reduce waste through quality checks.

GummyGenix by SaintyCo's gummy manufacturing equipment supports robust batch traceability through compatibility with advanced ERP and batch tracking systems. Specifically, the equipment can be upgraded with SIEMENS TP1200 or Allen Bradley PLC control systems, enabling seamless data connectivity for integration with third-party ERP solutions. This setup allows users to capture, track, and store critical production parameters, helping to simplify compliance with cGMP standards and documentation requirements.

Employee Training and Development

Well-trained employees are pivotal to efficient production processes. Regular training sessions ensure that workers are up-to-date with the latest techniques and technologies. Develop a comprehensive training program19 that focuses on skill enhancement, safety procedures, and equipment handling.

- Skill Enhancement: Foster expertise in operating machinery.

- Safety Procedures: Minimize accidents and downtime.

- Equipment Handling: Ensure optimal use of technology.

Automated systems improve material handling efficiency.True

Automated systems streamline workflows by reducing manual handling delays.

Employee training is not essential for process efficiency.False

Regular training updates employees on new techniques, enhancing productivity.

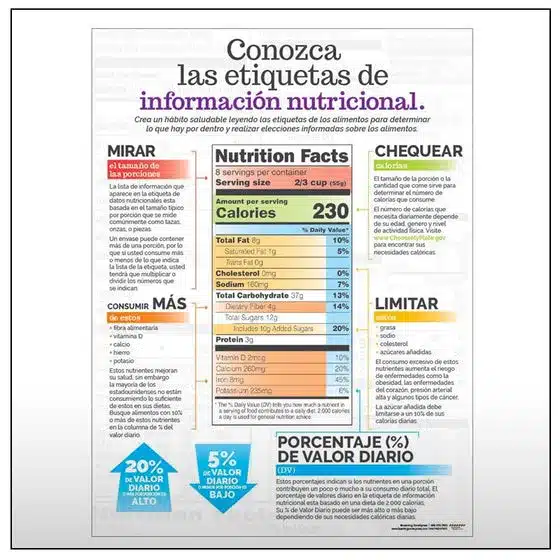

How Can You Optimize Packaging and Labeling for Gummy Products to Meet Spanish Market Standards?

Navigating the packaging and labeling landscape for the Spanish market involves strict adherence to EU and local regulations. Mastering this ensures compliance and boosts product appeal in a competitive market.

To optimize packaging and labeling for the Spanish market, adhere to EU regulations, such as the Food Supplements Directive, and local laws like Royal Decree 1055/2022. Ensure clarity in nutritional information and allergen declarations.

Understanding Regulatory Requirements

Spain, aligned with EU regulations, demands precise packaging standards. Adhering to the Food Supplements Directive20 is essential. This means accurate ingredient listing and dosage information.

For more recent obligations, Royal Decree 1055/2022 introduces guidelines for sustainable packaging practices, promoting recycling.

| Regulation | Key Requirement |

|---|---|

| Food Supplements Directive | Accurate ingredient listing |

| Royal Decree 1055/2022 | Sustainable packaging practices |

Design Considerations for Compliance

When designing packaging, consider both aesthetic appeal and functionality. Labels must be legible, including mandatory nutritional and allergen details. Incorporate CLP requirements21 for safety.

Consider Country of Origin22 marking, which enhances transparency and trust.

Implementing Sustainable Practices

To meet modern consumer expectations and regulations, implement eco-friendly materials. This not only complies with Spanish laws but also appeals to environmentally conscious consumers.

Utilize biodegradable materials or recycled content where possible.

Leveraging Technology for Labeling

Use advanced printing technologies for precise labeling, ensuring all necessary information is displayed clearly. Real-time tracking systems can help manage supply chains effectively.

Adopting smart labeling technology, such as QR codes, provides consumers with easy access to detailed product information and sustainability practices.

Common Challenges and Solutions

Adapting to Spanish standards can be challenging due to the complexity of regulations and market expectations.

-

Challenge: Complex regulatory landscape.

- Solution: Partner with local regulatory experts.

-

Challenge: Eco-friendly material sourcing.

- Solution: Collaborate with suppliers focused on sustainability.

For further insights on sustainable practices, consider resources on eco-friendly packaging23. This can provide a competitive edge in the Spanish market.

Developing a thorough understanding of these elements will enable businesses to thrive in Spain's dynamic market environment without facing regulatory setbacks.

Spain mandates ingredient listing on packaging.True

Spain follows EU regulations requiring accurate ingredient listings.

Royal Decree 1055/2022 is about food labeling.False

Royal Decree 1055/2022 focuses on sustainable packaging practices.

Conclusion

Setting up a supplements and OTC gummies factory in Spain requires compliance with EU regulations, efficient facility design, proper equipment selection, and strategic partnerships for successful operations.

At GummyGenix by SaintyCo, we're here to support your journey with cutting-edge, GMP-compliant gummy manufacturing equipment designed for efficiency, precision, and adaptability. Our machines are fully compatible with regulatory standards, and we offer reliable after-sales support to keep your operations running smoothly.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality gummy products to life—together.

-

Find guidelines on designing facilities that meet regulatory standards effectively. ↩

-

Learn the advantages of hiring a consultant to navigate complex compliance landscapes. ↩

-

Understand the AEMPS's function in overseeing compliance within Spain's pharmaceutical industry. ↩

-

Explore essential components that enhance production efficiency through effective layout planning. ↩

-

Learn about zoning regulations that impact facility layouts for safe and compliant operations. ↩

-

Understand how GMP standards influence facility design for quality assurance. ↩

-

Discover key safety protocols necessary for manufacturing facilities to ensure worker safety. ↩

-

Understand the ingredients allowed in gummy formulations to ensure compliance. ↩

-

Learn how to maintain high standards in gummy manufacturing. ↩

-

Discover machinery that grows with your production needs. ↩

-

Gain insights into mandatory manufacturing practices. ↩

-

Ensure your gummy recipes meet necessary regulatory guidelines. ↩

-

Explore how coating machines improve gummy aesthetics and texture, crucial for market competitiveness. ↩

-

Learn why drying trays are essential for optimizing gummy curing and ensuring product consistency. ↩

-

Find out how software aids in streamlining production processes, crucial for efficiency. ↩

-

Explore how workflow analysis can improve efficiency by identifying bottlenecks and optimizing steps. ↩

-

Learn how automation can increase speed, reduce errors, and enhance overall efficiency. ↩

-

Discover how lean principles empower employees and streamline processes for better efficiency. ↩

-

Find out how comprehensive training programs can boost employee skills and safety. ↩

-

Learn about the key requirements of the EU Food Supplements Directive to ensure compliance. ↩

-

Explore CLP labeling requirements to enhance product safety and compliance. ↩

-

Understand how country of origin marking can build consumer trust. ↩

-

Discover eco-friendly packaging solutions to enhance your brand's sustainability. ↩