Ready to take your gummy production to the next level? Scaling up involves more than just increasing ingredients—it requires the right machinery.

The most important gummy manufacturing equipment for scaling production, in order of priority, includes depositors, cooking and mixing systems, cooling and drying systems, coating and polishing equipment, packaging machines, quality control equipment, and auxiliary equipment like conveyors and storage bins. These key components ensure production efficiency, product consistency, and high-quality output as you scale up.

While the primary equipment provides the backbone of gummy production, understanding each piece's role and how they interact is vital for a smooth scale-up. Let’s delve deeper into the specifics of these essential machines and their impact.

Depositors ensure precise gummy mold filling.True

Depositors fill molds accurately, reducing waste and ensuring uniformity.

Why Are Depositors Crucial in Gummy Manufacturing? (Top Priority)

Ever wondered what makes gummy production efficient and consistent? The answer lies in the depositors.

Gummy Depositors are essential in high-volume production because they ensure precise filling of molds, leading to consistent size and reduced waste. Automated depositors allow manufacturers to scale operations efficiently, maintaining quality while reducing manual labor.

The Role of Depositors in Maintaining Consistency

In the world of gummy manufacturing, achieving consistent size and shape is non-negotiable. High-quality depositors1 fill this role by ensuring each mold receives the exact amount of gummy mixture needed. This precision not only maintains uniformity but also enhances the aesthetic appeal of the final product, which is crucial for brand reputation.

Efficiency and Reduced Waste

Accurate depositing reduces overfill and spillage, directly impacting the bottom line by minimizing waste. This efficiency is particularly vital in large-scale operations where even minor errors can lead to significant financial losses. Automated depositors streamline this process by reducing the need for manual intervention, allowing workers to focus on other critical tasks.

| Benefits of Using High-Output Gummy Depositors |

|---|

| Consistent gummy size and shape |

| Reduced material wastage |

| Lower labor costs due to automation |

| Ability to handle varying viscosities |

| Increased production speed |

Scalability and Production Speed

As demand grows, so does the need for increased production speed. Manual depositing becomes impractical at this stage. Automated depositors2 cater to various viscosities and maintain consistent output rates, enabling manufacturers to scale efficiently. The ability to rapidly switch between different recipes without compromising quality is a significant advantage.

Technological Innovations in Depositors

Modern depositors are equipped with advanced features such as programmable controls and recipe storage, allowing manufacturers to seamlessly adapt to market changes. These innovations enhance flexibility and ensure that manufacturers can meet diverse consumer preferences without extensive downtime.

By understanding the critical role depositors play in gummy manufacturing, businesses can make informed decisions about investing in equipment that supports their scaling objectives.

Depositors ensure uniform gummy size and shape.True

They accurately fill molds, maintaining consistent product dimensions.

Manual depositing is efficient for large-scale gummy production.False

Automated depositors are needed to efficiently scale production.

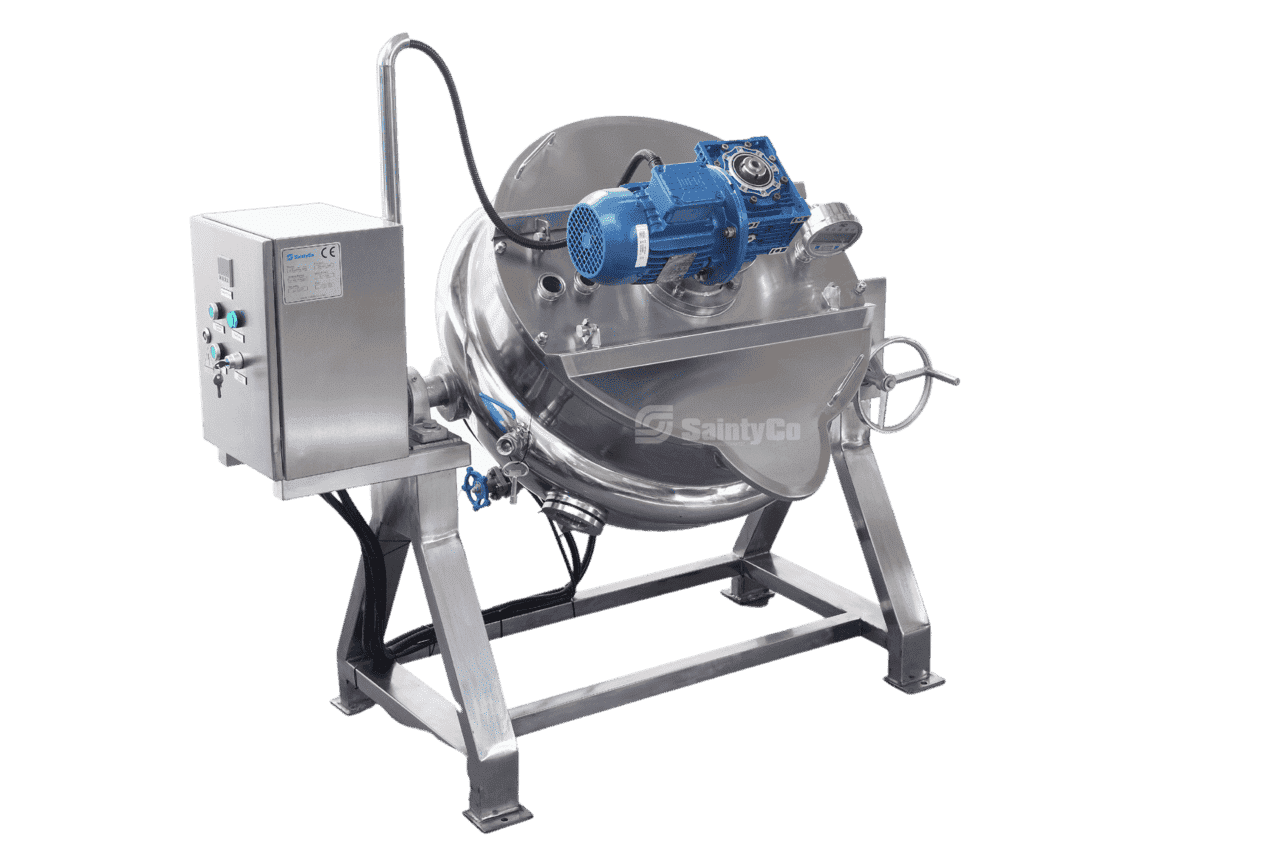

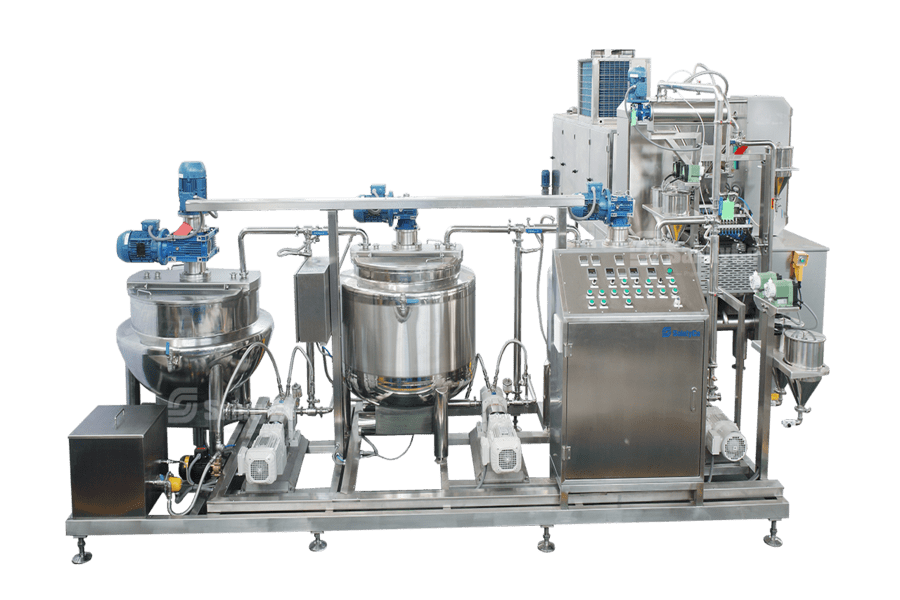

How Do Cooking and Mixing Systems Affect Gummy Quality?

In gummy production, the cooking and mixing phase is where flavors and textures are born. But why is this equipment so vital?

Cooking and mixing systems are crucial for achieving the perfect texture, flavor, and consistency in gummies. They ensure even heating, proper ingredient integration, and control over the cooking process, directly impacting the final product's quality.

The Science Behind Cooking Systems

The cooking phase is fundamental in defining the texture and flavor profile of gummies. Achieving the right Brix level, which is a measure of sugar concentration, is critical. A well-calibrated cooking system3 ensures that the sugar concentration reaches the desired level, affecting the gummy's firmness and shelf life. Precision in temperature control is vital to prevent burning or undercooking, which can result in inconsistent texture and flavor.

Additionally, continuous cooking systems offer a streamlined approach by providing consistent heat and mixing, essential for large-scale production. This method minimizes variations between batches, ensuring uniformity across each gummy produced.

The Role of Mixing Systems

Proper mixing ensures that all ingredients are evenly distributed within the gummy matrix. This process is crucial for flavor distribution, color uniformity, and texture consistency. High-efficiency mixing equipment4 allows for precise ingredient ratios and homogeneity.

For instance, in crafting fruit-flavored gummies, it's essential to achieve a consistent blend of fruit extracts and other components to ensure that each bite offers the same taste experience. Mixing systems that offer gentle but thorough agitation prevent air incorporation, which can lead to undesirable textures or bubbles in the final product.

Balancing Scalability and Quality

As demand for gummies grows, scaling up production without compromising quality becomes a challenge. Batch cookers are ideal for small to medium productions, while continuous systems suit large-scale operations. Regardless of size, automation in both cooking and mixing processes enhances precision and reduces human error.

A comprehensive automation system5 monitors temperature and ingredient ratios, adjusting settings in real-time to maintain quality standards. By integrating advanced sensors and controls, manufacturers can ensure consistent product quality while meeting increased production demands.

Considerations for Equipment Investment

Investing in robust cooking and mixing systems can be costly but necessary for maintaining high-quality standards. When selecting equipment, consider scalability options, ease of maintenance, and energy efficiency. Equipment that offers quick changeover capabilities can also help streamline production when switching between different gummy types or flavors.

A comparative table of cooking systems may help:

| Cooking System Type | Best For | Pros | Cons |

|---|---|---|---|

| Batch Cooker | Small to Medium Production | Flexibility, Control | Labor-intensive |

| Continuous Cooker | Large Production | Consistency, Efficiency | High Initial Cost |

In conclusion, effective cooking and mixing systems are indispensable for producing high-quality gummies at scale. They provide the control necessary to achieve desired characteristics while supporting efficient production processes.

Continuous cooking systems ensure uniform gummy batches.True

They provide consistent heat and mixing, minimizing batch variations.

Batch cookers are ideal for large-scale gummy production.False

Batch cookers are better suited for small to medium productions.

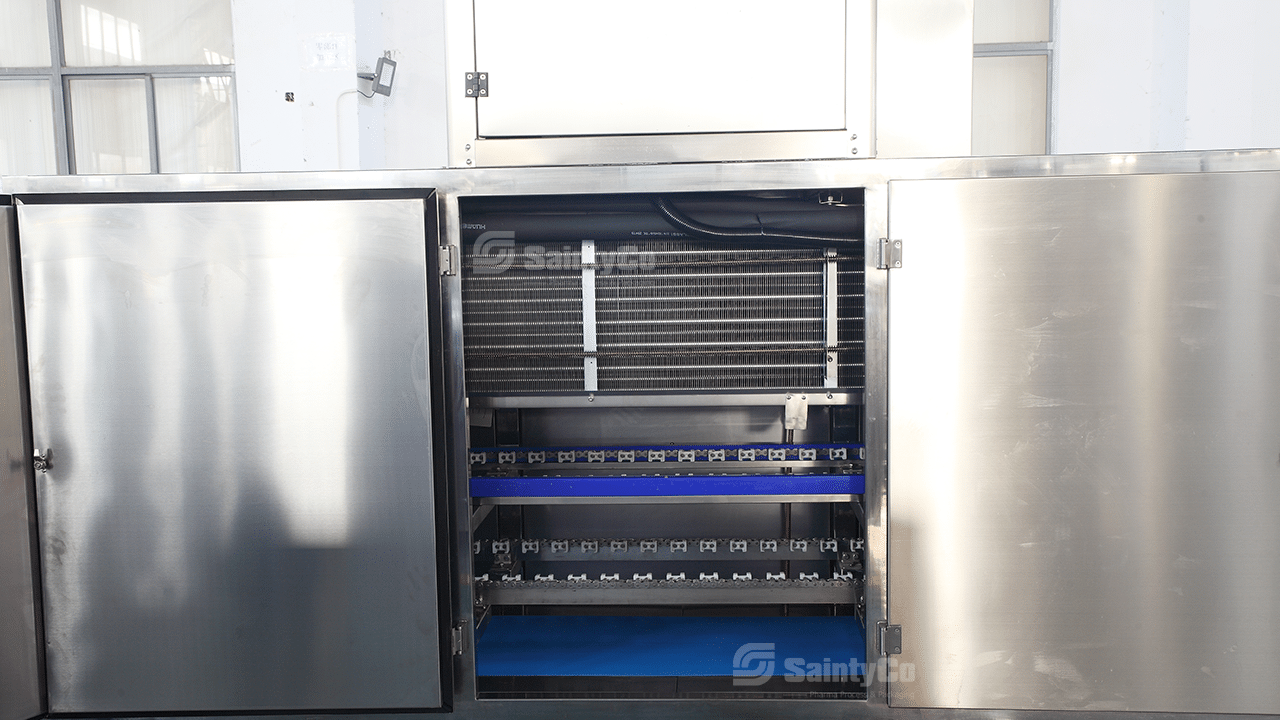

What Role Do Cooling and Drying Systems Play in Scaling Production?

Cooling and drying systems are pivotal in gummy production, ensuring the right texture and longevity as production scales.

Cooling and drying systems stabilize gummies post-deposition by controlling temperature and humidity. This process is critical for achieving the desired consistency and shelf-life, thus preventing product deformation and spoilage during storage and transit.

Understanding the Cooling Process

Cooling systems are responsible for rapidly lowering the temperature of freshly deposited gummies. This step is crucial because it allows the gelatin or pectin within the gummies to set properly. Without adequate cooling, gummies may become sticky, lose shape, or fail to achieve the desired chewiness.

Cooling tunnels or cabinets are typically used, equipped with automated temperature controls to ensure uniform cooling. These systems prevent overheating, which can lead to product shrinkage or moisture loss. Efficient cooling6 is thus essential to maintain product integrity as production scales.

The Importance of Drying Systems

Once cooled, gummies must undergo a drying process. Drying ensures that excess moisture is removed, which is vital for preventing mold growth and extending shelf-life. This is achieved through drying cabinets that regulate both temperature and humidity.

Automated drying systems maintain consistent conditions, crucial when scaling up production. By precisely controlling these parameters, manufacturers can ensure that each gummy meets quality standards without risking spoilage. Uniform drying7 also minimizes the likelihood of gummy clumping during packaging and storage.

Integrating Automation in Cooling and Drying

Automation is key when scaling production. Automated systems can adjust parameters in real-time based on sensor feedback8, ensuring optimal conditions are maintained at all times. This not only improves efficiency but also reduces the need for manual intervention, allowing staff to focus on other aspects of production.

Furthermore, automated cooling and drying systems can be integrated with existing manufacturing lines, enhancing overall workflow without requiring extensive modifications. This flexibility is especially beneficial for manufacturers looking to scale their operations quickly without significant downtime.

The use of automated drying cabinets9 further ensured that each batch of gummies achieved consistent moisture levels, reducing the incidence of spoilage and enhancing shelf-life.

Ultimately, investing in scalable cooling and drying solutions can dramatically impact a gummy manufacturer's ability to grow while maintaining high standards of quality and efficiency.

Cooling systems prevent gummy stickiness in production.True

Cooling systems stabilize gummy structure, preventing stickiness.

Manual drying is more efficient than automated systems.False

Automated systems ensure precise control, improving efficiency over manual methods.

Why Are Coating and Polishing Equipment Essential in Gummy Production?

In gummy production, the finishing touches often determine the final product's appeal and shelf-life. This is where coating and polishing equipment plays a vital role.

Coating and polishing equipment ensures that gummies are uniformly covered with coatings like sugar, oils, or other protective layers. These processes enhance both the visual appeal and the longevity of the product, all while ensuring consistency in appearance.

Enhanced Aesthetic and Protection

Coating and polishing not only give gummies a glossy and attractive finish but also protect the gummy from environmental factors. A smooth, well-polished exterior keeps moisture and other contaminants out, ensuring a longer shelf life and better product presentation.

| Benefits of Using Coating and Polishing Equipment |

|---|

| Attractive glossy finish |

| Improved shelf life |

| Enhanced consumer appeal |

| Uniform application of coatings |

| Reduction in manual labor |

Scalability and Consistency

Automated coating and polishing systems improve production speed and reduce human error. This technology ensures every batch receives a consistent finish, crucial for brands that prioritize uniformity in each product.

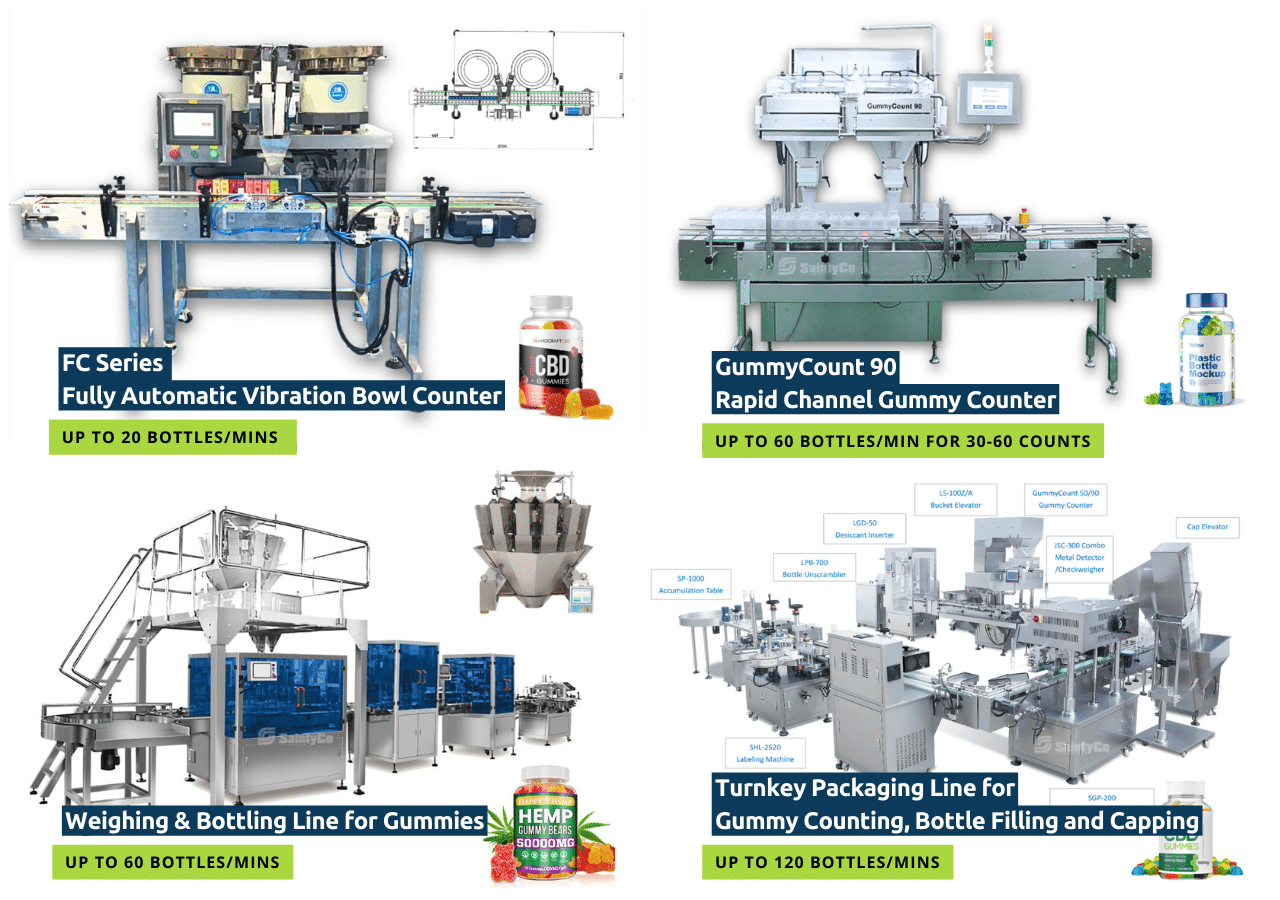

How Can Packaging Machines Enhance Gummy Production Efficiency?

Streamlining gummy production is crucial for meeting market demands, and packaging machines play a key role in boosting efficiency.

Packaging machines enhance gummy production efficiency by automating the packaging process, reducing manual labor, and ensuring consistency in packaging quality. They enable faster, more accurate, and flexible packaging options, which are essential as production scales.

The Role of Automation in Packaging

Automation in gummy packaging is a game-changer. Automated machines can handle diverse packaging formats, from bottles to bags and jars. This flexibility allows manufacturers to cater to varied consumer preferences while maintaining a high throughput. Automated systems reduce the reliance on manual labor, decreasing the likelihood of human error and significantly speeding up the packaging process.

For instance, automated pouch filling machines or flow wrappers can package gummies at a consistent rate, ensuring that each package is sealed correctly and ready for distribution. These machines are equipped with sensors and controls that monitor each step of the process, from filling to sealing, to ensure high standards of quality and safety are met consistently.

Cost Efficiency and Scalability

Investing in advanced packaging machines10 can lead to substantial cost savings over time. By minimizing the need for manual labor, companies can reduce payroll expenses and shift workforce resources to other critical areas of production.

Moreover, as production demands increase, scalable packaging solutions become vital. Machines with modular designs allow for easy upgrades and expansions, accommodating increased capacity without requiring significant downtime or new machinery investments.

Ensuring Consistency and Quality

One of the main benefits of using automated packaging machines is the ability to maintain consistency across all products. Each package receives the same amount of product, is sealed with the same precision, and is labeled uniformly, ensuring that consumers receive a reliable product every time. Consistency is key in building brand trust and loyalty among consumers.

Additionally, advanced packaging machines often come with integrated quality control11 systems that detect discrepancies or defects in real-time, preventing compromised products from reaching the market.

Adapting to Market Demands

The market for gummies is ever-evolving, with new flavors and dietary preferences emerging regularly. Packaging machines that offer versatility enable manufacturers to quickly adapt to these trends. Machines that can easily switch between different packaging sizes or materials are invaluable in a dynamic market environment.

Table: Features of Advanced Packaging Machines

| Feature | Benefit |

|---|---|

| Automated Filling | Reduces manual labor and increases speed |

| Flexible Formats | Adapts to various package types and sizes |

| Real-time Quality Checks | Ensures product integrity |

| Modular Design | Easy upgrades for scaling |

By investing in robust packaging solutions, gummy manufacturers can not only meet current production needs but also position themselves to respond swiftly to future market changes.

Automated machines increase gummy production speed.True

Automation reduces manual labor, speeding up the packaging process.

Manual packaging is faster than automated systems.False

Automated systems reduce human error, increasing packaging speed.

Why Quality Control Equipment is a Game-Changer in Gummy Manufacturing?

Quality control equipment ensures that only the best gummies leave the production line, guaranteeing safety and customer satisfaction.

From weight checks to texture analysis, quality control tools play a pivotal role in ensuring that every gummy is consistent in size, shape, and flavor. Automated quality checks prevent defects and ensure that each batch meets industry standards.

Streamlining Production and Minimizing Defects

With quality control systems, manufacturers can detect defects early in the process, preventing compromised products from reaching consumers. These systems can handle everything from visual inspection to measuring the consistency of the final product, thus reducing the need for manual oversight and ensuring higher-quality production.

| Benefits of Quality Control Equipment |

|---|

| Early detection of product defects |

| Ensures compliance with industry standards |

| Improves consumer satisfaction |

| Reduces costs related to defects |

| Enhances production efficiency |

Why Auxiliary Equipment like Conveyors Are Crucial in Gummy Production?

In gummy production, auxiliary equipment like conveyors, dollies, drying strays, and storage bins are not just supporting players—they are vital to ensuring smooth and efficient operations.

Conveyors and storage bins help streamline material handling, reduce downtime, and ensure a continuous production flow. Properly designed systems transport raw materials, finished products, and waste, optimizing the overall workflow.

Improving Workflow Efficiency

By automating the transportation and storage of materials, conveyors and storage bins reduce bottlenecks in production. This seamless integration speeds up the manufacturing process and minimizes disruptions, enabling manufacturers to meet higher production demands without compromising efficiency.

| Benefits of Auxiliary Equipment |

|---|

| Increased production speed |

| Minimized downtime |

| Improved material handling |

| Easier waste disposal |

| Organized storage for raw materials and finished goods |

Conclusion

Investing in the right equipment is crucial for scaling gummy production efficiently. Focus on core systems like depositors and cookers for immediate impact, then expand to enhance overall operations.

GummyGenix by SaintyCo is here to support your promising gummy making journey. With over 23 years of experience, we specialize in end-to-end gummy production solutions—from innovative, industry-compliant machinery to expert guidance at every step. Whether you're a new business or expanding production, our customized solutions, efficient equipment, and dedicated after-sales support can help you meet your goals.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality gummy products to life—together.

-

Learn how accurate depositors enhance product consistency and reduce waste.: A Candy Depositor. It has unique features that will enable the successful pouring and forming of candy ingredients to form candy. ↩

-

Explore how automated depositors improve scalability and efficiency.: The automation process allows an increase in the speed at which the gummy depositing takes place. An increase in the gummy depositing process ... ↩

-

Learn how Brix levels influence gummy texture and longevity.: Try to work based on your measured brix, and once you have a satisfactory formulation, correlate that brix with a final temperature for your SOP. ↩

-

Discover techniques for achieving uniform ingredient distribution.: Mix gelatin gently. Mixing too roughly results in extra air, creating air bubbles and making the gummies less smooth and clear. Why should you use fruity ... ↩

-

Explore how automation enhances precision and reduces errors.: One of the key benefits of automation in gummy production is the reduction in human error, leading to consistent quality and uniformity in each ... ↩

-

Learn how efficient cooling prevents product shrinkage and maintains quality.: Skillful and intentional indoor climate control can help maintain consistent and predictable conditions for gummy facilities. ↩

-

Discover why uniform drying prevents spoilage and extends shelf life.: Drying is known as the best method to preserve fruits, vegetables, and herbs, decreasing not only the raw material volume but also its weight. ↩

-

Discover how sensor technology optimizes automated production for better efficiency.: Manufacturing sensors measure physical conditions on a machine and ensure that data can be collected from equipment that is not IoT-enabled. ↩

-

Learn about automated drying cabinets' role in enhancing food manufacturing processes.: The dryer cabinet based on the automation system has the advantage of being able to carry out and organize work so that it does not require human supervision. ↩

-

Discover how automation reduces costs and improves packaging efficiency.: Automated systems comfortably handle high volumes of products, reducing the need for manual labor and increasing production efficiency. ↩

-

Learn about systems that enhance product quality during packaging.: IPM quality control inspection systems use barcode readers including side view cameras, overhead cameras, remote control panel, and an automatic reject system. ↩