For new gummy manufacturers, navigating production challenges is crucial to success.

To produce high-quality, shelf-stable gummies, manufacturers must prioritize seven critical factors: temperature control, ingredient consistency, pH levels, water activity, Brix levels, humidity levels, and packaging integrity. These elements work together to ensure product quality and meet industry standards.

While this summary provides a basic overview, delving deeper into each factor will uncover practical tips and strategies to enhance your production process. Let's explore each factor in detail to ensure your gummies not only meet but exceed market expectations.

Temperature control is crucial for gummy quality.True

Maintaining the right temperature ensures proper texture and shelf stability.

Ignoring pH levels won't affect gummy production.False

pH levels influence flavor stability and microbial growth, affecting quality.

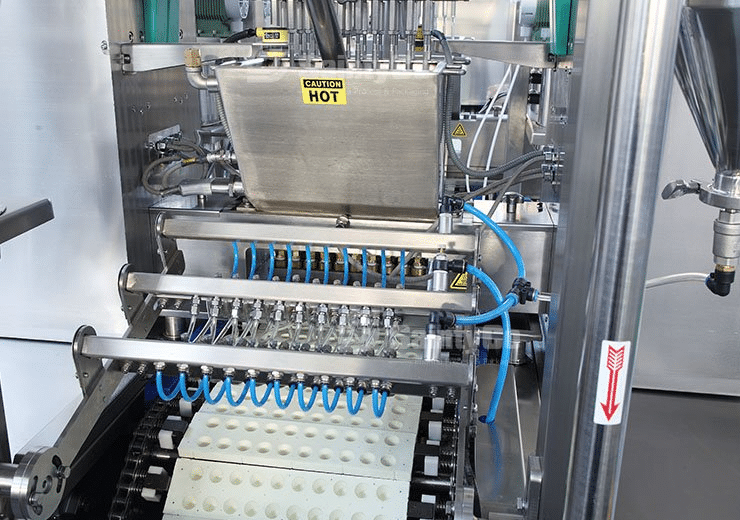

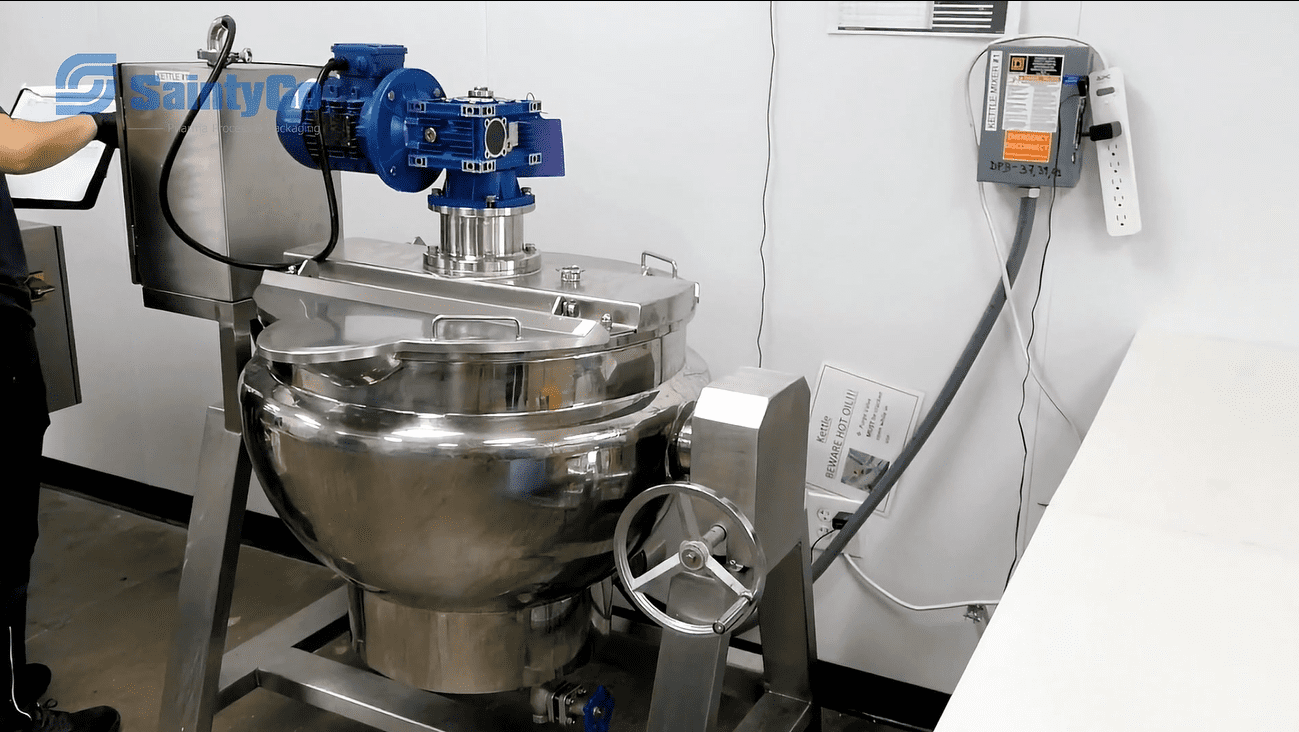

Temperature Control: How Cooking and Cooling Affect Gummy Quality?

Temperature control is crucial in gummy production. It influences texture, shelf life, and active ingredient stability. Proper management ensures consistent quality, while poor control can lead to defective gummies.

Temperature control is vital for maintaining gummy quality. It affects texture, stability, and shelf life. Proper cooking and cooling temperatures ensure optimal gelling and prevent issues like stickiness or brittleness.

|

|

|---|

Jacket Cooker with High-Shear Mixer blending vibrant gummy candy mixture and precisely controlling temperature for a flawless gummy slurry in a production facility | Machine Brand: SaintyCo

The Role of Cooking Temperature

Cooking temperature is pivotal in determining the texture and stability of gummies. Reaching the correct target temperature ensures the syrup gels properly, activating any included active ingredients1. Variations can lead to poorly set gummies, affecting the final product.

| Parameter | Ideal Range | Effects on Gummies |

|---|---|---|

| Cooking Temp | 230-240°F | Proper gelling and activation |

| Cooling Temp | 70-80°F | Prevents sticking and sweating |

| Storage Temp | 60-70°F | Maintains stability and texture |

Importance of Cooling Temperature

Once cooked, gummies require careful cooling to set correctly. Rapid cooling can cause brittleness, while slow cooling might result in stickiness. Consistent cooling temperatures help achieve the desired firmness and prevent issues like sweating.

Impact of Storage Temperature

Storage conditions play a crucial role in preserving gummy quality over time. Fluctuating storage temperatures can lead to melting or hardening, compromising the product's integrity. Keeping the storage environment stable is essential for maintaining the gummies' intended texture2 and shelf life.

Automation for Consistency

Utilizing automated temperature sensors can reduce human error, ensuring precise control over both cooking and cooling processes. This technology helps maintain the quality of each batch, aligning with production standards and regulatory requirements.

Incorporating such systems can streamline operations, allowing for scalability without compromising product consistency3. Automated systems not only enhance quality control but also provide data-driven insights for ongoing improvements.

Cooking temperature affects gummy texture.True

Proper cooking temperature ensures the syrup gels properly, affecting texture.

Storage temperature doesn't impact gummy quality.False

Fluctuating storage temperatures can compromise gummies' integrity and texture.

Ingredient Consistency: Ensuring Uniformity in Gummy Production

Ingredient consistency is crucial in gummy production, affecting texture, flavor, and dosage accuracy. Without it, manufacturers face issues like uneven textures or ineffective doses, impacting product quality.

Ingredient consistency ensures uniform texture, taste, and active ingredient distribution in gummies. It minimizes production errors, meeting quality and regulatory standards. Accurate mixing and dosing ensures that each gummy contains the right amount of active ingredients (e.g., vitamins, CBD) and that the texture and flavor are consistent across batches.

Importance of Ingredient Consistency

Consistency in ingredients plays a pivotal role in the quality of gummy products. It ensures each gummy has the same texture and flavor, which is essential for customer satisfaction. Additionally, it guarantees uniform distribution of active ingredients like vitamins or CBD oil4, crucial for products targeting specific health benefits.

Factors Affecting Consistency

- Raw Material Quality: Using high-quality raw materials ensures the ingredients behave predictably during production. Variations can lead to inconsistencies in the final product.

- Mixing Processes: Proper mixing times and speeds ensure that each gummy contains the correct amount of each ingredient. Automating this process can significantly enhance consistency by reducing human error.

Consequences of Inconsistency

Inconsistent ingredient mixing can lead to several problems:

- Texture Variability: Gummies might turn out too soft or too hard, affecting consumer experience.

- Flavor Discrepancies: Uneven flavor distribution can lead to some gummies tasting different than others within the same batch.

Tools to Ensure Consistency

| Tool | Purpose |

|---|---|

| Automated Mixers | Maintain uniform mixing speeds and times |

| Dosing Systems | Ensure precise ingredient quantities |

| Quality Control Sensors | Monitor consistency throughout production |

Using advanced technologies like automated dosing systems5 can help maintain consistency by accurately measuring and mixing ingredients, reducing the likelihood of errors.

Regulatory Implications

Consistency is not only about quality but also about compliance. Products must meet specific regulatory standards6 for active ingredient dosage, especially in the nutraceutical sector, to avoid recalls and legal issues.

By understanding these aspects, gummy manufacturers can enhance their production processes, ensuring product quality and compliance with industry standards.

Ingredient consistency affects gummy texture and flavor.True

Uniform ingredient distribution ensures each gummy has consistent texture and flavor.

Inconsistent mixing leads to uniform active ingredient distribution.False

Inconsistent mixing results in uneven distribution of active ingredients.

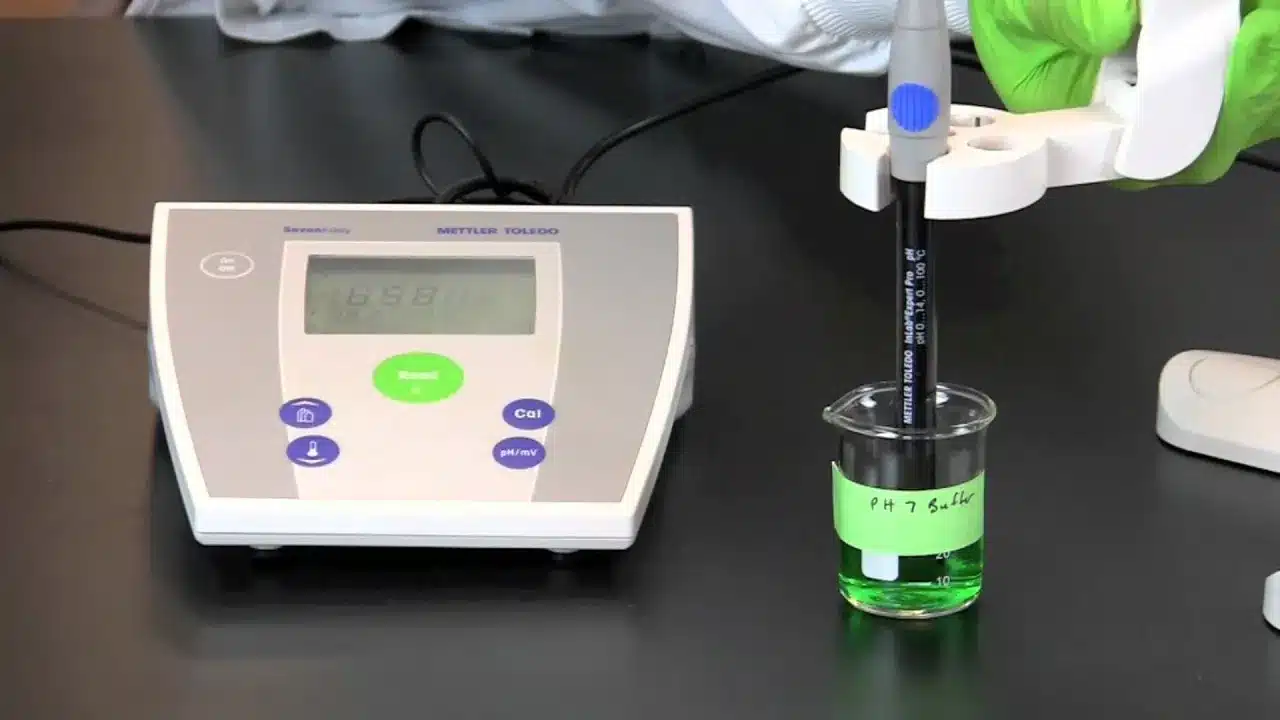

pH Levels and Acidity: Using a pH Meter Is Essential for Gummy Stability

Monitoring pH levels is crucial in gummy production to ensure the right texture and shelf life. Proper pH prevents microbial growth, ensuring gummies remain stable and enjoyable for consumers.

Monitoring pH levels ensures gummies have the correct texture and stability by controlling the gelation process. A pH between 3.5 and 4.5 is ideal to prevent microbial growth and maintain consistency.

The Role of pH in Gummy Production

In the intricate world of gummy production, maintaining the right pH level is pivotal. It affects not only the texture but also the stability and shelf life of the product. For pectin-based gummies7, pH is a critical factor in controlling gelation. If the pH is too high or too low, the gummies may become overly soft or sticky.

Ideal pH Range

The recommended pH range for gummy production is between 3.5 and 4.5. This range ensures that the gelation process occurs effectively, resulting in a desirable texture. Maintaining this acidity level helps prevent microbial growth, which can spoil the product.

Monitoring Techniques

Using a pH meter8 during the cooking process is essential to ensure that the mixture reaches the correct acidity level. Regular monitoring can prevent issues such as improper setting or inconsistency in texture.

| Stage | Recommended pH |

|---|---|

| Cooking | 3.5 - 4.5 |

| Cooling | Consistent |

| Storage | Consistent |

Impact on Flavor and Texture

The acidity level not only affects the setting of the gummies but also influences their flavor profile. A balanced pH ensures that the flavors remain sharp and appealing. Excessive acidity can overpower flavors, while too little can lead to blandness.

Practical Tips

- Regular Checks: Implement routine checks at various stages of production to maintain consistency.

- Acid Addition: Carefully control when and how much acid you add to avoid texture issues.

By closely monitoring these parameters, you can achieve a consistent, high-quality product that meets consumer expectations.

Gummies with pH below 3.5 spoil faster.False

A pH below 3.5 does not necessarily cause faster spoilage but affects texture.

pH affects gummy flavor profile.True

The acidity level influences the sharpness and appeal of flavors.

Water Activity: How It Impacts the Shelf-Life of Gummies?

Ever noticed how some gummies stay fresh for months while others go bad quickly? The secret lies in understanding water activity. Let’s dive into how it affects gummy shelf-life.

Water activity, or Aw, measures free water in gummies, impacting their shelf-life. Lower Aw levels inhibit microbial growth, reducing spoilage and extending shelf-life. Aim for an Aw between 0.55 and 0.70 for optimal stability.

The Science Behind Water Activity

Water activity (Aw) isn't just about moisture content; it's about the water available for chemical reactions and microbial growth. In gummies, maintaining an Aw between 0.55 and 0.70 is crucial. This range helps prevent issues like mold growth and textural changes. When gummies have a high Aw, they become a breeding ground for microbes, leading to spoilage.

Monitoring Aw in Production

To keep gummies fresh, measuring Aw during production is essential. Use a water activity meter to ensure levels are within the desired range before packaging. This process is critical because even minor fluctuations can impact gummy stability. Learn more about Aw measurement9.

| Stage | Ideal Aw Range | Outcome |

|---|---|---|

| Curing | 0.55 - 0.70 | Prevents spoilage |

| Finished Product | 0.55 - 0.70 | Ensures longevity |

Packaging: A Shield Against Moisture

Proper packaging acts as a barrier to external moisture, maintaining internal water activity levels. Airtight seals and moisture-resistant materials are vital to protect gummies from ambient humidity. Without proper packaging, the Aw can increase, compromising shelf-life.

The Role of Humidity in Storage

Storage conditions significantly affect water activity. Keeping storage areas with controlled humidity levels (30% to 50%) is key to preventing unwanted moisture exchange with the environment. Installing dehumidifiers can maintain these conditions efficiently.

Impact on Texture and Flavor

Besides spoilage, improper water activity affects texture and flavor. High Aw can cause gummies to become sticky or lose their shape, while low Aw might lead to brittleness. Consistent monitoring ensures quality and consumer satisfaction.

By understanding and controlling water activity, manufacturers can ensure their gummies remain delicious and safe for consumption longer. Discover packaging techniques10 that help maintain ideal Aw levels.

Gummies with Aw above 0.70 spoil faster.True

High water activity promotes microbial growth, leading to quicker spoilage.

Airtight packaging increases gummy shelf-life.True

Proper packaging prevents moisture ingress, maintaining ideal water activity levels.

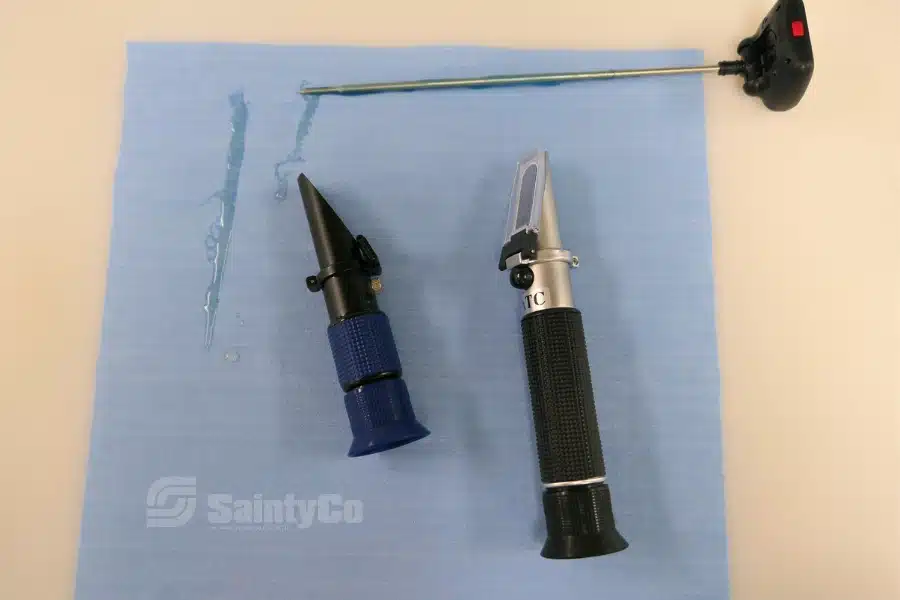

Brix Levels: Monitoring for Optimal Gummy Thickness and Quality

Ensuring the right Brix level is critical in gummy production. Brix measures the percentage of soluble solids (mainly sugars) in the gummy slurry, which directly affects texture, set time, and overall product quality.

Without precise control over Brix levels, manufacturers risk producing gummies with inconsistent texture and poor shelf stability.

|

|

|---|

Brix Meter (Refractometer) measuring soluble solids in gummy slurry to ensure proper thickness and prevent stickiness in pectin and gelatin recipes.

Let’s explore how monitoring Brix can optimize your gummy production process.

Why Brix Levels Matter in Gummy Production

Brix levels impact the thickness and viscosity of the slurry, which is essential to achieving the desired gummy texture. Proper Brix management ensures that:

- The syrup sets correctly in molds.

- Gummies have a consistent chewiness.

- Issues like stickiness or brittleness are prevented.

Whether using pectin-based or gelatin-based gummies, maintaining the right Brix level ensures smooth, uniform production.

| Production Stage | Ideal Brix Range | Effect on Gummies |

|---|---|---|

| Before Cooking | 50-55% | Ensures proper initial viscosity |

| During Cooking | 60-65% | Controls gelation and smooth texture |

| Final Slurry (Before Pour) | 62-67% | Prevents stickiness and improves set time |

How to Monitor Brix Levels in Gummy Production

Using a Brix meter (refractometer) is a practical way to measure the concentration of soluble solids in the gummy slurry. The meter works by shining light through the liquid and measuring how much it bends (refracts), giving an accurate Brix percentage.

Best Practices for Brix Monitoring

- Regular Calibration: Ensure your Brix meter is accurate by calibrating it frequently.

- Multiple Stage Checks: Measure the Brix level before, during, and after cooking.

- Adjust Syrup Concentration: Use the Brix readings to fine-tune your slurry’s composition.

Consequences of Incorrect Brix Levels

| Issue | Cause | Impact on Gummies |

|---|---|---|

| Low Brix | Insufficient sugar | Sticky, under-gelled, and sweaty gummies |

| High Brix | Excess sugar | Brittle, overly chewy gummies |

💡 Pro Tip: Maintaining the Brix within the 62-67% range before pouring ensures that the slurry has the right consistency for optimal gummy texture and shelf stability.

Key Takeaway

Monitoring Brix levels is a simple yet effective way to ensure consistent gummy quality. By investing in refractometers and maintaining a standardized process, manufacturers can produce gummies that are:

- Consistently textured

- Long-lasting on shelves

- Free from common production issues

Humidity Levels: Best Practices for Managing Moisture in Gummy Production

Humidity can make or break the comfort and health of your living environment. Managing it properly ensures better air quality and prevents damage to your home.

To manage humidity levels effectively, maintain a balance between 30% and 50% relative humidity. Use dehumidifiers, ventilation, and hygrometers to monitor and adjust indoor moisture levels.

Why Humidity Management Matters

Managing humidity is crucial for maintaining a healthy indoor environment. High humidity can lead to mold growth, while low humidity causes dry skin and respiratory issues. Balancing indoor moisture11 levels helps preserve home structure and contents.

Tools for Measuring Humidity

Using hygrometers, which are available in both analog and digital forms, allows you to measure indoor humidity accurately. Place them in different rooms to gauge variations. Regular monitoring helps in making timely adjustments.

| Tool | Purpose |

|---|---|

| Hygrometer | Measures indoor humidity levels |

| Dehumidifier | Reduces excess moisture |

| Humidifier | Adds moisture to dry air |

Effective Use of Dehumidifiers

Dehumidifiers are essential when dealing with excessive humidity. Choose the right size for your space to ensure efficiency. In humid areas like basements, a high-capacity unit is beneficial. Position them centrally and ensure airflow is not obstructed.

Improving Ventilation

Good ventilation helps maintain balanced humidity levels. Use exhaust fans in kitchens and bathrooms to expel excess moisture. Opening windows allows natural air circulation, which can be particularly effective in reducing indoor moisture.

Consider using ventilation systems12 that integrate with your HVAC system for optimal performance.

Seasonal Adjustments

Humidity levels vary with seasons; therefore, adjust your strategies accordingly. In winter, when air is naturally drier, use humidifiers. During summer, focus on cooling solutions that include dehumidification.

Maintaining Ideal Indoor Conditions

Strive to keep relative humidity between 30% and 50%. This range minimizes health risks and material damage. Regular checks with hygrometers ensure you stay within this safe zone.

| Season | Recommended Action |

|---|---|

| Winter | Use humidifiers |

| Summer | Employ cooling and dehumidification |

Utilize smart home technology13 to automate and monitor these processes efficiently.

High humidity leads to mold growth indoors.True

Excess moisture creates an ideal environment for mold to thrive.

Hygrometers can only measure outdoor humidity.False

Hygrometers are designed to measure both indoor and outdoor humidity.

Packaging Integrity: Preventing Contamination and Ensuring Product Safety

Packaging integrity is crucial in safeguarding products from contamination, ensuring they remain safe and effective for consumer use. Faulty packaging can lead to spoilage, product recalls, and damage to brand reputation.

Packaging integrity is vital for preventing contamination by maintaining a barrier against external pollutants. It involves using quality materials, ensuring airtight seals, and regularly testing for leaks to protect product safety.

The Role of Packaging Materials

Choosing the right packaging materials is the first step in preventing contamination. Materials need to be moisture-resistant14 and durable to withstand environmental factors. For instance, multi-layer laminates can offer added protection by providing barriers against oxygen and light.

| Material Type | Advantages | Disadvantages |

|---|---|---|

| Glass | Non-reactive, clear | Breakable, heavy |

| Plastic | Lightweight, flexible | Non-biodegradable |

| Metal | Strong, opaque | Can corrode |

Ensuring Airtight Seals

Airtight seals are essential for keeping contaminants out. Vacuum sealing, for example, removes air from the package before sealing, providing an extra layer of protection. Regular seal integrity tests15 should be conducted to verify that seals remain intact throughout the product's shelf life.

- Methods for Testing Seal Integrity:

- Vacuum Leak Test: Detects any air leakage in packaging.

- Burst Testing: Measures the pressure required to burst the package.

The Importance of Regular Testing

Implementing a schedule for regular testing ensures that packaging maintains its integrity over time. Tests should include checking for leaks, examining material durability, and ensuring that packaging meets regulatory standards. Investing in automated testing systems can enhance accuracy16 and efficiency.

Regulatory Considerations

Adhering to industry regulations is crucial for packaging integrity. Regulations often specify the types of materials that can be used and require specific testing procedures to ensure safety. Understanding these regulations can help in designing compliant packaging solutions17.

Each of these factors plays a significant role in ensuring that your products remain uncontaminated and safe for consumer use, highlighting the multifaceted importance of packaging integrity in production processes.

Glass packaging is non-reactive and clear.True

Glass is chemically inert and transparent, making it non-reactive.

Plastic packaging is biodegradable.False

Plastic is generally not biodegradable, persisting in the environment.

Conclusion

New gummy manufacturers should monitor seven critical factors: temperature control, ingredient consistency, pH levels, water activity, Brix levels, humidity levels, and packaging integrity to ensure high-quality products.

At GummyGenix by SaintyCo, we don’t just provide equipment—we empower your gummy business with solutions tailored to your success. Here’s what makes us the ideal partner for your venture:

- Competitive Pricing: Top-tier machinery at affordable rates, ensuring a strong return on investment.

- High-Quality Machinery: GMP-compliant, precision-engineered equipment designed to meet evolving industry standards.

- Equipment Financing & Referral Support: Access flexible payment options and financing resources through our trusted partners, helping you secure affordable payments and potential tax advantages.

- Quick Startup SOPs: Basic recipes and production workflows for a fast, hassle-free start. Additionally, we can connect you with leading formulation consultants and global ingredient suppliers for more advanced product development.

- Custom Molds & Recipes: Stand out in the market with bespoke gummy shapes and innovative recipes tailored to your brand.

- Comprehensive After-Sales Support: From setup and training to troubleshooting, we provide the guidance needed to ensure smooth operations and sustained success.

Contact GummyGenix by SaintyCo, you’ll gain the expertise, resources, and support to build a thriving gummy production business. Let’s succeed together.

Gummy Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Discover how activating ingredients at correct temperatures enhances gummy efficacy and quality. ↩

-

Explore how improper storage temperatures affect gummy texture and longevity. ↩

-

Learn how automation improves consistency and quality in gummy manufacturing. ↩

-

Learn how CBD oil contributes to the health benefits of gummies. ↩

-

Discover how automated systems improve accuracy in gummy manufacturing. ↩

-

Understand the regulatory requirements for gummy production to ensure compliance. ↩

-

Learn how pH affects the gelation process in pectin-based gummies, crucial for achieving desired texture. ↩

-

Discover effective ways to use a pH meter to maintain consistency in gummy production. ↩

-

Discovering reliable methods to measure water activity ensures your gummies are consistently safe and high-quality. ↩

-

Finding effective packaging solutions helps maintain water activity levels, preserving the quality and shelf-life of your gummies. ↩

-

Discover methods to balance indoor moisture for a healthier living environment. ↩

-

Explore advanced ventilation systems that integrate with HVAC for improved humidity control. ↩

-

Learn about smart home devices that automate and monitor humidity management. ↩

-

Explore various moisture-resistant packaging options to choose the best fit for your product, enhancing its shelf life and safety. ↩

-

Discover effective methods for testing seal integrity to ensure airtight protection against contamination. ↩

-

Learn about automated systems that improve accuracy and efficiency in packaging integrity testing. ↩

-

Understand regulatory standards to ensure your packaging complies with safety requirements. ↩