Have you ever wondered what goes into producing those sweet, chewy gummies you enjoy? It's not just magic—it's a precise orchestration of essential utilities that ensure quality and efficiency in every batch.

Essential utilities for efficient gummy manufacturing include a stable electricity supply for heating systems, compressed air for operational functions, cooling systems for temperature management, vacuum systems for syrup quality, and a reliable water supply for syrup preparation and equipment cleaning.

While we’ve highlighted the basic utilities, the real magic lies in understanding how they work together. Let’s dive deeper into each utility to elevate your gummy manufacturing process!

Electricity is essential for gummy production efficiency.True

Electricity powers heating systems and machinery, ensuring consistent quality.

How Does Electricity Impact Gummy Manufacturing Efficiency?

Electricity is the backbone of gummy production, powering everything from heating systems to automated machinery.

Electricity is crucial in gummy manufacturing, powering heating systems for precise cooking, ensuring consistent quality, and supporting machine operation. Different machines have specific power demands, impacting efficiency and production reliability.

Heating Systems and Precision Cooking

In gummy production, achieving the right heat is essential—much like baking cookies to perfection. Many machines use electric heating or steam-heated thermal oil to ensure precise cooking, which is crucial for consistent texture and taste. For example, electric heating systems enhance operational reliability by maintaining stable temperatures needed for mixing and cooking.

Power Demand and Compatibility

Different production lines have unique power demands. For instance, while GummyGenix by SaintyCo's fully automated G300 gummy line demands 120 kW, larger lines like the SaintyCo's G800X gummy production line may require up to 405 kW. Most machinery operates on a three-phase power supply ranging from 220V to 480V. Ensuring voltage compatibility is crucial to avoid interruptions during production. It is recommended that clients check their facility's voltage against the machine's requirements to ensure smooth operation.

| Machine Model | Power Requirement | Voltage Range |

|---|---|---|

| G300 | 120 kW | 220V/380V/480V |

| G800X | 405 kW | 220V/380V/480V |

Electricity and Operational Reliability

Electricity ensures that all parts of the gummy-making process work together like a well-oiled machine. From controlling heating systems to powering critical components, a stable electricity supply keeps everything humming along, minimizing downtimes and maximizing output.

Integrating Electricity into Facility Planning

When setting up a gummy production facility, integrating a reliable electrical supply is paramount. Tailored facility planning1 can help seamlessly incorporate electricity along with other utilities like air and water into the manufacturing setup, ensuring each machine's specific power needs are met efficiently.

Electricity is essential for gummy heating systems.True

Electricity powers heating systems crucial for processing materials.

Gummy production lines operate on single-phase power.False

Most machinery operates on a three-phase power supply.

Why Is Compressed Air Crucial in Gummy Manufacturing?

Compressed air is vital in gummy manufacturing, ensuring efficient coating and valve operations for consistent production quality.

Compressed air is vital in gummy production for coating applications, controlling valves, and ensuring high-output efficiency. It supports the oil spray systems for coating and manages valve operations, such as those at the pot bottom, crucial for smooth production flows.

Key Functions and Requirements of Compressed Air

Compressed air powers essential processes in gummy manufacturing, including oil spray systems for consistent coating and pot bottom valve controls that ensure smooth material flow between stages, critical for maintaining batch quality.

For instance, machines like our SaintyCo G40AW gummy production line model require 0.4-0.6 MPa of compressed air to function effectively. Keeping this pressure range stable is crucial for reliable component operation throughout production.

Compressed Air Consumption by Gummy Production Line

Compressed air consumption varies based on production line capacity. High-output systems, such as the SaintyCo G800X gummy production line, consume around 1.20 m³/min, underscoring the need for a reliable, continuous air supply to avoid production delays and maintain quality standards.

| Machine Model | Compressed Air Requirement (m³/min) |

|---|---|

| G40AW | 0.4-0.6 |

| G800X | 1.20 |

Managing Compressed Air Systems

To effectively manage compressed air systems, manufacturers need to focus on three main areas: monitoring air pressure2, maintaining equipment efficiency, and ensuring system integration with other utilities.

Monitoring Air Pressure

Keeping a constant check on air pressure levels ensures that machinery operates within the required specifications, preventing any potential downtime due to pressure fluctuations.

Equipment Efficiency

Regular maintenance and servicing of compressors can prevent air leaks, optimizing energy use and reducing costs. This also extends the lifespan of the equipment, contributing to overall production efficiency.

System Integration

Integrating compressed air systems with other utilities like electricity and water can streamline operations, making it easier to control and adjust production parameters as needed.

In summary, compressed air is an indispensable utility in gummy manufacturing, supporting both the mechanical operations and the quality assurance processes that ensure each gummy meets consumer expectations.

Compressed air is used for gummy coating.True

Compressed air powers oil spray systems for even gummy coating.

Gummy production doesn't need compressed air.False

Compressed air is crucial for operating machinery and ensuring quality.

What Role Does Cooling Play in Ensuring Gummy Quality?

Cooling is crucial in gummy manufacturing, affecting texture, appearance, and overall product quality.

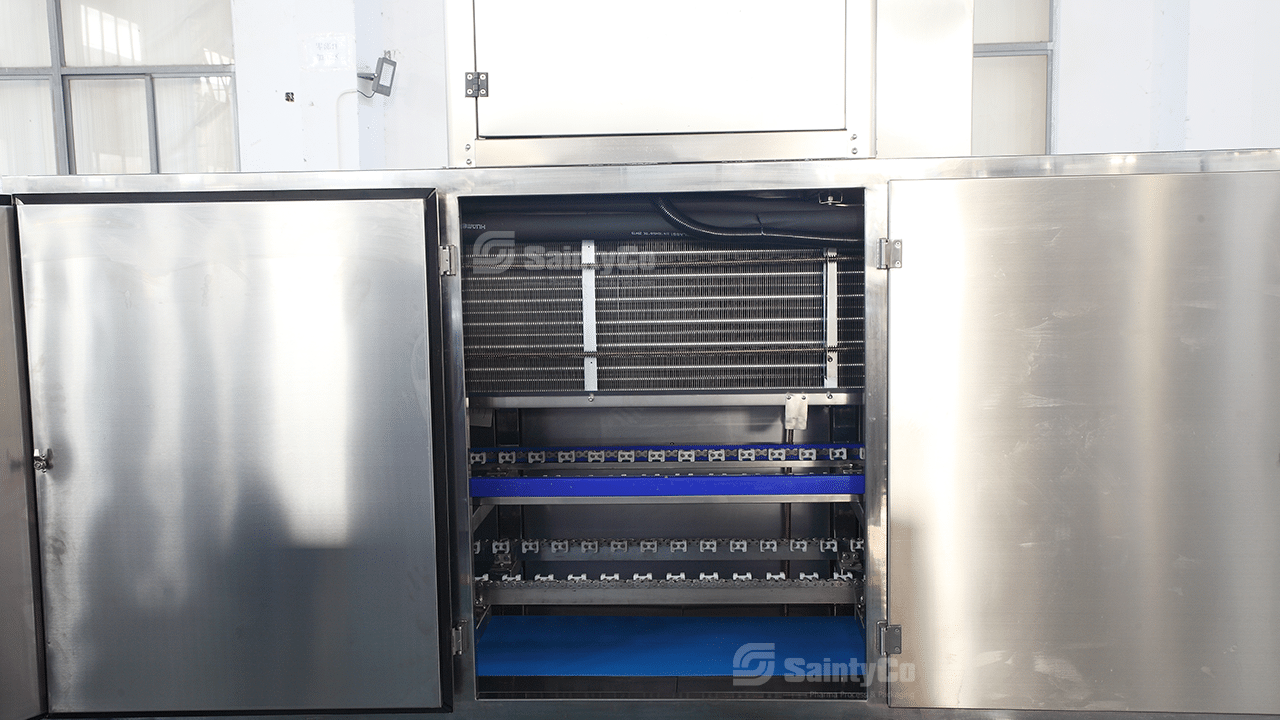

Cooling is pivotal in gummy manufacturing as it solidifies the texture, preserves the flavor, and maintains the gummy's shape. Effective cooling ensures that gummies achieve the desired consistency and prevents issues like stickiness and deformation, especially in sensitive products like pectin-based gummies.

Importance of Temperature Management for Gummy Manufacturing

In the gummy manufacturing process, precise temperature control is essential. Cooling systems maintain a stable environment by regulating temperatures between 0-20°C, which helps in preserving the desired gummy texture. This is especially vital for pectin-based gummies that are sensitive to temperature fluctuations.

Humidity Control and Its Effects

Humidity levels play a significant role in gummy production. Maintaining a relative humidity (RH) of 55% within the cooling tunnels can prevent gummies from becoming sticky or losing their shape. Systems like those in the G800X line offer the flexibility to adjust these parameters, ensuring consistency across batches.

Multi-layer Cooling: Space-Saving Solutions

For businesses tight on space, multi-layer cooling belts like those in SaintyCo G80 and G800X gummy production models are a blessing. These systems maximize cooling efficiency while saving on floor space, perfect for manufacturers looking to optimize their production environment.

| Feature | Benefit |

|---|---|

| Multi-layer cooling | Maximizes cooling efficiency in small spaces |

| Precise temperature | Ensures consistent gummy texture and quality |

| Humidity control | Prevents gummy stickiness and deformation |

Integration with Other Utilities in a Gummy Production Facility

Effective cooling does not work in isolation. It integrates seamlessly with other utilities like vacuum systems to prevent sugar inversion during syrup cooking. This interconnectedness is crucial for maintaining high-quality syrup, which is foundational to excellent gummy production.

For more detailed information on how controlled cooling impacts gummy quality, explore additional resources such as temperature management techniques3 and humidity control strategies4.

Cooling prevents gummy crystallization.True

Cooling stabilizes gummies, preventing unwanted crystallization and deformation.

Humidity control is irrelevant in gummy production.False

Humidity control prevents gummies from becoming sticky or losing shape.

How Do Vacuum Systems Improve Syrup Clarity for Making Gummies?

Understanding the role of vacuum systems in syrup production is key to enhancing gummy quality and clarity.

Vacuum systems improve syrup production by preventing sugar inversion, maintaining clarity, and minimizing degradation during the cooking process, ensuring high-quality gummy production.

Preventing Sugar Inversion

Sugar inversion occurs when sucrose breaks down into glucose and fructose, leading to undesirable changes in syrup sweetness and consistency. Vacuum systems are vital as they lower the boiling point of the syrup, allowing it to cook at reduced temperatures. This controlled environment preserves the integrity5 of the syrup, reducing the likelihood of inversion and resulting in a more stable product.

Controlling Moisture Content

Moisture is another factor that affects syrup clarity. Excess moisture can lead to cloudiness, which isn't ideal for gummy products where clarity is key. Vacuum systems effectively control the moisture content by removing excess water without overcooking the syrup. This ensures that the final product is crystal clear and visually appealing.

Minimizing Degradation for Quality Control

During syrup production, exposure to high temperatures can lead to degradation, affecting both flavor and color. Vacuum systems minimize this risk by facilitating cooking at lower temperatures. This approach not only maintains the original flavor profile6 but also preserves the vibrant colors crucial for consumer appeal.

Efficiency in Production Processes

Vacuum systems streamline production by speeding up the syrup cooking process. By reducing the boiling point, they enable faster evaporation of excess moisture, leading to quicker batch cycles. This efficiency is crucial for high-output operations looking to maximize throughput without compromising quality.

| Benefits of Vacuum Systems | Description |

|---|---|

| Prevents Sugar Inversion | Maintains sweetness and consistency through controlled cooking. |

| Enhances Clarity | Reduces air bubbles, ensuring a clear syrup for premium gummies. |

| Minimizes Degradation | Preserves flavor and color by cooking at lower temperatures. |

| Increases Efficiency | Speeds up processes by reducing boiling points for faster evaporation. |

Understanding these advantages helps manufacturers choose the right vacuum systems for their needs, ensuring high-quality gummy production with every batch.

Vacuum systems prevent sugar inversion in syrup production.True

They lower boiling points, reducing inversion risks and maintaining stability.

Vacuum systems increase syrup degradation during cooking.False

They minimize degradation by enabling lower temperature cooking.

Conclusion

Efficient gummy manufacturing hinges on the effective integration of essential utilities—electricity for heating, compressed air for operational control, cooling for texture management, vacuum systems for syrup quality, and a reliable water supply. These utilities form the backbone of consistent, high-quality production.

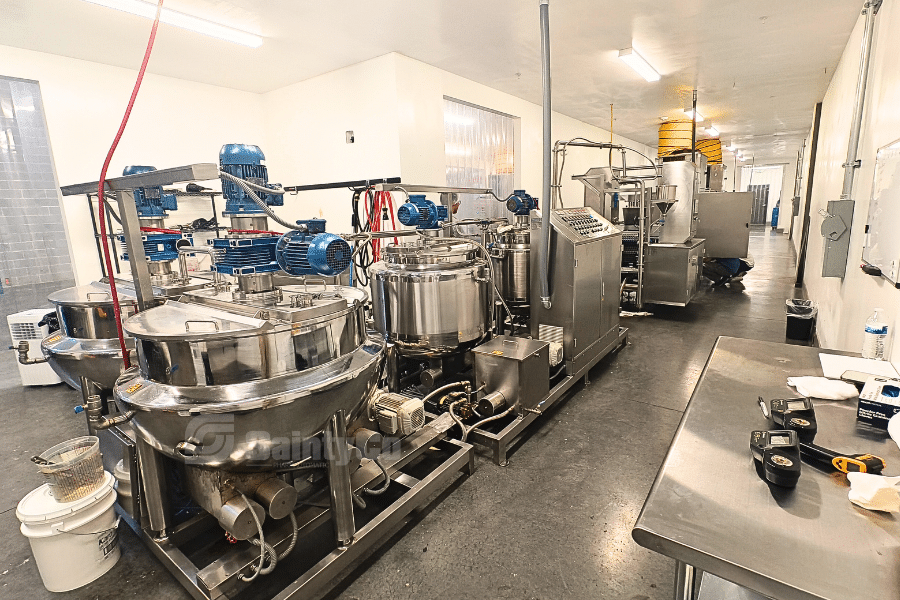

As a manufacturer and supplier of gummy manufacturing equipment, GummyGenix by SaintyCo brings extensive hands-on experience from working closely with gummy production facilities. This experience enables us to offer practical, tailored recommendations that fit your specific setup. Drawing from insights in both gummy production and machine manufacturing, our team provides layout suggestions that maximize efficiency—optimizing machine placement and streamlining production flow from raw materials to finished products, all within your available space.

We can also guide you in integrating essential utilities, such as power, air, water, and environmental controls, to ensure each machine’s utility requirements are met smoothly. Alongside complete support and consulting, we provide detailed specifications for each machine to help you prepare with precision.

For more information on optimizing your gummy manufacturing facility, feel free to reach out to GummyGenix by SaintyCo today.

-

Learn how to integrate essential utilities for efficient gummy production.: Make sure that the gummy manufacturer you chose has GMP and ISO certifications, along with FDA-approved facilities and OSHA certification. One ... ↩

-

Explore benefits of maintaining optimal compressed air pressure.: Want to reduce energy costs? Compressed air monitoring gives you real-time insight into your factory's energy consumption. Read here what you need to know. ↩

-

Learn advanced methods to optimize temperature control in production.: Temperature control is a critical factor in gummy production, as it directly affects the final texture, flavor, and shelf life of the candies. ↩

-

Discover effective ways to maintain optimal humidity levels.: The Bry-Air desiccant dehumidifiers maintain optimum humidity levels in confectionery manufacturing. In spite of ambient conditions, they can maintain RH at 1% ... ↩

-

Explore how vacuum systems help maintain syrup integrity.: When the concentration part is over, producers can turn off the vacuum cooking system, add the granulated sugar and raise the temperature to 80 ... ↩

-

Discover how vacuum systems protect the original syrup flavor.: This article covers some of the basics of maple sap flow, mechanical pumps, and natural vacuum systems used to boost maple sap production. ↩